Professional Documents

Culture Documents

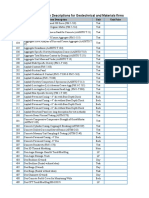

A and S Processes Matrix 1 Mar 08

Uploaded by

Teo DorOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A and S Processes Matrix 1 Mar 08

Uploaded by

Teo DorCopyright:

Available Formats

To report problems with any of the links in this document contact HQ AFMC PRODUCT SUPPORT CAMPAIGN DSN 674-2758

ORG/PLAYERS SAF, HQ, LOG MECHANISMS CONTROLS IT Systems TRIGGER

AFMC A4A Product Support Campaign@wpafb.af.mil

SDD (INTEGRATION) DEVELOP & ACQUIRE SUPPORT RETIRE PRODUCTS SDD (DEMONSTRATION) DESIGN SUPPORT IMPROVEMENT OPPORTUNITIES DETERMINE SUPPORT REQUIREMENTS FIELD SUPPORT PLAN SUPPORT PRODUCTION & DEPLOYMENT OPERATIONS & SUPPORT TECHNOLOGY DEVELOPMENT MANAGE CAPABILITIES CONCEPT REFINEMENT RESOURCES CONSUMED CYCLE TIME

MAINTAIN PRODUCTS

TASK DESCRIPTION

ANALYZE MATERIAL SOLUTION TO CAPABILITIES REVIEW AND RISK ASSESSMENT (CRRA) CAPABILITY SHORTFALLS (FSA) (INCLUDE LOGISTICS EXPERTISE ON TEAM)

Enterprise Information Capabilities Review & Capabilities Review & Technology Data Risk Assessment Risk Assessment Repository (EITDR) (CRRA) Outputs (CRRA) Process MAJCOM/Wing Identify Capability Gaps N/A Changes to National Military Strategy, Defense Planning Guidance, etc Joint Capabilities Integration and Development System (JCIDS) Process

National Military AF/A5, MAJCOM Strategy, Defense Requirements Planning Guidance, etc. Organizations

Potential Material Solutions for inclusion into Initial Capabilities Document (ICD) Initial Capabilities Document (ICD)

Joint Capabilities Integration and Development System (JCIDS) Process Joint Capabilities Integration and Development System (JCIDS) Process

Functional Subject Matter Experts (SME)s Participation in FSA

ANALYZE REQUIREMENTS FROM SOURCES OTHER THAN THE CAPABILITIES REVIEW AND RISK ASSESSMENT (CRRA) (INCLUDE LOG EXPERTISE ON TEAM)

DEFINE SUPPORTABILITY OBJECTIVES

N/A

Initial Capabilities Document (ICD) Development

Joint Capabilities Integration and Development System (JCIDS) Process

Updated National Military Strategy, Defense Planning Guidance, etc (Top Down directed Capability Requirements) Potential materiel solutions

Functional Capability Boards, Combatant Commands, AF/A5, MAJCOM Requirements Organizations

Functional Subject Matter Experts (SME)s Participation in FSA X X

INCLUDE SUPPORTABILITY OBJECTIVES IN INITIAL CAPABILITIES DOCUMENT (ICD)

N/A

Initial Capabilities Document (ICD) Development

Joint Capabilities Integration and Development System (JCIDS) Process DoDI 5000.2 (Requirements for Alternative of Action (AOA) for ACAT I programs)

INCLUDE PRODUCT SUPPORT CAPABILITIES IN ALTERNATIVE N/A OF ACTION (AOA) PLAN

Decision to proceed to Concept Decision point or Appropriate Milestone

ACQUIRE CONCEPT DECISION FROM MILESTONE DECISION AUTHORITY (MDA)

N/A

Concept Decision Point DoDI 5000.2 Review by Milestone Decision Authority (MDA)

EVALUATE PRODUCT SUPPORT CAPABILITY IN ALTERNATIVE N/A OF ACTION (AOA) FOR THE BEST MATERIAL APPROACHES

Alternative of Action (AOA) Study Begun

Alternative of Action (AOA) Study Plan

Functional Capability Boards, Combatant Commands, AF/A5, MAJCOM Requirements Organizations Potential materiel Functional Capability solutions Boards, Combatant Commands, AF/A5, MAJCOM Requirements Organizations DPA&E, Supportability OUSD(AT&L), Objectives that need to AF/A5, MAJCOM be addressed in Requirements Alternative of Action Organizations, any (AOA) Acquisition Leads identified, Office of Aerospace Studies Documentation Milestone Decision Required by DoDI Authority (MDA), 5000.2 Whatever Acquisition Leads identified, AF/A5, MAJCOM Requirements Organizations Initial Capabilities OUSD AT&L, DPA&E, Document (ICD) FSA AF/A5, MAJCOM Analysis and Alternative Requirements of Action (AOA) Study Organizations, any Plan Acquisition Leads identified, Office of Aerospace Studies Initial Capabilities Document (ICD) FSA Analysis and Alternative of Action (AOA) Study Plan OUSD AT&L, DPA&E, AF/A5, MAJCOM Requirements Organizations, any Acquisition Leads identified, Office of Aerospace Studies OUSD AT&L, DPA&E, AF/A5, MAJCOM Requirements Organizations, any Acquisition Leads identified, Office of Aerospace Studies Acquisition Lead, MAJCOM Requirements Org

Initial Capabilities Document (ICD)

Joint Capabilities Integration and Development System (JCIDS) Process

Functional Subject Matter Experts (SME)s Participation in FSA

Initial Capabilities Document (ICD)

Joint Capabilities Integration and Development System (JCIDS) Process MAJCOM Led Process

Functional Subject Matter Experts (SME)s Participation in FSA

Alternative of Action (AOA) Study Plan

Functional Subject Matter Experts (SME)s Participation in Alternative of Action (AOA) Planning

Approval to Proceed Into Concept Refinement Phase

Milestone Decision Authority (MDA) Led Meeting

Functional Subject Matter Experts (SME)s Participation in Documentation Developed to Support CD Review

Alternative of Action (AOA) Results

MAJCOM Led Alternative of Action (AOA) Process

Functional Subject Matter Experts (SME)s Participation in Alternative of Action (AOA) Studies

PARTICIPATE IN AND DOCUMENT THE INITIAL TECHNOLOGY REVIEW

N/A

Alternative of Action (AOA) Study Begun

Alternative of Action (AOA) Study Plan

Understanding of Technology issues, maturity for each potential Alternative of Action (AOA) solution.

MAJCOM Led Alternative of Action (AOA) Process

Functional Subject Matter Experts (SME)s Participation in Alternative of Action (AOA) Studies

INCLUDE PRODUCT SUPPORT CONCEPTS IN PREFERRED SYSTEM CONCEPT

N/A

Alternative of Action (AOA) Study Draft Results

Alternative of Action (AOA) Study Plan

Identification of Preferred Concept

Initial information MAJCOM Led related to PS Concept Alternative of Action for Alternative of Action (AOA) Process (AOA) preferred system concept

Functional Subject Matter Experts (SME)s Participation in Alternative of Action (AOA) Studies

PARTICIPATE IN DEFINING, ANALYZING & SELECTING COURSE OF ACTION (INCREMENTS & PROGRAM STRATEGIES) (PER AFI 63-101)

Reduction inTotal Ownership Cost (RTOC)

Preferred System Concept Identified

AFI 63-101

Information concerning Preferred System Concept from Alternative of Action (AOA) Study Information concerning Preferred System Concept from Alternative of Action (AOA) Study Information concerning Preferred System Concept from Alternative of Action (AOA) Study Information concerning Preferred System Concept from Alternative of Action (AOA) Study, Approved Course of Action (COA) approach Information concerning Preferred System Concept from Alternative of Action (AOA) Study, Approved Course of Action (COA) approach Information concerning Preferred System Concept from Alternative of Action (AOA) Study, Approved Course of Action (COA) approach Information concerning Preferred System Concept from Alternative of Action (AOA) Study, Approved Course of Action (COA) approach Information concerning Preferred System Concept from Alternative of Action (AOA) Study, Approved Course of Action (COA) approach

PARTICIPATE IN TEST & EVALUATION STRATEGY

N/A

Preferred System Concept Identified

AFI 63-101, DoDI 5000.2

Acquisition Lead, MAJCOM Requirements Org, Test Community Acquisition Lead, any Engineering Support ( eg. Center EN Staff)

MAJCOM Agreed Course of Action (COA) for delivering capability. (Evolutionary Strategy or Single Step to Completion) Initial Test Strategy for Program at MS A

Acquisition Led Process

Functional Subject Matter Experts (SME)s Participation in Development of Course of Action (COA)s

Acquisition Led Process

Test Community Participation in Development of Initial Test Strategy

PARTICIPATE IN SYSTEM ENGINEERING PLAN (SEP) DEVELOPMENT

N/A

Preferred System Concept Identified

AFI 63-101, DoDI 5000.2

Initial Systems Engineering Plan (Systems Engineering Plan (SEP)) for MS A TDS

Acquisition Led Process

Engineers Participation in Development of Initial Systems Engineering Plan

DEVELOP TECHNOLOGY DEVELOPMENT STRATEGY (INCLUDING PRODUCT SUPPORT)

N/A

Preferred System Concept Identified

AFI 63-101, DoDI 5000.2

Acquisition Lead

Acquisition Led Process

Functional Subject Matter Experts (SME) participation in development of TDS X X

DEVELOP INITIAL PRODUCT SUPPORT STRATEGY IN LIFE CYCLE MANAGEMENT PLAN (LCMP) (PERFORMANCE-BASED LOGISTICS , PUBLIC-PRIVATE PARTNERSHIPS (PPP), LOGISTICS ELEMENTS, ETC)

Logistics Planning and Preferred System Requirements System Concept Identified (LOGPARS) Army System

AFI 63-101, DoDI 5000.2, Life Cycle Management Plan (LCMP) Guide, AF Federal Acquisition Regulation (FAR)S AFI 63-101, DoDI 5000.2, Life Cycle Management Plan (LCMP) Guide, AF Federal Acquisition Regulation (FAR)S AFI 63-101, DoDI 5000.2, Life Cycle Management Plan (LCMP) Guide, AF Federal Acquisition Regulation (FAR)S AFI 63-101, DoDI 5000.2, Life Cycle Management Plan (LCMP) Guide, AF Federal Acquisition Regulation (FAR)S

Acquisition Lead

Life Cycle Management Acquisition Led Plan (LCMP) or Acq Process Plan depending on ACAT level

Functional Subject Matter Experts (SME) participation in development of Life Cycle Management Plan (LCMP)/Acq Plan

REVIEW REQUIREMENTS DOCUMENTS/ INITIAL CAPABILITY OBJECTIVE (ICD)

