Professional Documents

Culture Documents

Rule Sheet For The B Division Bottle Rocket and C Division Bottle

Uploaded by

Utah Science OlympiadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rule Sheet For The B Division Bottle Rocket and C Division Bottle

Uploaded by

Utah Science OlympiadCopyright:

Available Formats

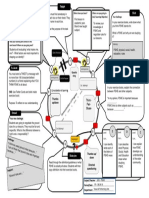

BOTTLE ROCKETS UTAH B DIVISION 1.

DESCRIPTION: Prior to the tournament, teams construct two rockets designed to stay aloft for the greatest amount of time. 2. TEAM OF UP TO: 2 IMPOUND: No EYE PROTECTION: #5 APPROXIMATE TIME: 10 min. 3. EVENT PARAMETERS: a. Teams must design, build, and bring up to two rockets to the tournament (only 1 launch per rocket). Parts from one rocket must not be used on another rocket. b. Teams without proper eye protection must be immediately informed and given a chance to obtain eye protection if time allows, otherwise they will not be allowed to compete and scored as a no-show. c. Event supervisors must provide the launcher and water. 4. CONSTRUCTION PARAMETERS: a. Rocket pressure vessels must be made out of a single 1 liter or less plastic carbonated beverage bottle with a neck/nozzle opening internal diameter of approximately 2.2 cm (a 1/2 inch Schedule 40 PVC pipe must fit tightly inside the nozzle opening). Labels may be removed from the bottle but must be presented at the safety inspection. b. Only tape must be used to attach fins and other components to the pressure vessel. No glues of any type may be used on the pressure vessel. Glue may be used in other parts of the rocket assembly. Metal of any type and commercial model rocket parts are prohibited anywhere on the rocket. c. The structural integrity of the pressure vessel must not be altered. This includes, but is not limited to: physical, thermal or chemical damage (e.g., cutting, sanding, using hot or super glues, spray painting). d. Alteration to the structural integrity of the pressure vessel results in a safety violation of the rocket and it must not be launched. Event supervisors assess structural integrity by looking through the nozzle and sides of the bottle for discoloration, bubbles, thinning or cuts in the walls. e. The nose of the rocket must be rounded or blunt at the tip and designed such that when a standard 2 liter bottle cap (~3.1 cm diameter x 1.25 cm tall) is placed on top of the nose, no portion of the nose touches the inside top of the bottle cap (see Figure 1). Teams must not use a nose that is sharp, pointed, or consisting of a rigid spike regardless of the material used. f. Explosives, gases other than air, chemical reactions, pyrotechnics, electric or electronic devices, elastic powered flight assists, throwing devices, remote controls, and tethers are prohibited at any time. All energy imparted to the rocket at launch must originate from the water/air pressure combination. Figure 2 g. All rockets must be launched using the launcher provided by the supervisor. Fins and other parts added to the bottle must be 5 cm or higher above the level of the bottles opening, to ensure rockets fit on the launcher (see Figure 2). h. Rockets must not change shape or deploy any type of recovery system. 5. THE COMPETITION: a. Teams must arrive at the competition site ready to launch. Following the safety inspection of the rockets, teams may add any amount of water to the inspected rocket(s). When called to launch, the teams have a total of 10 minutes to launch the rockets (only 1 launch per rocket). Any rocket launched before the time expires must be scored. b. Rockets must be launched at 60 psi. Once pressurized, teams must not touch or approach the rocket. c. Parts of the rocket must not fall off or become separated during launch or flight. d. Time aloft is recorded in hundredths of a second. Timing begins when the rocket separates from the launcher and stops when any part of the rocket touches the ground, goes out of sight, or comes to rest on an obstruction (e.g. a tree or building). e. Event supervisors are strongly encouraged to use three independent timers on all launches. The middle value of the three timers must be the officially recorded time. 6. SCORING: Rockets with construction or safety violations will not be launched due to safety. Teams that are unable to launch a rocket because of construction violations will receive participation points only. a. Ranking within each tier is determined by the combined greatest time aloft of both rocket flights. If a team only launches one rocket then that team will receive only the flight time for that launch. b. Tiers: Teams with a Tier 1 rocket and a rocket with a violation are scored as if they had only one rocket. i. Tier 1: Rockets launched without construction or competition violations. ii. Tier 2: Any Launch with competition violations. c. Ties are broken by the greatest time aloft by a single rocket. Recommended Resources: All reference and training resources including the Bottle Rocket DVD are available on the Official Science Olympiad Store or Website at http://www.soinc.org

