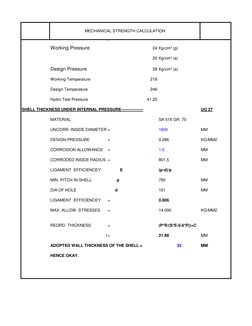

MECHANICAL STRENGTH CALCULATION `

Working Pressure

24 Kg/cm (g) 25 Kg/cm (a)

Design Pressure

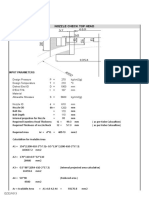

Working Temperature Design Temperature Hydro Test Pressure SHELL THICKNESS UNDER INTERNAL PRESSURE---------------MATERIAL UNCORR. INSIDE DIAMETER = D DESIGN PRESSURE CORROSION ALLOWANCE P = =C

28 Kg/cm (a) 218 246 41.25 UG 27 SA 516 GR. 70 1600 0.286 1.5 801.5 E p d = =S E (p-d)/p 780 151 0.806 14.090 KG/MM2 MM MM MM KG/MM2 MM MM

CORRODED INSIDE RADIUS = R LIGAMENT EFFICIENCEY MIN. PITCH IN SHELL DIA OF HOLE LIGAMENT EFFICIENCEY MAX. ALLOW. STRESSES

REQRD. THICKNESS

= tr tr =

(P*R/(S*E-0.6*P))+C 21.98 32 MM MM

ADOPTED WALL THICKNESS OF THE SHELL = HENCE OKAY.

�MECHANICAL STRENGTH CALCULATION

Tubesheet thickness under Internal PressureCalculations A) the Minimum thickness of the stay tubes asper UG 47 Sec VIII Div I

P t = p SC

Where

p is the maximum pitch in the tube sheet 27 Kg/cm(G)

119 mm 28 Kg/cm (A) = 0.28

P is the maximum working pressure

S is the maximum allowable pressure C is the correction factor Mean diameter dm t t = = =

14.07 Kg/mm 2.2 (63.5+53.74)/2 = 58.62

273x SQRT(0.28/(14.07*2.25)) 11.3 mm

Hence provided thickness

32 mm

B) Load to be supported by the Stay tubes as per ASME Sec -VIII The Maximum allowable working pressure for stay tubes as per UG 47 t x S C P = p Allowable stress as per code ASME Sec II part D = S = 14.07 Kg/mm C = 2.2 p = 119 mm dm = 58.62 mm P = 32 x 14.07 x 2.2 119 2.2383233 kg/mm 223.83233 Kg/cm

a) Required area of the stay tube at minimum cross section A = PI() x dm x t = 5893 mm 58.93 cm

�MECHANICAL STRENGTH CALCULATION

Load =

P x A

13191 Kg 13.191 tons

Maximum load on Two stay tubes (as per drawing enclosed) As per UG 50 ASME Sec VIII,

2 x 13.191 26.381

a)Therefore Required cross sectional area of stay tubes = A A A Taking Margin of 10% = 9.37x 1.1 = = = =

Max Load / Maximum allowable Stress 13191/14.07 937.51 mm 9.375067 cm 10.31 cm

whereas we have provided cross sectional area of the stay tube of 58.93 cm and hence it is safe.

B) Check for actual load on Unsupported Tube Sheet area as per UG -50 As per tube sheet drawing attached, two nos of stay tubes carry the load due to unsuppoerted area of tube sheet. Design pressure on the shell side = 27 Kg/cm(g) 28 Kg/cm (a)

Actual Load on the Unsupported area = = = 28 x PI()/4 x (27.3) - 58.93 3055 Kgs 3.055 Tons 26.381

Where as maximum load on stay tubes (2) holding unsupported tube sheet =

Hence from Eqn 5 & Eqn 6 The stay tube area is adequeatly designed to carry the unsupported area of the tube sheet as per ASME Sec VIII

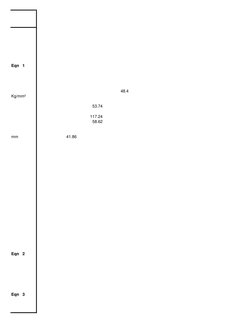

�Eqn 1

48.4 Kg/mm 53.74 117.24 58.62

mm

41.86

Eqn 2

Eqn 3

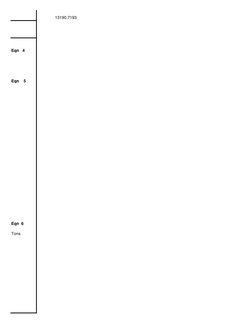

�13190.7193

Eqn 4

Eqn

Eqn 6 Tons

�MECHANICAL STRENGTH CALCULATIONS

Dished end thickness calculations As per UG 32, The required thickness of the dished end of semiellipsodial form shall be determine by ( PxD) t = ( 2 S E - 0.2 x P) + C

