Professional Documents

Culture Documents

4a Fe Engine

Uploaded by

xthanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4a Fe Engine

Uploaded by

xthanCopyright:

Available Formats

92

ENGINE4AFE ENGINE

4AFE ENGINE

J DESCRIPTION

The 4AFE engine is the dependable, lightweight and compact DOHC engine that is currently carried in the Corolla AllTrac/4WD station wagons (89 model AE95 series). Although the basic construction and operation are identical to the engine used in the 89 model AE95 series, the crankshaft pulley, intake manifold, throttle body, engine mount, etc., were modified to ensure a better match with the new Celica.

ENGINE4AFE ENGINE

93

J ENGINE SPECIFICATIONS AND PERFORMANCE CURVE

Engine Item No. of Cyls. & Arrangement Valve Mechanism Combustion Chamber Manifolds Displacement Bore x Stroke Compression Ratio Max. Output Max. Torque Fuel Octane Number Oil Grade (SAENET) (SAENET) (RON) cu. in. (cc) in. (mm) 4A FE 4AFE (for new Celica) 4cylinder, Inline 4 Valves, DOHC, Belt & Gear Drive Pentroof Type Crossflow 96.8 (1587) 3.19 x 3.03 (81 x 77) 9.5 : 1 103 HP @ 6000 rpm 102 HP @ 5800 rpm* 102 HP @ 3200 rpm 101 ft.lbs @ 4800 rpm* 91 API SG 4A FE 4AFE (for 89 model AE95 series) 100 HP @ 5600 rpm 101 ft.lbs @ 4400 rpm API SF or SG

*:

Applicable only to California specification vehicles.

94

ENGINE4AFE ENGINE

J ENGINE 1. Crankshaft Pulley

The crankshaft pulley has a torsional damper that reduces torsional vibration of the crankshaft. In addition, it has a longitudinal damper to reduce longitudinal vibration of the crankshaft. These dampers jointly minimize vibration and noise.

2. Intake Manifold

The intake manifold is integrated with the intake air chamber to reduce the overall weight. The intake pipe length and the port diameter were optimized to further increase torque in low to medium speed ranges.

ENGINE4AFE ENGINE

95

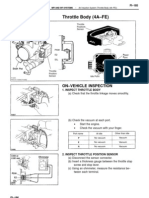

3. Throttle Body

The construction of the throttle body has been changed from the type with incorporated air valve in the 89 model AE95 series to the type with separate air valve. The basic operation is unchanged.

J ENGINE MOUNTING 1. Cylindrical Liquidfilled Compound Mount

A newlydeveloped cylindrical liquidfilled compound mount is used in both the left and right mounts. See page 75 under 5SFE engine for detail.

96

ENGINE4AFE ENGINE

J ENGINE CONTROL SYSTEM 1. General

The engine control system of the 4AFE engine for the new Celica is basically the same functionally as the 4AFE engine carried in the Corolla AllTrac/4WD station wagons (89 model AE95 series), but it incorporates some modifications. The following table compares the engine control systems between the new Celica and the 89 model AE95 series: Engine System EFI (Electronic Fuel Injection) ESA (Electronic Spark Advance) ISC (Idle Speed Control) EGR CutOff Control Fuel Pump Control Air Conditioner CutOff Control OD Gear Shift Lockout Control* New 4A FE 4AFE (for new Celica) Previous 4A FE 4AFE (for 89 model AE95 series)

S A Dtype EFI system is used which S

indirectly detects intake air volume by the manifold pressure sensor signal. The fuel injection system is simultaneously an all injection system.

Ignition timing is determined by the ECU (Electronic Control Unit) based on signals from various sensors. ACV regulates air volume by passing throttle valve and controls idling speed. The EGR is cut off under light engine loads or low temperature conditions to maintain drivability. Fuel pump operation is controlled by signals from ECU. By controlling the air conditioner compressor in accordance with the throttle valve opening angle and the vehicle speed, drivability is maintained. Prohibits OD gear shift depending on engine condition to main good drivability and acceleration performance.

N.A.

N.A.

N.A.

S When a malfunction occurs, the ECU

Diagnosis

diagnoses and memorizes the failed section. 14 diagnostic items are monitored by the ECU.

FailSafe *:

When a malfunction occurs, the ECU stops or controls the engine according to the data already stored in memory.

Applicable only to automatic transaxle models.