BOTTLE ROCKETS UTAH C DIVISION 2013 DESCRIPTION: Prior to the tournament, teams design and construct up to two rockets designed to stay aloft for the greatest amount of time. TEAM OF UP TO: 2 IMPOUND: No EYE PROTECTION: Safety Spectacles with Side Shields TIME: 10 min. 1. EVENT PARAMETERS: a. Teams must design, build, and bring up to two rockets to the tournament (only 1 launch allowed per rocket). Parts from one rocket must not be used on another rocket. Teams must wear eye protection during the loading, launching, and retrieving of their rockets. Teams may also bring their own funnels, measuring devices and other necessary tools to prepare their rockets. b. Event supervisors must provide the launcher and water. They may also provide funnels and measuring devices. 2. CONSTRUCTION PARAMETERS: a. PRESSURE VESSEL: Rocket pressure vessels must be made out of a single 2 liter or less plastic CARBONATED beverage bottle with a neck/nozzle opening internal diameter of approximately 2.2 centimeters (a 1/2 inch Schedule 40 PVC pipe must fit tightly inside the nozzle opening). i. Labels: Labels may be removed from the pressure vessel bottle but must still be presented at the safety inspection. Failure to present the labels at safety inspection will result in disqualification of the rocket and it must not be launched. ii. Attachment: Only tape may be used to attach fins and other components directly to the pressure vessel. iii. Materials: Metal of any type and/or commercial model rocket parts are prohibited anywhere on the rocket. iv. Structural Integrity: The structural integrity of the pressure vessel must not be altered. This includes, but is not limited to: physical, thermal, or chemical damage (e.g., cutting, sanding, using hot or super glues, spray painting). Alteration to the structural integrity of the pressure vessel results in a safety violation of the rocket and it must not be launched. Event supervisors must assess the structural integrity by looking through the nozzle and sides of the bottle for abrasions, discoloration, distortion, bubbles, thinning or cuts in the walls. b. NOSE: Rockets must use a blunt or rounded nose. The nose must be designed such that when a standard 2 liter bottle cap is placed on top of the nose, no portion of the nose touches the inside top of the bottle cap (see Figure 1). c. FINS: Fins and other parts added to the bottle must be five centimeters or higher above the level of the bottles opening to ensure rockets fit on the launcher (see Figure 2). Figure 2 d. ENERGY: Explosives, gases other than air, chemical reaction, pyrotechnics, electric or electronic devices, elastic powered flight assists, throwing devices, remote controls, and tethers are prohibited at any time. All energy imparted to the rocket at launch must originate from the water/air pressure combination. e. RECOVERY SYSTEM: Rockets may use any type of free-fall recovery system; however, the recovery system must be judged as safe and not violate any other rules. 3. THE COMPETITION: a. Teams must arrive at the competition site ready to launch. Following the safety inspection of rockets, teams may add any amount of water to the inspected rockets. All rockets must be launched using the launcher provided by the supervisor. b. When called to launch, the teams have a total of 10 minutes to launch 1 or 2 rockets (only 1 launch per rocket). Any rocket launched before the time expires must be scored. c. All rockets must be launched at 60 psi. Once the rocket is pressurized, teams must not touch or approach the rocket. d. Time aloft is recorded in hundredths of a second. Timing begins when the rocket separates from the launcher and stops when any part of the rocket touches the ground, goes out of sight, or comes to rest on an obstruction (e.g., a tree or building). e. Event supervisors are strongly encouraged to use three independent timers on all launches. The middle value of the three timers must be the officially recorded time. 4. SCORING: a. Ranking within each tier is determined by the greatest time aloft of a single rocket i. Tier 1: Any launch without construction or competition violations. ii. Tier 2: Any launch with competition violations. iii. Tier 3: Rockets with construction violations will not be launched due to safety. Ties may result in this situation. iv. Failure to properly wear eye protection will result in disqualification. b. Ties in tiers 1 and 2 are broken by the better score of each tied teams other rocket.

