Professional Documents

Culture Documents

Thickness Calculation of Pressure Vessel Shell

Uploaded by

Noman Abu-FarhaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thickness Calculation of Pressure Vessel Shell

Uploaded by

Noman Abu-FarhaCopyright:

Available Formats

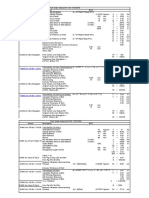

Source ASME Sec VIII Div 1 UG-27

Shell Under Internal Pr/ / Dt. 17/07/2010 Description

MOC

ASME Sec.II Part D Table 1A

Longitudinal Stress Cicumferential Stress

ts = (P*R)/((2*S*E)+(0.4*P)) THICKNESS OF SHELL Shell side Design Pressure Inside Radius of shell Wall Thickness of Shell Wall Thickness of Dish Max Allowable stress for Shell Material SS 304 L Max Allowable stress for Dish Material SS 304 L Crown Radius Knuckle Radius Joint Efficiency Dish Joint Efficiency Shell Calculated Thickness of Shell ts = (P*R)/((2*S*E)+(0.4*P)) Calculated Thickness of Shell ts = (P*R)/((S*E)-(0.6*P))

39.78 625 16 18

Kgs/cm2 mm mm mm

1250 125

P R ts td S S L r Ed Es ts ts ts ts

= = = =

= = = = = = = =

ASME Sec VIII Div 1 UG-32

Add Corrosion Allowance Thickness of Shell with corrosion allowance Calculated Thickness is 19.49 mm We are using 16 mm Increase Thickness of Shell td THICKNESS OF DISH TORISPHERICAL = (0.885* P * L ) / ( ( S * E) - ( 0.1 * P ) ) Calculated Thickness of Dish Add Thinning Allowances Add Corrosion Allowances Noiminal Thickness of Dish Calculated Thickness of Dish 36.02 mm We are using 18 mm Increase Thickness of Dish THICKNESS OF DISH ELLIPSOIDAL td = ( P * D ) / ( ( 2* S * E) - ( 0.2 * P ) ) Calculated Thickness of Dish Add Thinning Allowances Add Corrosion Allowances Noiminal Thickness of Dish Calculated Thickness of Dish We are using Increase Thickness of Dish

566 24.61 0.63 0.71 20000 20000 49.21 4.92 1.00 1.00 0.35 8.79 0.71 17.99 1.50 19.49

Psi In In in Psi Psi In In

In mm In mm

Td Td

= =

1.24 31.38 3.14 1.50 36.02

In mm mm mm mm

ASME Sec VIII Div 1 UG-32

Td Td

= =

0.70 17.73 1.77 1.50 21.00

In mm mm mm mm

21.00 18

mm mm

Shell Under External Pr// Dt. 17/07/2010 Source Description ASME Sec VIII Div 1 UG-28 THICKNESS OF SHELL Shell External Pressure Outside Diameter of shell Shell Thickness Dish Thickness Dish SF ASME Sec.II Part D Max Allowable stress for Shell Material Table 1A Max Allowable stress for Dish Material Crown Radius Joint Efficiency Dish Dish Depth Unsupported Length of Shell

MOC

4.3 1282 8 16 40 SS 304 L SS 304 L 1282 336.4 150

Kgs/cm2 mm mm mm mm

P Do ts td S S L Ed h L L/Do Do/t

= = = = =

mm mm

= = = = = =

61 50.47 0.31 0.63 1.57 15800 15800 50.47 1.00 13.24 5.91 0.12 160.25

Psi In in in in Psi Psi In in in

If Do/t >= 10 ASME Sec II part D Fig G From Fig G using L/Do and Do/t From Fig HA-3 for 304L ASME Sec VIII Div 1 Maximum Allowable external working UG-28 Pressure A B Pa = 4B/(3*(Do/t))

2 4.97232 Kgs/cm

= 0.01 = 8500.00 = 70.72 psi

Pa

Hence Safe ASME Sec VIII Div 1 THICKNESS OF DISH UG-32 Calculated Thickness of Dish Add Thinning Allowances Add Corrosion Allowances Calculated Thickness of Dish ASME Sec VIII Div 1 A = 0.125/(Ro/t) UG-33 ASME Sec II part D Fig G From Fig HA-3 for 304L ASME Sec VIII Div 1 Maximum Allowable external working UG-28 Pressure

td = (0.885*1.67*P * L ) / ( ( S * E) - ( 0.1 *1.67* P ) )Td Td

= =

0.29

In mm mm mm mm

7.34 0.73 1.00 9.07 = 0.00156

B Pa = B/(Ro/t)

