Professional Documents

Culture Documents

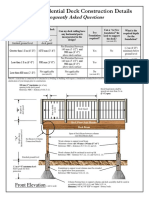

15 Most Common Deck Construction Mistakes

Uploaded by

Chin Thau WuiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

15 Most Common Deck Construction Mistakes

Uploaded by

Chin Thau WuiCopyright:

Available Formats

15 Most common deck construction mistakes

15 MOST COMMON DECK CONSTRUCTION MISTAKES

Feb, 2012

Mistakes to avoid

The 15 most common mistakes are easy to avoid, we look at the main causes for these mistakes and how to avoid them.

Matt Shutkowski

Matt Shutkowski Copyright 2012

15 Most common deck construction mistakes

FOOTINGS

#1- Hitting underground water, power and/or gas mains

The consequences of hitting a water, power and/or gas main have the potential for serious to fatally injuring you! Not to mention the inconvenience of not having no power or water. So to avoid this unnecessary and dangerous frustration, do all your checks with your local government agency and service providers (call Dial before you dig on 1100 in Australia). Once you have the locations for the services, mark them out on the ground when you mark out your footing locations so as not to hit them when you dig your footings. When you dig you footings it is highly recommended that you dig them by hand with a shovel and crow bar. This way if you are unfortunate enough to hit one, you have more chance of not seriously damaging the service. Something to keep in mind, if you hit a water, power and/or gas main and you have spoken to Dial before you dig and have done as much as possible for locating the mains, you will greatly minimise your liability.

#2 Timber posts rotting away within a few years of the deck being completed

There can be many reasons for this, the most common are as follows: iTimber posts that are concreted directly into the concrete footing. This is a problem because concrete is porous and absorbs ground moisture. This has the timber post be continually moist, the perfect environment for timber rot. The post will rot in the location shown below the quickest, as it is the last place to dry out and the first place to get wet.

Where the rot most occurs in timber posts

Timber post

Concrete footing

Matt Shutkowski Copyright 2012

15 Most common deck construction mistakes

ii-

Timber posts having gardens or dirt/soil built up around them and/or touching the timber post will cause the post to rot. Below is a picture of a timber post that has rotted away because of soil build up.

To solve this problem the best way is to install galvanised stirrups into domed concrete footings where the base of the timber post is raised 75mm above the top of the domed concrete. This also allows for any water to run off the top of the concrete footing which greatly aids in the life of the galvanised stirrup (a stirrup is a metal bracket that holds the timber post out of the concrete).

Hot dipped galvanised steel stirrup

75mm gap between the domed concrete and timber post

Domed concrete

Matt Shutkowski Copyright 2012

15 Most common deck construction mistakes

#3 - Sinking deck frames

The most common reason is incorrect footing size, normally due to not having an engineer design the structural components of the deck. Any other reason is the owner bolts the deck posts directly to an existing concrete slab that is untested, usually a pathway. Most concrete paths over 20years old do not have any form of concrete/steel reinforcing. The best and only recommended way to install deck posts is directly into dug footings using galvanised steel stirrups making sure the footing hole is dug straight down and not what is called in the industry belled.

Belled hole

Square hole

The sides of the hole are curved and rounded

The sides of the hole are straight and flat giving a square shape

SUBFLOOR FRAMING

#4 Deck floor sagging

99% of the time this is due to incorrect timber/timber size being used. If you have an engineer design your deck you will not have this problem. The two main types of timber is softwood (all types of pines, etc) and hardwood, as you can imagine just by the name one is stronger than the other. You can swap softwood with a hardwood and not have a problem keeping in mind that you must use structurally rated timber. However if you go the other way, swaping hardwood for a softwood (usually done in an attempt to save money) you will have major problems if not a collapsed deck.

Matt Shutkowski Copyright 2012

15 Most common deck construction mistakes

#5 Timber cracking and breaking

Aside from swapping hardwoods for softwoods as mentioned in the above problem, this is most commonly caused by too much timber cut out of the joins. The maximum amount of timber that can be cut out of a joint is 1/3 of the height, width or thickness. There are a few ways this can be measured:

Less than 1/3 - OK More than 1/3 Not OK Here you can see in red over 2/3 of the timber in the joists height has been left to sit on top of the bearer.