Preferred System Concept Identified

Acquisition Lead

Life Cycle Management Acquisition Led Plan (LCMP) or Acq Process Plan depending on ACAT level

REVIEW STRATEGIES FOR SIMILAR PRODUCTS/ STRATEGIES

Preferred System Concept Identified

Acquisition Lead

Life Cycle Management Acquisition Led Plan (LCMP) or Acq Process Plan depending on ACAT level

DEVELOP ALTERNATIVES FOR PRODUCT SUPPORT STRATEGY

Preferred System Concept Identified

Acquisition Lead

Life Cycle Management Acquisition Led Plan (LCMP) or Acq Process Plan depending on ACAT level X X

CONDUCT RISK ASSESSMENT FOR ALTERNATIVES

Preferred System Concept Identified

AFI 63-101, DoDI 5000.2, Life Cycle Management Plan (LCMP) Guide, AF Federal Acquisition Regulation (FAR)S

Information concerning Acquisition Lead Preferred System Concept from Alternative of Action (AOA) Study, Approved Course of Action (COA) approach

Life Cycle Management Acquisition Led Plan (LCMP) or Acq Process Plan depending on ACAT level X X

DEVELOP COST ESTIMATE FOR ALTERNATIVES

Preferred System Concept Identified

AFI 63-101, DoDI 5000.2, Life Cycle Management Plan (LCMP) Guide, AF Federal Acquisition Regulation (FAR)S

Information concerning Acquisition Lead Preferred System Concept from Alternative of Action (AOA) Study, Approved Course of Action (COA) approach

Life Cycle Management Acquisition Led Plan (LCMP) or Acq Process Plan depending on ACAT level X X

EDIT AND COORDINATE WRITING OF LIFE CYCLE MANAGEMENT PLAN (LCMP)

Preferred System Concept Identified

AFI 63-101, DoDI 5000.2, Life Cycle Management Plan (LCMP) Guide, AF Federal Acquisition Regulation (FAR)S

Information concerning Acquisition Lead Preferred System Concept from Alternative of Action (AOA) Study, Approved Course of Action (COA) approach

Life Cycle Management Acquisition Led Plan (LCMP) or Acq Process Plan depending on ACAT level X X

REVIEW ENTIRE LIFE CYCLE MANAGEMENT PLAN (LCMP) FOR DISCONNECTS

Preferred System Concept Identified

AFI 63-101, DoDI 5000.2, Life Cycle Management Plan (LCMP) Guide, AF Federal Acquisition Regulation (FAR)S AFI 63-101, DoDI 5000.2, Life Cycle Management Plan (LCMP) Guide, AF Federal Acquisition Regulation (FAR)S AFI 63-101, DoDI 5000.2, Life Cycle Management Plan (LCMP) Guide, AF Federal Acquisition Regulation (FAR)S AFI 63-101

APPROVE PRODUCT SUPPORT STRATEGY(S) (ACQUISITION STRATEGY PANEL (ASP))

Preferred System Concept Identified

FINALIZE LIFE CYCLE MANAGEMENT PLAN (LCMP) BASED ON ACQUISITION STRATEGY PANEL (ASP) RECOMMENDATIONS

Preferred System Concept Identified

ENSURE SUPPORTABILITY INCLUDED IN EXPECTATION MANAGEMENT AGREEMENTS (EMAs)

N/A

Preferred System Concept Identified

Information concerning Preferred System Concept from Alternative of Action (AOA) Study, Approved Course of Action (COA) approach Information concerning Preferred System Concept from Alternative of Action (AOA) Study, Approved Course of Action (COA) approach Information concerning Preferred System Concept from Alternative of Action (AOA) Study, Approved Course of Action (COA) approach Information concerning Preferred System Concept from Alternative of Action (AOA) Study, Approved Course of Action (COA) approach

Acquisition Lead

Life Cycle Management Acquisition Led Plan (LCMP) or Acq Process Plan depending on ACAT level

Acquisition Lead

Life Cycle Management Acquisition Led Plan (LCMP) or Acq Process Plan depending on ACAT level

Acquisition Lead

Life Cycle Management Acquisition Led Plan (LCMP) or Acq Process Plan depending on ACAT level

Acquisition Lead, Lead MAJCOM Requirements Org

Expectation Acquisition Led Management Process Agreement (although since you don't have a Capability Development Document (CDD) yet an Expectation Management Agreement is really premature at this point.)

Functional Subject Matter Experts (SME) participation in development of Expectation Management Agreement

INCLUDE SUPPORTABILITY IN THE SOURCE SELECTION PLAN N/A (SSP)

Preferred System Concept Identified

Federal Acquisition Regulation (FAR) / AF Federal Acquisition Regulation (FAR)s

PARTICIPATE IN ACQUISITION STRATEGY REVIEW

N/A

Preferred System Concept Identified

AFI 63-101, DoDI 5000.2, Life Cycle Management Plan (LCMP) Guide, AFFARS

ENSURE ACQUISITION STRATEGY PLAN SUPPORTABILITY TEMPLATE COMPLETED

N/A

Preferred System Concept Identified

AFI 63-101, DoDI 5000.2, Life Cycle Management Plan (LCMP) Guide, AFFARS

INCLUDE SUPPORTABILITY REQUIREMENTS IN REQUEST FOR PROPOSAL (RFP)

Pre Award Information Preferred System Exchange System Concept Identified (PIXS) ConWrite FEDBIZOPS

Federal Acquisition Regulation (FAR)/AF Federal Acquisition Regulation (FAR)s

Information concerning Preferred System Concept from Alternative of Action (AOA) Study, Approved Course of Action (COA) approach Information concerning Preferred System Concept from Alternative of Action (AOA) Study, Approved Course of Action (COA) approach Information concerning Preferred System Concept from Alternative of Action (AOA) Study, Approved Course of Action (COA) approach Information concerning Preferred System Concept from Alternative of Action (AOA) Study, Approved Course of Action (COA) approach

Acquisition Lead, Source Selection Plan Acquisition Led Center Contracting Org (if required at this point) Process

Functional Subject Matter Experts (SME) participation in development of Source Selection Plan (SSP)

Acquisition Lead. OSD IPTs, Defense Acquisition Executive (DAE)

ASR (Only ACAT ID and IAM programs)

Acquisition Led Process and IPT process

Functional Subject Matter Experts (SME) participation in development of Acq Strategy X X

Acq Lead

Acquisition Strategy Panel (ASP) Charts (if Acquisition Strategy Panel (ASP) req'd at this point)

Acquisition Strategy Panel (ASP) Process

Functional Subject Matter Experts (SME) participation in development of Acq Strategy X X

Acquisition Lead, Request for Proposal Center Contracting Org (RFP)

Acquisition Led Process

Functional Subject Matter Experts (SME) participation in development of Request for Proposal (RFP)

1 OF 156

IMPROVE PRODUCTS

OUTPUT

INPUT

SDD (INTEGRATION)

ORG/PLAYERS SAF, HQ, LOG

DEVELOP & ACQUIRE SUPPORT

TASK DESCRIPTION

ANALYZE DATA MATERIAL SOLUTION TO CAPABILITIES REVIEW INCLUDE RIGHTS IN THE REQUEST FOR PROPOSAL AND RISK ASSESSMENT (CRRA) CAPABILITY SHORTFALLS (RFP) (FSA) (INCLUDE LOGISTICS EXPERTISE ON TEAM)

Unique Identification (UID) Registry

Preferred System Concept Identified

Federal Acquisition Regulation (FAR)/AF Federal Acquisition Regulation (FAR)s, Public Law

REVIEW BERRY AMENDMENT FOR APPLICATION TO YOUR PROGRAM AND ENSURE COMPLIANCE IN ALL CONTRACTING ACTIONS INCLUDE OPTIONS FOR RADIO-FREQUENCY IDENTIFICATION (RFID) IN THE REQUEST FOR PROPOSAL (RFP) INCLUDE OPTIONS FOR UNIQUE IDENTIFICATION (UID) IN THE REQUEST FOR PROPOSAL (RFP) PARTICIPATE IN RISK MANAGEMENT N/A

Contractual actions

Public Law 10 USC 2533

Information concerning Preferred System Concept from Alternative of Action (AOA) Study, Approved Course of Action (COA) approach Contractor and Organic design data

Acquisition Lead, Request for Proposal Center Contracting Org (RFP)

Acquisition Led Process

Functional Subject Matter Experts (SME) participation in development of Request for Proposal (RFP)

Acquisition lead, Contractor, Legal

Contractual language, Compliance data

Acquisition Led Process

Compliance with law, support National Security Strategies

Preferred System Concept Identified

INCLUDE LOGISTICS ACTIVITIES IN THE INTEGRATED MANAGEMENT PLAN / INTEGRATED MANAGEMENT SCHEDULE (IMP/IMS)

N/A

Preferred System Concept Identified

PARTICIPATE IN SOURCE SELECTION (LOGISTICIAN)

EZ Source, Contractor Performance Assessment Report System (CPARS) Navy System

Preferred System Concept Identified

ENSURE COST ESTIMATE INCLUDES LIFE CYCLE SUPPORT COSTS

Logistics Composite Model (LCOM)

Preferred System Concept Identified

PREPARE DOCUMENTATION REQUIRED FOR MILESTONE A

N/A

Preferred System Concept Identified

AFI 63-101, DoD 5000 Information concerning Preferred System Concept from Alternative of Action (AOA) Study, Approved Course of Action (COA) approach Integrated Master Plan / Information concerning Integrated Master Preferred System Schedule (IMP/IMS) Concept from Guide Alternative of Action (AOA) Study, Approved Course of Action (COA) approach Federal Acquisition Source Selection Plan Regulation (FAR)/AF (if required at this point) Federal Acquisition Information concerning Regulation (FAR)s Preferred System Concept from Alternative of Action (AOA) Study, Approved Course of Action (COA) approach AFI 63-101, DoDI Information concerning 5000.2 Preferred System Concept from Alternative of Action (AOA) Study, Approved Course of Action (COA) approach AFI 63-101, DoDI Information concerning 5000.2 Preferred System Concept from Alternative of Action (AOA) Study, Approved Course of Action (COA) approach

Acquisition Lead, Appropriate Logistics Rep

Program Planning, Including Risk Management

Acquisition Led Process

Functional Subject Matter Experts (SME) participation in Risk Management Planning X X

Acquisition Lead, Appropriate Logistics Rep

Integrated Master Plan / Acquisition Led Integrated Master Process Schedule (IMP/IMS)

Functional Subject Matter Experts (SME) participation in development of Integrated Master Plan / Integrated Master Schedule (IMP/IMS)

Acquisition Lead, Appropriate Logistics Rep

Source Selection Decision

Acquisition Led Process

Functional Subject Matter Experts (SME) participation in Source Selection X X

Acquisition Lead, Appropriate Logistics Rep

Program Documentation

Acquisition Led Process

Functional Subject Matter Experts (SME) participation in Program Cost Estimating X X

Acquisition Lead, Appropriate Logistics Rep, MAJCOM Requirements Org, AF/A5, Test Community, Cost Community

Program Documentation Required at MILESTONE A

Various Functional Lead processes depending on Document

Functional Subject Matter Experts (SME) participation in Developing Program Documentation X X

MILESTONE A DECISION VERIFY THE MISSION ASSIGNMENT DECISION FOR ACQUISITION & SUSTAINMENT MANAGEMENT

N/A

Milestone A decision

AF process on mission assignment (old XOX?)