ENGINE4AFE ENGINE

97

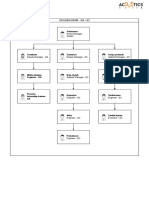

2. Construction

The engine control system can be divided into three groups; the sensors, ECU and actuators.

*1: Applicable only to California specification vehicles. *2: Applicable only to automatic transaxle models.

98

ENGINE4AFE ENGINE

3. Engine Control System Diagram

ENGINE4AFE ENGINE

99

4. Arrangement of Engine Control System Components

100

ENGINE4AFE ENGINE

5. EGR CutOff Control

This system actuates the VSV to replace intake manifold vacuum acting on the EGR vacuum modulator with atmospheric air and thus cuts the EGR from the system. Operation To maintain vehicle drivability and durability of the EGR components, the ECU actuates off the VSV and cuts the EGR when the coolant temperature is below 127F (53C) and the engine load is above a predetermined level.

6. Air Conditioner CutOff Control

The ECU sends a signal to the air conditioner amplifier to disengage the air conditioner compressor magnet clutch and cuts off the air conditioning operation according to the engine speed, intake manifold pressure, vehicle speed and throttle valve opening angle. Operation The air conditioner is turned off during quick acceleration from a low engine speed, depending on the vehicle speed, throttle valve position and the intake manifold pressure. This helps maintain good acceleration performance. The air conditioner is also turned off when the engine is idling at a speed below 500 rpm. This prevents the engine from stalling. RELEVANT SIGNALS

S Throttle position (IDL, PSW) S Vehicle speed (SPD) S Intake manifold pressure (PIM) S Engine speed (Ne) S Neutral start switch* (NSW)

*: Applicable only to automatic transaxle models.

ENGINE4AFE ENGINE

101

7. OD Gear Shift Lockout Control (for A240L Automatic Transaxle Models)

The ECU turns the OD solenoid valve of the automatic transaxle on depending on the coolant temperature and the acceleration condition of the vehicle. This prohibits shifting to the OD gear to maintain good drivability and acceleration performance. Operation This control is used when the coolant temperature is below 122F (50C) to maintain good drivability. The same control used to be done by the water temperature switch in the previous engine, but is now done by the engine ECU in the new 4AFE engine. Shifting to the OD gear is also prohibited during quick acceleration in low to medium speed ranges to maintain good acceleration performance. RELEVANT SIGNALS

S Coolant temperature (THW) S Vehicle speed (SPD) S Engine speed (Ne) S Throttle position (PSW) S Intake manifold pressure (PIM)

102

ENGINE4AFE ENGINE

8. Diagnosis

The diagnostic system in the 4AFE engine for the new Celica monitors fourteen conditions in the chart below. The purpose of this system is the same as the 4AFE engine for 89 model AE95 series, but diagnostic items have been changed to match the 4AFE engine for the new Celica. Diagnostic Items Code No. Item Diagnosis Trouble Area CHECK ENGINE Lamp ON

12

RPM Signal

No Ne signal to ECU within 2 seconds after the engine is cranked.

13

RPM Signal

No Ne signal to ECU when the engine speed is above 1000 rpm. No IGf signal to ECU 4 times in succession. During airfuel ratio feedback correction, voltage output from the oxygen sensor does not exceed a set value on the lean side and the rich side continuously for a certain period. Open or short circuit in water temp. sensor signal (THW). Open or short circuit in intake air temp. sensor signal (THA).

14

Ignition Signal

S S S S S S S S S S

Distributor circuit Distributor Starter signal circuit ECU Distributor circuit Distributor ECU Igniter circuit Igniter ECU

ON

ON

21

Oxygen Sensor Signal

S Oxygen sensor circuit S Oxygen sensor S S S S S S S S S S S S S S S S S S S S S S S S

Water temp. sensor circuit Water temp. sensor ECU Intake air temp. sensor circuit Intake air temp. sensor ECU Injector circuit Injector Fuel line pressure Oxygen sensor circuit Oxygen sensor Manifold pressure sensor Water temp. sensor ECU Injector circuit Injector Fuel line pressure Oxygen sensor circuit Oxygen sensor Cold start injector circuit Cold start injector Manifold pressure sensor Water temp. sensor ECU

ON

22

Water Temp. Sensor Signal Intake Air Temp. Sensor Signal

ON

24

ON*

25

Airfuel Ratio Lean Malfunction

1)* When airfuel ratio feedback correction value or adaptive control value continues at the upper (lean) or lower (rich) limit for a certain period of time or adaptive control value is not renewed for a certa n s certain period of time. 2)* When marked variation is detected in engine revolutions for each cylinder during idle switch on and feedback condition. 3)Open or short circuit in oxygen sensor signal (Ox).

