Professional Documents

Culture Documents

eBroc-VXT Open Type Cooling Tower

Uploaded by

Jurizal Julian LuthanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

eBroc-VXT Open Type Cooling Tower

Uploaded by

Jurizal Julian LuthanCopyright:

Available Formats

VXT - B 1

VXT

Open Cooling Towers

Open Cooling Towers

Product Detail

VXT Open Cooling Tower ........................................................................ B2 Benefits ....................................................................................................... B4 Construction Details .................................................................................. B6 Custom Features and Options .................................................................. B8 Accessories ............................................................................................... B10 Engineering Data ..................................................................................... B12 Structural Support .................................................................................. B19 Engineering Specifications ..................................................................... B22

VXT - B 2

VXT Open Cooling Tower

Capacity

Single Cell Capacity: From 1,6 l/s to 1230 l/s

VXT

General Description

Open Circuit Cooling Towers with centrifugal fans, deliver fully rated thermal performance over a wide range of flow and temperature requirements. This type of cooling towers can be installed indoors and can accommodate limited ceiling or enclosure heights. Cooling towers with centrifugal fans minimise sound levels and installation costs, provide year round operating reliability, and simplify maintenance requirements. Cooling Towers provide an answer to the growing need to save water and energy and help protect the environment by providing the highest system efficiency.

Key Features

Suitable for indoor and outdoor installations Suitable for high temperature applications Low sound Single side air inlet Low energy consumption Low installed cost Easy maintenance Reliable year-round operation Long service life

Baltimore Aircoil

VXT - B 3

Open Cooling Towers

... because temperature matters

VXT - B 4

Benefits

Installation and Application Flexibility

Indoor Installations Centrifugal fans can overcome the static pressure imposed by external ductwork, allowing this type of cooling towers to be installed indoors. High Temperature Applications A range of wet deck and construction options are available to accommodate entering water temperatures of up to 65C.

VXT

Low Sound

Centrifugal Fan - Centrifugal fans have inherently low sound characteristics. Single Side Air Inlet - Particularly sound-sensitive areas can be accommodated by facing the quiet side (back panel) to the sound-sensitive direction.

Low Energy Consumption

Evaporative Cooling Equipment minimizes the energy consumption of the entire system because it provides lower operating temperatures. The owner saves money while conserving natural resources and reducing environmental impact.

Low Installed Cost

Support All models mount directly on two parallel I-beams (supplied by others) and ship complete with motors and drives, factory-installed and aligned. Modular Design Large models ship in multiple sections to minimize the size and weight of the heaviest lift, allowing for the use of smaller, less costly cranes.

Easy Maintenance

Internal Access - The interior of the unit is easily accessible for adjusting the float valve, cleaning the strainer or flushing the basin.

The water level control is easily reached from the access door.

External V-belt drive system (shown here with panel removed)

Reliable Year-Round Operation

V-Belt Drive The fans, motor, and drive system are located outside of the moist discharge airstream, protecting them from moisture, condensation and icing hence allowing a safe yearround operation.

Baltimore Aircoil

VXT - B 5

Long Service Life

Materials of Construction Various materials are available to meet the corrosion resistance, unit operating life, and budgetary requirements of any project.

Note: For more information, please refer to the section Technical Resources, Materials of Construction.

Low Ocean Freight Cost

Size - C models are designed to fit in standard closed box containers to minimize ocean freight costs. All containerized models are shipped in a bottom fan section and a top coil section, which fit together into a 40' box container, no crating required. In order to fit the bottom fan section through the doors of the container, the fan enclosures are shipped loose inside the water basin area and are easily mounted on site.

Open Cooling Towers

C Model in Dry Van Container

Fan Enclosures are shipped loose

... because temperature matters

VXT - B 6

Construction Details

VXT

Upper Section

Lower Section

Baltimore Aircoil

VXT - B 7

1. Heavy Duty Construction

Z600 hot-dip galvanized steel panels

2. Fan Drive System

V-belt drive Heavy-duty bearings and fan motor

Open Cooling Towers

3. Centrifugal Fan(s)

Quiet Operation

4. Water Distribution System

Plastic spray header and branches Large orifice, non-clog nozzles Grommetted for easy maintenance

5. BACount Wet Deck Surface

Plastic material Impervious to rot, decay and biological attack Self extinguishing High temperature wet deck option

6. Strainer

Anti-vortex design to prevent air entrainment

7. Access Door

Circular access door

8. Drift Eliminators

UV resistant non-corrosive material, impervious to rot, decay and biological attack Three distinct changes in air direction to reduce drift loss significantly Assembled in easy to handle sections, which can be removed for access to the equipment interior

... because temperature matters

VXT - B 8

Custom Features and Options

Construction Options

Standard Construction: Steel panels and structural elements are constructed of Z600 heavy-gauge hot-dip galvanized steel protected with the Baltiplus Corrosion Protection on the outside of the unit.

VXT

Optional BALTIBOND Corrosion Protection System: The BALTIBOND Corrosion Protection System, a hybrid polymer coating used to extend equipment life, is applied before assembly to all hot-dip galvanized steel components of the unit.

Unit with Stainless Steel Option

Optional Stainless Steel Construction: Steel panels and structural elements are constructed of stainless steel either type 304 or 316. Optional Water-Contact Stainless Steel Cold Water Basin: A cost-effective alternative to an all stainless steel unit. The critical components in the cold water basin and the cold water basin itself are provided in stainless steel. The remaining components are protected with the BALTIBOND Corrosion Protection System.

Note: See section Technical Resources, Material of Construction for more details on the materials described above.

Fan Drive System

The fan drive system provides the cooling air necessary to reject heat from the system to the atmosphere. Centrifugal fans, forwardly curved, are driven by matched V-belts with taper lock sheaves.

The Baltiguard Drive System

The BALTIGUARD Drive System consists of two standard single-speed fan motors and drive assemblies. One drive assembly is sized for full speed and load, and the other is sized for approximately 2/3 speed and consumes only 1/3 of the design kilowatt power. This configuration allows the system to be operated like a two-speed motor, but with the reserve capacity of a standby motor in the event of failure. As a minimum, approximately 70% capacity will be available from the low kilowatt motor, even on a design wet-bulb day. Controls and wiring are the same, as those Baltiguard Drive System required for a two-speed, two-winding motor. Significant energy savings are achieved when operating at low speed during periods of reduced load and/or low wet-bulb temperatures.