ENSURE ADEQUATE LOGISTICS RESOURCES ARE ASSIGNED Sustainment / Milestone A decision FOR PROGRAM Acquisition Composite Model (SACOM), CMS

ESTABLISH A TECHNICAL ORDER ACQUISITION PROGRAM

Milestone A decision

Command mil/civ/ktr manning and control process (entitlements from AFPC), Contract Estimating & Pricing (CEP), $$ TO 00-5-3, Technical Manual Contract Requirements (TMCR) Document TM-86-01

ASR, Acquisition Strategy Panel (ASP), Alternative of Action (AOA), any program direction documents Milestone Decision, Mission Assignment, New Work package

was AF/XO, will now include AFMC/A8

Mission Assignment direction

Paper/MS Office

60 days

HQ AFMC, AF, SAF

Making the decision this early IS THE improvement X X

Prod/Log Centers

New Work Command and center Package/Program processes Objective Memorandum (POM) input

6 months

Prod/Log Centers

Opportunity to centralize this work in a new work Group/ACE/XR

Initial Capabilities Document (ICD), Draft Capability Development Document (CDD), Maintenance Strategy, Product Support Strategy

Program Office, MAJCOM, Technical Order Manager, Prime Contractor, TO Integrated Program Team

Technical Manual TO Planning & Contract Requirements Requirements (TMCR) Document TM- Conference 86-0, Updated Initial Capabilities Document (ICD), Draft Capability Development Document (CDD), Maintenance Strategy, Product Support Strategy

Program Office, MAJCOM, Technical Order Manager, Prime Contractor, TO Integrated Program Team X X

ASSIGN TECHNICAL ORDER MANAGER INITIATE DEPOT SOURCE OF REPAIR (DSOR) PROCESS AND THE DEPOT MAINTENANCE INTERSERVICING (DMI)

N/A

Milestone A decision

HQ process

Mission assignment, technical data

Prod/Log Centers, HQ AFMC/A4

DETERMINE CORE & ASSIGN CANDIDATE DEPOT (REF NEW SOURCE of REPAIR ASSIGNMENT PROCESS (SORAP))

N/A

Milestone A decision

HQ process

Mission assignment, technical data

Prod/Log Centers, HQ AFMC/A4

ESTABLISH DEPOT MAINTENANCE ACTIVATION WORKING GROUP (DMAWG) TEAM

N/A

Milestone A decision

HQ process for Source of Repair Assignment Process (SORAP) and Cost Oriented Resource Estimating (CORE) Contracting process, Federal Acquisition Regulation (FAR) Policy

Source of Repair Assignment Process (SORAP), Cost Oriented Resource Estimating (CORE), Program Data Technical information, studies, $$, lab input Requirements, Acquisition Strategy, Contractor Data

Prod/Log Centers, Contractor

Source of Repair Assignment Process (SORAP)/Depot Maintenance Interservicing (DMI) started Source of Repair Assignment Process (SORAP)/Depot Maintenance Interservicing (DMI) started Depot Maintenance Activation Working Group (DMAWG) team officially names and responsible

Source of Repair Assignment Process (SORAP) process

Prod/Log centers, HQ AFMC

Doing it this early is an improvement X X

Source of Repair Assignment Process (SORAP) process

Prod/Log centers, HQ AFMC

Doing it this early is an improvement X X

MS Office, face to face 30 days meetings

Prod/Log Centers, contractor

Establishing this early AND having them meet X X

ESTABLISH PERIODIC LOGISTICS PLANNING AWARD THE TECHNOLOGY DEVELOPMENT CONTRACT

X Navy Air Force Interface (NAFI) Milestone A decision, $$ Program Office Cadre Contract AMOS, Pre Award Information Exchange System (PIXS) IT System approval process, Acquisition Strategy approval process 150 days total Program Office Cadre MAJCOMs Prod/Log Centers, contractor Standing Basic Ordering Agreement (BOA) for multiple efforts Reduce proliferation of IT systems X

X X

ENSURE WEAPON SYSTEM PROGRAM COMPLIES WITH AIR FORCE POLICY FOR NO NEW MANAGEMENT INFORMATION SYSTEM DEVELOPMENT WITHOUT AF/CIO APPROVAL. THIS EXCLUDES MISSION CRITICAL COMPUTER RESOURCES (MCCR) AND NATIONAL SECURITY SYSTEMS ENSURE SUPPORTABILITY INCLUDED IN EXPECTATION MANAGEMENT AGREEMENT (EMA)s

Enterprise Information Contractual Actions Technology Data Repository (EITDR)

Acquisition and Sustainment Organizations, Base IT Organization

Contractual direction, Technical requirements, Approved new IT System

N/A

Expectation Management Agreement (EMA) required or update

Expectation Management Agreement (EMA) process

Technical information, Prod/Log Centers, studies, $$, lab input, MAJCOM's Source of Repair Assignment Process (SORAP) mission assignment, Required Life Cycle Management Plan (LCMP) if available Technical data, Prod/Log Centers, Prod/Log center MAJCOM's assessment, FM status, issues, risk assessment Data from site visits, MAJCOM/log center info, Technical data, $$ Prod/Log Center, MAJCOM's

Expectation Management Agreement (EMA)s

Expectation Management Agreement (EMA) process and templates

60 days

Prod/Log Centers, MAJCOMs

Work Expectation Management Agreement (EMA)s a single process initiative where feasible to have umbrella Expectation Management Agreement (EMA)s

INITIATE SUPPORTABILITY REPORTING TEMPLATE FOR ALL PROGRAM EXECUTIVE OFFICER (PEO) REVIEWS

N/A

Program Executive Sustainment Template, Officer (PEO) review or controlled by HQ any review AFMC/A4 requirements Site Activation Task Force (SATAF) planning, MAJCOM planning Preferred System Concept Identified $$$

Sustainment template chart with backup

Template

<30 days

Prod/Log Center, MAJCOM This is an improvement X X

PARTICIPATE IN OPERATIONAL SITE REVIEWS

N/A

Site plans, input for TDY's, meetings, facilities reports, MS Office budgets/Program products Objective Memorandum (POM) Inputs to SEP, LCMP, TEMP, ICD, CDD, CPD, MER, LCCE, Training Plans IPT Meeting with Government and contractor on supportability, manpower, and personnel

30 + days

Prod/Log Centers, MAJCOMs

Need a better sharing mechanism for site data (politics of Base Realignment and Closure Comittee (BRACC) an issue) Minimize life cycle cost while maximizing system readiness and personnel and system effectiveness

DETERMINE MANPOWER AND PERSONNEL REQUIREMENTS

REMIS, CAMS

AFI 10-601, AFI 10602, 10 USC 2434, DoD 5000.2, AFI 38201, AFI 38-202, Defense Acquisition Guide Book AFH 32-1084, AFI 321021,

System Requirements, ICD, CDD, CPD, SEP, LCMP, Functional Baseline, , TAD, CARD

DEFINE AND IMPLEMENT MILITARY CONSTRUCTION (MILCON) REQUIREMENTS

N/A

Facility requirement Identified

Logisticians, Acquisition Lead, Systems Engineering, Sustainment Engineering, Training Personnel, Manpower personnel ICD, CDD, Site Survey, MAJCOM, Product / SATAF, Facilities Logistics Center, Base Requirements Plan from Civil Engineering, Contractor Contractor

Pre source selection through end of program

Site plans, input for TDY, Meetings, facilities budgets / International Building MILCON, Programmatic Code, Environmental Environment Safety and Compliance, Health Evaluation (PESHE) Defense Contracts Management Agency (DCMA) Memorandum of Agreement (MOA) MS Word 30 - 60 days

MAJCOM, Product / Start planning as early as Logistics Center, Base Civil possible due to MILCON lead Engineering, Contractor time X X

INCLUDE SUPPORTABILITY REQUIREMENTS IN DEFENSE N/A CONTRACTS MANAGEMENT AGENCY (DCMA) MEMORANDUM OF AGREEMENT (MOA)

Contract award

Defense Contracts Management Agency (DCMA) mission cope

Previous Memorandum of Agreement (MOA) & Memorandum of Agreement (MOA)s in force at that plant location

Defense Contracts Management Agency (DCMA), Program Office, ALC, Prime Contractor, MAJCOMs

PM team, Procuring Contracting Officer (PCO), ALC, Defense Contracts Management Agency (DCMA)

Apply single process initiative philosophy X X

REVIEW LOGISTICS ACTIVITIES IN THE INTEGRATED MASTER N/A PLAN / INTEGRATED MASTER SCHEDULE (IMP/IMS)

Requirement for Integrated Master Plan / Integrated Master Schedule (IMP/IMS) identified Continuous Risk Mitigation Activities

Integrated Master Plan / Identification of required ALC and Product Integrated Master logistics activities and Center logisticians, Schedule (IMP/IMS) associated timelines Procuring Contracting Data Item Description Officer (PCO) (DID) Risk Management Guidelines Identified Supportability Risks and Current Assessment Contractor, ALC and PC logisticians, Procuring Contracting Officer (PCO), Engineers Program Office, Contractor

Completed Integrated Integrated Master Plan / 45 days Master Plan / Integrated Integrated Master Master Schedule Schedule (IMP/IMS) (IMP/IMS) Data Item Description (DID)/Template Updated Risk Status/Mitigation Plans Meetings with contractor and Govt IPTs Continuous

ALC and PC logisticians, Procuring Contracting Officer (PCO)

PARTICIPATE IN RISK MANAGEMENT

N/A

Govt and Contractor Logisticians, Engineers, PM, Procuring Contracting Officer (PCO) Increased risk less oversight/ Navy model

PARTICIPATE IN CONTRACT OVERSIGHT AND REVIEW

N/A

Contract award

Details of contract, Federal Acquisition Regulation (FAR) clauses, AFI's, Contractor, security reqts