You might also like

- Opa1 Impacto MuscularDocument23 pagesOpa1 Impacto MuscularRafael GermanoNo ratings yet

- IVYT Physical Science 101, Chapter 2 QuizDocument2 pagesIVYT Physical Science 101, Chapter 2 Quizwxcar08No ratings yet

- GRanD Technical DocumentationDocument12 pagesGRanD Technical DocumentationHari Ram UpadhayayNo ratings yet

- Physical Science Midterm Study GuideDocument11 pagesPhysical Science Midterm Study GuideeherrerahghsNo ratings yet

- Project Management For Construction - Organization and Use of Project InformationDocument16 pagesProject Management For Construction - Organization and Use of Project InformationFarid MorganNo ratings yet

- Why Democracies Ban Political PartiesDocument31 pagesWhy Democracies Ban Political PartiesVasile CioriciNo ratings yet

- Massachusetts Institute of Technology v. VizioDocument17 pagesMassachusetts Institute of Technology v. VizioPriorSmartNo ratings yet

- Evalution of Management ThoughtDocument16 pagesEvalution of Management ThoughtShweta SharmaNo ratings yet

- Physical Science SyllabusDocument4 pagesPhysical Science Syllabusapi-325499687No ratings yet

- Management in Profit-Seeking and Not-For-Profit Organizations Large BusinessesDocument4 pagesManagement in Profit-Seeking and Not-For-Profit Organizations Large BusinessesВалентина АпостоловаNo ratings yet

- Physics Exam QuestionsDocument8 pagesPhysics Exam Questionspetesqueeler7052No ratings yet

- A. Multiple Choice - Write The Letter of Your Answer (10 PTS)Document3 pagesA. Multiple Choice - Write The Letter of Your Answer (10 PTS)Mikee TanquecoNo ratings yet

- Worksheet For Class 10Document9 pagesWorksheet For Class 10rishit allamNo ratings yet

- Organisational Study Project (At Emertxe) : CMR UniversityDocument41 pagesOrganisational Study Project (At Emertxe) : CMR UniversitySunanditha SundaramNo ratings yet

- Human Resource Mba 4th SemDocument4 pagesHuman Resource Mba 4th SemSahil SethiNo ratings yet

- 1 What Management Organization and Technology Factors Were Behind TheDocument1 page1 What Management Organization and Technology Factors Were Behind TheAmit PandeyNo ratings yet

- B 4 Stress ManagementDocument10 pagesB 4 Stress ManagementSourabh GargNo ratings yet

- MIT6 041F10 FinalDocument20 pagesMIT6 041F10 FinalGokce TuncerNo ratings yet

- TP Leadership and Management 2015 A Final Copy1Document92 pagesTP Leadership and Management 2015 A Final Copy1gladz25No ratings yet

- Lesson 1 1.1 ManagementDocument15 pagesLesson 1 1.1 ManagementWilliam EstacioNo ratings yet

- Master of Labour WelfareDocument14 pagesMaster of Labour WelfareumangcmodiNo ratings yet

- Methodology of Environmental Management System Process ModellingDocument11 pagesMethodology of Environmental Management System Process ModellingKomalNo ratings yet

- Chapter IDocument6 pagesChapter IZandro Umangay IcoNo ratings yet

- PSHE - Lesson Plan 1Document1 pagePSHE - Lesson Plan 1Sowole JideNo ratings yet