Maximum working Pressure

28 Kg/cm 0.28 Kg/mm 1.5 1492 mm 1495 mm 14.07 Kg/mm 1

Corrosion allowance UnCorroded Inside Diameter Corroded Inside Diameter Allowable Stress

C D Di S E

= = = = =

0.28 x 1492 t = 2 x 14.07 - 0.2 x 0.28 16.41 mm Therefore required thickness t Provided thickness t = = 16.41 mm 32 mm 3

��MECHANICAL STRENGTH CALCULATIONS

Nozzle thickness calculations:

Drain Nozzle, Blow down

Nozzle size

40 NB

OD 27 Kg/cm (g)

48.3 mm 28 Kg/cm (a) 1.5 mm for shell 1203 Kg/cm 1407 Kg/cm

4.83 cm 0.28 Kg/mm 1.5 mm for Nozzle 12.03 Kg/mm 14.07 Kg/mm

Max Pressure : Corrosion allowance : Max allowable stress for Nozzle material: Max allowable stress for Shell material:

A) The Minimum required thickness of shell for internal pressure Shell Inner Diameter: ID R E ( PxR) t = ( S E - 0.6 x P) + C = (1407 x 1 - 0.6 x 28) = 1492 mm 746 mm 1 (28 x 74.6) 1.5 149.2 cm 74.6 cm

Joint Efficiency

1.50

1.5

3.00 mm

Adopted thickness of Nozzle: B) Nozzle size :

7.14 mm

The minimum thickness of Nozzle as per ASME Sec-VIII 40 NB OD ( PxR) t = ( S E - 0.6 x P) = As per ASME Sec VIII of Standard Nozzle thickness = Taking Thinning allowance 12.5% = Thickness t = 0.875 x 3.68 = 3.22+1.5 0.49 + C = (1206 x 1 - 0.6 x 28) 1.5 = #REF! mm #REF! #REF! mm mm 1.99 mm 48.3 mm 4.83 cm (28 x 24.2) + 1.5 R = 24.2 mm

C)

D)

Thickness of nozzle selected as lower of (B) and (C) is The final nozzle thickness is selected as higher of (B) and (D) is Therefore, the nozzle thickness is higher for D is Adopted thickness is = =

1.99 mm 1.99 mm 1.99 mm 7.14 7.14 x 0.875 = 6.25 mm 1.99 mm + 1.5 = 6.25 mm #### mm

Therefore 6.25 > Also from overall design consideration,the nozzle should have thickness of = #REF! Therefore For 40 NB Nozzle we provided 160 Sch So that thickness selected is 7.14 mm > Hence it is safe

�MECHANICAL STRENGTH CALCULATIONS

Nozzle thickness calculations: Nozzle size : 150 NB Max Pressure : Corrosion allowance : Max allowable stress for Nozzle material: Max allowable stress for Shell material:

Riser & Down comer Stubs OD 168.3 mm 27 Kg/cm (g) 28 Kg/cm (a) 1.5 mm for shell 1203 Kg/cm 1407 Kg/cm

16.83 cm 0.28 Kg/mm 1.5 mm for Nozzle 12.03 Kg/mm 14.07 Kg/mm

A) The Minimum required thickness of shell for internal pressure Shell Inner Diameter: ID R E ( PxR) t = ( S E - 0.6 x P) + C = (1407 x 1 - 0.6 x 28) = 1492 mm 746 mm 1 (28 x 74.6) 1.5 149.2 cm 74.6 cm

Joint Efficiency

1.50

1.5

3.00 mm

Adopted thickness of Nozzle: B) Nozzle size :

18.26 mm

The minimum thickness of Nozzle as per ASME Sec-VIII 150 NB OD ( PxR) t = ( S E - 0.6 x P) = As per ASME Sec VIII of Standard Nozzle thickness = Taking Thinning allowance 12.5% = Thickness t = 0.875 x 3.68 = 6.22+1.5 1.69 + C = (1206 x 1 - 0.6 x 28) 1.5 = #REF! mm #REF! #REF! mm mm 3.19 mm 168.3 mm 16.83 cm (28 x 84.2) + 1.5 R = 84.2 mm

C)

D)

Thickness of nozzle selected as lower of (B) and (C) is The final nozzle thickness is selected as higher of (B) and (D) is Therefore, the nozzle thickness is higher for D is Adopted thickness is = =

3.19 mm 3.19 mm 3.19 mm

18.26 18.26 x 0.875 =

15.98 mm 3.19 mm + 1.5 = 8.61 mm #### mm

Therefore 15.98 > Also from overall design consideration,the nozzle should have thickness of = #REF! Therefore For 150 NB Nozzle we provided 160 Sch So that thickness selected is 18.26 mm > Hence it is safe

�Mechanical Strength Calculations

OPENING REINFORCEMENTS Design Pressure Allowable stress of shell Allowable stress of nozzle Allowable stress of Pad Joint efficiency Factor of safety Corrosion allowance Uncorroded thk of shell Corroded thk of shell MANHOLE OPENING OD of Nozzle Thk of nozzle Corr. Inside dia. Of nozzle Corr Nozzle Thk Max. Limit of Reinforcement

