Professional Documents

Culture Documents

Jaggery Plant Powered by Free of Cost Steam

Uploaded by

Michael OdiemboCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jaggery Plant Powered by Free of Cost Steam

Uploaded by

Michael OdiemboCopyright:

Available Formats

JAGGERY PLANT POWERED BY FREE OF COST STEAM

In Jaggery making plants, sugarcane crusher is driven by electric motor or diesel engine. To get electric connection in farms is very difficult, expensive and time taking and then also electric power is not supplied round the clock. So electric connection is not enough. Where sugarcane crusher is driven by diesel engine, it becomes too costly as diesel has become expensive. I can suggest very simple innovative scheme to run entire jaggery plant with free of cost energy i.e.with steam engine and simultaneously double the production of jaggery with the same quantity of bagasse. So you will not require electricity and you will not require diesel. This innovative scheme is described as under. Lot of heat is wasted in a flue gases going to chimney in a juice boiling furnace run by bagasse. This heat going to waste can be utilized to generate steam by installing long steel chimney of 600mm dia x 10m long and installing mono tube boiler inside the chimney at the bottom. We can supply chimney and mono tube boiler both if you cannot make it. MONOTUBE BOILER Mono tube boiler will consist of 1" pipe coil of 47 cm OD (18.5" OD) and coil pitch will be 3" and 18 turns just like spring. Total height of the coil will be 18 x 3 = 54". Total length of the 1" pipe used in this coil will be 80 ft or say 24 m. On the top of this coil will be placed another smaller coil of 1" dia pipe, 14" OD and 18 turns with 3" pitch as per previous coil. Total length of the one 1" pipe used in this coil will be 60 ft or say 18 m. So total height of both the coils, one above another will be 54" + 54" = 108" i.e 9 ft. Both these coils will be inside the chimney from the bottom to 9 ft height. Water will be introduced in to the coil at the top of the smaller coil and steam can be taken out from the bottom of the bigger coil. The cubic content of this mono tube boiler will be less than 21 liters and hence Boiler Act will not be applicable. Water feed pump will be required to push the water into mono tube boiler. It may be powered by 1 HP electric motor with variable drive. Mostly it is expected that dry steam will be available at the discharge of the mono tube boiler but for ensuring dry steam, centrifugal water separator will be

installed before steam goes to steam engine. It is expected that this mono tube boiler will be able to give 250 to 300 kg of steam per hour which will be more than enough to drive 14 HP steam engine produced by us, which will run sugarcane crusher of 30 tons capacity per hour. This will be the simplest and the cheapest arrangement as investment in boiler will be the lowest and steam is obtained free of cost from the waste heat of the juice boiling furnace. Anybody having some technical skill can manufacture this mono tube boiler and put into the chimney, which also can be, fabricated locally anywhere. If this becomes successful, then it will bring revolution in the entire world because it will save 35 to 40 liter diesel every day and hence jaggery plant will become highly viable and big sugar factories cannot compete to it. CHIMNEY PERFORMANCE One engineer has made experiment of installing 30 ft chimney of 600mm dia and he found very encouraging result that juice boiling becomes double faster so that double quantity of jaggery is produced from the same furnace and still going huge quantity of heat into the flue gases. He did not install any mono tube boiler. He found that flue gas temperature was 380 degree Celsius and flow rate was 40 cubic meter per hour at the speed of 4.7 meter per second. One highly experienced thermal engineer of South India confirmed that about 20 KW power can be generated from the waste heat of the chimney by installing mono tube boiler in the chimney. So there is huge scope of utilizing the waste heat and to generate steam free of cost. We can supply complete set of equipments i.e. mono tube boiler, chimney, steam engine, water feed pump, centrifugal separator etc. Proforma invoice on request. V K DESAI AADHUNIK GLOBAL ENERGY TINYTECH PLANTS TAGORE ROAD RAJKOT 360002 INDIA PHONES 91 281 248 0166 (office) 91 281 246 7552 (fax) 91 92 27 60 65 70 (mobile)

EMAIL energy@tinytechindia.com tinytech@tinytechindia.com WEB www.tinytechindia.com

AADHUNIK GLOBAL ENERGY

C/oTINYTECH PLANTS,Tagore Road, Rajkot - 360 002, INDIA Mobile # 91-92 27 60 65 70, Tel. 91-281-2480166 Fax # 91-281-2467552 Email : tinytech@tinytechindia.com Website : www.tinytechindia.com

5-10-2012 To, Michel Fleurant <emfleurant@yahoo.com>

PROFORMA INVOICE STEAM POWERED JAGGERY PLANT

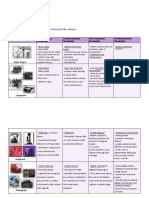

Complete steam powered jaggery plant consisting of:-

(1) 3 Roller Sugarcane crusher for jaggery making, capacity 1250 Kg. per hour with oil bath closed gear box. complete with all standard accessories i.e. beltings, pulleys, foundation bolts etc.