Joist

Joist

Bearer

Here you can see in red less than 1/3 of the timber in the joists height has been left to sit on top of the bearer. This is where the timber will crack and break due to the little amount of timber sitting on top of the bearer.

Bearer

Joist

1/3 max

A hole can only be a maximum of 1/3 the height of the joist.

When more than 1/3 of the timber height, width or thickness needs to be cut out additional support needs to be added. This can be in the form of metal brackets.

Matt Shutkowski Copyright 2012

15 Most common deck construction mistakes

#6 Bolts, nails and steel rusting

USE GALVANISED BOLTS, NAILS AND STEEL!!!!!! This is not optional. You will have your deck start to fall apart in a matter of months if you do not use galvanised bolts, nails and steel. Galvanising is where zinc coats the steel, usually done by dipping the steel into a molten vat of zinc. Zinc as a metal is more corrosive than steel, so when steel is coated in zinc the zinc will corrode before the steel corrodes. This in turn will leave your steel corrosion free for a very long time.

Galvanised bolt versus a nongalvanised bolt A non-galvanised steel beam. Make note of the amount of rust that has occurred.

DECKING

#7 Black and other marks on decking boards

The black marks are caused by leaving metal on a wet deck. The only way to stop this from happening, is to clean the deck after each day of construction. Pick up all tools, nails, bolts and anything else metal and sweep the deck down. When you nail in nails there is a small amount of metal filings that fall off the nail when hammering it in. Finially do not use a grinder on the deck or anywhere near the deck or where people will walk on to the deck. Grinding sparks leave metal filings everywhere and as you will see in the pictures below leave a very ugly mark.

Matt Shutkowski Copyright 2012

15 Most common deck construction mistakes

Bolt & nail marks

Bracket mark

Grinding sparks

There is a couple of ways to remove these black marks however it will take a lot of elbow grease: Option one- Clean the deck with a product called Deck clean (a mild acid) and scrub like you have never scrubbed before; Option two- Sand the marks out, best to do this by hand as power sanders can end up making more of a mess than the black mark itself.

Matt Shutkowski Copyright 2012

15 Most common deck construction mistakes

#8 Decking boards not installed to a straight line

There are many ways to install your decking boards in a straight line. The easiest way to do this is to use a chalk line (a chalk line is a string line coated in chalk that when you flick it leaves a straight line of chalk) and mark out every forth/fifth board (called a grid board) and completely nail that board to every floor joist. Once you have installed all the grid boards, place all the other boards in between them and use wedges to evenly space the boards between the grid boards. Make sure when you do this that you allow a 2-3mm gap between each board.

Grid board

Grid board

#9 Greying and rotten of decking boards

This can be caused by not coating the deck with a decking oil or stain once the deck was complete. This is also caused from not maintaining the decking oil or stain in years to come. If your deck is does not have a roof over it, the sun will deteriorate the coating faster than a covered deck. A good rule of thumb, is that the moment any of the coating is starting to fade or look grey it is time to re-coat the deck.

Matt Shutkowski Copyright 2012

15 Most common deck construction mistakes

ROOF FRAME, ROOFING & CEILINGS

#10 Losing your deck roof in a severe storm

To avoid this you need to engage an engineer to design all structural aspects of your deck. This is not a recommendation, this is a must. If you build your deck without the appropriate engineering and something goes wrong, you are liable. If someone gets hurt you can be charged with assault etc.

#11 Leaking roofs

The most common and sometimes not the most obvious reason is that the roof screws have been over tightened. The roof screw has a rubber washer at the base of the head of the screw. This washer seals the hole that the roof screw has made in the roof sheet when screwed. When the screw has been over tightened it squashes the rubber washer and breaks it, allowing water to enter into the screw hole. See below.

Rubber washer

Screw over tighten where you can see the rubber washer has broken away from the screw

Screw tighten correctly where you can see the intact rubber washer

#12 Sagging ceiling

The most common reason is the ceiling supports are positioned to far apart. Once the ceiling is installed, the ceiling maybe flat and straight. However over time usually in about 6 months moisture in the air will soften the ceil enough for gravity to start to sag the ceiling sheets causing a wave like effect on the ceiling.

