Professional Documents

Culture Documents

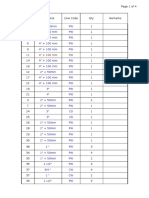

WRC Input Instruction

WRC Input Instruction

Uploaded by

pandiangvOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WRC Input Instruction

WRC Input Instruction

Uploaded by

pandiangvCopyright:

Available Formats

UTILITY CONNECTION (N8-2"x3"): FEA-Nozzle Results

Results were generated with the finite element program FE/Pipe®. Stress results are post-processed in

accordance with the rules specified in ASME Section III and ASME Section VIII, Division 2.

Analysis Time Stamp: Wed Sep 07 12:48:54 2016.

Model Notes

Load Case Report

Solution Data

ASME Code Stress Output Plots

Stress Results - Notes

ASME Overstressed Areas

Highest Primary Stress Ratios

Highest Secondary Stress Ratios

Highest Fatigue Stress Ratios

Stress Intensification Factors

Allowable Loads

Flexibilities

Graphical Results

Model Notes

Model Notes

Input Echo:

Model Type

: Elliptical Head

Parent Outside Diameter

:

Thickness

:

Ellipse Ratio

:

Straight Flange Length :

Attached Shell Length :

Attached Shell Thick

:

Shell Transition Length:

Shell Transition SCF

:

Fillet Along Shell

:

Parent Properties:

Cold Allowable

Hot Allowable

Material ID #2

Ultimate Tensile (Amb)

Yield Strength (Amb)

Yield Strength (Hot)

Elastic Modulus (Amb)

Poissons Ratio

Weight Density

Nozzle Outside Diameter

Thickness

Length

Nozzle Weld Length

RePad Width

RePad Thickness

Location perpendicular

to the head centerline

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

Nozzle Tilt Angle

Nozzle Properties

Cold Allowable

Hot Allowable

Material ID #2

Ultimate Tensile (Amb)

Yield Strength (Amb)

Yield Strength (Hot)

Elastic Modulus (Amb)

Poissons Ratio

Weight Density

:

:

:

:

:

:

:

:

:

COMPRESS 2015 Build 7500

4534.000

13.800

1.888

50.000

2600.000

25.000

24.000

0.000

9.000

mm.

mm.

mm.

mm.

mm.

mm.

mm.

mm.

118.0 MPa

118.0 MPa

Low Alloy Steel

414.0 MPa

221.0 MPa

189.0 MPa

201307.0 MPa

0.300

0.7682E-04 N /cu.mm.(NOT USED)

100.650

11.675

530.943

9.000

70.000

25.000

mm.

mm.

mm.

mm.

mm.

mm.

1750.000 mm.

0.000 deg.

118.0 MPa

118.0 MPa

Low Alloy Steel

414.0 MPa

241.0 MPa

207.0 MPa

201307.0 MPa

0.300

0.7682E-04 N /cu.mm. (NOT USED)

NASH Engineering FZCO

You might also like

- Acme Thread DesignstdDocument7 pagesAcme Thread DesignstdFilipe Martinho100% (2)

- Basics of Pipe Stress Analysis-PartDocument5 pagesBasics of Pipe Stress Analysis-Part7761430No ratings yet

- Wind Load SheetDocument2 pagesWind Load SheetpandiangvNo ratings yet

- Comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2Document13 pagesComparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2IAEME PublicationNo ratings yet

- Aterial Specification & All Thickness CalculationDocument35 pagesAterial Specification & All Thickness CalculationPanjiUte100% (1)

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Basic of Piping Stress Analysis - Part-1Document9 pagesBasic of Piping Stress Analysis - Part-1zafarbadal100% (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- ASME Section II C 2015 ChangesDocument3 pagesASME Section II C 2015 Changespandiangv0% (1)

- Caesar II TrainingDocument61 pagesCaesar II TrainingReaderRRGHT86% (7)

- Line Stop Welded To Shoe CalculationDocument16 pagesLine Stop Welded To Shoe CalculationmohdnazirNo ratings yet

- Studding Outlet DimensionDocument2 pagesStudding Outlet DimensionpandiangvNo ratings yet