(2) Steam Engine 14 HP with Water Feed Pump driven by variable drive of 1 hp. (3) Centrifugal Water Separator (4) Centrifugal pump for juice transfer. (5) Mono Tube Boiler of 1" pipe coil, 140 ft long wound into coils 9 ft high. (6) 10 mt Long Flue Gas Chimney for jaggery boiling furnace complete with base flange. (600mm dia x 3.75m + 500mm dia x 6.25m)

COST FOB INDIAN PORT = US $ 8000/STEAMER FREIGHT TO MOMBASA = US$ 1000/COST C & F MOMBASA = US$ 9000/Payment & Delivery :-

We will dispatch equipments within 20 days only on receipt of payment at our account no. 12667 of AADHUNIK GLOBAL ENERGY at Corporation Bank, Dhebar Road, Rajkot - 360 002. INDIA. Swift. CORPINBB 191. Correspondent Bank of Corporation Bank in USA is Account no. 890-0385-987 The Bank of New York, One Wall Street, New York, N. Y. 10286, USA Swift : IRVT US3N, ABA NUMBER IS :- 021000018 You have to construct furnace and procure boiling pan at your cost. I suggest single boiling pan of 2.5 mt dia with 6mm bottom plate x 250mm high border of 3mm sheet to be fitted on the single furnace. You have to make RCC foundations for chimney and erect it at your cost. Our quotation is for supply of machinery and equipments mentioned above only. V K DESAI AADHUNIK GLOBAL ENERGY C/oTINYTECH PLANTS Tagore Road, RAJKOT - 360002, INDIA 91 92 27 60 65 70 ( MOBILE) 91 281 243 1086 91 281 246 7552 (FAX) tinytech@tinytehindia.com www.tinytechindia.com IF THE PLANT DOES NOT WORK SATISFACTORILY WITH MONO TUBE BOILER ALONE, THEN YOU WILL HAVE TO PURCHASE WATER TUBE BOILER WORKING ON BAGASSE WHICH WILL COST US$5000/-. BUT I HOPE THAT BAGASSE BOILER WILL NOT BE REQUIRED.

You might also like

- Organic JaggeryDocument7 pagesOrganic JaggeryPushpender HoodaNo ratings yet

- Percentage Replacement of Bitumen With Sugarcane Waste MolassesDocument10 pagesPercentage Replacement of Bitumen With Sugarcane Waste MolassesIAEME Publication100% (1)

- Unlocking the Power of the Sun Agrivoltaics and Sustainable AgricultureFrom EverandUnlocking the Power of the Sun Agrivoltaics and Sustainable AgricultureNo ratings yet

- KPMG Report Exec SummaryDocument19 pagesKPMG Report Exec SummaryNawin KumarNo ratings yet

- Ayurvet HPonics DubaiDocument28 pagesAyurvet HPonics DubaidrgsainiNo ratings yet

- Jaggery Making: How To Make Jaggery?Document5 pagesJaggery Making: How To Make Jaggery?Subham BhattacharyaNo ratings yet

- Production Technology of Drumstick: (Moringa oleifera Lam.)From EverandProduction Technology of Drumstick: (Moringa oleifera Lam.)No ratings yet

- Greenhouse Farming in India Beginner Guide 2018Document11 pagesGreenhouse Farming in India Beginner Guide 2018amarNo ratings yet

- Handbook of Processing of JaggeryDocument34 pagesHandbook of Processing of JaggerySachinNo ratings yet

- Industry Overview: - Grain ProcessingDocument11 pagesIndustry Overview: - Grain ProcessingVishal AgarwalNo ratings yet

- Stevia CultivationDocument3 pagesStevia CultivationRavi Chandra100% (2)

- Aloe Vera Farming Is Known To Be A Profitable Business and Over The YearsDocument14 pagesAloe Vera Farming Is Known To Be A Profitable Business and Over The YearsKavish BhandoyNo ratings yet

- Solvent Extraction For Jatropha OilDocument4 pagesSolvent Extraction For Jatropha OilRichard AmorinNo ratings yet

- Hydroponic Fodder Technical DataDocument1 pageHydroponic Fodder Technical DatapipestressNo ratings yet