Matt Shutkowski Copyright 2012

15 Most common deck construction mistakes

STAIRS & HANDRAILS

#13 Out of level stairs

When the stair set height is measured, called the rise (height from ground to top of decking boards) this has been measured straight down from the edge of the deck however not where the stairs meet the ground, called the run (distance from edge of decking board to front edge of bottom step tread). In the diagram below you can see the height difference between straight down from the edge of the deck compared to where the stairs actually meet the ground. If rise height is measured close to the deck and not where the stairs meet the ground in you will have too many/not enough step treads required for your set of stairs. This will result in your step treads either tilt forward or backwards.

Run Deck

Post Rise

Ground

Matt Shutkowski Copyright 2012

15 Most common deck construction mistakes

#14 Stairs handrails to low

Firstly if you dont know what the minimum height of handrails are, check with your local building authority or engineer. The top of the handrail is measured straight up and down from the top front edge of the step tread which is called the nosing line. The nosing line is an imaginary line that runs along the top front edge of every step tread. This is where your local government agency will measure your handrail from, to check that the handrail meets building regulations.

Where you measure your handrail from

Deck Handrail

Nosing Line, always measure to the top of your handrail to this line.

THE BIGGEST MISTAKE MADE

#15 local government agency having the deck changed or removed

This is a very easy mistake to avoid, get your deck approved before building it. If you choose to try and do it without the correct approvals this can end up costing far more than just local government agencies fees saved. The local government agency may not have you remove the deck, they may just want you to change the size or even location of the deck. As you can imagine this is going to be a major re-work for your deck.

Matt Shutkowski Copyright 2012

You might also like

- Practical hints to builders and those contemplating buildingFrom EverandPractical hints to builders and those contemplating buildingNo ratings yet

- Building A Garden Shed Step By Step Instructions and PlansFrom EverandBuilding A Garden Shed Step By Step Instructions and PlansRating: 2 out of 5 stars2/5 (1)

- Installing a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersFrom EverandInstalling a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersNo ratings yet

- Build Your Own Sheds & Outdoor Projects Manual, Sixth EditionFrom EverandBuild Your Own Sheds & Outdoor Projects Manual, Sixth EditionNo ratings yet

- Steel Square - Use Of The Scales, Roof Framing, Illustrative Problems And Other UsesFrom EverandSteel Square - Use Of The Scales, Roof Framing, Illustrative Problems And Other UsesNo ratings yet

- Basement Waterproofing: A Practical Guide & Handbook to Waterproofing Your BasementFrom EverandBasement Waterproofing: A Practical Guide & Handbook to Waterproofing Your BasementRating: 4 out of 5 stars4/5 (1)

- Carpentry and Framing Inspection Notes: Up to CodeFrom EverandCarpentry and Framing Inspection Notes: Up to CodeRating: 5 out of 5 stars5/5 (1)

- Common-Sense Stair Building And Handrailing - Handrailing In Three Divisions Showing Three Of The Simplest Methods Known In The Art: With Complete Instructions For Laying Out And Working Handrails Suitable For Any Kind Of A Stair, Straight, Circular Or Elliptical, Or For Stairs With Landings And CylindersFrom EverandCommon-Sense Stair Building And Handrailing - Handrailing In Three Divisions Showing Three Of The Simplest Methods Known In The Art: With Complete Instructions For Laying Out And Working Handrails Suitable For Any Kind Of A Stair, Straight, Circular Or Elliptical, Or For Stairs With Landings And CylindersNo ratings yet

- Ultimate Guide: Decks, 5th Edition: 30 Projects to Plan, Design, and BuildFrom EverandUltimate Guide: Decks, 5th Edition: 30 Projects to Plan, Design, and BuildNo ratings yet

- The Modern Bricklayer - A Practical Work on Bricklaying in all its Branches - Volume III: With Special Selections on Tiling and Slating, Specifications Estimating, EtcFrom EverandThe Modern Bricklayer - A Practical Work on Bricklaying in all its Branches - Volume III: With Special Selections on Tiling and Slating, Specifications Estimating, EtcRating: 5 out of 5 stars5/5 (1)

