Professional Documents

Culture Documents

Euro 20 PM2009

Uploaded by

Michelle HarrisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Euro 20 PM2009

Uploaded by

Michelle HarrisCopyright:

Available Formats

STUDY CASE- TAMPING TOOLS WITH THE REINFORCEMENT BY TUNGSTEN CARBIDE AT THE TINE C. Besleaga**, I.C. Popescu*, R.M.

Negriu**, S.G. Badea** *Polytechnic University of Bucharest, Splaiul Independentei nr.313, 77206, sect.6, Romania **Econet Prod, Pades nr. 16, Bucharest, Romania Abstract: An important operation in the technical process of building or maintenance of the railways is tamping. Tamping operation is made by different tamping machine, using tamping tools. Tamping tools are the most stress part of the tamping machine, being stress like bending, oscillations, abrasive wear, a.s.o. The main part of a tamping tool, which influences in present the lastingness of this, is the active part (tine). We propose a study cases with CAD, a new composite material, with tungsten carbide, for the tine and we made the researches regarding to the behavior in situ for the different tamping tools. Keywords: tamping tools, composite material, tungsten carbide, CAD, weariness 1. Introduction The researches regarding to increasing of tamping tools have been made on the three main directions: Theoretical researches regarding to situations stress of a tamping tool, having in view the system stress (forces) and the CAD analyzing; Theoretical and experimental researches regarding to establishing of some new material composition for tamping tine and also, of technological processes by made of this; Experimental researches (in situ), regarding to the behavior of different tamping tools. 2. Study case- tamping tool type BNRI- 85 models 94 For to theoretical study case of the tamping tool BNRI- 85, model 94 (Fig.1), was used two CAD soft (Autodesk Inventor Professional 2008 and ANSYS Workbench, rev. 11), in collaboration with the Thermal Research Center, in the Faculty of Mechanical Engineering and Mechatronics of the Polytechnic University in Bucharest [1, 2]. There are used more then 200000 elements and 3% convergence.

Fig. 1: The Model of tamping tool BNRI 85 types, model 94 For this model were made 6 cases of stress, two from them are presented below. 2.1. Case 3- Checking/ behavior of the tamping tool BNRI- 85, model 94, at case 3 of stress Concentrated force, perpendicular to the lower side (active edge) of the tine, operating in the center of the area (Fig.2 Fig.7).

Fig.2: Scheme of loading

Fig.3: Equivalent stresses (tensions)

Fig.4: Stress (tension) intensity

Fig.5: Life (number of runs)

Fig.6: Total Deformation

Fig.7: Defects (damages)

2.2. Case 5- Checking/ behavior of the tamping tool BNRI- 85, model 94, at case 5 of stress Concentrated force, perpendicular to the active main side of the tine, operating in the center of the area (Fig. 8 Fig.13).

Fig. 8: Scheme of loading

Fig.9: Equivalent stresses (tensions)

Fig.10: Stress (tension) intensity

Fig.11: Life (number of runs)

Fig.12: Total Deformation

Fig.13: Defects (damages)

3. New composite material with metallic carbides For the main piece of wear (tine), we have proposed and achieved a new technological process of casting at the check parameters of a steel, with an original composition, having the role of joint material of the waste from metallic carbide (the waste from metallic carbides are coming from the damage cutting tools, for metal, wood a.s.o.). The original composite material which has been achieved is made from particles of metallic carbides, with a certain granulometry (size), incorporation through diffusion into metallic matrix. The matrix of the composite material is heating over the melting point of the binding material from waste composition of sintered metallic carbides (WC-Co, WC-Ni, WC-Co-Ni and TiC-X) and it is casting into relative cold form (shape). The binding metal (Co-Ni) is dissolved and diffusion into metallic matrix and after that it is solidifies. We have achieved a composite material, which is able to satisfied the hard wear conditions, at the local abrasive wear stress, vibrations, having a hardness bigger than the limit conditions impose by the crushed stone abrasiveness [3, 4, 5, 6, 7].