Baltimore Aircoil

VXT - B 9

Low Sound Operation

The low sound levels generated by BAC Products with centrifugal fans make them suitable for most installations. For situations when one direction is particularly sound sensitive, the unit can be oriented so that the side opposite the air inlet faces the sound-sensitive direction. Units with centrifugal fans are also available with factory designed, tested and rated sound attenuation for both the air inlet and discharge.

Note: For more information, please refer to the section Technical Resources, Sound Reduction Options.

Open Cooling Towers

Remote Sump Execution

Units with Intake and Discharge Sound Attenuation

The use of an auxiliary sump within a heated space is the most satisfactory way to protect sump water from freezing. When the circulating pump is shut off, all the water in the water distribution, in suspension and in the sump will drain freely to the auxiliary sump.

Note: For detailed information on the calculation of the remote sump tank, please refer to the section "Technical Resources, Selection of Remote Sump Tank".

High Temperature Wet Deck

If operation above 55C is anticipated, an optional high temperature wet deck material is available which increases the maximum allowable entering water temperature to 65C.

... because temperature matters

VXT - B 10

Accessories

Ladder, Safety Cage and Handrails

In the event the owner requires easy access to the top of the unit, the unit can be furnished with ladders extending from the base of the unit to the top, as well as safety cages, and handrail packages.

VXT

Note: When these access options are employed, the unit must be equipped with steel drift eliminators.

Basin Heaters

Units exposed to below freezing ambient temperatures require protection to prevent freezing of the water in the cold water basin when Ladder and Safety Cage, Handrails around top of unit the unit is idle. Factory-installed heaters, which maintain the water temperature at 4C, are a simple and inexpensive way of providing such protection. The heater package includes the heaters, a thermostat and a low level cut out switch to protect the heaters if the water level is too low. Standard electric heaters are selected for -18C ambient temperature.

Model No. VXT VXT 10-25 VXT 30-55 VXT 65-85 VXT 95-135 VXT 150-185 VXT N215-N265 VXT N310-N395 VXT N430-N535 VXT C215-C265 VXT C310-C395 VXT C430-C535 VXT S220-S320 VXT S345-S470 VXT S530-S640 VXT S690-S940 VXT 315-400 VXT 470-600 VXT 630-800 VXT 870-1200

Heater -18 C (kW) 1 x 1,5 1 x 1,5 1 x 2,5 1x3 1x4 1x6 2x4 2x6 1x6 2x4 2x6 1x6 2x4 2x6 4x4 1x6 2x5 2x6 4x5

Baltimore Aircoil

VXT - B 11

Electric Water Level Control Package

The electric water level control replaces the standard mechanical make-up valve when a more precise water level control is required. This package consists of a float switch mounted in the basin and a solenoid activated valve in the makeup water line. The valve is slow closing to minimize water hammer.

Open Cooling Towers

Electric Water Level Control Package

Extended Lubrication Lines

Extended lubrication lines with grease fittings are available for lubrication of the fan shaft bearings.

Capacity Control Dampers

Modulating capacity control dampers are available to provide better leaving water temperature control than can be obtained from fan cycling alone. Fan discharge dampers consist of a single airfoil type damper blade located in the discharge of each fan housing. A standard electrical control package for dampers is available from BAC.

Extended Lubrication Lines

Solid Bottom Panels

Factory-installed bottom panels are required when intake air is ducted to the unit.

Discharge Hoods

Discharge hoods reduce the risk of re-circulation in tight enclosures by increasing discharge air velocity, and can be used to elevate the unit discharge above adjacent walls to comply with layout guidelines.

Basin Sweeper Piping

Basin sweeper piping provides an effective method of preventing sediment from collecting in the cold water basin of the unit. A complete piping system, including nozzles, is provided in the unit basin for connection to side stream filtration equipment.

Note: For more information, please refer to the section "Technical Resources, Filtration".

Basin Sweeper Piping

... because temperature matters

VXT - B 12

Engineering Data

REMARK: Do not use for construction. Refer to factory certified dimensions & weights. This brochure includes data current at time of publication, which should be reconfirmed at the time of purchase. In the interest of product improvement, specifications, weights and dimensions are subject to change without notice. Up-to-date engineering data and more can be found at www.BaltimoreAircoil.com.

VXT 10 - 185

VXT

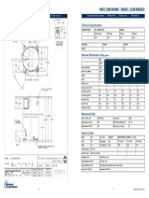

1. Drain ND 50; 2. Water Outlet; 3. Overflow ND50 (Overflow VXT 150 185: ND80); 4. Make Up ND25; 5.Water Inlet; 6.Access Door. On models VXT-10 to VXT-135 sufficient space must be provided on the back of the unit for entry to access doors located on side opposite air entry side.

Operating Shipping Weight Weight (kg) (kg) 405 410 425 435 655 685 695 780 1050 1075 1135 1140 1255 1445 1475 1665 2215 2360 2565 325 330 350 360 490 520 530 615 715 740 805 810 890 1080 1110 1300 1590 1740 1940

Model VXT VXT 010 VXT 015 VXT 020 VXT 025 VXT 030 VXT 040 VXT 045 VXT 055 VXT 065 VXT 070 VXT 075 VXT 085 VXT 095 VXT 105 VXT 120 VXT 135 VXT 150 VXT 165 VXT 185

Heaviest Section (kg) 325* 330* 350* 360* 490* 520* 530* 440 715* 740* 540 540 890* 575 605 700 915 915 980**

H (mm) 2036 2036 2036 2036 2036 2036 2036 2506 2036 2220 2506 2506 2036 2675 2675 3350 3128 3585 4042

L (mm) 914 914 914 914 1829 1829 1829 1829 2737 2737 2737 2737 3658 3658 3658 3658 3645 3645 3645

W (mm) 1207 1207 1207 1207 1207 1207 1207 1207 1207 1207 1207 1207 1207 1207 1207 1207 1438 1438 1438

Air Flow (m3/s) 1,79 1,94 2,19 2,50 3,74 4,48 4,97 5,16 7,22 8,12 8,02 8,83 11,04 10,90 12,58 12,46 15,79 15,53 16,94