- NAmkeen PPRDocument46 pagesNAmkeen PPRFăÍż SăįYąð100% (1)

- Jaggery Making ProcessDocument12 pagesJaggery Making ProcessSugar Technology100% (4)

- Simple Bio-Gas Plant Design and ConstructDocument15 pagesSimple Bio-Gas Plant Design and ConstructWaadNo ratings yet

- Guar - A Promising Crop For Gum IndusryDocument3 pagesGuar - A Promising Crop For Gum IndusryS Ishvara ReddyNo ratings yet

- Technical Program - Horticulture 2005-06Document19 pagesTechnical Program - Horticulture 2005-06Dr.Eswara Reddy SiddareddyNo ratings yet

- Sugar Report PDFDocument50 pagesSugar Report PDFsanjeev raikarNo ratings yet

- SteviaDocument7 pagesSteviaRavi KumarNo ratings yet

- 9.transportation of MilkDocument3 pages9.transportation of MilkdairyNo ratings yet

- Factors For Site SelectionDocument4 pagesFactors For Site SelectionHiren AjwaniNo ratings yet

- Project On National Horticulture BoardDocument9 pagesProject On National Horticulture Boardrupeshmore145No ratings yet

- Final Main Report HariomDocument50 pagesFinal Main Report HariomVijay ChauhanNo ratings yet

- Jaggery ProcessDocument4 pagesJaggery ProcessAsh1ScribdNo ratings yet

- Jaggery Manufacturing Unit Jaggery Unit Investment MachinesDocument4 pagesJaggery Manufacturing Unit Jaggery Unit Investment MachinesFarooq Ameer Jordan WalaNo ratings yet

- Agro Seed Processing Plant PDFDocument9 pagesAgro Seed Processing Plant PDFNagendra Patel100% (1)

- Coconut VarietiesDocument6 pagesCoconut VarietiesJBNo ratings yet

- 10-Hectare Venlo GreenhouseDocument41 pages10-Hectare Venlo GreenhousePaola Lucchesi50% (2)

- Thaifex Foodtech Ebrochure FinalDocument17 pagesThaifex Foodtech Ebrochure FinalkishoreNo ratings yet

- Sugar Production ProcessDocument2 pagesSugar Production ProcessedmarkNo ratings yet

- 21 CFR 158-170 Frozen Peas PDFDocument3 pages21 CFR 158-170 Frozen Peas PDFngoc98No ratings yet

- Sugar Sector & Initiating Coverage Apr'20Document69 pagesSugar Sector & Initiating Coverage Apr'20VINAYAK AGARWALNo ratings yet

- Advanced Preservation Methods and Nutrient PDFDocument16 pagesAdvanced Preservation Methods and Nutrient PDFTânia NunesNo ratings yet

- CFTRIDocument6 pagesCFTRIKumareshangrdcsNo ratings yet

- Final Dissertation (Jaggery)Document26 pagesFinal Dissertation (Jaggery)Hassan KhanNo ratings yet

- Processing of TurmericDocument9 pagesProcessing of TurmericTarsem MittalNo ratings yet

- Fertiliser SectorDocument9 pagesFertiliser SectorShreemayee PandaNo ratings yet

- Production Technology of GingerDocument14 pagesProduction Technology of GingerYanamandala VaishnaviNo ratings yet

- Pre Fesiblity of Medicinal PlantsDocument17 pagesPre Fesiblity of Medicinal Plantsbaloch75No ratings yet

- Role of Sugar, Gur, Liquid SweetnersDocument10 pagesRole of Sugar, Gur, Liquid SweetnersBharath Jaganathan100% (1)

- Project Profile On Soya Milk, Paneer & CurdDocument9 pagesProject Profile On Soya Milk, Paneer & CurdShashank ChauhanNo ratings yet

- Button Mushroom - Compost ProductionDocument80 pagesButton Mushroom - Compost ProductionShivendra SinghNo ratings yet

- Grains and Its Starch ContentDocument2 pagesGrains and Its Starch ContentkrishnaNo ratings yet

- Sorghum PDFDocument8 pagesSorghum PDFmominhadiNo ratings yet

- Production Process of JaggeryDocument22 pagesProduction Process of Jaggerys.sabapathy100% (1)

- Spice Grinding Unit Chilli, Turmeric, CuminDocument12 pagesSpice Grinding Unit Chilli, Turmeric, Cuminveer marathaNo ratings yet