Contract

Accepted contract MS Office tools deliverables, briefing charts, studies, reports, System Metric & Reporting Tool (SMART), Management Asset Review (MAR), Defense Acquisition Executive (DAE), Program Executive Officer (PEO) review Study reports Disciplined scientific approach, contract vehicles

On going life of contract Program + Office/ALC/Contractor, MAJCOMs

ADVOCATE PROPOSED LOGISTICS ENGINEERING DESIGN CHANGES & TRADE STUDIES (NON-DESTRUCTIVE INSPECTION (NDI), CORROSION, HAZARDOUS MATERIALS, PRECIOUS METALS) CONSIDER THE LIFE CYCLE IMPLICATIONS OF TECHNICAL ORDERS EVALUATE TECHNOLOGY DEMO FOR SUPPORTABILITY

Environmental Safety and Occupational Health (ESOH)

Engineering review identifying areas for trade studies, any design reviews

$$, AFI's on system engineering, Mil Std, CDRL

Technical data, $$

Contractor, ALC and PC logisticians, , Engineers, lab personnel,

On-going

Prod/log center, Lab, contractors

Master data base to share info X X

N/A

Contract, milestone direction, Key Performance Parameters (KPP)s Acquisition Program Baseline (APB) Air drop requirement, Key Performance Parameters (KPP)s, Operational Requirements Document (ORD), contract, program schedule Preferred System Concept Identified

$$, AF procedures

Technical data, demo plan

Prod/Log Center, MAJCOMs, test centers, contractors

Report

Various

Average less than 120 days

Prod/Log Center, MAJCOMs, test centers, contractors

CONTACT AIR TRANSPORTABILITY TEST LOAD AGENCY (ATTLA) FOR AIR TRANSPORTABILITY REQUIREMENTS / ISSUES (AIR DROP AND TEST LOADING I.E. G-FORCE)

N/A

DoD 4140.7

Performance spec, technical data, funding, tech orders

ASC/EN, Contractor, Program Office personnel

signed Air Worthiness certification

manpower and dollars, ATTLA equipment, weapon system platform,

target 6 months

ASC/EN, Contractor, Program Office personnel X X

ADDRESS HUMAN SYSTEMS INTEGRATION (HSI) FACTORS

REMIS, CAMS

AFI 10-601, AFI 10System Requirements, 602, DoD 5000.2, AFI ICD, CDD, CPD, SEP, 63-107, AFI 63-111, LCMP, Functional Defense Acquisition Baseline, TAD, CARD Guide Book, MIL-HDBK502

Logisticians, Acquisition Inputs to SEP, LCMP, Lead, Systems TEMP, ICD, CDD, Engineering, CPD, MER, LCCE, Sustainment Training Plans Engineering, Training, Personnel

IPT Meeting with Pre source selection Government and through end of program contractor on supportability/training/sy stems engineering, manpower and personnel 2 OF 156

Minimize life cycle cost while maximizing system readiness and personnel and system effectiveness X X

RETIRE PRODUCTS

SDD (DEMONSTRATION)

DESIGN SUPPORT

IMPROVEMENT OPPORTUNITIES

DETERMINE SUPPORT REQUIREMENTS

FIELD SUPPORT

PLAN SUPPORT

PRODUCTION & DEPLOYMENT

OPERATIONS & SUPPORT

TECHNOLOGY DEVELOPMENT

MANAGE CAPABILITIES

MECHANISMS

CONCEPT REFINEMENT

RESOURCES CONSUMED

CYCLE TIME

CONTROLS

MAINTAIN PRODUCTS

IMPROVE PRODUCTS

IT Systems

TRIGGER

OUTPUT

INPUT

SDD (INTEGRATION)

ORG/PLAYERS SAF, HQ, LOG

DEVELOP & ACQUIRE SUPPORT

TASK DESCRIPTION

ANALYZE MATERIAL SOLUTION TO CAPABILITIES REVIEW REFINE SUPPORTABILITY OBJECTIVES AND RISK ASSESSMENT (CRRA) CAPABILITY SHORTFALLS (FSA) (INCLUDE LOGISTICS EXPERTISE ON TEAM)

N/A

Initial Capabilities Document (ICD) Development

Joint Capabilities Integration and Development System (JCIDS) Process

Potential materiel solutions

Functional Capability Boards, Combatant Commands, AF/A5, MAJCOM Requirements Organizations Government, Contractor and MAJCOM personnel

Initial Capabilities Document (ICD)

Joint Capabilities Integration and Development System (JCIDS) Process

Prod/Log Center, MAJCOM, contractor, HQ AFMC X X

CONSIDER APPLICATION OF MODELING AND SIMULATION TOOLS

N/A

Requirements for analysis in preparation for decision making Preferred System Concept Identified

Individual model, Instructions and Operations, DoD 5000.2 E5.1.1.10 AFI 63-101, DoDI 5000.2

Government and Contractor Data

Analysis results

Applicable models to be used (see checklist)

Prod/Log Center, MAJCOM, Better decision making contractor, HQ AFMC

REVIEW TEST & EVALUATION STRATEGY FOR SUPPORTABILITY CONSIDERATIONS

N/A

Information concerning Preferred System Concept from Alternative of Action (AOA) Study Information concerning Preferred System Concept from Alternative of Action (AOA) Study Acquisition or modification that involves software and computer systems Supportability Concept, Plan, Cost Oriented Resource Estimating (CORE), technical data Supportability Concept, Plan, Cost Oriented Resource Estimating (CORE), technical data Supportability Concept, Plan, Cost Oriented Resource Estimating (CORE), technical data

Acquisition Lead, Initial Test Strategy for MAJCOM Program at MS A Requirements Org, Test Community

Acquisition Led Process

30 days

Prod/Log Center, MAJCOM, Test Centers, Contractor X X

PARTICIPATE IN SYSTEMS ENGINEERING PLAN (SEP) DEVELOPMENT

N/A

Preferred System Concept Identified

AFI 63-101, DoDI 5000.2

Acquisition Lead, any Engineering Support ( eg. Center EN Staff)

Initial Systems Acquisition Led Engineering Plan (SEP) Process for MS A

30 days

Prod/Log Center, MAJCOM, Test Centers, Contractor X X

PARTICIPATE IN THE COMPUTER RESOURCES WORKING GROUP (CRWG) OR THE COMPUTER RESOURCES INTEGRATED PRODUCT TEAM (CR-IPT) INCORPORATE SUPPORTABILITY REQUIREMENTS IN DRAFT CAPABILITY DEVELOPMENT DOCUMENT (CDD)

N/A

Acquisition or modification that involves software and computer systems

Best Practice (rescinded AFI 800-14 & AFMCI 800-21)

Prod/Log Centers, MAJCOM's, Contractors Prod/Log Centers

Computer Resources Lifecycle Management Plan (CRLCMP)

Systems Engineering Plan (SEP)

Prod/Log Centers, MAJCOM's, Contractors

Life Cycle Support for computer resources

N/A

Capability Development AFIs, DoDIs Document (CDD) development

Capability Development The document, meeting, 60 days Document (CDD) emails

Prod/Log Centers, contractor

Guides and AFI should require logistics participation for Capability Development Document (CDD)s

DEVELOP SUPPORTABILITY KEY PERFORMANCE PARAMETERS (KPPs)

N/A

Key Performance Parameters (KPP)s development

AFIs, DoDIs

Prod/Log Centers

Key Performance Parameters (KPP)s

The document, meeting, 60 days emails

Prod/Log Centers, contractor X X

INCLUDE SUPPORTABILITY REQUIREMENTS IN THE SYSTEM PERFORMANCE SPECIFICATION

N/A

SYS Performance Spec AFIs, DoDIs

Prod/Log Centers

SYS Performance Spec The document, meeting, 60 days emails

Prod/Log Centers, contractor X X

ENSURE CONSIDERATION OF DESIGN INTERFACE FOR LIFE CYCLE LOGISTICS CHECKLIST

INCLUDE SUPPORTABILITY REQUIREMENTS IN THE COST ANALYSIS REQUIREMENT DESCRIPTION (CARD), PROGRAM OFFICE ESTIMATE (POE), COMPONENT COST ANALYSIS (CCA), INDEPENDENT COST ESTIMATE (ICE), AFFORDABILITY ASSESSMENT

N/A

Cost Analysis Requirement Description (CARD), Program Office Estimate (POE), Component Cost Analysis (CCA), ICE, Affordability Assessment Cost Analysis Requirement Description (CARD), Program Office Estimate (POE), Component Cost Analysis (CCA), ICE, Affordability Assessment

AFIs, DoDIs

Supportability Concept, Plan, Cost Oriented Resource Estimating (CORE), technical data

Prod/Log Centers

Cost Analysis Requirement Description (CARD), Program Office Estimate (POE), Component Cost Analysis (CCA), ICE, Affordability Assessment Cost Analysis Requirement Description (CARD), Program Office Estimate (POE), Component Cost Analysis (CCA), ICE, Affordability Assessment, ensure that support equipment replacement costs are included

The document, meeting, 60 days emails

Prod/Log Centers, contractor

INCLUDE SUPPORT EQUIPMENT (SE) IN LIFE CYCLE COST DOCUMENTS INCLUDING REPLACEMENT COSTS

N/A

AFIs, DoDIs

Supportability Concept, Prod/Log Centers Plan, Cost Oriented Resource Estimating (CORE), technical data, any support equipment available, cost data

The document, meeting, 60 days emails

Prod/Log Centers, contractor

INITIATE THE STRATEGIC SOURCE of REPAIR (SSOR) PROCESS

N/A

Source of Repair Assignment Process (SORAP) process

SECA Policy Memo (pending - currently at HQ AFMC/A4 for coord); AFI 63-107; Source of Repair Assignment Process (SORAP) Implementation Guide Acquisition Program Baseline (APB) Guidelines

Program data to fill in Template A, Phase 1 data elements

System Program Manager (SPM)s, PGMs

Request for candidate depot/core analyses; Template A, Phase 1 data

Automated Source of Repair Assignment Process (SORAP) Electronic Manager (in work); Emails

30 work days

System Program Manager (SPM)s, PGMs

INCLUDE SUPPORTABILITY IN THE ACQUISITION PROGRAM BASELINE (APB)

N/A

Acquisition Program Baseline (APB)

Supportability Concept, Plan, Cost Oriented Resource Estimating (CORE), technical data Supportability Concept, Plan, Cost Oriented Resource Estimating (CORE), technical data

Prod/Log Centers

Acquisition Program Baseline (APB)