2 4.82608 Kgs/cm

= 5500 = 68.64 psi

Pa

304L

You might also like

- Design Calculations For Pressure VesselsDocument24 pagesDesign Calculations For Pressure VesselsMichael Lageman93% (15)

- Section VIII CalDocument21 pagesSection VIII CalRuben Samoel Barros RochaNo ratings yet

- Thickness Calculation of Pressure Vessel ShellDocument17 pagesThickness Calculation of Pressure Vessel ShellVishnuGK100% (1)

- Design Calculations For Pressure VesselsDocument32 pagesDesign Calculations For Pressure VesselsGeorge Georgian100% (3)

- Design Calculations For Pressure VesselsDocument73 pagesDesign Calculations For Pressure Vesselsshani5573No ratings yet

- Weight Estimation of Vessels AppsDocument28 pagesWeight Estimation of Vessels AppsAlvin Smith60% (5)

- Shell and Tube HE CalculationDocument16 pagesShell and Tube HE CalculationPradip ShindeNo ratings yet

- Shell CalculationsDocument3 pagesShell CalculationsBaher Elsheikh100% (7)

- 26 Pressure Vessel.Document21 pages26 Pressure Vessel.mishtinil93% (14)

- ASME Pressure Vessel Design-ADocument190 pagesASME Pressure Vessel Design-AWidyAdityaNo ratings yet

- Mechanical Design Calculations of Pressure Vessel - SampleDocument27 pagesMechanical Design Calculations of Pressure Vessel - SampleSakthi Vel100% (1)

- 2 - 1 Ellipsoidal Head Blank DiameterDocument1 page2 - 1 Ellipsoidal Head Blank Diameterdownloadmonster100% (2)

- Pressure Vessel Design ManualDocument32 pagesPressure Vessel Design ManualAris Purniawan100% (1)

- Pressure Vessel THCK CalcDocument8 pagesPressure Vessel THCK Calcmkchy12100% (1)

- Design of Pressure Vessel (Int & Ext)Document394 pagesDesign of Pressure Vessel (Int & Ext)api-3824026100% (8)

- Pressure Vessel Design-Excel-sheet-basic-designing-non-critical-PDocument1 pagePressure Vessel Design-Excel-sheet-basic-designing-non-critical-Pabhi_mohit200569% (13)

- Reinf S1Document2 pagesReinf S1tasingenieriaNo ratings yet

- Design Calculations For Pressure VesselsDocument54 pagesDesign Calculations For Pressure VesselsEdgar A. Arredondo QuirozNo ratings yet

- Pressure Vessel Design CalculationsDocument127 pagesPressure Vessel Design Calculationsajayghosh314086% (22)

- Calculation - ASME VIII Div.1Document10 pagesCalculation - ASME VIII Div.1bargez100% (1)

- Pressure Vessel Assessment SpreadsheetDocument3 pagesPressure Vessel Assessment SpreadsheetrawirabbatNo ratings yet

- Pressure VesselDocument507 pagesPressure Vesselpradip11100% (1)

- External Pressure DesignDocument395 pagesExternal Pressure DesignrsubramaniNo ratings yet

- Vessel Thickness CalculationDocument60 pagesVessel Thickness CalculationSaurabh SinghNo ratings yet

- Pressure Vessel Design Calc - ASME VIII Div 1Document22 pagesPressure Vessel Design Calc - ASME VIII Div 1aauppalNo ratings yet

- External Pressure CalculationsDocument40 pagesExternal Pressure Calculationsmisterdavi50% (2)

- Pressure Vessel Calculation Report PDFDocument12 pagesPressure Vessel Calculation Report PDFVictor Fakoya50% (2)

- Design of Pressure Vessel NewDocument442 pagesDesign of Pressure Vessel NewkhanfaqihNo ratings yet

- Reinforcement Pad DesignDocument3 pagesReinforcement Pad DesignAkshat JainNo ratings yet

- Super CalculationsDocument9 pagesSuper CalculationsNoé MarínNo ratings yet

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George RaczNo ratings yet

- Ibr Calc GSRDocument4 pagesIbr Calc GSRAniket GaikwadNo ratings yet

- Weight Estimation of Vessels AppsDocument39 pagesWeight Estimation of Vessels Appsmacwan23No ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleChagar HarshpalNo ratings yet