ON*

ON

26

Airfuel Ratio Rich Malfunction

ON*

*:

Applicable only to California specification vehicles.

ENGINE4AFE ENGINE

103 CHECK ENGINE Lamp ON

Code No.

Item

Diagnosis

Trouble Area

S Manifold pressure sensor

31 Manifold Open or short circuit in manifold Pressure Sensor pressure sensor signal (PIM). Signal Throttle The IDL and PSW signals are Position Sensor output simultaneously for several Signal seconds. Vehicle Speed Sensor Signal Open or short circuit in vehicle speed sensor signal. No STA signal to ECU until engine speed reaches 800 rpm with vehicle not moving.

41

42

43

Starter Signal

S S S S S S S S S S S S S S S S S S S S S S S

circuit Manifold pressure sensor ECU Throttle position sensor circuit Throttle position sensor ECU Vehicle speed sensor circuit Vehicle speed sensor ECU Starter signal circuit Ignition switch, main relay circuit ECU EGR system components EGR gas temp. sensor circuit EGR gas temp. sensor ECU A/C amplifier A/C switch circuit Neutral start switch circuit Neutral start switch Accelerator pedal and cable Throttle position sensor circuit Throttle position sensor ECU

ON*

OFF

OFF

S EGR gas temp. below a

71* EGR System Malfunction

predetermined level during EGR operation. Open circuit in EGR gas temp. sensor signal (THG).

ON

51

Switch Condition Signal

No IDL signal or No NSW signal or A/C signal to ECU, with the check terminals T and E1 connected.

OFF

*:

Applicable only to California specification vehicles.

NOTE:

S If two or more malfunctions are present at the same time, the lowestnumbered diagnostic code will be

displayed first.

S All detected diagnostic codes, except 51, will be retained in memory by the ECU from the time of detection S S

until cancelled out. Once the malfunction is corrected, the CHECK ENGINE warning lamp will go out but the diagnostic code(s) will remain stored in the ECU memory (except for code 51). After the malfunction is corrected, the diagnostic code is cleared by removing the EFI fuse for more than 10 seconds with the ignition switch off.

104

ENGINE4AFE ENGINE

J EMISSION CONTROL SYSTEM 1. System Purpose

System Positive crankcase ventilation Evaporative emission control Exhaust gas recirculation Threeway catalyst Electronic fuel injection Abbreviation PCV EVAP EGR TWC EFI Purpose Reduces blowby gas (HC) Reduces evaporative HC Reduces NOx Reduces HC, CO and NOx Regulates all engine conditions for reduction of exhaust emission

2. Component Layout and Schematic Drawing

*:

Applicable only to California specification vehicles.

You might also like

- 4A-FE Throttle AdjustmentsDocument7 pages4A-FE Throttle AdjustmentsHongda Zhuo100% (12)

- 4AFE Wiring DiagramDocument35 pages4AFE Wiring DiagramFarabi Ardhianto100% (3)

- 4age VacuumDocument6 pages4age VacuumSharul Hakimi100% (5)

- Body Electrical Echo/yaris 2002Document117 pagesBody Electrical Echo/yaris 2002Tomas Dominguez100% (1)

- Ep82 Diagnostics - StreetLegalStarletDocument1 pageEp82 Diagnostics - StreetLegalStarletSagittarius41278100% (1)

- 4AGE To 7AGE ConversionDocument7 pages4AGE To 7AGE Conversionmellymoyo100% (1)

- Toyota 4a Fe Engine Reference PDFDocument57 pagesToyota 4a Fe Engine Reference PDFeviton luisNo ratings yet

- Toyota Corolla 1991 Wiring DiagramDocument29 pagesToyota Corolla 1991 Wiring DiagramMisko Buncic90% (21)

- Toyora Corolla Wiring Diagram 1998Document14 pagesToyora Corolla Wiring Diagram 1998Chien Luu Van64% (14)

- Manual Corolla Engine 4A-FE 3S-GTE 5S-FEDocument311 pagesManual Corolla Engine 4A-FE 3S-GTE 5S-FEanto_jo95% (39)

- 1NZ FE EngineDocument59 pages1NZ FE Engineimtiaz_masud_175% (4)