Fig.14. Micro dilution of carbides particles Carbides - Detail x 12000 The main types of analyzed particles are titan carbides (TiC) and tungsten carbides (WC). The infiltrations analyze with particles from metallic carbides has showed the fact that the TiC has a finest particles shape, with relative round shape, which confer a good plasticity of the reinforced matrix, while the WC has a rough morphology, with sharp edge and corner, conferring resistance and hardness. The combination of both effects has a good results, by point of view of the behavior in function, if are resolved the problems regarding to the fragility and fissure tendency of the composite metallic material. The phenomenon which occur at the interface between metallic matrix and carbide particle are depending in a big measure by the size, chemistry and physics characteristics of these, and also, by the manufacturing. 4. Experimental procedure We have established an experimental procedure [8], for evaluated the lastingness of a tamping tool. The lastingness of a tamping tool is the period of time, in which the tamping tool work in the established parameters (until to reaching the limits of wear of an active partthe tine), until to a new regeneration (Fig. 15). The lastingness of a tamping tool can be evaluated through meters (kilometers) of tamping, hours of tamping or, number of insertion. Because the evaluation of lastingness in meters (kilometers) can be use more easily, we have adopted this unit. For the limits of the wear of tine, having in view indications [8] and our experience, we have adopted the following size of wear: 15 mm on side; 20 mm at the corner (40 mm on diagonals).

Fig.15. The limits of the wear for active part (tine) of a tamping tool

Ui = h hi; i= 1 6; Umed = (U1+ U2+....+ U6): 6 5. Researches in situ on the different lots of the tamping tools After the researches, regarding to established which is the main tamping tool (having in view the quantity, consumption criteria) which is use in present, from all types of tamping tools which are used, the researches in situ have been concentrated on the tamping tool BNRI- 85, model 94, followed that the conclusions of these researches to be extended to all types of the tamping tools. 5.1. Experimental researches in situ on the lot 1 of the tamping tools The experimental researches (in situ) have been made with BNRI- 85 tamping machines, on three tamping tools type BNRI-85, model 94, identified with G4, G6 and G8(7), with the tine which have been made on the base of a new composite material, with tungsten carbide (Fig.16, 17, 18). The behavior of these tools, taking in account the weariness [mm] depending by [km] of tamping is present in Fig. 19.

Fig.16. Tamping tool G4 Fig.17. Tamping tool G6 Fig.18. Tamping tool G8 (7) 5.2. Experimental researches in situ on the lot 2 of the tamping tools For comparison, we have established another lot, number 2, with 8 tamping tools type BNRI-85, model 94, which have been made by another producer, having as main material for the body of tamping tool and the active part (tine) of this, the alloy steel 42MoC11. The active part (tine) of a tamping tools, in areas which are the most stress at wear (abrasive wear a.s.o.), have been protected through welding with a hard material like EI 58 H electrode. The lot 2 (with 8 pieces) it have been identified with B21 B 28. The behavior of these tools, taking in account the weariness [mm] depending by [km] of tamping is present in Fig. 19. 5.3. Experimental researches in situ on the lot 3 of the tamping tools The eight tamping tools type BNRI-85, model 94, which were presented above, after it work until to the admissible limits (see chapter 4), it has been reconditioning at the active part (tine) through welding, with two materials: 4 pieces with EI 58 H electrode, which have been identified with B21 (R1) B 24(R1) and 4 pieces with EI 16 Mn electrode, which have been identified with B25 (R1) B 28(R1). The behavior of these tools, taking in account the weariness [mm] depending by [km] of tamping is present in Fig. 19.

[mm] 32 30 28 26 24 22 20 18 16 14 12 10 8 6 4 2 0 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39

Ciocane BNRI - 85

G4 G6 G8(7) B21 B22 B23 B24 B25 B26 B27 B28 B21(R1) B22(R1) B23(R1) B24(R1) B25(R1) B26(R1) B27(R1) B28(R1)

[km]