- Software Deck GuideDocument19 pagesSoftware Deck GuideEdward EncarnacionNo ratings yet

- A Complete Guide To Building Your Own Deck PDFDocument16 pagesA Complete Guide To Building Your Own Deck PDFr1greenNo ratings yet

- Basic Deck Construction DetailsDocument3 pagesBasic Deck Construction Detailssea_jazzNo ratings yet

- Cross Strapping DeckDocument22 pagesCross Strapping DeckChristopher Laliberte0% (1)

- 5 Roof StructureDocument5 pages5 Roof StructureFathi RashidNo ratings yet

- Ch17 Carpentry SeDocument38 pagesCh17 Carpentry SeKenaia AdeleyeNo ratings yet

- Black & Decker Here's How... DecksDocument98 pagesBlack & Decker Here's How... DecksVic Cumpas100% (2)

- Detached Residential Accessory BuildingsDocument32 pagesDetached Residential Accessory Buildingsvasty.overbeekNo ratings yet

- Design A Deck Planning PDFDocument18 pagesDesign A Deck Planning PDFdvsNo ratings yet

- A Complete Guide To Building Your Own DeckDocument16 pagesA Complete Guide To Building Your Own DeckAdrian Berna100% (5)

- Foundation DesignDocument7 pagesFoundation Designdinu69inNo ratings yet

- Deck Construction GuideDocument13 pagesDeck Construction Guidefaxtackley100% (2)

- Typical Roof Patio CoverDocument4 pagesTypical Roof Patio Cover63ragtop100% (1)

- Wood Garage Doors Owners ManualDocument2 pagesWood Garage Doors Owners ManualRonnie DoberNo ratings yet

- 13 Ext Walls FramingDocument35 pages13 Ext Walls FramingAnonymous 4SVSd7jN100% (1)

- Wood Deck PlansDocument12 pagesWood Deck PlansLindsay Coleman100% (1)

- Figure B Framing: Pre-Assembled Dormer Wall Roof Framing (Install After Wall Sheathing) Wall FramingDocument13 pagesFigure B Framing: Pre-Assembled Dormer Wall Roof Framing (Install After Wall Sheathing) Wall FramingMúsica viajera MX0% (1)

- Floor Truss GuideDocument4 pagesFloor Truss GuideSamia H. BhuiyanNo ratings yet

- Deck, Porch and Gazebo Planning and Construction Guide: 3rd EditionDocument28 pagesDeck, Porch and Gazebo Planning and Construction Guide: 3rd EditionAhmed Emad AhmedNo ratings yet

- Building Deck Framing Connection GuideDocument28 pagesBuilding Deck Framing Connection GuideMelendres Benito100% (2)

- Typical Garage / Storage Shed / Shop DetailsDocument28 pagesTypical Garage / Storage Shed / Shop DetailskennypetersNo ratings yet

- WRCLA Installing SidingDocument16 pagesWRCLA Installing SidingITLHAPNNo ratings yet

- Lintel DesignDocument7 pagesLintel DesignDan AielloNo ratings yet

- Home The Steps of Building A HomeDocument7 pagesHome The Steps of Building A HomeAngel Lisette LaoNo ratings yet

- Decks and PorchesDocument12 pagesDecks and Porchesdnl_vicars0% (1)

- Typical Deck Details Master HAO B70-1120P - ADA - 201803071309540634Document27 pagesTypical Deck Details Master HAO B70-1120P - ADA - 201803071309540634Diego Jaramillo BeckerNo ratings yet

- GHD PlansDocument4 pagesGHD PlansRyan BezzNo ratings yet

- III. Sill Floor JointsDocument8 pagesIII. Sill Floor JointsCristian Morar-BolbaNo ratings yet

- Complex Roof Framing HandoutDocument23 pagesComplex Roof Framing HandoutMaria ComanNo ratings yet

- E Spec Guide BCI and VL PDFDocument36 pagesE Spec Guide BCI and VL PDFcphammond83No ratings yet