- Toyota 1988 Corolla (FWD) - Wiring DiagramsDocument13 pagesToyota 1988 Corolla (FWD) - Wiring DiagramsKieen Lee50% (2)

- 1993 Toyota CorollaDocument10 pages1993 Toyota Corollaabkdlo100% (1)

- 1nz 2nzDocument25 pages1nz 2nzEthan Eliezer Lim Pabalan80% (15)

- Caldina ElectricalDocument73 pagesCaldina ElectricalАльказар Рагнару100% (5)

- Pin Out ToyotaDocument60 pagesPin Out Toyotaariboro100% (9)

- 1kr Fe Starting Starting MotorDocument320 pages1kr Fe Starting Starting MotorTalleban Tal0% (1)

- Toyota Yaris IIIDocument2 pagesToyota Yaris IIIIoniță Sorin CristianNo ratings yet

- 4a FeDocument16 pages4a FeJohn Simmonds78% (18)

- Toyota YarisDocument5 pagesToyota YarisMohammed Yusuf100% (1)

- Engine Control (1KR-FE) ECS-1KR PDFDocument1 pageEngine Control (1KR-FE) ECS-1KR PDFMuhammad Abbas Khan Niazi100% (1)

- 1992 Toyota Engine Wiring DiagramDocument6 pages1992 Toyota Engine Wiring Diagramsamialoqby aloqby0% (3)

- ES - 1NZ-FXE Engine Control SystemDocument480 pagesES - 1NZ-FXE Engine Control SystemHari Prasad Ambaripeta84% (19)

- Toyota Sensors Basic WaveformsDocument6 pagesToyota Sensors Basic Waveformscartronix2010100% (5)

- 4A-Fe Engine: DescriptionDocument13 pages4A-Fe Engine: DescriptionbyazdaaniNo ratings yet

- Toyota Engine 4afeDocument13 pagesToyota Engine 4afecjtrybiecNo ratings yet

- 905sfe PDFDocument23 pages905sfe PDFElvis MantillaNo ratings yet

- EMILIANO - Acrobat Distiller 6.0 (Windows) - 000645Document2 pagesEMILIANO - Acrobat Distiller 6.0 (Windows) - 000645Cristian Gallegos MuñozNo ratings yet

- c4.4 Marine Genset SpecsheetDocument4 pagesc4.4 Marine Genset SpecsheetBilel Ben SlamaNo ratings yet

- NEF45 SM1 65kWm EDocument9 pagesNEF45 SM1 65kWm ECamilo Marcelo Burgos BustosNo ratings yet

- NEF60 TE2 DS P4A04N016E Mar06Document2 pagesNEF60 TE2 DS P4A04N016E Mar06SONNo ratings yet

- NEF67 TM3 DS P4A04N018E Mar06Document2 pagesNEF67 TM3 DS P4A04N018E Mar06altieresmirandaNo ratings yet

- NEF67 TM3 DS P4A04N018E Apr05Document2 pagesNEF67 TM3 DS P4A04N018E Apr05Blas ViniciusNo ratings yet

- Lehm20288-00 Marine AuxiliaryDocument4 pagesLehm20288-00 Marine AuxiliaryDedi MaryadiNo ratings yet

- NEF67 SM1 138kWm EDocument6 pagesNEF67 SM1 138kWm EJaimeCoello100% (1)

- 62 5 Kva Silent DG SetDocument3 pages62 5 Kva Silent DG SetArjun GhoshNo ratings yet

- Supercopter 2020Document16 pagesSupercopter 2020Yamahauki SusukiNo ratings yet

- Turbomeca Arriel 1-2 Engine ManualDocument337 pagesTurbomeca Arriel 1-2 Engine ManualPaulean Cunha Costa100% (1)

- Ka4h-Ufka24 ProposalDocument9 pagesKa4h-Ufka24 ProposalStevenNo ratings yet

- Tad550Ge: 4.76 Liter, In-Line 4 CylinderDocument2 pagesTad550Ge: 4.76 Liter, In-Line 4 CylinderAzilan AriaNo ratings yet

- Tad1651Ge: 16.12 Liter, In-Line 6 CylinderDocument2 pagesTad1651Ge: 16.12 Liter, In-Line 6 CylinderSze TimNo ratings yet

- Tad1351Ge: 12.78 Liter, In-Line 6 CylinderDocument2 pagesTad1351Ge: 12.78 Liter, In-Line 6 CylinderJoséNo ratings yet

