Professional Documents

Culture Documents

Casing Cuter Pioner

Uploaded by

Jorge ForeroOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Casing Cuter Pioner

Uploaded by

Jorge ForeroCopyright:

Available Formats

Sir William Smith Road, Kirkton Industrial Estate, Arbroath, Angus, Scotland, U.K.

DD11 3RD Tel: +44 (0) 1241 877776. Fax: +44 (0) 1241 871037 E-mail: sales@pioneeroiltools.com Website: www.pioneeroiltools.com

TYPE CCH HYDRAULIC CASING CUTTER

CCH 10/10

copyright 2010

TYPE CCH CASING CUTTER

INTRODUCTION

HYDRAULIC CASING CUTTER

The Pioneer CCH Range of Casing Cutters is designed to be tough, reliable and easy to operate whilst giving the operator maximum control over the operation. The CCH Cutter is hydraulically actuated through an arrangement consisting of Piston and Flotel Assemblies. A drop in pressure created when the cutting knives have reached a pre-set diameter advises the operator that the casing has been cut through. Various Knife lengths are available depending on the diameter of casing to be cut. Hydraulic pressure is used to activate the three Tungsten Carbide Alloy coated Knives. Single and Multiple strings of casing may be cut. The Pioneer Hydraulic Casing Cutter may be used below the Pioneer Single Trip Retrieval System, details of this system are available in publication STR.

When time is of the essence, Pioneer delivers

TYPE CCH CASING CUTTER

OPERATION

In order to achieve maximum stability, a suitable Non-rotating Stabilizer/Centralizer should be fitted below the Casing Cutter. The Cutter is attached to the drill string. The Knives should be held in the closed position with wire located and secured in its purpose machined groove in the Body. (This wire breaks on Knife activation). The Cutter is lowered to the required depth, and rotation started. Once rotating, pump pressure is started. The pump pressure acts on the Flotel/Piston pivoting the Knives about the Knife Pins, and into the casing. When the Knives have reached the previously set diameter, the Piston separates from the Flotel (by Flotel movement restriction) causing a sudden pressure drop indicated on the pump pressure gauge, thereby alerting the operator.

KNIFE SETTING With Knives selected and assembled, fit Piston Assembly then Flotel Assembly, push down until Knives are extended out to the required diameter. The Flotel Spider (item 33) is then rotated on the Flotel Stem so that it locates on the Shoulder in the Body whilst the Knives are still at the required diameter, the spider is then locked on to the stem with cap screws. (item 37) NOTE : It may be more practicable to fit only one Knife for this operation.

TYPE CCH CASING CUTTER

MAINTENANCE

After use, the Pioneer CCH Casing Cutter must be thoroughly cleaned and washed to ensure the evacuation of all fragments of debris. The Cutter should be dismantled and examined in detail for signs of wear or damage. If satisfactory, moving parts should be greased and the cutter re-assembled, painted and stored.

DISMANTLING Grip Body (item 02) in vice and break out Top Sub (item 01) Remove Flotel Assembly (item 30A) Remove Piston Assembly (item 20) To remove Knives (item 03), first extract Split Cotter Pin (item 05) from Knife Pin (item 04), then knock out Knife Pin to allow removal of Knife. All Parts should be checked for damage and wear and repaired or replaced as required.

ASSEMBLY All moving parts must be greased prior to assembly. Select 3 Knives appropriate for casing to be cut, set Knives into slots and insert Knife Pins, secure with Split Cotter Pins, check Knives for free movement into the slots. Set Knives as detailed in page 2. Fit Piston Assembly Fit Flotel Assembly Fit Top Sub and Torque up, gripping Body above the Knives. Hold Knives in Closed position by winding 1/16 Dia. soft iron tying wire around the Body in the groove provided.