Fan Motor Fluid Inlet Fluid Outlet Make Up (kW) ND (mm) ND (mm) ND (mm) (1x) 0,75 (1x) 1,1 (1x) 1,5 (1x) 2,2 (1x) 1,5 (1x) 2,2 (1x) 4,0 (1x) 5,5 (1x) 5,5 (1x) 5,5 (1x) 5,5 (1x) 7,5 (1x) 7,5 (1x) 7,5 (1x) 11 (1x) 11 (1x) 15 (1x) 15 (1x) 18,5 (1x) 80 (1x) 80 (1x) 80 (1x) 80 (1x) 80 (1x) 80 (1x) 80 (1x) 80 (1x) 100 (1x) 100 (1x) 100 (1x) 100 (1x) 100 (1x) 100 (1x) 100 (1x) 100 (1x) 150 (1x) 150 (1x) 150 (1x) 80 (1x) 80 (1x) 80 (1x) 80 (1x) 80 (1x) 80 (1x) 80 (1x) 80 (1x) 100 (1x) 100 (1x) 100 (1x) 100 (1x) 100 (1x) 100 (1x) 100 (1x) 100 (1x) 150 (1x) 150 (1x) 150 25 25 25 25 25 25 25 25 25 25 25 25 25 25 25 25 25 25 25

* Units ship in one piece, ** Casing is heaviest section

Baltimore Aircoil

VXT - B 13

VXT N215 - N535

Open Cooling Towers

1. Drain ND 50; 2. Water Outlet; 3. Overflow ND 80; 4. Make Up ND50; 5.Water Inlet; 6.Access Door.

Model VXT VXT N215 VXT N240 VXT N265 VXT N310 VXT N345 VXT N370 VXT N395 VXT N430 VXT N480 VXT N510 VXT N535

Operating Weight (kg) 3640 3850 4080 5300 5580 5860 5890 7330 7730 8110 8200

Shipping Weight (kg) 2100 2310 2540 3060 3340 3620 3650 4190 4590 4980 5060

Heaviest Section (kg) 1395 1395 1435 1875 1875 1875 1895 2758 2758 2758 2839

H L W Air Flow Fan Motor Fluid Inlet Fluid Outlet Make Up (mm) (mm) (mm) (m3/s) (kW) ND (mm) ND (mm) ND (mm) 3112 3569 4026 3112 3569 4026 4026 3112 3569 4026 4026 3550 3550 3550 5385 5385 5385 5385 7226 7226 7226 7226 2397 2397 2397 2397 2397 2397 2397 2397 2397 2397 2397 23,49 23,33 24,26 34,12 33,82 33,60 36,15 46,98 46,65 46,44 48,94 (1x) 22 (1x) 22 (1x) 30 (1x) 30 (1x) 30 (1x) 30 (1x) 37 (2x) 22 (2x) 22 (2x) 22 (2x) 30 (1x) 150 (1x) 150 (1x) 150 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (2x) 150 (2x) 150 (2x) 150 (2x) 150 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 250 (1x) 250 (1x) 250 (1x) 250 50 50 50 50 50 50 50 50 50 50 50

... because temperature matters

VXT - B 14

VXT C215 - C535

VXT

1. Drain ND 50; 2. Water Outlet; 3. Overflow ND 80; 4. Make Up ND50; 5. Water Inlet; 6. Access Door

Operating Weight (kg) 4035 4225 4420 5960 6230 6490 6615 8120 8520 8900 8980

Model VXT-C VXT C215 VXT C240 VXT C265 VXT C310 VXT C345 VXT C370 VXT C395 VXT C430 VXT C480 VXT C510 VXT C535

Shipping Weight (kg) 2335 2535 2750 3435 3725 4010 4090 4650 5050 5480 5560

Heaviest Section (kg) 1620 1620 1645 2260 2260 2260 2345 1620 1620 1620 1645

H (mm) 3112 3569 4026 3112 3569 4026 4026 3112 3569 4026 4026

L (mm) 3550 3550 3550 5385 5385 5385 5385 7226 7226 7226 7226

W (mm) 2245 2245 2245 2245 2245 2245 2245 2245 2245 2245 2245

Air Flow (m3/s) 23,49 23,33 24,26 34,12 33,82 33,60 36,15 46,98 46,65 46,44 48,94

Fan Motor (kW) (1x) 22 (1x) 22 (1x) 30 (1x) 30 (1x) 30 (1x) 30 (1x) 37 (2x) 22 (2x) 22 (2x) 22 (2x) 30

Fluid Inlet ND (mm) (1x) 150 (1x) 150 (1x) 150 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (2x) 150 (2x) 150 (2x) 150 (2x) 150

Fluid Outlet ND (mm) (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 250 (1x) 250 (1x) 250 (1x) 250

Make Up ND (mm) 50 50 50 50 50 50 50 50 50 50 50

Baltimore Aircoil

VXT - B 15

VXT S220 - S940

Open Cooling Towers

1. Drain ND 50; 2. Water Outlet; 3. Overflow ND 80; 4. Make Up ND50; 5. Water Inlet; 6. Access Door

Model VXT-S VXT S220 VXT S240 VXT S265 VXT S300 VXT S320 VXT S345 VXT S370 VXT S415 VXT S445 VXT S470 VXT S530 VXT S600 VXT S640 VXT S690 VXT S740 VXT S830 VXT S890 VXT S940

Operating Weight (kg) 4120 4140 4170 4400 4760 6030 6070 6430 6880 6930 8390 8860 9570 12110 12190 12910 13810 13910

Shipping Weight (kg) 2380 2400 2430 2660 3020 3380 3420 3770 4220 4270 4850 5310 6030 6750 6830 7530 8430 8530

Heaviest Section (kg) 1450 1470 1500 1500 1540 2050 2090 2090 2130 2140 2990 2990 3070 4090 4170 4170 4260 4270

H (mm) 3479 3479 3479 4012 4437 3479 3479 4012 4437 4437 3479 4012 4437 3479 3479 4012 4437 4437

L (mm) 3550 3550 3550 3550 3550 5385 5385 5385 5385 5385 7226 7226 7226 10903 10903 10903 10903 10903