- Hip, Valley, & Jack Rafters: Chapter ObjectivesDocument26 pagesHip, Valley, & Jack Rafters: Chapter ObjectivesdamindaNo ratings yet

- V. Roof Joinery Excluding TrussesDocument10 pagesV. Roof Joinery Excluding TrussesCristian Morar-BolbaNo ratings yet

- Wood Shingles and ShakesDocument6 pagesWood Shingles and Shakesjack.simpson.changNo ratings yet

- Why Install A Skillion Roof?: Ridge PitchDocument2 pagesWhy Install A Skillion Roof?: Ridge PitchTeodoro Miguel Carlos IsraelNo ratings yet

- Construction of Roof SystemsDocument25 pagesConstruction of Roof SystemsAlbert LiuNo ratings yet

- Basic Steps For Building A DeckDocument5 pagesBasic Steps For Building A DeckRi SovannaphumiNo ratings yet

- Accepted Practices For Post-Frame Building Construction: Framing TolerancesDocument12 pagesAccepted Practices For Post-Frame Building Construction: Framing TolerancesChuck Achberger100% (3)

- MiTeK Gable End and BracingDocument4 pagesMiTeK Gable End and BracingSam LeungNo ratings yet

- Gabion Baskets For Retaining WallDocument2 pagesGabion Baskets For Retaining WallChin Thau WuiNo ratings yet

- About Us: Teyi Gabion Baskets FactoryDocument2 pagesAbout Us: Teyi Gabion Baskets FactoryChin Thau WuiNo ratings yet

- Shotcrete and GunitingDocument30 pagesShotcrete and GunitingChin Thau WuiNo ratings yet

- Incheon Bridge ProjectDocument51 pagesIncheon Bridge ProjectChin Thau WuiNo ratings yet

- Operations Manual 2012Document102 pagesOperations Manual 2012MuhaiminNo ratings yet

- Lecture 4 Characterization of GeotextilesDocument71 pagesLecture 4 Characterization of GeotextilesChin Thau WuiNo ratings yet

- Heinke Tunnel Segment GasketsDocument6 pagesHeinke Tunnel Segment GasketsChin Thau WuiNo ratings yet

- Application For Approval of Works Affecting Public Sewerage System-25 Nov 2009 ADocument4 pagesApplication For Approval of Works Affecting Public Sewerage System-25 Nov 2009 AChin Thau WuiNo ratings yet

- BizSAFE Level 2 Course On Risk ManagementDocument98 pagesBizSAFE Level 2 Course On Risk ManagementChin Thau WuiNo ratings yet

- Basketball Skills & Drills - 3rd EditionDocument326 pagesBasketball Skills & Drills - 3rd EditionChin Thau WuiNo ratings yet

- NBA Coaches Playbook - Techniques, Tactics, and Teaching PointsDocument371 pagesNBA Coaches Playbook - Techniques, Tactics, and Teaching PointsChin Thau Wui100% (2)

- 33 Breakthrough Basketball Plays PDFDocument95 pages33 Breakthrough Basketball Plays PDFbarok79100% (1)

- Get File PDFDocument83 pagesGet File PDFVenu MadhavNo ratings yet

- Marina Bay SandsDocument100 pagesMarina Bay SandsChin Thau WuiNo ratings yet

- Nurturing Sense of Place: Twenty Years of Tourism Development in Sabah, MalaysiaDocument7 pagesNurturing Sense of Place: Twenty Years of Tourism Development in Sabah, MalaysiaChin Thau WuiNo ratings yet

- 6 0 PDFDocument1 page6 0 PDFChin Thau WuiNo ratings yet

- 2 KKIP (Slide Presentation)Document42 pages2 KKIP (Slide Presentation)Chin Thau WuiNo ratings yet

- Senior Resident Engineer (SRE) : Senior Cow 2 Senior Cow 1 Senior Cow 3 Senior Cow 4Document1 pageSenior Resident Engineer (SRE) : Senior Cow 2 Senior Cow 1 Senior Cow 3 Senior Cow 4Chin Thau WuiNo ratings yet

- Laws of BasketballDocument98 pagesLaws of Basketballapi-443437521No ratings yet