Fig.19. The wear curves of the active part (tine) for experimental tamping tools

Conclusions: - Designing a tamping tool and checking of this, to the different stress, with especially CAD simulation, can offer many advantages, possibilities and reduce a lot of time and more accurate results. - The new composite material with tungsten carbide, on which we have proposed, has a good potential and goods properties for wear, being chip and use the waste from different damage parts from tungsten carbide. - In comparison, the average of weariness of tamping tools, after 9 km, with new composite material (with tungsten carbide) for the tine (lot 1: G4, G6, G8 (7)) is with 4,5 times smaller than the average of weariness of new tamping tools (lot 2: B21 B28) and with 6,5 times smaller than the average of weariness of reconditioning tamping tools (lot 3: B21 (R1) B28 (R1)). In the end, the average of lastingness for lot 1 (G4, G6, G8 (7)) is with 2,8 times bigger than average of lastingness for lot 2 (B21 B28) and lot 3 ((B21 (R1) B28 (R1)). This fact, make the possibility to reduce the cost of a tamping tool, a tamping operation and maintenance of railways. References: [1] I.C. Popescu, Introduction in computer aided analysis of the process equipments , Printech Publisher, ISBN 973- 652- 951- 7, Bucharest, (2004) [2] I.C. Popescu, T. Prisecaru, B. Finite elements Analysis of Pressure Equipment, Computer Aided Engineering Solutions for Design, Analysis and Innovation, (ANSYS & FLUENT User Group Meeting), 26-27 Aprilie 2007, Sinaia [3] P. Georgeoni, N. Arnici, I.C. Popescu, and s.a., Using the isostatical pressing at the manufacturing of big machine parts by high performances from sintered metallic carbides, Metallurgical Researches, ICEM, Vol.26, page. 463 - 475, 1985, Bucharest. [4] P. Georgeoni, I.C. Popescu, Considerations regarding to manufacturing of machine parts from metallic carbides type WC-Co with A.I.P. destination , Metallurgical Researches, ICEM, Vol.26, page. 477 - 483, 1985, Bucharest. [5] V.V.Jinescu, I.C. Popescu, Reactors by very high pressure with the elements manufactured from the tungsten carbides and cobalt , Chemistry Review, nr. 12, 1997, page. 981 - 991, ISSN 0034-7752, (ISI-MJL 7569); [6] V.V.Jinescu, I.C. Popescu, Reactors by very high pressure with the elements manufactured from the tungsten carbides and cobalt , II, Chemistry Review, nr. 1, 1998, page. 56 - 63, ISSN 0034-7752, (ISI-MJL 7569); [7] P. Georgeoni, I.C. Popescu, M. Istrtescu, L. Argeanu, The behavior of different types hardness alloys from WC Co system, used at manufacturing of dies for reactors by very high pressure, Mechanical Breakage, nr. 9, page. 8 - 14, 2000, ISSN 1453-8148; [8] Cr. Besleaga, Contributions regarding to increase the lastingness of the tamping tools, Doctorate thesis, 625.144.5(043-2876) B-UP 1, Bucharest, (2006).

You might also like

- JESR201101V17S01A0005Document8 pagesJESR201101V17S01A0005Michelle HarrisNo ratings yet

- Euro PM 2012Document59 pagesEuro PM 2012Michelle HarrisNo ratings yet

- POSTER EUROPM 2012-95x100Document1 pagePOSTER EUROPM 2012-95x100Michelle HarrisNo ratings yet

- Theoretical and Experimental Studies On Heat Transfer in Multi-Layer CompositeDocument10 pagesTheoretical and Experimental Studies On Heat Transfer in Multi-Layer CompositeMichelle HarrisNo ratings yet

- C1.1 Lucrari Indexate ISI ADocument128 pagesC1.1 Lucrari Indexate ISI AMichelle HarrisNo ratings yet

- PM12 ParticipantsDocument16 pagesPM12 ParticipantsMichelle HarrisNo ratings yet

- Program ARM 4Document39 pagesProgram ARM 4Michelle HarrisNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- NIC:NAC:SILDocument19 pagesNIC:NAC:SILSiva KumarNo ratings yet

- Suitable Star For Marriage MatchingDocument12 pagesSuitable Star For Marriage MatchingVenkata RamaNo ratings yet

- PCP VenezuelaDocument6 pagesPCP VenezuelakurtbkNo ratings yet

- Water: Vertical Electrical Sounding (VES) For Estimation of Hydraulic Parameters in The Porous AquiferDocument15 pagesWater: Vertical Electrical Sounding (VES) For Estimation of Hydraulic Parameters in The Porous AquiferGustavo MiguelNo ratings yet