W (mm) 2397 2397 2397 2397 2397 2397 2397 2397 2397 2397 2397 2397 2397 2397 2397 2397 2397 2397

Air Flow (m3/s) 24,8 26,3 29,2 29,0 29,1 38,2 41,0 40,6 40,4 43,2 58,4 58,0 58,2 76,4 82,0 81,2 80,8 86,4

Fan Motor (kW) (1x) 18,5 (1x) 22 (1x) 30 (1x) 30 (1x) 37 (1x) 30 (1x) 37 (1x) 37 (1x) 37 (1x) 45 (2x) 30 (2x) 30 (2x) 37 (2x) 30 (2x) 37 (2x) 37 (2x) 37 (2x) 45

Fluid Inlet ND (mm) (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (2x) 200 (2x) 200 (2x) 200 (2x) 200 (2x) 200 (2x) 200 (2x) 200 (2x) 200

Fluid Outlet ND (mm) (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 250 (1x) 250 (1x) 250 (2x) 200 (2x) 200 (2x) 200 (2x) 200 (2x) 200

Make Up ND (mm) 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50

... because temperature matters

VXT - B 16

VXT 315 - 1200

VXT

1. Drain ND50; 2. Water Outlet; 3. Overflow ND 80; 4. Make Up ND50 and 870 - 1200: ND80; 5.Water Inlet; 6.Access Door.

Operating Weight (kg) 4905 5195 5505 5535 7305 7750 8245 8325 9805 10385 11005 11055 14570 14680 15560 16490 16570

Model VXT VXT 315 VXT 350 VXT 375 VXT 400 VXT 470 VXT 525 VXT 560 VXT 600 VXT 630 VXT 700 VXT 750 VXT 800 VXT 870 VXT 945 VXT 1050 VXT 1125 VXT 1200

Shipping Weight (kg) 2960 3260 3560 3590 4360 4810 5290 5370 5900 6490 7110 7160 8720 8830 9710 10640 10720

Heaviest Section (kg) 1945 1945 1945 1970 2770 2770 2770 2845 3885 3885 3885 3925 5670 5785 5785 5785 5855

H (mm) 4030 4487 4944 4944 4030 4487 4944 4944 4030 4487 4944 4944 4030 4030 4487 4944 4944

L (mm) 3550 3550 3550 3550 5388 5388 5388 5388 7226 7226 7226 7226 10903 10903 10903 10903 10903

W (mm) 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000

Air Flow Fan Motor Fluid Inlet Fluid Outlet Make Up (m3/s) (kW) ND (mm) ND (mm) ND (mm) 34,55 34,31 34,10 36,62 51,82 51,44 50,92 54,93 69,09 68,62 68,20 73,25 94,37 103,64 102,93 102,30 109,87 (1x) 30 (1x) 30 (1x) 30 (1x) 37 (2x) 22 (2x) 22 (2x) 22 (2x) 30 (2x) 30 (2x) 30 (2x) 30 (2x) 37 (3x) 22 (3x) 30 (3x) 30 (3x) 30 (3x) 37 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 250 (1x) 250 (1x) 250 (1x) 250 (2x) 200 (2x) 200 (2x) 200 (2x) 200 (3x) 200 (3x) 200 (3x) 200 (3x) 200 (3x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 200 (1x) 250 (1x) 250 (1x) 250 (1x) 250 (1x) 300 (1x) 300 (1x) 300 (1x) 300 (2x) 250 (2x) 250 (2x) 250 (2x) 250 (2x) 250 50 50 50 50 50 50 50 50 50 50 50 50 80 80 80 80 80

General Notes

1. All connections 100 mm and smaller are MPT. Connections 150 mm and larger are bevelled-for-welding. 2. Fan kW is at 0 Pa ESP. To operate against external static pressure up to 125 Pa, increase each fan motor one size. 3. The drawings show the standard right hand arrangement, which has the air inlet side on the right when facing the connection end. Left hand arrangement can be furnished by special order. 4. Water outlet, overflow and make-up are always located on the same end of the unit. For units with two water outlet connections an additional overflow connection will be installed on the other end of the unit.

Baltimore Aircoil

VXT - B 17

Sound Attenuation

XA + XB Sound Attenuation for VX-Line Cooling Towers

Open Cooling Towers

1. Access Door; L1= Intake Attenuator Length; L2= Discharge Attenuator Length; W & H= unit dimensions (see Engineering Data).

XC Sound Attenuation for VX-Line Cooling Towers

1. Access Door; L1= Intake Attenuator Length; L2= Discharge Attenuator Length; W & H= unit dimensions (see Engineering Data)

... because temperature matters

VXT - B 18

Model No. VXT

Unit + # Access Atten. # doors (3) pieces XA, XB, XC shipped XA, XB, Disch. Int. XC Att. Att.

Dimensions (mm) W2 XA, XB 2352 2352 2352 2352 2583 3542 3542 3542 3390 3390 3390 3542 3542 3542 3542 4145 4145 4145 4145 XC N.A. N.A. N.A. N.A. 3728 4687 4687 4687 4687 4687 4535 4687 4687 4687 4687 5290 5290 5290 5290 H1 W1 L1 L2 XA 900 1815 2730 3645 3645 3645 5480 110 175 230 300 380 500 660 Intake XB XC Solid Bottom 30 50 70 100 120 190 300 380 190 300 380 190 300 380 600 230 350 460 690

Weights (kg) Discharge XA 130 175 280 360 440 530 760 XB 150 220 350 420 520 650 970 XC N.A. N.A. N.A. N.A. XA 270 400 580 760 Total XB 310 490 720 890 XC N.A. N.A. N.A. N.A.