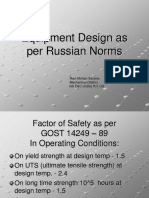

- Equipment Design As Per Russian Norms - 20090218Document45 pagesEquipment Design As Per Russian Norms - 20090218vikas100% (1)

- Ibr CalcDocument4 pagesIbr CalcUmesh Kondkar100% (7)

- Boiler Drum Thickness CalculationDocument3 pagesBoiler Drum Thickness Calculationsumang254567% (3)

- Doshi Ion Exchange & Chemical Ind. LTD.: Material DataDocument7 pagesDoshi Ion Exchange & Chemical Ind. LTD.: Material DataMakrand Sakpal100% (5)

- Shell & Dish ThicknessDocument3 pagesShell & Dish Thicknesskirandas_mullasseryNo ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of Nozzlehardik5818No ratings yet

- Steam Drum, Water Wall & Evaporator - VWHA054Document36 pagesSteam Drum, Water Wall & Evaporator - VWHA054Mani SunNo ratings yet

- Design Calculations For Pressure VesselsDocument30 pagesDesign Calculations For Pressure VesselsVinoth Rajendra100% (3)

- Design Calculations For Pressure VesselsDocument30 pagesDesign Calculations For Pressure VesselsPeña Eepesa100% (2)

- Aspen HX Design ReportDocument78 pagesAspen HX Design ReportberylqzNo ratings yet

- Asme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoDocument72 pagesAsme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoSivateja NallamothuNo ratings yet

- SPAN Calc.Document48 pagesSPAN Calc.yoi_123No ratings yet

- Lug Support DesignDocument3 pagesLug Support DesignSajal KulshresthaNo ratings yet

- Design Calculations For Pressure ShellDocument33 pagesDesign Calculations For Pressure ShellGeorge GeorgianNo ratings yet

- Design Calculations For Pressure VesselsDocument28 pagesDesign Calculations For Pressure VesselsUmair AwanNo ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document3 pagesCalculation of Pipe Reinforcement ASME B31 3Brant AkkanNo ratings yet

- Engineering Example CalculationDocument78 pagesEngineering Example Calculationkae kaeNo ratings yet

- Calculation of Pipe Reinforcement ASME B31.3Document9 pagesCalculation of Pipe Reinforcement ASME B31.3yhnsharma80% (5)

- E4.5 Flange Cover CalcDocument10 pagesE4.5 Flange Cover CalcTanCM100% (1)

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- Super CalculationsDocument12 pagesSuper CalculationsCarlos Tijerina0% (1)

- Calculation of PipeReinforcement ASMEB31.1Document3 pagesCalculation of PipeReinforcement ASMEB31.1jayaarnav100% (1)

- L 8 IhjnmklgfDocument27 pagesL 8 IhjnmklgfbrintopvNo ratings yet

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezNo ratings yet

- Asme Viii CalcsDocument20 pagesAsme Viii CalcsSriram VjNo ratings yet

- Asme Sec Ix WPS PQRDocument41 pagesAsme Sec Ix WPS PQRwentroprem100% (1)

- Design Calculations For Anchor BoltDocument1 pageDesign Calculations For Anchor BoltAkshat JainNo ratings yet

- G3ir 4 0201 01 00025 1 - AwDocument1 pageG3ir 4 0201 01 00025 1 - AwAkshat JainNo ratings yet

- Design Calculations For Pressure VesselsDocument30 pagesDesign Calculations For Pressure VesselsPeña Eepesa100% (2)

- Nozzle Neck CalculationDocument4 pagesNozzle Neck CalculationAkshat JainNo ratings yet

- Sizing The Air ReceiverDocument1 pageSizing The Air ReceiverSreevathsa Gururaj100% (1)

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design CalculationHoracio RodriguezNo ratings yet

- Cone CalculationDocument4 pagesCone CalculationAkshat JainNo ratings yet

- Painting Specification For Storage Tanks.Document27 pagesPainting Specification For Storage Tanks.Akshat Jain80% (5)

- Ladder and Self Closing Gate For Storage TankDocument15 pagesLadder and Self Closing Gate For Storage TankAkshat JainNo ratings yet

- Reinforcement Pad DesignDocument3 pagesReinforcement Pad DesignAkshat JainNo ratings yet