- Engine 3 VZ VS2 VZDocument32 pagesEngine 3 VZ VS2 VZDustNo ratings yet

- N67 TM3A: Engine For Power Generation ApplicationsDocument4 pagesN67 TM3A: Engine For Power Generation ApplicationsВладислав ЛеоновNo ratings yet

- 2023 Maverick Tremor Tech SpecsDocument4 pages2023 Maverick Tremor Tech SpecsJesus A. IrizarryNo ratings yet

- Engine PerformanceDocument1,301 pagesEngine PerformanceAlexis Yureni Rodriguez Rojas100% (1)

- New Features: 5L-E Engine 1. GeneralDocument1 pageNew Features: 5L-E Engine 1. GeneralSébastien EsseivaNo ratings yet

- Data - Sheet - 915 Is - Isc - A4 - 18.01.2018Document1 pageData - Sheet - 915 Is - Isc - A4 - 18.01.2018Awan AJaNo ratings yet

- Emd F7 PDFDocument144 pagesEmd F7 PDFAnup KumarNo ratings yet

- QSX15-G9 XpiDocument3 pagesQSX15-G9 XpiMd ShNo ratings yet

- Informacion Tecnica 3RZDocument8 pagesInformacion Tecnica 3RZjuan riveraNo ratings yet

- The EA888 2.0L TSI Engine Gen III B: Self Study Program 820173Document21 pagesThe EA888 2.0L TSI Engine Gen III B: Self Study Program 820173MARIO100% (1)

- 1006TAG2 ElectropaK PN1793 PDFDocument2 pages1006TAG2 ElectropaK PN1793 PDFAnas BasarahNo ratings yet

- TAD754GEDocument2 pagesTAD754GEIgor LNo ratings yet

- Inrd Pe04021 18337Document91 pagesInrd Pe04021 18337Zulfikrysuhaimin gmail.comNo ratings yet

- Construction N45 ENT 125 KW (170 HP) at 2200 RPMDocument2 pagesConstruction N45 ENT 125 KW (170 HP) at 2200 RPMHorea CordunianuNo ratings yet

- 4045TF220Document2 pages4045TF220victoros27No ratings yet

- John Deere 4045HF285Document2 pagesJohn Deere 4045HF285Mihai Popa50% (2)

- V2500-RR-Line and Base Maintenance - Course NotesDocument541 pagesV2500-RR-Line and Base Maintenance - Course NotesM AliNo ratings yet

- Sanctuary Policy PomonaDocument3 pagesSanctuary Policy PomonaGabriel EliasNo ratings yet

- Business Plan Example - Little LearnerDocument26 pagesBusiness Plan Example - Little LearnerCourtney mcintosh100% (1)

- Biopolymers: Overview of Several Properties and Consequences On Their ApplicationsDocument10 pagesBiopolymers: Overview of Several Properties and Consequences On Their ApplicationsrafacpereiraNo ratings yet

- Method Statement (RC Slab)Document3 pagesMethod Statement (RC Slab)group2sd131486% (7)

- BMJ 40 13Document8 pagesBMJ 40 13Alvin JiwonoNo ratings yet

- Kyocera Fleet Services White Paper: SecurityDocument20 pagesKyocera Fleet Services White Paper: SecurityHoratiu OanaNo ratings yet

- Study Notes On Isomers and Alkyl HalidesDocument3 pagesStudy Notes On Isomers and Alkyl HalidesChristian Josef AvelinoNo ratings yet

- Covid-19 Mitigation PlanDocument8 pagesCovid-19 Mitigation PlanEkum EdunghuNo ratings yet

- Reaction Paper-RprDocument6 pagesReaction Paper-Rprapi-543457981No ratings yet

- Case Report CMV RetinitisDocument27 pagesCase Report CMV RetinitistaniamaulaniNo ratings yet

- CONTROLTUB - Controle de Juntas - New-Flare-Piping-Joints-ControlDocument109 pagesCONTROLTUB - Controle de Juntas - New-Flare-Piping-Joints-ControlVss SantosNo ratings yet

- Food Processing NC II - SAGDocument4 pagesFood Processing NC II - SAGNylmazdahr Sañeud DammahomNo ratings yet

- Chemical Reaction Engineering-II - R2015 - 10-04-2018Document2 pagesChemical Reaction Engineering-II - R2015 - 10-04-201818135A0806 MAKKUVA BHAVYANo ratings yet