- Inspection Engineer Interview Points Piping: Commonly Used Construction CodesDocument39 pagesInspection Engineer Interview Points Piping: Commonly Used Construction CodesAshat Ul Haq100% (1)

- 7 MotorCADDocument18 pages7 MotorCADkhodabandelouNo ratings yet

- Pipe Stress Analysis Complete Course From PassDocument2 pagesPipe Stress Analysis Complete Course From Passsleiman shokr100% (1)

- Design Procedure For Aes He PDFDocument30 pagesDesign Procedure For Aes He PDFRyan Goh Chuang HongNo ratings yet

- Vivek Paul Engineer (Tech.) KLG Systel LTDDocument61 pagesVivek Paul Engineer (Tech.) KLG Systel LTDFirasat AliNo ratings yet

- Heat Exchanger Design2Document35 pagesHeat Exchanger Design2YunardiNo ratings yet

- Pipe Thickness Calculation For Internal PressureDocument12 pagesPipe Thickness Calculation For Internal PressurefsijestNo ratings yet

- Effect of Nozzle Stiffness On Nozzle Loads and StressesDocument12 pagesEffect of Nozzle Stiffness On Nozzle Loads and StressesJafer SayedNo ratings yet

- Flexibility Analysis of PipingDocument33 pagesFlexibility Analysis of PipingkurcekNo ratings yet

- Process Heat Transfer: Principles, Applications and Rules of ThumbFrom EverandProcess Heat Transfer: Principles, Applications and Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (11)

- Offcon DNV Zorro SkidDocument7 pagesOffcon DNV Zorro SkidRAMSINGH CHAUHANNo ratings yet

- Parametric Based Interactive Modeling ofDocument8 pagesParametric Based Interactive Modeling ofDavid VattuoneNo ratings yet

- API 570 Part 2 - Pipe DesignDocument34 pagesAPI 570 Part 2 - Pipe Designpeach5100% (10)

- WRC Input InstructionDocument2 pagesWRC Input InstructionpandiangvNo ratings yet

- A Comparitive Study To Find Bend Thickness Calculation Using PASS START ELEMENT TOOLDocument14 pagesA Comparitive Study To Find Bend Thickness Calculation Using PASS START ELEMENT TOOLJafer SayedNo ratings yet

- FE Pipe DocumentacionDocument160 pagesFE Pipe Documentacionricardobarort100% (2)

- Key 026 Sample Tri ClampDocument18 pagesKey 026 Sample Tri ClampBertrandMezatioNo ratings yet

- Appendix B3-05 Welding Procedure Specification ENB-MA-WPS-5 Rev. 0 - A4A2E4Document14 pagesAppendix B3-05 Welding Procedure Specification ENB-MA-WPS-5 Rev. 0 - A4A2E4Fadil WimalaNo ratings yet

- EMetahnex-23-43 Heat Exchangers Design & ConstructionDocument35 pagesEMetahnex-23-43 Heat Exchangers Design & ConstructionVincentNo ratings yet

- Exercise For Tutorial "A2 - Conjugate Heat Transfer": Contents of ReportDocument16 pagesExercise For Tutorial "A2 - Conjugate Heat Transfer": Contents of ReportRiken MangukiyaNo ratings yet

- By: Baher El Shaikh Mechanicalengineer EmetahnexDocument35 pagesBy: Baher El Shaikh Mechanicalengineer Emetahnexbai tap hoa vo coNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument30 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- Mechanical Design and Design CriteriaDocument32 pagesMechanical Design and Design CriteriaGhost RileyNo ratings yet

- Z. Gao, F. Krumphals, P. Sherstnev, N. Enzinger, J.T. Niu, C. SommitschDocument7 pagesZ. Gao, F. Krumphals, P. Sherstnev, N. Enzinger, J.T. Niu, C. SommitschmaximNo ratings yet

- FE/Pipe v4.5 Release DocumentationDocument160 pagesFE/Pipe v4.5 Release DocumentationSulist N WahyudieNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument35 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- Contoh StressDocument6 pagesContoh StressHeri KurniawanNo ratings yet

- Modeling FRP and Plastic Piping-R11Document15 pagesModeling FRP and Plastic Piping-R11balas838541No ratings yet