XA, XB, XC 1090 1030 890

10 - 25 30 - 55 65 - 85

3 3(1) 3

(1)

1 1 1 1 1 1 2 2 1 2 2 1 2 2 4 2 2 4 3

2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 3

130 N.A. 220 N.A. 300 N.A. 370 830

1090 1030 1800 1090 1030 2710 1090 1030 3635 1600 1420 3635 2070 1955 3510 2070 1955 5365 2070 1955 7185 2070 1955 3510 2070 1955 5365 2070 1955 7185 2070 2365 3550 2070 2365 5385 2070 2365 7226

VXT

95 - 135 150 - 185 N215 N265 N310 N395 N430 - N535 C215 - C265 C310 C395 C430 C535 S220 S320 S345 S470 S530 S640 S690 S940 315 - 400 470 - 600 630 - 800 870 - 1200

4(2) 4 4 4 7 4 4 7 4 4 7 7 4 4 7 10

480 1080 630 1420 860 1970

1070 940 1120 2270 1330 1220 1470 2940 1980 1720 2130 4250

7320 1000 1260 2840 3645 5480 500 660 630 1420 860 1970

1060 1300 2660 2440 2940 5880 530 760 650 970 1330 1220 1470 2940 1980 1720 2130 4250

7320 1000 1260 2840 3645 5480 500 660 630 1420 860 1970

1060 1300 2660 2440 2940 5880 660 800 1640 1350 1620 3250

830 1090 2240 1790 2250 4510 1320 1600 3280 2700 3240 6500 1660 2180 4480 3580 4500 9020 710 880 1820 1500 1820 3670

7322 1000 1260 2840

2070 2365 10903 10998 1320 1720 3940 2560 2965 3510 2560 2965 5365 2560 2965 7185 3645 5480 560 730 710 1620 980 2240

900 1210 2490 1980 2540 5080 1420 1760 3640 3000 3640 7340 2130 2640 5460 4500 5460 11010

7320 1120 1420 3240

2560 2965 10865 10995 1680 2130 4860

(1) (1) (2) (3) (3)

VXT-55 + attenuation is shipped in 4 pieces VXT-75 and VXT 85 + attenuation is shipped in 4 pieces VXT-95 + attenuation is shipped in 3 pieces Intake Attenuator: Access opening is 775 mm high, 406 mm wide and is located at each end of the unit.

Discharge Attenuator : Access opening is 400 mm high, 1080 mm wide and is located at blank off side of the unit (Access door of VXT 10-25 has 650 mm width)

Baltimore Aircoil

VXT - B 19

Structural Support

REMARK: Do not use for construction. Refer to factory certified dimensions & weights. This brochure includes data current at time of publication, which should be reconfirmed at the time of purchase. In the interest of product improvement, specifications, weights and dimensions are subject to change without notice. Up-to-date engineering data and more can be found at www.BaltimoreAircoil.com.

The recommended support arrangement for units consists of parallel I-beams running the full length of the unit, spaced as shown in the following drawing. Besides providing adequate support, the steel also serves to raise the unit above any solid foundation to ensure access to the bottom of the unit. To support units in an alternate steel support arrangement, consult your BAC Balticare Representative.

Open Cooling Towers

Units without Sound Attenuation

1. Outline of Unit; 2. Mounting Holes 22 mm; 3. Unit; 4. Air Intake.

C Center dis. Length (mm) 750 1664 2572 3492 3492 3238 3238 5074 5074 6914 3238 5074 D Center dis. Width (mm) 1153 1153 1153 1153 1378 2327 2934 2327 2934 2327 2175 2175

Model

A Unit Length (mm) 914 1829 2737 3658 3645 3550 3550 5388 5388 7226 3550 5385

B Unit Width (mm) 1207 1207 1207 1207 1438 2397 3000 2397 3000 2397 2245 2245

E (mm) 2496 2496 3238 2486

F (mm) 102 102 438 102

G (mm) -

H (mm) -

X Max. Deflection (mm) 2 5 8 10 10 10 10 13 13 13 10 13

Mounting Holes 4 4 4 4 4 4 4 8 8 8 4 8

VXT 10-25 VXT 30-55 VXT 65-84 VXT 95-135 VXT 150-185 VXT N215-N265 VXT 315-400 VXT N310-N395 VXT 470-600 VXT N430-N535 VXT C215C265 VXT C310-C395

... because temperature matters

VXT - B 20

Model

A Unit Length (mm) 7226 3550 5385 7226 10903 7226 10903

B Unit Width (mm) 2246 2397 2397 2397 2397 3000 3000

C Center dis. Length (mm) 6914 3238 5074 6914 10586 6914 10590

D Center dis. Width (mm) 2175 2327 2327 2327 2327 2934 2934

E (mm) 3238 2486 3238 2486 3238 3238

F (mm) 438 102 438 102 438 438

G (mm) 438 3238

H (mm) 438

X Max. Deflection (mm) 13 10 13 13 13 13 13

Mounting Holes 8 4 8 8 16 8 12

VXT C430-C535 VXT S220-S320 VXT S345-S470 VXT S530-S640 VXT S690-S940

VXT

VXT 630-800 VXT 870-1200

Units with Sound Attenuation

1. Outline of Unit; 2. Mounting Holes 22 mm; 3. Outline of attenuator (optional XA or XB); 4. Support Channel attached to optional XA or XB attenuator; 5. (3 + 5) Outline of Attenuator (optional XC); 6. (4 + 6) Support Channels attached to optional XC attenuator; 7. Unit; 8. Sound Attenuation (Type XA, XB or XC); 9. Air Intake.

Baltimore Aircoil

VXT - B 21

Notes:

1. The recommended support arrangement for VX units consists of parallel I-beams extending the full length of the unit. Supports and anchor bolts are to be designed and furnished by others. 2. All supporting beams are to be flush and level at top and must be oriented relative to gage line as shown. 3. Recommended design loads for each unit support beam should be 70% of the total unit operating weight applied as a uniform load to each of the unit beams. The support beam(s) for the optional intake attenuator(s) needs to carry attenuator only, uniform load of 250 kg/m. Beams should be designed in accordance with standard structural practice. For the maximum allowable deflection of beams under the unit refer to above table. 4. All mounting holes have a diameter of 22 mm at the locations shown. 5. If vibration isolators are used, a rail or channel must be provided between the unit (and optional attenuator) and the isolators to provide continuous unit support. Additionally the support beams must be designed to accommodate the overall length and mounting hole location of the isolators that may differ from those of the unit. Refer to vibration isolator drawings for these data.