The document, reports, 60 days meetings, presentations

Prod/Log Centers, contractor X X

INCLUDE SUPPORTABILITY REQUIREMENTS IN PROGRAM OBJECTIVE MEMORANDUM (POM) SUBMISSION

CMS

Program Objective Memorandum (POM) Data Call

FM regulations

Prod/Log Centers

Program Objective Memorandum (POM)

Future budget, reports, 60 days meetings, presentations

Prod/Log Centers, contractor X X

REFINE PRODUCT SUPPORT STRATEGY IN LIFE CYCLE MANAGEMENT PLAN (LCMP) (INCREMENTS, PERFORMANCEBASED LOGISTICS , PUBLIC-PRIVATE PARTNERSHIPS (PPP), LOG ELEMENTS, ETC)

Logistics Planning and Program cycle/major Requirements System changes dictates need (LOGPARS) Army for update System

Life Cycle Management Updated acquisition and Plan (LCMP) Guide, product support AFI63-107 strategy; cost schedule, performance, supportability data; updated Expectation Management Agreement (EMA)s

PM Team including logisticians, Program Executive Officer (PEO), ALC/CC, Test org; SAF/AQ, Acquisition Strategy Panel (ASP)/Life Cycle Management Plan (LCMP) approval authorities participants

Approved updated Life Cycle Management Plan (LCMP)

Established guidance, regulations; Protocol Process

120 days

PM Team including logisticians, Program Executive Officer (PEO), ALC/CC, Test org; SAF/AQ, Acquisition Strategy Panel (ASP)/Life Cycle Management Plan (LCMP) approval authorities participants

REVIEW REQUIREMENT DOCUMENT/ CAPABILITY OBJECTIVE (CDD)

Program cycle/major changes dictates need for update

Life Cycle Management Updated acquisition and Plan (LCMP) Guide, product support AFI63-107 strategy; cost schedule, performance, supportability data; updated Expectation Management Agreement (EMA)s

REVIEW STRATEGIES FOR SIMILAR PRODUCTS/ STRATEGIES

Program cycle/major changes dictates need for update

PM Team including logisticians, Program Executive Officer (PEO), ALC/CC, Test org; SAF/AQ, Acquisition Strategy Panel (ASP)/Life Cycle Management Plan (LCMP) approval authorities participants Life Cycle Management Updated acquisition and PM Team including Plan (LCMP) Guide, AFI product support logisticians, Program 63-107 strategy; cost schedule, Executive Officer performance, (PEO), ALC/CC, Test supportability data; org; SAF/AQ, updated Expectation Acquisition Strategy Management Panel (ASP)/Life Cycle Agreement (EMA)s Management Plan (LCMP) approval authorities participants Life Cycle Management Updated acquisition and Plan (LCMP) Guide, product support AFI63-107 strategy; cost schedule, performance, supportability data; updated Expectation Management Agreement (EMA)s PM Team including logisticians, Program Executive Officer (PEO), ALC/CC, Test org; SAF/AQ, Acquisition Strategy Panel (ASP)/Life Cycle Management Plan (LCMP) approval authorities participants PM Team including logisticians, Program Executive Officer (PEO), ALC/CC, Test org; SAF/AQ, Acquisition Strategy Panel (ASP)/Life Cycle Management Plan (LCMP) approval authorities participants PM Team including logisticians, Program Executive Officer (PEO), ALC/CC, Test org; SAF/AQ, Acquisition Strategy Panel (ASP)/Life Cycle Management Plan (LCMP) approval authorities participants PM Team including logisticians, Program Executive Officer (PEO), ALC/CC, Test org; SAF/AQ, Acquisition Strategy Panel (ASP)/Life Cycle Management Plan (LCMP) approval authorities participants PM Team including logisticians, Program Executive Officer (PEO), ALC/CC, Test org; SAF/AQ, Acquisition Strategy Panel (ASP)/Life Cycle Management Plan (LCMP) approval authorities participants PM Team including logisticians, Program Executive Officer (PEO), ALC/CC, Test org; SAF/AQ, Acquisition Strategy Panel (ASP)/Life Cycle Management Plan (LCMP) approval authorities participants PM Team including logisticians, Program Executive Officer (PEO), ALC/CC, Test org; SAF/AQ, Acquisition Strategy Panel (ASP)/Life Cycle Management Plan (LCMP) approval authorities participants

Approved updated Life Cycle Management Plan (LCMP)

Established guidance, regulations; Protocol Process

120 days

PM Team including logisticians, Program Executive Officer (PEO), ALC/CC, Test org; SAF/AQ, Acquisition Strategy Panel (ASP)/Life Cycle Management Plan (LCMP) approval authorities participants PM Team including logisticians, Program Executive Officer (PEO), ALC/CC, Test org; SAF/AQ, Acquisition Strategy Panel (ASP)/Life Cycle Management Plan (LCMP) approval authorities participants

Approved updated Life Cycle Management Plan (LCMP)

Established guidance, regulations; Protocol Process

120 days

REFINE ALTERNATIVE (S) FOR PRODUCT SUPPORT STRATEGY

Program cycle/major changes dictates need for update

Approved updated Life Cycle Management Plan (LCMP)

Established guidance, regulations; Protocol Process

120 days

PM Team including logisticians, Program Executive Officer (PEO), ALC/CC, Test org; SAF/AQ, Acquisition Strategy Panel (ASP)/Life Cycle Management Plan (LCMP) approval authorities participants PM Team including logisticians, Program Executive Officer (PEO), ALC/CC, Test org; SAF/AQ, Acquisition Strategy Panel (ASP)/Life Cycle Management Plan (LCMP) approval authorities participants PM Team including logisticians, Program Executive Officer (PEO), ALC/CC, Test org; SAF/AQ, Acquisition Strategy Panel (ASP)/Life Cycle Management Plan (LCMP) approval authorities participants

UPDATE RISK ASSESSMENT FOR ALTERNATIVE (S)

Program cycle/major changes dictates need for update

Life Cycle Management Updated acquisition and Plan (LCMP) Guide, AFI product support 63-107 strategy; cost schedule, performance, supportability data; updated Expectation Management Agreement (EMA)s

Approved updated Life Cycle Management Plan (LCMP)

Established guidance, regulations; Protocol Process

120 days

UPDATE COST ESTIMATE FOR ALTERNATIVE (S)

Program cycle/major changes dictates need for update

Life Cycle Management Updated acquisition and Plan (LCMP) Guide, product support AFI63-107 strategy; cost schedule, performance, supportability data; updated Expectation Management Agreement (EMA)s

Approved updated Life Cycle Management Plan (LCMP)

Established guidance, regulations; Protocol Process

120 days

UPDATE WRITING OF LIFE CYCLE MANAGEMENT PLAN (LCMP)

Program cycle/major changes dictates need for update

Life Cycle Management Updated acquisition and Plan (LCMP) Guide, product support AFI63-107 strategy; cost schedule, performance, supportability data; updated Expectation Management Agreement (EMA)s

Approved updated Life Cycle Management Plan (LCMP)

Established guidance, regulations; Protocol Process

120 days

PM Team including logisticians, Program Executive Officer (PEO), ALC/CC, Test org; SAF/AQ, Acquisition Strategy Panel (ASP)/Life Cycle Management Plan (LCMP) approval authorities participants

REVIEW ENTIRE LIFE CYCLE MANAGEMENT PLAN (LCMP) FOR DISCONNECTS

Program cycle/major changes dictates need for update

Life Cycle Management Updated acquisition and Plan (LCMP) Guide, product support AFI63-107 strategy; cost schedule, performance, supportability data; updated Expectation Management Agreement (EMA)s

Approved updated Life Cycle Management Plan (LCMP)

Established guidance, regulations; Protocol Process

120 days

PM Team including logisticians, Program Executive Officer (PEO), ALC/CC, Test org; SAF/AQ, Acquisition Strategy Panel (ASP)/Life Cycle Management Plan (LCMP) approval authorities participants

APPROVE PRODUCT SUPPORT STRATEGY (ACQUISITION STRATEGY PANEL (ASP))

Program cycle/major changes dictates need for update

Life Cycle Management Updated acquisition and Plan (LCMP) Guide, product support AFI63-107 strategy; cost schedule, performance, supportability data; updated Expectation Management Agreement (EMA)s

Approved updated Life Cycle Management Plan (LCMP)

Established guidance, regulations; Protocol Process

120 days

PM Team including logisticians, Program Executive Officer (PEO), ALC/CC, Test org; SAF/AQ, Acquisition Strategy Panel (ASP)/Life Cycle Management Plan (LCMP) approval authorities participants

FINALIZE LIFE CYCLE MANAGEMENT PLAN (LCMP) BASED ON SYSTEM REQUIREMENTS REVIEW (SRR) AND ACQUISITION STRATEGY PANEL (ASP) RECOMMENDATIONS

Program cycle/major changes dictates need for update

Life Cycle Management Updated acquisition and Plan (LCMP) Guide, AFI product support 63-107 strategy; cost schedule, performance, supportability data; updated Expectation Management Agreement (EMA)s

Approved updated Life Cycle Management Plan (LCMP)

Established guidance, regulations; Protocol Process

120 days

PM Team including logisticians, Program Executive Officer (PEO), ALC/CC, Test org; SAF/AQ, Acquisition Strategy Panel (ASP)/Life Cycle Management Plan (LCMP) approval authorities participants

3 OF 156

RETIRE PRODUCTS

SDD (DEMONSTRATION)

DESIGN SUPPORT

IMPROVEMENT OPPORTUNITIES

DETERMINE SUPPORT REQUIREMENTS

FIELD SUPPORT

PLAN SUPPORT

PRODUCTION & DEPLOYMENT

OPERATIONS & SUPPORT

TECHNOLOGY DEVELOPMENT

MANAGE CAPABILITIES

MECHANISMS

CONCEPT REFINEMENT

RESOURCES CONSUMED

CYCLE TIME

CONTROLS

MAINTAIN PRODUCTS

IMPROVE PRODUCTS

IT Systems

TRIGGER

OUTPUT

INPUT

SDD (INTEGRATION)

ORG/PLAYERS SAF, HQ, LOG

DEVELOP & ACQUIRE SUPPORT

TASK DESCRIPTION

ANALYZESUPPORTABILITY MATERIAL SOLUTION TO CAPABILITIES REVIEW ENSURE INCLUDED IN EXPECTATION AND RISK ASSESSMENT (CRRA) CAPABILITY SHORTFALLS MANAGEMENT AGREEMENT (EMA)s (FSA) (INCLUDE LOGISTICS EXPERTISE ON TEAM)

N/A

Receipt of Customer Requirement; annual update in conjunction with Program Management Directive (PMD) update

Expectation Management Agreement (EMA) Guide; System Metric & Reporting Tool (SMART) Guidelines