YOUR PIONEER CASING CUTTER IS NOW SET FOR DOWN-HOLE ACTION

TYPE CCH CASING CUTTER

CCH Casing Cutter Exploded View

4

TYPE CCH CASING CUTTER

PARTS LIST

Basic Details

Component Top Sub Body Knife Knife Pin Split Cotter Pin Piston Assembly Flotel Assembly Part No 1 2 3 4 5 20 30A Req. Qty 1 1 3 3 3 1 1

Piston assembly Piston Valve Seat Body Valve Seat Insert Piston Seal Circlip O Ring 21 22B 22C 23 24 25

Flotel assembly Flotel Stem Flotel Stem Insert Flotel Spider Flotel Choke Circlip O Ring Skt Hd Cap Screws 31C 31B 33 34 35 36 37

Ordering Procedure Please specify : Hydraulic Casing Cutter O.D. Top & Bottom Connection O.D. and weight of casing, or, if making multiple cuts please advise all Knife lengths to be used. Pioneer Oil Tools offer a comprehensive range of Fishing & Retrieval Tools, including Hydraulically Set Retrieval Spears to compliment this range of casing cutters, call our sales office to discuss your complete requirements.

TYPE CCH CASING CUTTER

Pioneer CCH series Hydraulic Casing Cutter data table

Cutter Assembly

CCH0213 CCH0263 CCH0313

Cutter OD

2 /8 2 5/8 3 1/8

1

Cutter Length

28.3 28.3 30.0

Tubing Casing

3 /2 4 1/2 3 1/2 4 1/2 4 1/2 5 5 1/2 4 1/2 5 5 1/2 7 5 1/2 6 5/8 7 7 5/8 8 5/8 9 5/8 10 3/4 11 3/4 9 5/8 13 3/8 20 30 36 9 5/8 13 3/8 20 30 36 13 3/8 20 30 36 42

1

Knife Part No

CCH0213-03 CCH0213-03A CCH0263-03 CCH0263-03A CCH0363-03 CCH0363-03C CCH0363-03A CCH0363-03 CCH0363-03C CCH0363-03A CCH0363-03B CCH0450-03-1 CCH0450-03-2 CCH0575-03-4 CCH0575-03-1 CCH0575-03-5 CCH0575-03-3 CCH0575-03-2 CCH0575-03-2 CCH0825-03-1 CCH0825-03-2 CCH0825-03-3 CCH0825-03-4 CCH0825-03-5 CCH0838-03-1 CCH0838-03-2 CCH0838-03-3 CCH0838-03-4 CCH0838-03-5 CCH1188-03-5 CCH1188-03-4 CCH1188-03-3 CCH1188-03-2 CCH1188-03-1

Knife Length

1.31 2.00 1.50 1.82 1.58 1.79 1.81 1.58 1.79 2.10 5.65 1.64 2.39 2.67 2.93 3.68 4.18 6.18 6.18 3.84 5.08 10.07 17.57 23.07 3.84 5.08 10.07 17.57 23.07 5.11 10.00 17.50 23.00 30.25

Knife Sweep 45

3.51 4.41 4.45 5.01 4.70 5.14 5.07 5.02 5.46 5.95 6.66 5.60 6.66 7.73 8.08 9.14 9.85 12.68 12.68 11.82 13.50 20.34 30.47 37.99 11.82 13.50 20.34 30.47 37.99 16.29 23.24 33.60 41.14 51.15

Knife Sweep Max

4.29 5.67 5.13 5.75 5.66 6.06 6.12 5.97 6.38 7.04 8.11 6.35 7.80 9.22 9.70 11.15 12.11 15.98 15.98 13.35 15.85 25.85 40.85 51.85 13.35 15.85 25.85 40.85 51.85 17.97 26.95 40.41 50.23 63.232

Rotary Speed

RPM 230 180 230 180 180 160 150 150 140 130 100 150 120 100 100 100 80 80 70 80 60 40 30 25 80 60 40 30 25 60 40 30 25 20

Orifice pressure differential

547 psi 836 psi 510 psi 620 psi 457 psi 517 psi 607 psi 361 psi 409 psi 480 psi 606 psi 188 psi 276 psi 216 psi 237 psi 297 psi 338 psi 500 psi 500 psi 74 psi 98 psi 195 psi 339 psi 464 psi 74 psi 98 psi 195 psi 339 psi 464 psi 205 psi 401 psi 701 psi 922 psi 1212 psi