- Robert Goddard BiographyDocument8 pagesRobert Goddard BiographyIzza AiniNo ratings yet

- Managing in Turbulent Times: True/False QuestionsDocument30 pagesManaging in Turbulent Times: True/False QuestionsGiang NgânNo ratings yet

- Managing in A Dynamic Environment Learning Objectives: Learning Objective 1: Define Managers and ManagementDocument4 pagesManaging in A Dynamic Environment Learning Objectives: Learning Objective 1: Define Managers and Managementmahmialter2948No ratings yet

- 2020-07-15 PSHE Consultation Before Delivery in 2020-21Document2 pages2020-07-15 PSHE Consultation Before Delivery in 2020-21isleworthsyonNo ratings yet

- AQUINO, Maria Gabriela 3LM1 - Discussion Activity 1Document4 pagesAQUINO, Maria Gabriela 3LM1 - Discussion Activity 1Ella AquinoNo ratings yet

- How To Read A Science TextDocument20 pagesHow To Read A Science TextCyra Ingrid CastilloNo ratings yet

- Boundary Permeability and Online-Offline Hybrid Organization A Case Study of Suning, ChinaDocument13 pagesBoundary Permeability and Online-Offline Hybrid Organization A Case Study of Suning, ChinaAANo ratings yet

- Physical Science Concept InventoryDocument7 pagesPhysical Science Concept Inventoryapi-260050817No ratings yet

- 8-IJBGM-Improving Maintenance Strategy FinalDocument24 pages8-IJBGM-Improving Maintenance Strategy Finaliaset123No ratings yet

- General Manager - Finance & Accounts: Job Description & Application FormDocument3 pagesGeneral Manager - Finance & Accounts: Job Description & Application FormBhagwatiprasad MathurNo ratings yet

- Chapter 1 - Introduction: Why Do We Study History?Document2 pagesChapter 1 - Introduction: Why Do We Study History?dfefewfNo ratings yet

- International Journal of Business and Management Invention (IJBMI)Document13 pagesInternational Journal of Business and Management Invention (IJBMI)inventionjournalsNo ratings yet

- PoM RevisionDocument38 pagesPoM RevisionGeraldwerreNo ratings yet

- 1136 Sayantan ChoudhuryDocument5 pages1136 Sayantan ChoudhuryStan leeNo ratings yet

- Akash ADocument42 pagesAkash ABalaKrishnaNo ratings yet

- President of An OrganizationDocument6 pagesPresident of An OrganizationJose CabalumNo ratings yet

- 12 Chapter3 PDFDocument39 pages12 Chapter3 PDFSevuga MoorthyNo ratings yet

- Pakistan Structural Geology Notes Axial BeltDocument2 pagesPakistan Structural Geology Notes Axial BeltRazi AbbasNo ratings yet

- Kelsey Clark 3 HR Frame WorksheetDocument4 pagesKelsey Clark 3 HR Frame Worksheetapi-538653350No ratings yet

- Organization and Management: LESSON 1: Evolution of Management TheoriesDocument16 pagesOrganization and Management: LESSON 1: Evolution of Management TheoriesMs. ArceñoNo ratings yet

- Chapter - Two The Development of Management Thoughts / Theories Value of TheoryDocument11 pagesChapter - Two The Development of Management Thoughts / Theories Value of Theoryይርዳው ሲሳይ ወርቀልዑልNo ratings yet

- Virtual Organizations: An OverviewDocument6 pagesVirtual Organizations: An OverviewLn VedanayagamNo ratings yet

- Weather Lesson 2nd GradeDocument2 pagesWeather Lesson 2nd Gradeapi-535070811No ratings yet

- Management and Organization BehaviorDocument13 pagesManagement and Organization BehaviorInterport Corporate AcademyNo ratings yet