Customer Requirements; discussions/agreement s with customer; contract terms and conditions; Expectation Management Agreement (EMA) Guidelines

Customer (Operator, Signed Expectation Maintainer and Management designated SES/GO); Agreement (EMA) System Program Manager (SPM) / Depot Supportability Manager (DSM) / System Supportability Manager (SSM); Program Executive Officer (PEO), ALC Commander Prod/Log Centers Key Performance Parameters (KPP)s

Meetings; System minimum once per year. Metric & Reporting Tool Initial Expectation (SMART) System, Management Guide Agreement (EMA): 6 months, 160 manhours; follow-on Expectation Management Agreement (EMA)s 2 months; 60 man-hours

PM Team, Customer, PEG, CAG, Program Executive Officer (PEO), ALC Commander, Customer Staff X X

ENSURE SUPPORTABILITY REQUIREMENTS ARE INCLUDED IN THE CAPABILITY DEVELOPMENT DOCUMENT (CDD) (REFINE KEY PERFORMANCE PARAMETERS (KPP)s

N/A

Key Performance Parameters (KPP)s development Determination of competitive acquisition

AFIs, DoDIs

INCLUDE SUPPORTABILITY IN THE SOURCE SELECTION PLAN N/A (SSP)

Federal Acquisition Regulation (FAR) 15, SS Guides and Template

Supportability Concept, Plan, Cost Oriented Resource Estimating (CORE), technical data Risk Assessment Results, Key Supportability Requirements

The document, meeting, 60 days emails

Prod/Log Centers, contractor

ALC and PC logisticians Approved Source Selection Plan (SSP)

Federal Acquisition Regulation (FAR), Guides, Templates

180 days

ENSURE ACQUISITION STRATEGY PANEL (ASP) SUPPORTABILITY TEMPLATE COMPLETED

N/A

Notification of Acquisition Strategy Panel (ASP)

PARTICIPATE IN ALTERNATIVE OF ACTION (AOA) UPDATE

N/A

Notification that update is required

Federal Acquisition Regulation (FAR) part 7, Acquisition Strategy Panel (ASP) Guides and Templates, local Acquisition Strategy Panel (ASP) procedures Alternative of Action (AOA) Regulations/Guidelines

Risk Assessment Results, Key Supportability Requirements and Strategy

ALC and PC logisticians Completed Acquisition Strategy Panel (ASP) Briefing; Action Items Completed

Federal Acquisition Regulation (FAR), Guides, Templates, Protocol

180 days

PM, Procuring Contracting Officer (PCO), ALC and PC logisticians, Source Selection Plan (SSP) approval chain of command, warfighter PM, Procuring Contracting Officer (PCO), ALC and PC logisticians, Acquisition Strategy Panel (ASP) Secretariat and Panel, warfighter

DT&E/OA assessment, Program Team including Completed Alternative Alternative of Action LMI Data Logisticians, warfighter of Action (AOA) Update (AOA) Regulations/Guidelines

Program Team including Logisticians, warfighter

X X

X X

PARTICIPATE IN SYSTEM REQUIREMENTS REVIEW (SRR) (DEMO CONCEPTS) REFINE SUPPORTABILITY REQUIREMENTS IN THE SYSTEM PERFORMANCE SPECIFICATION

N/A N/A SYS Performance Spec AFIs, DoDIs Supportability Concept, Plan, Cost Oriented Resource Estimating (CORE), technical data Draft Capability Production Document (CPD); Supportability Data from DT&E; Acquisition Strategy Prod/Log Centers SYS Performance Spec The document, meeting, 60 days emails Prod/Log Centers, contractor

INCLUDE SUPPORTABILITY REQUIREMENTS IN REQUEST FOR PROPOSAL (RFP)

Pre Award Information Notification to develop Exchange System Request for Proposal (PIXS) ConWrite (RFP) FEDBIZOPS

Federal Acquisition Regulation (FAR)

ALC and PC logisticians Defined/Approved Request for Proposal (RFP) Supportability Requirements

Request for Proposal (RFP) Template, Clauses

120 days

ALC and PC logisticians; Procuring Contracting Officer (PCO) X X

DEVELOP AND ACQUIRE SUPPORTABILITY DATA ADDRESS AUTOMATED TEST SYSTEMS (ATS) ACQUISITION ADDRESS SUPPORT EQUIPMENT MANAGEMENT ADDRESS CALIBRATION SUPPORT FOR NEW ACQUISITIONS PROVIDE RECOMMENDED SUPPORT EQUIPMENT Pre Award Information Notification to develop (SE) CONTRACT DATA REQUIREMENTS LIST (CDRL)s Exchange System Request for Proposal (PIXS) ConWrite (RFP) FEDBIZOPS

Federal Acquisition Regulation (FAR)

Draft Capability Production Document (CPD); Supportability Data from DT&E; Acquisition Strategy Contractor Support Equipment Requirements Document (SERD) list, program data

ALC and PC logisticians Support equipment Contract Data Requirements List (CDRL)s

Request for Proposal (RFP) Template, Clauses

120 days

ALC and PC logisticians; Procuring Contracting Officer (PCO) X X

REVIEW SUPPORT EQUIPMENT RECOMMENDATION DATA (SERD) CHECKLIST

N/A

Contractor Support Equipment Requirements Document (SERD) list

MIL STD 300, selection priority, Support Equipment Requirements Document (SERD) tracking system

Program Office, ALCs, users, contractor

Approved Form 9

Support Equipment Requirements Document (SERD) checklist, allowance source code

DEVELOP A TECHNICAL ORDER DATA REQUEST FOR PROPOSAL (RFP) INCLUDING THE TECHNICAL MANUAL CONTRACT REQUIREMENTS (TMCR) DOCUMENT TM-86-01 DEVELOP TECHNICAL ORDER MANAGEMENT PLAN (TOMP) INVOLVE GAINING ALC, USING COMMAND AND SAFETY PERFORM SUPPORTABILITY ANALYSES TO ACHIEVE PERFORMANCE BASED LOGISTICS (DoDD 5000.1 E1.17) -- SYSTEM ENGINEERING ANALYSES WHICH WILL MINIMIZE TOTAL OWNERSHIP COSTS WHILE DELIVERING REQUIRED MISSION CAPABILITY PERFORMANCE BASED LOGISTICS STRATEGY. THE PM SHALL IDENTIFY OPERATIONAL CAPABILITY ORIENTED MEASURABLE SUSTAINMENT REQUIREMENTS TO BE TRACKED DURING OPERATIONS THESE SHALL BE THE BASIS OF MEASURES OF SUCCESS FOR THE PRODUCT SUPPORT INTEGRATOR WHO SHALL BE IDENTIFIED BY ORGANIZATION AT MILESTONE B. THESE SHALL BE DEVELOPED IN A DRAFT PRODUCT SUPPORT AGREEMENT WHICH WILL BE NEGOTIATED WITH THE O&S EXPECTATION MANAGEMENT AGREEMENT. THE PRODUCT SUPPORT AGREEMENT SHALL BE DRAFTED IN PREPARATIO FOR THE MILSTONE B DECISION ENSURE INCORPORATION OF CONDITION BASED MAINTENANCE PLUS (CBM+) D220, Defense Preferred System Logistics Agency Concept Identified (DLA), Interactive Electronic Technical Manuals (IETMS), Reliability and Maintainability Information System (REMIS), Core Automated Maintenance System (CAMS), Joint Engineering Data Management Information Control System (JEDMICS), Advance Planning System (APS, Expeditionary Combat Support System (ECSS) Shared Data Warehouse, Program initiation, Notification to develop Request for Proposal (RFP) AFI 63-101, AFI 631201, DoDI 4151, AFPD 63-14, DoDI 4151.22 System Requirements, ICD, CDD, CPD, SEP, LCMP, Functional Baseline Acquisition Lead, Systems Engineering , Sustainment Engineering Inputs to SEP, LCMP, System Specification, Aircraft Information Program IPT Meeting with Government and Contractor engineers on supportability/RCM/SO RAP/FMECA analysis and prognostic data needs Pre source selection through end of program Minimize life cycle cost while maximizing system readiness through the performance of just in time maintenance and inspections Product Life Cycle Management data systems System Spec MIL PRF 49506 CDD, EMA.APB, Program Office, ALCs, users, contractor Supportability Analysis data, Source data for maintenance plans etc System Engineering Analyses, FMECA, RCM, RLA, maintenance task analysis, etc. 1 year SPO, Contractor, User, ALC, Stakeholders X X X

DEVELOP A DIMINSHING MANUFACTURING SOURCES AND MATERIAL SHORTAGES (DMSMS) PROGRAM

DoD 4140.1-R

Engineering Data, Industry Data, Shared Data Warehouse, Government Industry Data Exchange Program (GIDEP) alerts

DEVELOP SUPPLY SUPPORT STRATEGY

ADDRESS THE NEED FOR A FACILITIES REQUIREMENTS PLAN IN THE REQUEST FOR PROPOSAL (RFP)

D220, D200, D155, D035, D043, D0143C, DSOR, D040 WSSP workbench, D169, DoD eMall Pre Award Information Exchange System (PIXS) ConWrite FEDBIZOPS

Acquisition Strategy Panel, Request for Proposal, ICD, CDD, EMA

AFMAN 23-110, DoD 4100.39M Vol II, DoD 4160.21M, Title 10 USC

Contractor Data, User Requirements, Contract, Provisioning Parts List (PPL), DLA data, CONOPS Draft Capability Production Document (CPD); Supportability Data from DT&E; Acquisition Strategy

Notification to develop Request for Proposal (RFP)

Federal Acquisition Regulation (FAR)

AFRL/RXME, Program office, Acquisition & Sustainment Logistician, Contractor, OEM, System and Commodity level engineers, Other DoD Services, DLA Program office, Acquistion Logistician, Contractor, OEM, Other DoD Services, DLA, AFMC/A4SM, ALC, SSM ALC and Product Center logisticians

DMSMS program, Engineering resolution projects

Advanced Component Obsolescence Management (AVCOM)

AFRL/RXME, Program office, Acquisition & Sustainment Logistician, Contractor, OEM, System and Commodity level engineers, Other DoD Services, DLA Quarterly computation cycle Program office, Acquistion Logistician, Contractor, OEM, Other DoD Services, DLA, AFMC/A4SM, ALC, SSM ALC and Product Center logisticians; Procuring Contracting Officer (PCO)

Clean Data

Provisioning Item Order Provisioning (PIO), Contract, Conference, SORAP, Spares, Requirements / PBL, Program reviews general data to DLA,