Flow Rate

GPM 37.8 46.8 36.5 40.3 43.7 46.5 50.3 38.8 41.3 44.8 50.3 28.0 33.9 30.0 31.5 35.2 37.6 45.7 45.7 31.3 36.0 50.8 67.0 78.4 31.3 36.0 50.8 67.0 78.4 52.1 72.9 96.4 110.5 126.7

CCH0363

3 5/8

32.0

CCH0450 CCH0575 6 CCH0825

4 1/2 5 3/4

39.0 47.3

8 1/4

71.3

CCH0838

8 3/8

71.4

CCH1188

11 7/8

83.0

Other cutter assemblies available on request. All pioneer CCH knives are dressed with a Tungsten Carbide matrix, unless requested otherwise. Insert equipped knives are available on request.

Sir William Smith Road, Kirkton Industrial Estate, Arbroath, Angus, Scotland, U.K. DD11 3RD Tel: +44 (0) 1241 877776. Fax: +44 (0) 1241 871037 E-mail: sales@pioneeroiltools.com Website: www.pioneeroiltools.com

TYPE CCH HYDRAULIC CASING CUTTER

CCH 10/10

As the policy of Pioneer Oil Tools is one of continual product improvement, we reserve the right to change designs or specifications without notice

copyright 2010

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Sand Control OverviewDocument85 pagesSand Control OverviewAndrea Bandera100% (5)

- Acme Thread DimensionsDocument74 pagesAcme Thread DimensionsJorge Forero50% (4)

- DesalinationDocument4 pagesDesalinationsivasu1980aNo ratings yet

- Lockbox Br100 v1.22Document36 pagesLockbox Br100 v1.22Manoj BhogaleNo ratings yet

- 1934 PARIS AIRSHOW REPORT - Part1 PDFDocument11 pages1934 PARIS AIRSHOW REPORT - Part1 PDFstarsalingsoul8000No ratings yet

- Sending Emails With Python - Real PythonDocument2 pagesSending Emails With Python - Real PythonJorge ForeroNo ratings yet

- Viceversa Tarot PDF 5Document1 pageViceversa Tarot PDF 5Kimberly Hill100% (1)

- Moving and Rotating Faces: Publication Number Spse01520Document101 pagesMoving and Rotating Faces: Publication Number Spse01520Jorge ForeroNo ratings yet

- Spse 01510Document137 pagesSpse 01510Jorge ForeroNo ratings yet

- Spse 01515Document119 pagesSpse 01515Jorge ForeroNo ratings yet

- The Psychology of Appraisal Specific Emotions and Decision-MakingDocument14 pagesThe Psychology of Appraisal Specific Emotions and Decision-MakingJorge ForeroNo ratings yet

- Watson InformationDocument17 pagesWatson InformationJorge ForeroNo ratings yet

- How To Build A Data Science Portfolio - by Michael Galarnyk - Towards Data ScienceDocument2 pagesHow To Build A Data Science Portfolio - by Michael Galarnyk - Towards Data ScienceJorge ForeroNo ratings yet

- Underreamer MaintenanceDocument5 pagesUnderreamer MaintenanceJorge ForeroNo ratings yet

- Combining Data in Pandas With Merge, .Join, and Concat - Real PythonDocument2 pagesCombining Data in Pandas With Merge, .Join, and Concat - Real PythonJorge ForeroNo ratings yet

- Risk Marvel Avengers Edition - RulesDocument16 pagesRisk Marvel Avengers Edition - RulesJorge ForeroNo ratings yet

- The Appraisal-Tendency FrameworkDocument47 pagesThe Appraisal-Tendency FrameworkJorge ForeroNo ratings yet

- 08cutting Tool Angles and Their Significance PDFDocument37 pages08cutting Tool Angles and Their Significance PDFHeineken Ya PraneetpongrungNo ratings yet