- Organization Study GuidelinesDocument4 pagesOrganization Study GuidelinesbluespringsNo ratings yet

- Project Manager Competence: Putting The PMBOK To WorkDocument7 pagesProject Manager Competence: Putting The PMBOK To WorkAnthony ChandraNo ratings yet

- Cheat The Sims 4Document7 pagesCheat The Sims 4Fashla Haqqi SalamNo ratings yet

- Rocket Rocket Again RocksDocument34 pagesRocket Rocket Again RockserppibuNo ratings yet

- Tips For CSIR NET For Physical SciencesDocument24 pagesTips For CSIR NET For Physical SciencesboltuNo ratings yet

- PMO (Project Management Office) Integration Into Organizations: A Large Brazilian Company CaseDocument8 pagesPMO (Project Management Office) Integration Into Organizations: A Large Brazilian Company CaseRahmat AnharNo ratings yet

- Rapid Cap Revision For Physical Science Book 1Document229 pagesRapid Cap Revision For Physical Science Book 1Sheambom NelsonNo ratings yet

- Project Organization and StructureDocument13 pagesProject Organization and StructureSuvash RegmiNo ratings yet

- POM Unit 2-1Document26 pagesPOM Unit 2-1ankit singhNo ratings yet

- What Is Organization DevelopmentDocument11 pagesWhat Is Organization Developmenthedyaguila100% (2)

- Person-Organization Fit and Turnover Intention: The Mediating Role of Employee EngagementDocument5 pagesPerson-Organization Fit and Turnover Intention: The Mediating Role of Employee EngagementmasoorajeNo ratings yet

- 321blastoff A 2014Document2 pages321blastoff A 2014api-231534717No ratings yet

- C Teams Home BasesDocument1 pageC Teams Home BasesUtah Science OlympiadNo ratings yet

- Spectator EventsDocument1 pageSpectator EventsUtah Science OlympiadNo ratings yet

- Home Base AssignmentsDocument1 pageHome Base AssignmentsUtah Science OlympiadNo ratings yet

- B Teams Home BasesDocument1 pageB Teams Home BasesUtah Science OlympiadNo ratings yet

- Science Olympiad Water Quality PresentationDocument31 pagesScience Olympiad Water Quality PresentationUtah Science Olympiad50% (2)

- Utah Science Olympiad 2013 MapDocument1 pageUtah Science Olympiad 2013 MapUtah Science OlympiadNo ratings yet

- Utah Science Olympiad - 2012 State EventsDocument2 pagesUtah Science Olympiad - 2012 State EventsUtah Science OlympiadNo ratings yet

- Utah Forestry Tree List 2013Document3 pagesUtah Forestry Tree List 2013Utah Science OlympiadNo ratings yet

- Density ReagentsDocument1 pageDensity ReagentsUtah Science OlympiadNo ratings yet

- Utah Science Olympiad - 2013 State EventsDocument2 pagesUtah Science Olympiad - 2013 State EventsUtah Science Olympiad0% (1)

- 2012 Science Olympiad BrochureDocument4 pages2012 Science Olympiad BrochureUtah Science OlympiadNo ratings yet

- Utah Science Olympiad 2012Document74 pagesUtah Science Olympiad 2012Utah Science Olympiad100% (1)

- Utah Science Olympiad 2013 BrochureDocument2 pagesUtah Science Olympiad 2013 BrochureUtah Science OlympiadNo ratings yet

- Utah Science Olympiad - Scholarship Winners 2012Document9 pagesUtah Science Olympiad - Scholarship Winners 2012Utah Science OlympiadNo ratings yet

- 2012 Utah Science Olympiad ProgramDocument5 pages2012 Utah Science Olympiad ProgramUtah Science OlympiadNo ratings yet

- 2012 Utah Science Olympiad T-ShirtDocument2 pages2012 Utah Science Olympiad T-ShirtUtah Science OlympiadNo ratings yet

- Inspection References CaterpillarDocument58 pagesInspection References CaterpillarRforceIbañez100% (2)