Open Cooling Towers

... because temperature matters

VXT - B 22

Engineering Specifications

1.0 Cooling Tower

1.1 General: Furnish and install _____ factory-assembled, forceddraft, centrifugal fan, counter flow cooling tower(s) with vertical air discharge, conforming in all aspects to the specifications, schedules and as shown on the plans. Overall dimensions shall not exceed approximately _____ mm long x ______ mm wide x _____ mm high. The total connected fan power shall not exceed _____ kW. The cooling tower(s) shall be Baltimore Aircoil Model ____________. Corrosion Protection System. The system shall consist of Z600 metric hot-dip galvanized steel prepared in a four-step (clean, pre-treat, rinse, dry) process with an electrostatically sprayed, thermosetting, hybrid polymer fuse-bonded to the substrate during a thermally activated curing stage and monitored by a 23-step quality assurance program. (Alternate 1.3) Corrosion Resistant Construction (optional): Unless otherwise noted in this specification, all steel panels and structural members shall be constructed of Type 304 or 316 stainless steel and assembled with stainless steel nut and bolt fasteners. 1.4 Quality Assurance: The cooling tower manufacturer shall have a Management System certified by an accredited registrar as complying with the requirements of ISO-9001:2000 to ensure consistent quality of products and services. 1.5 Warranty: The manufacturers standard equipment warranty shall be for a period of not less than one year from date of startup or eighteen months from date of shipment, whichever occurs first.

VXT

1.2 Thermal Capacity: The cooling tower(s) shall be warranted by the manufacturer to cool _____ l/s of water from ______ C to _____C at _____C entering wet-bulb temperature. 1.3 Corrosion Resistant Construction (standard): Unless otherwise noted in this specification, all steel panels and structural members shall be constructed of heavy-gauge Z600 metric hot-dip galvanized steel with all edges given a protective coating of zinc-rich compound and the exterior protected with the BALTIPLUS Protection. (Alternate 1.3) Corrosion Resistant Construction (optional): Unless otherwise noted in this specification, all steel panels and structural members shall be protected with the BALTIBOND

2.0 Construction Details

2.1 Structure (VX-Line models): The cooling tower shall be constructed of heavy-gauge steel utilizing double-brake flanges for maximum strength and rigidity and reliable sealing of watertight joints. The heat transfer section shall be removable from the pan/fan section to facilitate shipping and handling. The fan(s) and fan drive system, including the fan motor, shall be factory mounted and aligned and located in the dry entering air stream to ensure reliable operation and ease of maintenance. 2.2 Heat Transfer Section: The heat transfer sections(s) shall consist of a wet deck surface, spray water distribution system and drift eliminators arranged for optimal thermal performance with minimal drift. 2.3 Wet Deck Surface: The wet deck surface shall be formed from self-extinguishing plastic material and shall be impervious to rot, decay, and fungus or biological attack. The wet deck surface shall be manufactured and performance tested by the cooling tower manufacturer to assure single source responsibility and control of the final product. 2.4 Water Distribution System: Water shall be distributed evenly over the wet deck surface by a water distribution system consisting of a header and spray branches of plastic pipe with large orifice, nonclog plastic distribution nozzles. The branches and spray nozzles shall be held in place by snap-in rubber grommets, allowing quick removal of individual nozzles or complete branches for cleaning or flushing. 2.5 Cold Water Basin: The cold water basin shall be provided with large area lift out strainers with perforated openings sized smaller than the water distribution system nozzles and an anti-vortexing device to prevent air entrainment. The strainer and anti-vortexing device shall be constructed of the same material as the basin to prevent dissimilar metal corrosion. Standard basin accessories shall include a brass make-up valve with large diameter polystyrene filled plastic float for easy adjustment of the operating water level. (Alternate2.5) Cold Water Basin: The cold water basin shall be constructed of heavy-gauge Type 304 or 316 stainless steel panels and structural members up to the heat transfer section/basin joint. The basin shall be provided with large area lift out strainers with perforated openings sized smaller than the water distribution system nozzles and an anti-vortexing device to prevent air entrainment. The strainer and anti-vortexing device shall be constructed of the same material as the basin to prevent dissimilar metal corrosion. Standard basin accessories shall include a brass make-up valve with large diameter polystyrene filled plastic float for easy adjustment of the operating water level.

3.0 Mechanical Equipment

3.1 Fan(s): Fan(s) shall be dynamically balanced, forwardly curved, centrifugal type selected to provide optimum thermal performance with minimal sound levels. Fan housings shall have curved inlet rings for efficient air entry and four-sided rectangular discharge cowls shall extend into the basin to increase fan efficiency and prevent water from splashing into the fans. 3.2 Bearings: Fan(s) and shaft(s) shall be supported by heavy-duty, self-aligning, relubricatable bearings with cast iron housings, designed for a minimum L10 life of 40 000 hours (280 000 Hr. Average. Life). 3.3 Fan Drive: The fan(s) shall be driven by matched V-belts with taper lock sheaves. Motor shall be located on a heavy-duty motor base, adjustable by a single threaded bolt-and-nut arrangement. Removable steel screens or panels shall protect the fan drive and all moving parts. 3.4 Fan Motor: Furnish _____ kW, ______ RPM Totally Enclosed, Fan Cooled (TEFC), squirrel cage, ball bearing type fan motors suitable for outdoor service. Motor(s) shall be suitable for ________ volt, ___ hertz, and __ phase electrical service. 3.5 BALTIGUARD Fan System (optional): Two-single speed fan motors, one sized for full speed and load, the other sized for 2/3 speed and approximately 1/3 of full load kW shall be provided in each cell for capacity control and stand-by protection from drive or motor failure. Two-speed motor(s) are not an acceptable alternative.

Baltimore Aircoil

VXT - B 23

4.0 Drift Eliminators

4.1 Drift Eliminators: Eliminators shall be constructed of specially formulated plastic material and be removable in easily handled sections. They shall have a minimum of three changes in air direction.

5.0 Access

5.1 Basin Access: Circular access doors shall be provided for easy access to the make-up water assembly and suction strainer for routine maintenance.

6.0 Sound

6.1 Sound Level: To maintain the quality of the local environment, the maximum sound pressure levels (dB) measured 15 m from the cooling tower operating at full fan speed shall not exceed the sound levels detailed below.