- Digital Communication Lab Report: Experiment Number 7Document9 pagesDigital Communication Lab Report: Experiment Number 7Saketh RaviralaNo ratings yet

- XL640 User ManualDocument213 pagesXL640 User ManualSIELAB C.A.No ratings yet

- +2 Physics Practical Readings 2019-2020Document11 pages+2 Physics Practical Readings 2019-2020Barkath Shalu100% (1)

- Horizontal Tank ChecklistDocument3 pagesHorizontal Tank ChecklistA.P.100% (1)

- NCR Departmental Exam Electrical Question Bank With Answer PDFDocument13 pagesNCR Departmental Exam Electrical Question Bank With Answer PDFMunish KumarNo ratings yet

- HFO HomeworkDocument2 pagesHFO HomeworkAna May Durante BaldelomarNo ratings yet

- Lab Manual.15 PDFDocument34 pagesLab Manual.15 PDFBoovarahan ChakravarthyNo ratings yet

- The Social Learning Theory (Tutorial WK 5)Document14 pagesThe Social Learning Theory (Tutorial WK 5)Hasfiyah AssanNo ratings yet

- Excavations OSHA Competent Person Course 2Document17 pagesExcavations OSHA Competent Person Course 2MelchezadekNo ratings yet

- 1-P1 P9-AIAG CQI-9 Pre 3rdDocument12 pages1-P1 P9-AIAG CQI-9 Pre 3rdSaravanan MNo ratings yet

- The Philips PavilionDocument12 pagesThe Philips PavilionNiket PaiNo ratings yet

- Master of Arts in Education (Physical Education)Document1 pageMaster of Arts in Education (Physical Education)Michael Mayo TaperoNo ratings yet

- Math 216 SyllabusDocument4 pagesMath 216 Syllabusdoney_78100% (1)

- Solar Battery Bank Sizing Calculator - Size Off-Grid BatteriesDocument8 pagesSolar Battery Bank Sizing Calculator - Size Off-Grid Batteriesamiteetumtech2013No ratings yet

- Major Challenges To Indian EconomyDocument12 pagesMajor Challenges To Indian EconomyAtharva KadamNo ratings yet

- Microbial Genomes !Document15 pagesMicrobial Genomes !talha153No ratings yet

- 6004 0100 ALE 0000 SH 0004 Up Dated Preferred Subcontractor List (04!02!15)Document23 pages6004 0100 ALE 0000 SH 0004 Up Dated Preferred Subcontractor List (04!02!15)romahi0% (1)

- APA 7th Edition Condensed Referencing Style Handout 2020Document13 pagesAPA 7th Edition Condensed Referencing Style Handout 2020Nia Singh100% (1)

- Tormax Automatic Sensor 7501Document12 pagesTormax Automatic Sensor 7501name familyNo ratings yet

- BS 598-106Document7 pagesBS 598-106muhammad iqbalNo ratings yet

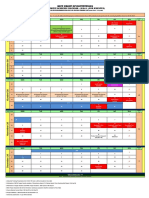

- Detroit Diesel - DD16 - Common Powertrain Controllor (CPC4, MD & HD, GHG17), VIHDocument11 pagesDetroit Diesel - DD16 - Common Powertrain Controllor (CPC4, MD & HD, GHG17), VIHMatthew Morin100% (2)

- Sakaka Project 405 MW: Checklist - Electrical Installation of ACCBDocument1 pageSakaka Project 405 MW: Checklist - Electrical Installation of ACCBVenkataramanan SNo ratings yet

- Academic Calendar Odd Sem 2020-21Document1 pageAcademic Calendar Odd Sem 2020-21NAMRATA SHARMANo ratings yet

- MR Collins Maths Year 11 HomeworkDocument6 pagesMR Collins Maths Year 11 Homeworkafeueffmk100% (1)

- The Mindset of Focusing For Success - Jane HolderDocument19 pagesThe Mindset of Focusing For Success - Jane HoldermehtavinNo ratings yet

- Cal2-Iu BT Chap3 Des SlidesDocument66 pagesCal2-Iu BT Chap3 Des SlidesHà Anh Minh LêNo ratings yet