- General Visual Inspection: Airframe and Power Plant SystemsDocument37 pagesGeneral Visual Inspection: Airframe and Power Plant SystemsAgustin GuzmanNo ratings yet

- CSR Paper ResearchDocument14 pagesCSR Paper ResearchJacqueline GalletoNo ratings yet

- Speech Act TheoryDocument3 pagesSpeech Act Theorypak updatesNo ratings yet

- Spectral Triad (AS7265x) Hookup Guide - SparkFun LearnDocument13 pagesSpectral Triad (AS7265x) Hookup Guide - SparkFun LearnFrancisco BoteroNo ratings yet

- Solar System Answer The Following QuotationsDocument7 pagesSolar System Answer The Following QuotationsSlash XmoNo ratings yet

- Integration of Facilities Management (FM) Practices With Building Information Modeling (BIM)Document8 pagesIntegration of Facilities Management (FM) Practices With Building Information Modeling (BIM)Shamiel AmirulNo ratings yet

- Podcaster Inc Issue 1Document38 pagesPodcaster Inc Issue 1Hubert NomamiukorNo ratings yet

- Shivam Garg - Curriculum Vitaé - CVDocument4 pagesShivam Garg - Curriculum Vitaé - CVSHUBHAM MAHARANANo ratings yet

- QHSE Training Answers FIELD PERSONNELDocument1 pageQHSE Training Answers FIELD PERSONNELMhanna AYNo ratings yet

- Stop Call Wait BDocument1 pageStop Call Wait BTuan Anh100% (1)

- MIDEL 7131 Technical Information Pack USDocument15 pagesMIDEL 7131 Technical Information Pack USkatherine100% (1)

- Enginerring Room Resource Management Section III/1-2 and STCW Code Section A III/1 Paragraph 1-10Document1 pageEnginerring Room Resource Management Section III/1-2 and STCW Code Section A III/1 Paragraph 1-10Global Inovasi BersamaNo ratings yet

- Theory of Thermal Energy He Atom Scattering From Ordered Submonolayers On Solid SurfacesDocument136 pagesTheory of Thermal Energy He Atom Scattering From Ordered Submonolayers On Solid SurfacesAntonio ŠiberNo ratings yet

- 08 - Chapter 5Document78 pages08 - Chapter 5RashaNo ratings yet

- Jurnal Ira FebrianiDocument8 pagesJurnal Ira FebrianiNada Anis FadhilahNo ratings yet

- 2011 Catalogue r1Document116 pages2011 Catalogue r1Özhan ÖzkanNo ratings yet

- Rpa W3Document15 pagesRpa W3MLCKB AMIRAH HAFIZAHNo ratings yet

- Ohmite Component Selector: Catalog 4000KDocument205 pagesOhmite Component Selector: Catalog 4000Klem abesamisNo ratings yet

- Original PDF Introduction To Logic by Paul Herrick PDFDocument41 pagesOriginal PDF Introduction To Logic by Paul Herrick PDFpearl.zinn592100% (35)

- Sailor Moon Vol 1 - Naoko TakeuchiDocument204 pagesSailor Moon Vol 1 - Naoko TakeuchiKate Yati100% (4)

- 08 Supply Chain Management v3.1Document3 pages08 Supply Chain Management v3.1BRAYAN ALEJANDRO REYES VILLANUEVANo ratings yet

- THE CLOUD EnglishDocument11 pagesTHE CLOUD Englishraman raghavNo ratings yet

- Electrostatics. ProblemsDocument3 pagesElectrostatics. Problemsscs942609No ratings yet

- Ideal Gas Law NotesDocument4 pagesIdeal Gas Law NotesPrincess Jean GalabinNo ratings yet

- Module 8 ANOVA or F TestDocument11 pagesModule 8 ANOVA or F TestArklon N. PerezNo ratings yet

- BayokibokDocument7 pagesBayokibokGreen Humilde AquinoNo ratings yet

- Relevel Admit CardDocument1 pageRelevel Admit CardSHAURYA VERMA BTechNo ratings yet

- The Second Term English ExamDocument3 pagesThe Second Term English ExamsamouNo ratings yet

- Construction Project Management - Guidelines: Indian StandardDocument14 pagesConstruction Project Management - Guidelines: Indian StandardSathishNo ratings yet

- Informed Consent Form (Sample) Research Studies by Students in ...Document3 pagesInformed Consent Form (Sample) Research Studies by Students in ...Djean TubinoNo ratings yet