- Optimization Heat SinkDocument7 pagesOptimization Heat Sinksolo habtuNo ratings yet

- Two Dimensional Finite Element Analysis For Large Diameter Steel FlangesDocument12 pagesTwo Dimensional Finite Element Analysis For Large Diameter Steel FlangesPiping_SpecialistNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument31 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- Design & Const. of Piping SystemsDocument10 pagesDesign & Const. of Piping Systemsunique wordlNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument37 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- Failure Analysis of The Flowline of Crude Oil in Pipes: Olafimihan E. O, Oyetunji O. R & Oladapo M. ADocument10 pagesFailure Analysis of The Flowline of Crude Oil in Pipes: Olafimihan E. O, Oyetunji O. R & Oladapo M. ARiki FernandesNo ratings yet

- M.E LAB 3 Experiment 4 Heat Losses From PipesDocument14 pagesM.E LAB 3 Experiment 4 Heat Losses From PipesDrw ArcyNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument38 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- Final Paper Large Rectangular FlangeDocument12 pagesFinal Paper Large Rectangular FlangeIsabel López TresgalloNo ratings yet

- IC TestingDocument62 pagesIC Testing劉彥廷100% (1)

- UEMK4353 Assignment - Mech DesignDocument2 pagesUEMK4353 Assignment - Mech DesignSaints Burner ChristopherNo ratings yet

- Main Exam Paper Nov08, Smt211tDocument6 pagesMain Exam Paper Nov08, Smt211tPortia ShilengeNo ratings yet

- ApipeDocument2 pagesApipecutefrenzyNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument37 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- Comparative Study Summary 07 2004 enDocument32 pagesComparative Study Summary 07 2004 enthmaraishriNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationFrom EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- As Me Certificate Holder ReportDocument5 pagesAs Me Certificate Holder ReportpandiangvNo ratings yet

- Crosby Eye Bolt G 291Document1 pageCrosby Eye Bolt G 291pandiangvNo ratings yet

- Xylan Offshore FlierDocument2 pagesXylan Offshore FlierpandiangvNo ratings yet

- UBC DIVISION-III (Wind Design) : Ce Combined Height, Exposure & Gust Factor CoeffDocument4 pagesUBC DIVISION-III (Wind Design) : Ce Combined Height, Exposure & Gust Factor CoeffpandiangvNo ratings yet

- Peppers Catalogue Approved AccessoriesDocument16 pagesPeppers Catalogue Approved AccessoriespandiangvNo ratings yet

- Input:-: Design of Base Plate Length of Base Plate (MM) W 0.11 Width of Base Plate (MM) A (MM) B (MM) Axil Load (M.T)Document6 pagesInput:-: Design of Base Plate Length of Base Plate (MM) W 0.11 Width of Base Plate (MM) A (MM) B (MM) Axil Load (M.T)pandiangvNo ratings yet

- Load-Carrying Capacity Analysis On Derrick of Offshore Module Drilling RigDocument12 pagesLoad-Carrying Capacity Analysis On Derrick of Offshore Module Drilling RigpandiangvNo ratings yet

- Design and Development PlanningDocument6 pagesDesign and Development PlanningpandiangvNo ratings yet

- S2 - Jaw and Jaw-136Document1 pageS2 - Jaw and Jaw-136pandiangvNo ratings yet

- Guidance Notes RevisionDocument8 pagesGuidance Notes RevisionpandiangvNo ratings yet

- Graphite PSM AsDocument2 pagesGraphite PSM AspandiangvNo ratings yet

- Level Gauge, Level Switch ModelDocument8 pagesLevel Gauge, Level Switch ModelpandiangvNo ratings yet

- TMCP Steels For Offshore StructuresDocument3 pagesTMCP Steels For Offshore StructurespandiangvNo ratings yet

- N1192-ST - Colour CoadingDocument4 pagesN1192-ST - Colour CoadingpandiangvNo ratings yet

- Api2000rev.6 02-13Document33 pagesApi2000rev.6 02-13pandiangvNo ratings yet

- Heat TreatmentDocument13 pagesHeat TreatmentpandiangvNo ratings yet