- Admixtures, Nanoconcrete, Glenium ConcreteDocument99 pagesAdmixtures, Nanoconcrete, Glenium Concretejitesh dhuleNo ratings yet

- 2 CUI PRODUCTS (Merged)Document17 pages2 CUI PRODUCTS (Merged)jechurchNo ratings yet

- M-I 19 - CorrosionDocument25 pagesM-I 19 - CorrosionShaykh AlthamasNo ratings yet

- WINTER INTERN REPORT by VARSHINIDocument36 pagesWINTER INTERN REPORT by VARSHINIMadhavi LathaNo ratings yet

- ASTM G80-88 (Specific Cathodic Disbonding of Pipeline Coatings)Document5 pagesASTM G80-88 (Specific Cathodic Disbonding of Pipeline Coatings)Daison Paul100% (1)

- AAC2010 Guideline For Hard Anodic Oxide CoatDocument3 pagesAAC2010 Guideline For Hard Anodic Oxide CoatPalaNo ratings yet

- Saep 43Document29 pagesSaep 43QcNo ratings yet

- Cast Iron PipesDocument226 pagesCast Iron Pipesbabmech6007No ratings yet

- Gas TurbineDocument93 pagesGas TurbineShubhankit Porwal100% (2)

- Passive Intake ScreensDocument4 pagesPassive Intake ScreensWendyNo ratings yet

- Pipeline Integrity Management ExternalDocument36 pagesPipeline Integrity Management ExternalJavierfox98100% (6)

- Castings, Nickel and Nickel Alloy: Standard Specification ForDocument6 pagesCastings, Nickel and Nickel Alloy: Standard Specification ForRafael CossolinoNo ratings yet

- Use Caution When Specifying "Seal Welds": Design FileDocument4 pagesUse Caution When Specifying "Seal Welds": Design FilePrabhat K KarnaNo ratings yet

- A Schiff Base Compound SALCNDocument9 pagesA Schiff Base Compound SALCNMaicol PérezNo ratings yet

- C929Document3 pagesC929dinhtung2210No ratings yet

- Weldwell Catalogue PDFDocument8 pagesWeldwell Catalogue PDFmitesh0% (1)

- Technology UpdatesDocument26 pagesTechnology Updatespartha6789No ratings yet

- USFDA On Stent UpdatesDocument10 pagesUSFDA On Stent UpdatesKarishmaNo ratings yet

- Inergen System Operation and Maintenance InstructionDocument16 pagesInergen System Operation and Maintenance InstructionchuminhNo ratings yet

- @airbus: Component Maintenance Manual With Illustrated Part ListDocument59 pages@airbus: Component Maintenance Manual With Illustrated Part ListAnh Tuan PhamNo ratings yet

- 2010 - SANDIA - Design Considerations For Concentrated Solar Tower Plants Using Molten Salts PDFDocument51 pages2010 - SANDIA - Design Considerations For Concentrated Solar Tower Plants Using Molten Salts PDFDavide FranziniNo ratings yet

- Astm B209Document26 pagesAstm B209Elias Cruz100% (2)

- ANODIZING (Autosaved)Document17 pagesANODIZING (Autosaved)Sonu JajamNo ratings yet

- Nuforte Barrier enDocument2 pagesNuforte Barrier enAlvin RejisNo ratings yet

- 3 Oxidation and ReductionDocument25 pages3 Oxidation and ReductiondonutNo ratings yet

- Api 650Document16 pagesApi 650cfpc10459No ratings yet

- Samoa-Section 4 Pages43-54Document12 pagesSamoa-Section 4 Pages43-54Wiki YuanditraNo ratings yet

- The Importance of PTFE - FEP - PFA Polymer Lined Pipes and Fittings in Chemical Process Industry - Sigma Polymers EnggDocument5 pagesThe Importance of PTFE - FEP - PFA Polymer Lined Pipes and Fittings in Chemical Process Industry - Sigma Polymers EnggAnonymous jlLBRMAr3ONo ratings yet

- Bearing MaterialsDocument32 pagesBearing MaterialsAleš NagodeNo ratings yet

- Corrosion RatesDocument25 pagesCorrosion RatesPanji Aji WibowoNo ratings yet