- Cargador de BateríaDocument34 pagesCargador de BateríaBenNo ratings yet

- Assignment - Lab Accidents and PrecautionsDocument6 pagesAssignment - Lab Accidents and PrecautionsAnchu AvinashNo ratings yet

- Bhert - EoDocument2 pagesBhert - EoRose Mae LambanecioNo ratings yet

- Organogram - Qa / QC: Srinivasan SrinivasanDocument4 pagesOrganogram - Qa / QC: Srinivasan SrinivasanGowtham VenkatNo ratings yet

- Potato Storage and Processing Potato Storage and Processing: Lighting SolutionDocument4 pagesPotato Storage and Processing Potato Storage and Processing: Lighting SolutionSinisa SustavNo ratings yet

- Installing Touareg R5 CamshaftDocument1 pageInstalling Touareg R5 CamshaftSarunas JurciukonisNo ratings yet

- Thesis ProposalDocument19 pagesThesis Proposaldharmi subedi75% (4)

- TC 10 emDocument7 pagesTC 10 emDina LydaNo ratings yet

- Neurocisticercosis PDFDocument7 pagesNeurocisticercosis PDFFiorella Alexandra HRNo ratings yet

- Mycotoxin in Food Supply Chain (Peanuts)Document2 pagesMycotoxin in Food Supply Chain (Peanuts)Ghanthimathi GvsNo ratings yet

- Dr. Sajjad Hussain Sumrra Isomerism (CHEM-305) Inorganic Chemistry-IIDocument48 pagesDr. Sajjad Hussain Sumrra Isomerism (CHEM-305) Inorganic Chemistry-IITanya DilshadNo ratings yet

- Contractor: Item No. MRS-1st 2021 Ref. Description Unit Quantity Rate of Contractor Unit Rate in Words AmountDocument1 pageContractor: Item No. MRS-1st 2021 Ref. Description Unit Quantity Rate of Contractor Unit Rate in Words AmountusmanaliNo ratings yet

- Epo-Fix Plus: High-Performance Epoxy Chemical AnchorDocument3 pagesEpo-Fix Plus: High-Performance Epoxy Chemical Anchormilivoj ilibasicNo ratings yet

- Classification of Speech ActDocument1 pageClassification of Speech ActDarwin SawalNo ratings yet

- Science and TechnologyDocument21 pagesScience and TechnologyPat MillerNo ratings yet

- MajorProjects 202112 e 1Document64 pagesMajorProjects 202112 e 1xtrooz abiNo ratings yet

- Join Our Telegram Channel: @AJITLULLA: To Get Daily Question Papers & SolutionsDocument24 pagesJoin Our Telegram Channel: @AJITLULLA: To Get Daily Question Papers & SolutionsNaveen KumarNo ratings yet

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerFrom EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerRating: 4.5 out of 5 stars4.5/5 (54)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]From EverandCDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]Rating: 5 out of 5 stars5/5 (2)

- The RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVFrom EverandThe RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVRating: 5 out of 5 stars5/5 (2)

- Troubleshooting and Repair of Diesel EnginesFrom EverandTroubleshooting and Repair of Diesel EnginesRating: 1.5 out of 5 stars1.5/5 (2)

- Automotive Electronic Diagnostics (Course 1)From EverandAutomotive Electronic Diagnostics (Course 1)Rating: 5 out of 5 stars5/5 (6)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- OBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceFrom EverandOBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceNo ratings yet

- Tips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)From EverandTips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)No ratings yet

- The Official Highway Code: DVSA Safe Driving for Life SeriesFrom EverandThe Official Highway Code: DVSA Safe Driving for Life SeriesRating: 3.5 out of 5 stars3.5/5 (25)

- Ford AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WFrom EverandFord AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WRating: 4.5 out of 5 stars4.5/5 (6)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Automotive Master Technician: Advanced Light Vehicle TechnologyFrom EverandAutomotive Master Technician: Advanced Light Vehicle TechnologyRating: 5 out of 5 stars5/5 (1)

- How to Fabricate Automotive Fiberglass & Carbon Fiber PartsFrom EverandHow to Fabricate Automotive Fiberglass & Carbon Fiber PartsRating: 5 out of 5 stars5/5 (4)

![CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]](https://imgv2-1-f.scribdassets.com/img/audiobook_square_badge/710834945/198x198/00b81cbbd3/1714482720?v=1)