Open Cooling Towers

Location Discharge Air Inlet End Back

63

125

250

500

1000

2000

4000

8000

dB(A)

... because temperature matters

VXT - B 24

VXT

Baltimore Aircoil

You might also like

- Oferta ZagmiDocument44 pagesOferta ZagmiMarian Florin MincinoiuNo ratings yet

- Carrier Commercial Systems 2008 List Prices: 30Rb Air Cooled ChillersDocument13 pagesCarrier Commercial Systems 2008 List Prices: 30Rb Air Cooled ChillersvickersNo ratings yet

- Vicarb Plate Heat ExchangersDocument17 pagesVicarb Plate Heat ExchangersFrederik BohyNo ratings yet

- Valves BarendsenDocument63 pagesValves BarendsenidontlikeebooksNo ratings yet

- Taco Phe PDFDocument4 pagesTaco Phe PDFDhirendra Singh RathoreNo ratings yet

- VCV WesperDocument12 pagesVCV Wesperciperu55No ratings yet

- RSW SystemsDocument4 pagesRSW Systemssaptop39No ratings yet

- Controlador Dixell Serie IC200LDocument35 pagesControlador Dixell Serie IC200LColossusNo ratings yet

- Nism GK567GBDocument16 pagesNism GK567GBsafwan azizNo ratings yet

- Hanla Vol1Document40 pagesHanla Vol1jasleenchhabraNo ratings yet

- 1tool Releasenotes 2 5 35 SP1Document14 pages1tool Releasenotes 2 5 35 SP1BJNE01No ratings yet

- SwepDocument2 pagesSweppiya_engineer2786No ratings yet

- 1905 - Carrier 30 GZ 190 PDFDocument6 pages1905 - Carrier 30 GZ 190 PDFbilal almelegyNo ratings yet

- Copeland Scroll Compressors For Air Conditioning ApplicationsDocument28 pagesCopeland Scroll Compressors For Air Conditioning ApplicationsSrikanta ChoudhuryNo ratings yet

- 09 - 10 E Pumps PDFDocument8 pages09 - 10 E Pumps PDFWedneslao LopezNo ratings yet

- NEMO Progressing Cavity PumpsDocument24 pagesNEMO Progressing Cavity PumpsPeñaloz GustavoNo ratings yet

- York CatalogueDocument92 pagesYork CatalogueRawadabdoNo ratings yet

- SMARDT Catalogue TW ClassWaterCooled-En WebDocument7 pagesSMARDT Catalogue TW ClassWaterCooled-En WebBrunoWelterNo ratings yet

- Wilo PDFDocument469 pagesWilo PDFlogiko81No ratings yet

- SAB120-151 Spare Parts 2015.05Document52 pagesSAB120-151 Spare Parts 2015.05Andrei Taranu100% (2)

- SAB 151 Engineering Service and Maintenance Manual 2014.03Document159 pagesSAB 151 Engineering Service and Maintenance Manual 2014.03nikvaanNo ratings yet

- Tube IceDocument51 pagesTube IceJoel Alberto GarciaNo ratings yet

- 4019 - 4019 - Mycom 2016 LSC-51Document153 pages4019 - 4019 - Mycom 2016 LSC-51Tam DuongNo ratings yet

- Manual Danfoss Valvulas PMDocument54 pagesManual Danfoss Valvulas PMRaúl RiveraNo ratings yet

- Bombas Recepcion Bunker-OIK 08enDocument72 pagesBombas Recepcion Bunker-OIK 08enManuel Cantoral0% (1)

- Price List Air Coolers enDocument78 pagesPrice List Air Coolers enCKS CateringNo ratings yet

- PNGF Rooftop 048 350 R410aDocument32 pagesPNGF Rooftop 048 350 R410aRayhan Sayeed100% (1)

- Final Documentation Sungdong SY Hull S3109, S3109 Air Compressor SSM 41010956Document23 pagesFinal Documentation Sungdong SY Hull S3109, S3109 Air Compressor SSM 41010956Raúl Oscar LedesmaNo ratings yet

- Allowable Pipe Span (In)Document2 pagesAllowable Pipe Span (In)komang arimbawaNo ratings yet

- Contherm® Core Scraped-Surface Heat ExchangerDocument2 pagesContherm® Core Scraped-Surface Heat ExchangerKhánh NgânNo ratings yet

- Clorius Actuator CARDocument4 pagesClorius Actuator CARCatalin BeuNo ratings yet

- Sondex S7A-S14A-S20A-IDocument2 pagesSondex S7A-S14A-S20A-IEdwin GallegosNo ratings yet

- Alfa Laval CentrifugaDocument40 pagesAlfa Laval CentrifugaClodoaldo BiassioNo ratings yet

- H23A383DBEADocument1 pageH23A383DBEABruno Monteiro0% (1)

- 1tool ReleaseNotes 2 7 46Document14 pages1tool ReleaseNotes 2 7 46BJNE01No ratings yet

- Manual InglesDocument34 pagesManual Inglesmamdouh musaddiNo ratings yet

- ATC E Bulletin 153E Final LR PDFDocument44 pagesATC E Bulletin 153E Final LR PDFMax JunghannsNo ratings yet

- Manual de Mantenimiento Compresor vt10Document76 pagesManual de Mantenimiento Compresor vt10Emmanuel MJ Hos AchieverNo ratings yet

- Amtrobox: Limit Switch Box For Pneumatic Actuators Actair and Dynactair, and Manual Actuators MRDocument12 pagesAmtrobox: Limit Switch Box For Pneumatic Actuators Actair and Dynactair, and Manual Actuators MRRijal HarunNo ratings yet

- Alfa Laval PHE For REFDocument4 pagesAlfa Laval PHE For REFNiraj ReginaldNo ratings yet

- P-07 - Samsung - Tank Cleaning Pump and Stripping Pump, Technical Manual PDFDocument162 pagesP-07 - Samsung - Tank Cleaning Pump and Stripping Pump, Technical Manual PDFchuminhNo ratings yet

- 9400 Series - Catalogue - AccessoriesDocument86 pages9400 Series - Catalogue - AccessoriesSaulo Leonardo Fabelo FontesNo ratings yet

- Valvula Reductora de Presion Bermad Area 675 720-ULDocument4 pagesValvula Reductora de Presion Bermad Area 675 720-ULChristian FherNo ratings yet