WSSP data to DLA, Updated policy and guidance, X X

Defined/Approved Request for Proposal (RFP) Supportability Requirements, CDRLs

Request for Proposal (RFP) Template, Clauses

120 days

ADDRESS MAINTENANCE PLANNING INCLUDE DATA RIGHTS IN THE REQUEST FOR PROPOSAL (RFP)

UID Registry

Notification to develop Request for Proposal (RFP)

Federal Acquisition Data Rights, UID Regulation (FAR); Data requirements Rights memo, UID Regulations

Logisticians

Defined/Approved Request for Proposal (RFP) Data Rights and UID Requirements

Request for Proposal (RFP) Template, Clauses

30 days

Logisticians, Procuring Contracting Officer (PCO) X X

REVIEW BERRY AMENDMENT FOR APPLICATION TO YOUR PROGRAM AND ENSURE COMPLIANCE IN ALL CONTRACTING ACTIONS INCLUDE OPTIONS FOR RADIO-FREQUENCY IDENTIFICATION (RFID) IN THE REQUEST FOR PROPOSAL (RFP) INCLUDE OPTIONS FOR UNIQUE IDENTIFICATION (UID) IN THE REQUEST FOR PROPOSAL (RFP) ENSURE COMPLETION OF THE STRATEGIC SOURCE OF REPAIR (SSOR) PROCESS N/A Source of Repair Assignment Process (SORAP) POC receives Candidate Depot/Core analysis and other Service Interest from Maintenance Specialists (HQ AFMC/A4BC) Requirement for Integrated Master Plan / Integrated Master Schedule (IMP/IMS) identified Schedule in Source Selection Plan (SSP) SECAF Policy Memo (pending - currently at HQ AFMC/A4 for coord); AFI 63-107; Source of Repair Assignment Process (SORAP) Implementation Guide; HQ staffing guidance AF Candidate HQ AFMC/CC, A4, and Strategic AF depot SOR Depot/Core analysis; HQ Staff Determination; Other Other Pertinent analysis DoD Service interest (for example, 50/50, other DoD Service interest) Automated Source of Repair Assignment Process (SORAP) Electronic Manager (in work); Emails 80 work days HQ AFMC/CC and/or A4, HQ Staff; Estimated persons hours: 60 hours Annual review of current guidance; updates

INCLUDE LOGISTICS ACTIVITIES IN THE INTEGRATED MASTER PLAN / INTEGRATED MASTER SCHEDULE (IMP/IMS)

N/A

Integrated Master Plan / Identification of required ALC and PC Integrated Master logistics activities and logisticians, Procuring Schedule (IMP/IMS) associated timelines Contracting Officer Data Item Description (PCO) (DID) Source Selection ROE, Source Selection Plan (SSP), Federal Acquisition Regulation (FAR) Source Selection Criteria/Standards (Sec L&M of Request for Proposal (RFP)); Source Selection Plan (SSP); Contractor Proposal Documentation Required by DoDI 5000.2 ALC and PC logisticians, Procuring Contracting Officer (PCO)

Completed Integrated Integrated Master Plan / 45 days Master Plan / Integrated Integrated Master Master Schedule Schedule (IMP/IMS) (IMP/IMS) Data Item Description (DID)/Template Source Selection Decision Source Selection ROE, 180 days Source Selection Plan (SSP), Federal Acquisition Regulation (FAR), Templates, EZ Source Milestone Decision Authority (MDA) Led Meeting

ALC and PC logisticians, Procuring Contracting Officer (PCO) X X

PARTICIPATE IN SOURCE SELECTION

EZ Source, Contractor Performance Assessment Reporting System (CPARS)S Navy System N/A

ALC and PC logisticians, Procuring Contracting Officer (PCO) X X

PREPARE DOCUMENTATION FOR MILESTONE DECISION AUTHORITY (MDA) REVIEW (OLD MILESTONE B)

Concept Decision Point DoDI 5000.2 Review by Milestone Decision Authority (MDA)

Milestone Decision Approval to Proceed Authority (MDA), Into Concept Whatever Acquisition Refinement Phase Leads identified, AF/A5, MAJCOM Requirements Organizations

MILESTONE DECISION AUTHORITY (MDA) REVIEW (OLD MILESTONE B) PROGRAM MANAGEMENT DIRECTIVE (PMD) ISSUED INCLUDING SUPPORTABILITY REQUIREMENTS STAND UP PROGRAM OFFICE WITH LOGISTICS PERSONNEL Sustainment / Acquisition Composite Model (SACOM), CMS (INPUT) Program Management Directive (PMD) or SAF/AQ direction, M/S B AFI 63-101, Product Support Sustainment/Acquisition Concept, Sustainment Composite Model Strategy (SACOM) Program Manager (PM), Depot Supportability Manager (DSM), System Supportability Manager (SSM), and supporting Centers Program Office Org structure, Manpower positions & personnel Core "XR" group expanded to effectively execute Acq + Supp strategies Pre-M/S B Manpower, facilities More interdependency between acquisition and logistics centers

X X X

4 OF 156

RETIRE PRODUCTS

SDD (DEMONSTRATION)

DESIGN SUPPORT

IMPROVEMENT OPPORTUNITIES

DETERMINE SUPPORT REQUIREMENTS

FIELD SUPPORT

PLAN SUPPORT

PRODUCTION & DEPLOYMENT

OPERATIONS & SUPPORT

TECHNOLOGY DEVELOPMENT

MANAGE CAPABILITIES

MECHANISMS

CONCEPT REFINEMENT

RESOURCES CONSUMED

CYCLE TIME

CONTROLS

MAINTAIN PRODUCTS

IMPROVE PRODUCTS

IT Systems

TRIGGER

OUTPUT

INPUT

SDD (INTEGRATION)

ORG/PLAYERS SAF, HQ, LOG

DEVELOP & ACQUIRE SUPPORT

TASK DESCRIPTION

ANALYZE MATERIAL SOLUTION TO REVIEW AWARD SYSTEM DEVELOPMENT & CAPABILITIES DEMONSTRATION AND RISK ASSESSMENT (CRRA) CAPABILITY SHORTFALLS CONTRACT (FSA) (INCLUDE LOGISTICS EXPERTISE ON TEAM)

Navy Air Force Interface (NAFI)

Final Evaluation Briefing Federal Acquisition Capability Development and Source Selection Regulation (FAR), Acq Document (CDD), Authority (SSA) Strategy and Life Cycle Request for Proposal Decision Management Plan (RFP) (LCMP) (ACAT I & II rqmt), Source Selection Plan

System Program Manager (SPM), Program Executive Officer (PEO), Source Selection Authority (SSA)

System Development & Source Selection Demonstration (SDD) process Contract

Capability Development Manpower Document (CDD) --> Source Selection Authority (SSA) decision

Early identification of product support strategy and integration of appropriate support center personnel in Capability Development Document (CDD) development and System Development & Demonstration (SDD) source selection process

ENSURE WEAPON SYSTEM PROGRAM COMPLIES WITH AIR FORCE POLICY FOR NO NEW SOFTWARE SYSTEM DEVELOPMENT WITHOUT AF/CIO APPROVAL ENSURE SUPPORTABILITY INCLUDED IN EXPECTATION MANAGEMENT AGREEMENT (EMA)s N/A Establishment of ACAT Program Life Cycle Management Plan (LCMP); Integrated Prod Support Planning (AFI 63-107); Log Support Readiness Rqmt (AFI 10-602); System Metric & Reporting Tool (SMART) Acquisition Program Baseline (APB); Capabilities Document; Funding Expectations; Risk Identification, Strategies and Acceptance; Changes in expectations relating to cost, schedule and performance; support strategy and sustainment. SAF/AQ, Program Executive Officer (PEO); Acquisition Program Office and Warfighter (User) Expectation Management Agreement (EMA) and executable program Face to face meetings; VTCs; Telecons At establishment of Manpower ACAT program and at a minimum, an annual review thereafter Increased credibility in the acquisition system

INCLUDE SUPPORTABILITY REQUIREMENTS IN DEFENSE N/A CONTRACTS MANAGEMENT AGENCY (DCMA) MEMORANDUM of AGREEMENT (MOA)

Program Office standup

Product Support Concept, Sustainment Strategy, Program Office - Defense Contracts Management Agency (DCMA) capability discussions

Depot Supportability Memorandum of Manager (DSM), Agreement (MOA) System Supportability Manager (SSM), and applicable Defense Contracts Management Agency (DCMA) office

Conduct Program Office - Defense Contracts Management Agency (DCMA) discussions matching Product Support concept & Sustainment strategy with Defense Contracts Management Agency (DCMA) capabilities. Capture agreements in Memorandum of Agreement (MOA)

Program Office stand- Manpower up to first Contract Line Item Number (CLIN) deliverable

Integrate Defense Contracts Management Agency (DCMA) into the acquisition team as early as possible. Insure supportability, besides the typical cost/schedule/performance criteria, is highlighted as a watch area.

REVIEW LOGISTICS ACTIVITIES IN THE INTEGRATED MASTER N/A PLAN / INTEGRATED MASTER SCHEDULE (IMP/IMS)

Program planning; Proposal Preparation; Source Selection; Sole Source Negotiation; Program Execution

Entry/Exit Criteria measurable indicators; Critical Path

Work Breakdown Structure; Statement of Work (SOW); EVMS data; Technical Data Key Performance Parameters

Government and Contractor Personnel

Roadmap; Integrated product development and systems integration; Efficient method for evaluating maturity of the program

Post Award Program Milestones Conference; Contractor Performance Assessment Reporting System (CPARS)/Award Fee; What If Exercises Complete a Team risk Pre-Source Selection assessment and follow- through the end of the up with risk program management plans to address significant known risks

Manpower

Improved program and project insight by both Government and Contractor personnel; Decreased risk; Increased probability of program success

PARTICIPATE IN RISK MANAGEMENT

N/A

Acquisition Strategy development

5000.1, Risk Mgmt Guide for DoD

Program technical assessment, market research, past experience

User, Program Office, Support Center, and Contractor (If already on contract). ACE assistance is available

Integrated Risk Assessment and ongoing risk management

Manpower

Enlarge the Team completing the assessment, utilize ACE tools and insight, and follow through with active risk management. This active management can include incorporating risk management plans into the Integrated Master Schedule Enlarge and thoroughly integrate the cross-functional IPT overseeing the contract. Insure automated, integrated tools are available to all Team members.