- Lecture - 1: Scope and Importance of Post Harvest Technology in Horticultural CropsDocument17 pagesLecture - 1: Scope and Importance of Post Harvest Technology in Horticultural CropsAGRI KUDUMIYANMALAINo ratings yet

- MADP Project - J K Singh - Training On Amla - FinalDocument67 pagesMADP Project - J K Singh - Training On Amla - FinalalchemistjkNo ratings yet

- Viability & Economic Preview: Commercial HydroponicsDocument44 pagesViability & Economic Preview: Commercial HydroponicsVarghese PNo ratings yet

- Ginger Cultivation Project Report, Farming Economics - Agri FarmingDocument1 pageGinger Cultivation Project Report, Farming Economics - Agri FarmingSulemanNo ratings yet

- 7 Hydroponics 2020Document55 pages7 Hydroponics 2020GawadNo ratings yet

- Isitions. What Changed During The COVID-19 pandemicEmeraldInsight - Citations - 20231204123859Document1 pageIsitions. What Changed During The COVID-19 pandemicEmeraldInsight - Citations - 20231204123859Michael OdiemboNo ratings yet

- Effect of Macroeconomic Variables OnDocument16 pagesEffect of Macroeconomic Variables OnMichael OdiemboNo ratings yet

- Business Failures, Macroeconomic Risk and The E Ect ofDocument24 pagesBusiness Failures, Macroeconomic Risk and The E Ect ofMichael OdiemboNo ratings yet

- WSP Cash Conversion Cycle - VFDocument8 pagesWSP Cash Conversion Cycle - VFMichael OdiemboNo ratings yet

- ROIC ExplanationAndExamplesDocument4 pagesROIC ExplanationAndExamplesMichael OdiemboNo ratings yet

- Biofuel - Rice Husk Briquette Machine - United Nations Industrial Development OrganizationDocument7 pagesBiofuel - Rice Husk Briquette Machine - United Nations Industrial Development OrganizationMichael OdiemboNo ratings yet

- How Do You Align Your Business Operations Metrics With Your Strategic Goals and VisionDocument6 pagesHow Do You Align Your Business Operations Metrics With Your Strategic Goals and VisionMichael OdiemboNo ratings yet

- Advanced Mortgage Amortization v2.0Document20 pagesAdvanced Mortgage Amortization v2.0Michael OdiemboNo ratings yet

- One Spa Excel WorksheetDocument2 pagesOne Spa Excel WorksheetMichael OdiemboNo ratings yet

- After Tax Analysis Model v1.12Document8 pagesAfter Tax Analysis Model v1.12Michael OdiemboNo ratings yet

- County Emergency Management Form Renal Network 11 Dialysis Facility Disaster Plan ChecklistDocument5 pagesCounty Emergency Management Form Renal Network 11 Dialysis Facility Disaster Plan ChecklistMichael OdiemboNo ratings yet

- Pages From Credit Suise-806230540Document8 pagesPages From Credit Suise-806230540Michael OdiemboNo ratings yet

- Invested Capital Formula Excel TemplateDocument24 pagesInvested Capital Formula Excel TemplateMichael OdiemboNo ratings yet

- After Tax Analysis Model v1.12Document8 pagesAfter Tax Analysis Model v1.12Michael OdiemboNo ratings yet

- Pond 14Document14 pagesPond 14Michael OdiemboNo ratings yet

- Ras Survey 2018Document4 pagesRas Survey 2018Michael OdiemboNo ratings yet

- Pond 15Document14 pagesPond 15Michael OdiemboNo ratings yet

- Lease Agreement Capital City001Document4 pagesLease Agreement Capital City001Michael OdiemboNo ratings yet

- Pond 12Document14 pagesPond 12Michael OdiemboNo ratings yet

- LuoDocument1 pageLuoMichael OdiemboNo ratings yet

- Pond 6Document8 pagesPond 6Michael OdiemboNo ratings yet

- Pond 11Document14 pagesPond 11Michael OdiemboNo ratings yet

- Pond 7Document8 pagesPond 7Michael OdiemboNo ratings yet

- Pond 10Document14 pagesPond 10Michael OdiemboNo ratings yet

- Pond 13Document14 pagesPond 13Michael OdiemboNo ratings yet

- Saturday, December 15, 2018 1:18 PM: Unfiled Notes Page 1Document8 pagesSaturday, December 15, 2018 1:18 PM: Unfiled Notes Page 1Michael OdiemboNo ratings yet

- Pond 8Document14 pagesPond 8Michael OdiemboNo ratings yet

- Steam CondenserDocument6 pagesSteam CondenserAnonymous Xc8C1hNo ratings yet

- Deck Machineries For Cargo ShipsDocument2 pagesDeck Machineries For Cargo ShipscristianNo ratings yet