- Underreamer MaintenanceDocument5 pagesUnderreamer MaintenanceJorge ForeroNo ratings yet

- Sample Annual BudgetDocument4 pagesSample Annual BudgetMary Ann B. GabucanNo ratings yet

- Financial Derivatives: Prof. Scott JoslinDocument44 pagesFinancial Derivatives: Prof. Scott JoslinarnavNo ratings yet

- Schmidt Family Sales Flyer English HighDocument6 pagesSchmidt Family Sales Flyer English HighmdeenkNo ratings yet

- PCDocument4 pagesPCHrithik AryaNo ratings yet

- Maths PDFDocument3 pagesMaths PDFChristina HemsworthNo ratings yet

- Doas - MotorcycleDocument2 pagesDoas - MotorcycleNaojNo ratings yet

- Prachi AgarwalDocument1 pagePrachi AgarwalAnees ReddyNo ratings yet

- Shubham Tonk - ResumeDocument2 pagesShubham Tonk - ResumerajivNo ratings yet

- LMU-2100™ Gprs/Cdmahspa Series: Insurance Tracking Unit With Leading TechnologiesDocument2 pagesLMU-2100™ Gprs/Cdmahspa Series: Insurance Tracking Unit With Leading TechnologiesRobert MateoNo ratings yet

- Experiment On Heat Transfer Through Fins Having Different NotchesDocument4 pagesExperiment On Heat Transfer Through Fins Having Different NotcheskrantiNo ratings yet

- BluetoothDocument28 pagesBluetoothMilind GoratelaNo ratings yet

- Droplet Precautions PatientsDocument1 pageDroplet Precautions PatientsMaga42No ratings yet

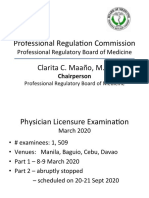

- Professional Regula/on Commission: Clarita C. Maaño, M.DDocument31 pagesProfessional Regula/on Commission: Clarita C. Maaño, M.Dmiguel triggartNo ratings yet

- Aisladores 34.5 KV Marca Gamma PDFDocument8 pagesAisladores 34.5 KV Marca Gamma PDFRicardo MotiñoNo ratings yet

- Section 8 Illustrations and Parts List: Sullair CorporationDocument1 pageSection 8 Illustrations and Parts List: Sullair CorporationBisma MasoodNo ratings yet

- Building and Other Construction Workers Act 1996Document151 pagesBuilding and Other Construction Workers Act 1996Rajesh KodavatiNo ratings yet

- Proceedings of SpieDocument7 pagesProceedings of SpieNintoku82No ratings yet

- The Rise of Populism and The Crisis of Globalization: Brexit, Trump and BeyondDocument11 pagesThe Rise of Populism and The Crisis of Globalization: Brexit, Trump and Beyondalpha fiveNo ratings yet

- Google App EngineDocument5 pagesGoogle App EngineDinesh MudirajNo ratings yet

- General Field Definitions PlusDocument9 pagesGeneral Field Definitions PlusOscar Alberto ZambranoNo ratings yet

- MDOF (Multi Degre of FreedomDocument173 pagesMDOF (Multi Degre of FreedomRicky Ariyanto100% (1)

- Oracle Exadata Database Machine X4-2: Features and FactsDocument17 pagesOracle Exadata Database Machine X4-2: Features and FactsGanesh JNo ratings yet

- HandloomDocument4 pagesHandloomRahulNo ratings yet

- 23 Things You Should Know About Excel Pivot Tables - Exceljet PDFDocument21 pages23 Things You Should Know About Excel Pivot Tables - Exceljet PDFRishavKrishna0% (1)

- Are Groups and Teams The Same Thing? An Evaluation From The Point of Organizational PerformanceDocument6 pagesAre Groups and Teams The Same Thing? An Evaluation From The Point of Organizational PerformanceNely Noer SofwatiNo ratings yet

- Introduction To Motor DrivesDocument24 pagesIntroduction To Motor Drivessukhbat sodnomdorjNo ratings yet