PARTICIPATE IN CONTRACT OVERSIGHT AND REVIEW

N/A

Contract Award

Contract, Federal Acquisition Regulation (FAR)

Contract requirements Program Team (Statement of Work (SOW), Contract Data Requirements List (CDRL)s, Contract Line Item Number (CLIN)s, and special clauses)

- Program understanding - Successful program execution - Contract & award fee payments - Possible corrective actions and penalties

IPT integrating various Contract award to end Govt and contractor of program organizations, focused on program success. Generally utilize progress measurement tools, such as EVM, IMS, Key Performance Parameters (KPP)s, to focus attention on problem areas; plus Risk assessment to help avert up-coming pitfalls

Manpower

ACCOMPLISH SUPPORT EQUIPMENT (SE) GUIDANCE CONFERENCE PROVIDE LOGISTICS SUPPORT DURING THE DEFICIENCY REPORTING (DR) PROCESS G021, Joint Deficiency Reporting System (JDRS) System deficiency TO 00-35D-54 Submission of Deficiency Report Product & Logistics Centers, MAJCOMS, Contractors Disposition or correction Deficiency Review Board, Materiel Improvement Process, Joint Deficiency Reporting System (JDRS) Approved Configuration Management Process Product / Logistics Center, Contractors, MAJCOM (Operators & Maintainers) Improved Weapon System operations, performance and support

PARTICIPATE IN THE CONFIGURATON CONTROL BOARDS (CCB)

N/A

Any Change Proposal required to meet the Configuration Control Board (CCB) Acquisition Strategy Panel, Contract

MIL HDBK 61A, EIA 649

Change proposal, Support considerations

Product & Logistics Centers, MAJCOMS, Contractors Program office, Acquistion Logistician, Contractor, OEM, Other DoD Services if joint, DLA, ALC, SSM, MAJCOM, Vendors

Disposition

Product / Logistics Center, Contractors, MAJCOM (Operators & Maintainers)

Improved Weapon System operations, performance and support

ACCOMPLISH SPARES PROVISIONING GUIDANCE CONFERENCE

AFMCI 23-101

Contractor Data, User Requirements, Contract, Provisioning Parts List (PPL), DLA data, CONOPS, Initial Provisioning Performance Specification (IPPS)

Approved AFMC Form PBL, Program reviews, 718 Provisioning warranties Performance Schedule, Official minutes, any required contract modifications

Program office, Acquistion Updated policy and guidance, Logistician, Contractor, OEM, Other DoD Services, DLA, ALC, SSM, MAJCOM, Vendors

ESTABLISH PERIODIC LOGISTICS PLANNING MEETINGS

Milestone A decision

IMP/IMS, ILS Plan, ICD, CDD, Funding, Contract DoD 5000.2, CDRLs, AFI 63-107, AFI 63-101

Prod/Log Centers, Minutes, Action Items, Contractor, MAJCOMs, Program DLA, HQ AFMC, Other Documentation Services and Agencies as required

MS Office, face to face meetings, TDY

Prod/Log Centers, Contractor, MAJCOMs, DLA, HQ AFMC, Other Services and Agencies as required

Establishing this early AND having them meet X X

ADVOCATE LOGISTICS ENGINEERING DESIGN CHANGES & TRADE STUDIES (NON-DESTRUCTIVE INSPECTION (NDI), CORROSION, HAZARDOUS MATERIALS, PRECIOUS METALS)

Environmental Safety and Occupational Health (ESOH)

Source Selection

Contract, AFPD 20-5, Contract requirements, AFPD 63-1, DODI sound system 5000.2, AFI 63-107, ILA engineering practices

Most cost effective, logistically supportable end product

Day-to-day involvement Source Selection to end Manpower with technical team, of program active participation in technical and program reviews, and participate in configuration control board process

Enlarge and thoroughly integrate the cross-functional IPT participating in technical decisions. Insure all Team members are aware of design changes and their long-term impacts.

CONTACT AFMC/LSO FOR FEE-FOR-SERVICE PACKAGING SUPPORT (FOR DEVELOPMENT OF SPECIALIZED CONTAINERS FOR TESTING)

Specialized item, fragile item, item without existing packaging, contractor notification, field requests

Funding (fee-forservice), tech orders, DoD regulations, international regulations, HAZMAT

Technical data, physical AFMC LSO/LOP item, funding, engineering support

Prototype specialized containers, test report, container drawings

Disciplined engineering process

6-9 months

Funding, metals, plastics, gases, water, items X X

BASELINE PS STRATEGY IN LIFE CYCLE MANAGEMENT PLAN (LCMP) (PERFORMANCE-BASED LOGISTICS , PUBLICPRIVATE PARTNERSHIPS (PPP), LOG ELEMENTS, ETC)

Logistics Planning and Pre-Source Selection Requirements System (LOGPARS) Army System

AFI 63-101, AFI 63-107 Product Support Concept, Sustainment Strategy, available resources, product and maintenance structure maturity

Program Team, Depot Supportability Manager (DSM), System Supportability Manager (SSM), Program Manager (PM), and Milestone Decision Authority (MDA) Program Team, Depot Supportability Manager (DSM), System Supportability Manager (SSM), Program Manager (PM), and Milestone Decision Authority (MDA)

Life Cycle Management Integrate experience, Plan (LCMP) product support concept, sustainment strategy, and program acquisition strategy

Manpower

REVIEW REQUIREMENT DOCUMENT/ CAPABILITY OBJECTIVE (CDD)

Pre-Source Selection

AFI 63-101, AFI 63-107 Product Support Concept, Sustainment Strategy, available resources, product and maintenance structure maturity

Life Cycle Management Integrate experience, Plan (LCMP) product support concept, sustainment strategy, and program acquisition strategy

Manpower

REVIEW STRATEGIES FOR SIMILAR PRODUCTS/ STRATEGIES

Pre-Source Selection

AFI 63-101, AFI 63-107 Product Support Concept, Sustainment Strategy, available resources, product and maintenance structure maturity

Program Team, Depot Supportability Manager (DSM), System Supportability Manager (SSM), Program Manager (PM), and Milestone Decision Authority (MDA)

Life Cycle Management Integrate experience, Plan (LCMP) product support concept, sustainment strategy, and program acquisition strategy

Manpower

REFINE ALTERNATIVE FOR PRODUCT SUPPORT STRATEGY

Pre-Source Selection

AFI 63-101, AFI 63-107 Product Support Concept, Sustainment Strategy, available resources, product and maintenance structure maturity

Program Team, Depot Supportability Manager (DSM), System Supportability Manager (SSM), Program Manager (PM), and Milestone Decision Authority (MDA)

Life Cycle Management Integrate experience, Plan (LCMP) product support concept, sustainment strategy, and program acquisition strategy

Manpower

UPDATE RISK ASSESSMENT FOR ALTERNATIVE

Pre-Source Selection

AFI 63-101, AFI 63-107 Product Support Concept, Sustainment Strategy, available resources, product and maintenance structure maturity

Program Team, Depot Supportability Manager (DSM), System Supportability Manager (SSM), Program Manager (PM), and Milestone Decision Authority (MDA)

Life Cycle Management Integrate experience, Plan (LCMP) product support concept, sustainment strategy, and program acquisition strategy

Manpower

UPDATE COST ESTIMATE FOR ALTERNATIVE

Pre-Source Selection

AFI 63-101, AFI 63-107 Product Support Concept, Sustainment Strategy, available resources, product and maintenance structure maturity

Program Team, Depot Supportability Manager (DSM), System Supportability Manager (SSM), Program Manager (PM), and Milestone Decision Authority (MDA)

Life Cycle Management Integrate experience, Plan (LCMP) product support concept, sustainment strategy, and program acquisition strategy

Manpower

UPDATE WRITING OF LIFE CYCLE MANAGEMENT PLAN (LCMP) (if req'd)

Pre-Source Selection

AFI 63-101, AFI 63-107 Product Support Concept, Sustainment Strategy, available resources, product and maintenance structure maturity

Program Team, Depot Supportability Manager (DSM), System Supportability Manager (SSM), Program Manager (PM), and Milestone Decision Authority (MDA)

Life Cycle Management Integrate experience, Plan (LCMP) product support concept, sustainment strategy, and program acquisition strategy

Manpower

5 OF 156

RETIRE PRODUCTS

SDD (DEMONSTRATION)

DESIGN SUPPORT

IMPROVEMENT OPPORTUNITIES

DETERMINE SUPPORT REQUIREMENTS

FIELD SUPPORT

PLAN SUPPORT

PRODUCTION & DEPLOYMENT

OPERATIONS & SUPPORT

TECHNOLOGY DEVELOPMENT

MANAGE CAPABILITIES

MECHANISMS

CONCEPT REFINEMENT

RESOURCES CONSUMED

CYCLE TIME

CONTROLS

MAINTAIN PRODUCTS

IMPROVE PRODUCTS

IT Systems

TRIGGER

OUTPUT

INPUT

SDD (INTEGRATION)

ORG/PLAYERS SAF, HQ, LOG

DEVELOP & ACQUIRE SUPPORT

TASK DESCRIPTION

ANALYZE MATERIAL SOLUTION TO CAPABILITIES REVIEW REVIEW ENTIRE LIFE CYCLE MANAGEMENT PLAN AND RISK ASSESSMENT (CRRA) CAPABILITY SHORTFALLS (LCMP) FOR DISCONNECTS (FSA) (INCLUDE LOGISTICS EXPERTISE ON TEAM)

Pre-Source Selection

AFI 63-101, AFI 63-107 Product Support Concept, Sustainment Strategy, available resources, product and maintenance structure maturity

Program Team, Depot Supportability Manager (DSM), System Supportability Manager (SSM), Program Manager (PM), and Milestone Decision Authority (MDA)

Life Cycle Management Integrate experience, Plan (LCMP) product support concept, sustainment strategy, and program acquisition strategy

Manpower

APPROVE PRODUCT SUPPORT STRATEGY (SYSTEM REQUIREMENTS REVIEW (SRR) ASP)

Pre-Source Selection

AFI 63-101, AFI 63-107 Product Support Concept, Sustainment Strategy, available resources, product and maintenance structure maturity

Program Team, Depot Supportability Manager (DSM), System Supportability Manager (SSM), Program Manager (PM), and Milestone Decision Authority (MDA)

Life Cycle Management Integrate experience, Plan (LCMP) product support concept, sustainment strategy, and program acquisition strategy

Manpower

FINALIZE LIFE CYCLE MANAGEMENT PLAN (LCMP) BASED ON ACQUISITION STRATEGY PANEL (ASP) RECOMMENDATIONS

Pre-Source Selection

AFI 63-101, AFI 63-107 Product Support Concept, Sustainment Strategy, available resources, product and maintenance structure maturity

Program Team, Depot Supportability Manager (DSM), System Supportability Manager (SSM), Program Manager (PM), and Milestone Decision Authority (MDA)

Life Cycle Management Integrate experience, Plan (LCMP) product support concept, sustainment strategy, and program acquisition strategy

Manpower