- Industrial Internship ReportDocument48 pagesIndustrial Internship Reportshuvrabanik33% (3)

- 1956 - Colinese - Boiler Efficiencies in SugarDocument7 pages1956 - Colinese - Boiler Efficiencies in SugarPaul DurkinNo ratings yet

- A Thermodynamics HistoryDocument8 pagesA Thermodynamics HistoryJaster Monloise Baña SanicoNo ratings yet

- Steam Turbine PerformanceDocument16 pagesSteam Turbine PerformanceVILLANUEVA_DANIEL2064100% (2)

- Factorio Cheat Sheet v7-2023Document22 pagesFactorio Cheat Sheet v7-2023Alex NevskiyNo ratings yet

- 1435657068mechanical EngineeringDocument22 pages1435657068mechanical EngineeringShadow007No ratings yet

- Marine Gas TurbinesDocument6 pagesMarine Gas TurbinesAqeila Muz DalifahNo ratings yet

- Spirax Sarco - PRODUCT HANDBOOK AUGUST 2017 PDFDocument1,900 pagesSpirax Sarco - PRODUCT HANDBOOK AUGUST 2017 PDFboom1086% (7)

- Implications of Sustainable Development in Philippine IndustrializationDocument21 pagesImplications of Sustainable Development in Philippine IndustrializationFaridaPangaySudiod100% (1)

- WSA Engineering Branch Training 3Document30 pagesWSA Engineering Branch Training 3rene almonacidNo ratings yet

- Tender Document GSM1Document78 pagesTender Document GSM1Varsha Vaishali KotharyNo ratings yet

- SolarSteamPump EthiopiaDocument125 pagesSolarSteamPump EthiopiaNick JeffriesNo ratings yet

- Universiti Malaysia Pahang: Faculty of Mechanical EngineeringDocument13 pagesUniversiti Malaysia Pahang: Faculty of Mechanical EngineeringFirdaus IliasNo ratings yet

- "Steam Generator": Submitted By: Alberca, June Marc Lofranco, Richard Sterwen Sinajon, JohnlyndonDocument3 pages"Steam Generator": Submitted By: Alberca, June Marc Lofranco, Richard Sterwen Sinajon, JohnlyndonRichster LofrancoNo ratings yet

- Training Report G.H.T.P, Lehra MohabbatDocument47 pagesTraining Report G.H.T.P, Lehra Mohabbatgoyalz100% (2)

- 1 - 303 - Feedwater Level Control SystemsDocument31 pages1 - 303 - Feedwater Level Control SystemsAnonymous 3fTYXaW7WNo ratings yet

- STS - Industrial Revolution (Manabat, Angelika Mae C. - BSBA-MM2A)Document5 pagesSTS - Industrial Revolution (Manabat, Angelika Mae C. - BSBA-MM2A)Angelika Mae ManabatNo ratings yet

- Soal USBN Sastra InggrisDocument21 pagesSoal USBN Sastra Inggrisgunung nugrohoNo ratings yet

- Vapour Power Cycles - 275Document53 pagesVapour Power Cycles - 275aditya yadavNo ratings yet

- ME Law (RA 8495)Document22 pagesME Law (RA 8495)Angielo U. ComiaNo ratings yet

- Master DegreeDocument87 pagesMaster DegreeAida AliyevaNo ratings yet

- Mech Engg Question Bank - I Sem For MechanicalDocument124 pagesMech Engg Question Bank - I Sem For Mechanicalanon_102708056No ratings yet

- Continuous Assessment Cover Sheet Faculty of Engineering: Student Statement and SignatureDocument33 pagesContinuous Assessment Cover Sheet Faculty of Engineering: Student Statement and SignatureAriharan KumaranNo ratings yet

- MOSS Tank DetailsDocument26 pagesMOSS Tank DetailsRajesh KrishnamoorthyNo ratings yet

- To Download List of A Books Available in Library I - 59d42dbc1723dd1de323c9b4 PDFDocument188 pagesTo Download List of A Books Available in Library I - 59d42dbc1723dd1de323c9b4 PDFRISHIKESH KUMARNo ratings yet

- Question Bank BCMDocument11 pagesQuestion Bank BCMamsk24_24No ratings yet

- Final Report 2 PsDocument27 pagesFinal Report 2 PsNishant AsharNo ratings yet

- Ihp ReportDocument15 pagesIhp ReportVinod ShindeNo ratings yet