- Differential Pressure Transmitter Model 3051 With Air Capillary For Waste Water Surge VesselDocument6 pagesDifferential Pressure Transmitter Model 3051 With Air Capillary For Waste Water Surge Vesselmltgb1No ratings yet

- Innopack KistersDocument2 pagesInnopack KistersDrdbuoiu Poiñhb Monihugy100% (2)

- Isotherm CoolingDocument12 pagesIsotherm CoolingsaxonpirateNo ratings yet

- InteliLite AMF25 1 7 0 Global Guide PDFDocument741 pagesInteliLite AMF25 1 7 0 Global Guide PDFYuriyNo ratings yet

- Data Sheet Filter Drier With Interchangeable Solid Core Type DCRDocument8 pagesData Sheet Filter Drier With Interchangeable Solid Core Type DCRDima ArfNo ratings yet

- Carrier Serie 50TC (15-27.5 Ton) PDFDocument98 pagesCarrier Serie 50TC (15-27.5 Ton) PDFRafael CentenoNo ratings yet

- DV DVW Series - Catalog - For 2015Document39 pagesDV DVW Series - Catalog - For 2015adeel_akhtarNo ratings yet

- 12E Spare PartsDocument66 pages12E Spare PartsСергей КонкинNo ratings yet

- Installation Manual: Switzerland (Head Office) New ZealandDocument20 pagesInstallation Manual: Switzerland (Head Office) New ZealandTelapia MaachNo ratings yet

- BTPX Series BTPX 305 SDocument4 pagesBTPX Series BTPX 305 SmcsabeeraliNo ratings yet

- JBT Freezer PortfolioDocument36 pagesJBT Freezer Portfoliomohammed sallem100% (2)

- 1079Document3 pages1079Mahmoud MohamedNo ratings yet

- VXC Evaporative CondenserDocument22 pagesVXC Evaporative CondenserSenthil Murugesan100% (2)

- 3000 Brochure PDFDocument24 pages3000 Brochure PDFFarooque ShaikhNo ratings yet

- Catalogo Unidad Manejadora AP60DX22 Americana AHRIDocument16 pagesCatalogo Unidad Manejadora AP60DX22 Americana AHRIAndres FelipeNo ratings yet

- BAC ProdAppHBii2007SupplDocument52 pagesBAC ProdAppHBii2007SupplmihdragosNo ratings yet

- BAC Brochure GeneralDocument12 pagesBAC Brochure GeneralTran Ngoc HaNo ratings yet

- SN Octoate - Dow PDFDocument6 pagesSN Octoate - Dow PDFAngga Tri PrasetyoNo ratings yet

- Chapter 4 Drainage DesignDocument47 pagesChapter 4 Drainage DesignhamzaNo ratings yet

- Biology FullDocument217 pagesBiology FullNaskaNo ratings yet

- Standard Specifications OF rOADS AND bRIDGES PDFDocument572 pagesStandard Specifications OF rOADS AND bRIDGES PDFSushmit SharmaNo ratings yet

- Guidelines For Drainage StudiesDocument300 pagesGuidelines For Drainage Studiescharles Ike100% (1)

- Ppe Midterm Project 1Document14 pagesPpe Midterm Project 1Joanne EscolanoNo ratings yet

- JAGNA ELA CapDev 2013 2016Document59 pagesJAGNA ELA CapDev 2013 2016Shella Santiago100% (2)

- EMP ReportDocument51 pagesEMP ReportInaam UllahNo ratings yet

- Abattoir Waste Treatment in SivakasiDocument8 pagesAbattoir Waste Treatment in SivakasivinothNo ratings yet

- 23617950NRCP BackgrpundDocument2 pages23617950NRCP BackgrpundClock 9No ratings yet

- 714 Irrometer Reference Book-WEBDocument24 pages714 Irrometer Reference Book-WEBDiego Lopez MontalvoNo ratings yet

- Blaster Sprayer Trade TestDocument7 pagesBlaster Sprayer Trade TestSteven Flynn100% (1)

- Final ThesisDocument74 pagesFinal ThesisPeter Castillo79% (34)

- Power GenerationDocument42 pagesPower GenerationFTR LoneWolfNo ratings yet

- SCELP Enforcement Project Moves ForwardDocument6 pagesSCELP Enforcement Project Moves ForwardSouth Carolina Environmental Law ProjectNo ratings yet

- Flexible PackagingDocument15 pagesFlexible PackagingAngela GarciaNo ratings yet

- History of Industrial HygieneDocument23 pagesHistory of Industrial HygieneJohnCarloTolibasNo ratings yet

- Distilled Water From Dirty Water SolarDocument3 pagesDistilled Water From Dirty Water SolarbatcavernaNo ratings yet

- An Overview of Water Sensitive Urban Design Practi PDFDocument9 pagesAn Overview of Water Sensitive Urban Design Practi PDFyamini sainiNo ratings yet

- Mediterranean SeaDocument36 pagesMediterranean SeaKarl GustavNo ratings yet

- Water ManagementDocument9 pagesWater Managementtonmoy sajibNo ratings yet

- VFA FittingsCatalogueDocument164 pagesVFA FittingsCatalogueDimitar KondinskiNo ratings yet

- Design of Movable Weirs WG26Document10 pagesDesign of Movable Weirs WG26zmogoNo ratings yet

- Test Report 179 - Copper Tape B Bond Clamp - BB32BDocument18 pagesTest Report 179 - Copper Tape B Bond Clamp - BB32BannamalaiNo ratings yet

- Mining and Its Impacts On Environment With Special Reference To IndiaDocument7 pagesMining and Its Impacts On Environment With Special Reference To Indiaana maria borda contrerasNo ratings yet

- AdaptationsDocument4 pagesAdaptationsJack BarkerNo ratings yet

- TDP 796-060 PreviewDocument8 pagesTDP 796-060 PreviewSusan LamNo ratings yet

- Project Standards and Specifications Civil and Structural Design Package Rev01Document16 pagesProject Standards and Specifications Civil and Structural Design Package Rev01LleiLleiNo ratings yet

- Mineral Based Industry For Kerala by ThrivikramjiDocument34 pagesMineral Based Industry For Kerala by ThrivikramjiDrThrivikramji KythNo ratings yet

- LANZONESDocument13 pagesLANZONESJoshua ReyesNo ratings yet