..UG 36,37,40 P Sv Sn Sp E F C Ts T = = = = = = = = = 2800 140723.00 120376.00 140723.00 1 1 1.5 32 30.5 kg/mm kg/mm kg/mm kg/mm

fr1 = (MIN Sn/Sv,1) fr2 = (MIN Sn/Sv,1) fr3 = (MIN SP/Sv,1) fr4 = (MIN SP/Sv,1)

..UG 36, 37, 40 d t dn tn = = = = 600 32 598.5 31.25 mm mm mm mm

2d or 2(Rn+tn+t) Whicherever is larger 2d Rn=d/2 2(Rn+tn+t) = = = = = = = = 1200 300 726.5 800 25 7.059 15.67 250.00

Pad outside Dia Provided Pad thk. trn = P*0.5*dn/(Sn*E-0.6*P) tr = P*0.5*d/(Sv*E-0.6*P) Height of nozzle

Dp te trn tr h

�Mechanical Strength Calculations

Area Required

= =

(dn*tr*F)+2*tn*tr(1-fr) 9518 d*(Ts-tr) 9799.74 2*(tn-trn)*te*fr1 1034.65 2*(t-C)*fr1*h 13045.02 144 (Dp-d-2*tn)*te*fr4 3437.5 A1+A2+A3+A4+A5 27460.91 m (Greater than Required) Hence Okay mm

Area available in shell

A1

= =

Area availble in nozzle outside

A2

= =

Area availble in nozzle inside

A3

= =

Area in fillet weld Area ava. In comp. Pad

A4 A5

= = =

Total available Area

= =

�Mechanical Strength Calculations

HAND HOLE OPENING IN SHELL Size

..UG 36,37,40 = ID230 x ID 127 x 32 Thk PR --------------SE-0.6P 2800.00 a/b 230 127 416.54 mm kg/mm

Minimum required thickness

Maximum allowable Pressure Outside Diameter of Nozzle

P D a b D

= = = = = = =

Max. allowable Stress Corrosion allowance

S C

140720.00 kg/mm 1.5

t Provided thickness is Thickness of attached reinforcing pad, mm Thickness of vessel wall Reqd. thk. Of vessel wall Nominal thickness of nozzle Reqd.thk of nozzle wall Dia. in the Plane under consideration of the finished opening

= =

5.69 32 te t tr tn trn d mm = = = = = =

F Dist. Of nozzle projects inward from the outer surface of the vessel wall h

= =

�Mechanical Strength Calculations

Allowable stress in nozzle Allowable stress in vessel Allowable stress in reinforcement Sn/Sv for nozzle wall inserted through vessel (Lesser of Sn or Sp)/Sv Sp/Sv Area Required (d + 2tn)trF

Sn Sv Sp fr1 fr2 fr3 A A1

= = = = = = = =

Area available in shell (use larger value) (d-2tn)(t-F tr) or 2 t (t - F tr) Area available in nozzle projecting outward 2(tn - trn)(2.5 t fr1) or 2(tn - trn)(2.5 tn+ te) fr1 (use minimum value) Area avail. in nozzle projecting inward (2xtnxfr1xh) Area available in outward nozzle weld (WL1 x fr2) Area available in inward nozzle weld (WL3 x fr2) Area provided through compensation pad Total Area (A1+A2+A3+A4+A5+Ac)

A2

A3 A4 A5 Ac

= = = = =

��= (MIN Sn/Sv,1) = (MIN Sn/Sv,1) = (MIN SP/Sv,1) = (MIN SP/Sv,1)

0.9 0.9 1.0 1.0

36

�(Greater than Required)

�40 32 20.60 32 5.69 127

1 64

�140720.00 140720.00 140720.00 1 1 1 3934.60 729.60 mm mm

4208.94

mm

4096 144 144 21600 30922.54

mm mm mm mm > A Hence OK

��CAP OF MAN HOLE STUBS As per ASME Sec VIII UG 32,The required thickness of dished head of semiellipsoidal form shall be determined by P x D t = C ( 2 x S x E - 0.2 x P)

MATERIAL UNCORR. INSIDE DIAMETER DESIGN PRESSURE P D

= = = = = = =

SA 516 GR. 70 406 0.28 1.5 409 1 14.07 KG/MM2 MM KG/MM2 MM MM

CORROSION ALLOWANCE (SHELL) C CORRODED INSIDE DIAMETER JOINT EFFICIENCEY MAX. ALLOW. STRESSES E S D1

REQRD. THICKNESS

tr1

= = =

((P*D1)/(2*S*E-0.2*P))+C ((0.28 x 703)/(2 x 14.07 x 1 -0.6 x 0.28))+1.5 4.094 5.58 4.88 10.46 = 32 MM MM MM MM 1.5

tr1 Taking 12.5% thinning allowance Hence Required thickness ADOPTED WALL THICKNESS OF THE SHELL

= = =

Hence Okay