- Erpi Admin 11123510Document416 pagesErpi Admin 11123510prakash9565No ratings yet

- BSS Steel Guide CataloguesDocument52 pagesBSS Steel Guide Cataloguessaber66No ratings yet

- CV PDFDocument4 pagesCV PDFSIVA0% (1)

- (Lab Report Operation Unit) Experiment 3: Separation of An Ordinary Binary Mixture Consisting of Acetic Acid and Water by Using Simple Batch Distillation Technique.Document8 pages(Lab Report Operation Unit) Experiment 3: Separation of An Ordinary Binary Mixture Consisting of Acetic Acid and Water by Using Simple Batch Distillation Technique.Fazsroul100% (9)

- Lecture 3 Bending and Shear in Beams PHG A8 Oct17 PDFDocument30 pagesLecture 3 Bending and Shear in Beams PHG A8 Oct17 PDFEvi32No ratings yet

- Systemd CheatsheetDocument1 pageSystemd Cheatsheetzaffa11No ratings yet

- Wind Load Analysis For Open StructureDocument3 pagesWind Load Analysis For Open Structurehitesh gandhiNo ratings yet

- ML10 OwnersManualDocument16 pagesML10 OwnersManualSalvador OlivasNo ratings yet

- S3F94xx BatteryCharger An REV000 060109-0Document40 pagesS3F94xx BatteryCharger An REV000 060109-0Jack ChanNo ratings yet

- Embraco Standard Aftermarket Portfolio PDFDocument2 pagesEmbraco Standard Aftermarket Portfolio PDFJOR4CHNo ratings yet

- Design CriteriaDocument6 pagesDesign CriteriaAllyssa Jane ErcillaNo ratings yet

- CRISC BrochureDocument2 pagesCRISC BrochureSpipparisNo ratings yet

- 022-000015B NvcaDocument229 pages022-000015B NvcaCarlos Terraza OyagaNo ratings yet

- Standard Rain GaugeDocument43 pagesStandard Rain GaugeAku PalsuNo ratings yet

- 40 kVA Specification SheetDocument2 pages40 kVA Specification SheetAlex MohanNo ratings yet

- General Description: Dual Retriggerable Precision Monostable MultivibratorDocument17 pagesGeneral Description: Dual Retriggerable Precision Monostable Multivibratorsajad hejaziNo ratings yet

- Lab 4Document14 pagesLab 4rhinsaokiNo ratings yet

- Melde's MethodDocument2 pagesMelde's MethodDR.P.V.Kanaka Rao0% (1)

- Cs Acrovyn CatalogueDocument83 pagesCs Acrovyn CatalogueBoboc AndreiNo ratings yet

- Energy Saving Basics - EsdsDocument40 pagesEnergy Saving Basics - Esdsapi-238581599No ratings yet

- ANtenna PropagationDocument63 pagesANtenna PropagationPrasanna PandeyNo ratings yet

- PMAC720Document3 pagesPMAC720felipeNo ratings yet

- MANSAVER Catalog PDFDocument155 pagesMANSAVER Catalog PDFDejanNo ratings yet

- Peri Up Flex Core ComponentsDocument50 pagesPeri Up Flex Core ComponentsDavid BourcetNo ratings yet

- NAPCA TrainingDocument149 pagesNAPCA TrainingalejandroNo ratings yet

- Simple (Ideal) Vapor Compression Refrigeration Cycle ProblemsDocument3 pagesSimple (Ideal) Vapor Compression Refrigeration Cycle Problemssajawal hassanNo ratings yet

- NexstarcommprotDocument8 pagesNexstarcommprotskirmixNo ratings yet

- York Ducted Split Ac Yefe 18-48Document6 pagesYork Ducted Split Ac Yefe 18-48DANISH0% (1)

- Gapura Company Profile - 17mar17Document43 pagesGapura Company Profile - 17mar17als izmiNo ratings yet