Professional Documents

Culture Documents

Bacteriocine LAB Sucuri

Uploaded by

danaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bacteriocine LAB Sucuri

Uploaded by

danaCopyright:

Available Formats

Available online at www.sciencedirect.

com

International Journal of Food Microbiology 121 (2008) 123 138 www.elsevier.com/locate/ijfoodmicro

Review

Application of bacteriocins in vegetable food biopreservation

Luca Settanni 1 , Aldo Corsetti

Dipartimento di Scienze degli Alimenti, Sezione di Microbiologia Agro-Alimentare ed Ambientale, Universit degli Studi di Teramo, V. C.R. Lerici 1, 64023 Mosciano Sant'Angelo (TE), Italy Received 15 May 2007; received in revised form 15 August 2007; accepted 3 September 2007

Abstract Bacteriocins are generally recognized as natural compounds able to influence the safety and quality of foods. In the past years, a lot of works have been aimed to the detection, purification and characterisation of bacteriocins, as well as to their use in food preservation strategies. A list of review articles dealing with the application of bacteriocins to the protection of foods of animal origin is also available in literature, but it lacks for a summary on the utilization of bacteriocins in vegetable foods. These biopreservatives can be used in a number of ways in food systems and this paper mainly focuses on the state-of-the-art application of bacteriocins from lactic acid bacteria (LAB) to promote the microbial stability of both fermented and non-fermented vegetable food products using bacteriocinogenic strains as starter cultures, protective cultures or co-cultures and the employment of pure bacteriocins as food additives. In addition, applications of bacteriocins from non-LAB are also reviewed. The scopes of future directions of research are summarised. 2007 Elsevier B.V. All rights reserved.

Keywords: Bacteriocins; Biopreservation; Food additives; Vegetable foods

Contents 1. 2. 3. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Classification, determination of activity, mode of action and vegetable matrices of isolation of bacteriocins Application of bacteriocinogenic LAB strains as co-culture, protective or starter cultures . . . . . . . . . . 3.1. Fermented vegetables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1.1. Table olives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1.2. Sourdough . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1.3. Miso . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1.4. Sauerkrauts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2. Non-fermented vegetables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2.1. Refrigerated pickles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2.2. Mungbean sprouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Interactions between bacteriocins and undesired bacteria in model systems . . . . . . . . . . . . . . . . . Application of bacteriocins from LAB as food additives . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.1. Fermented vegetables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.1.1. Kimchi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.1.2. Cider . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124 125 126 126 126 127 127 127 129 129 129 129 130 130 130 130

4. 5.

Corresponding author. Tel.: +39 0 861 266896; fax: +39 0 861 266915. E-mail address: acorsetti@unite.it (A. Corsetti). 1 Present address: Istituto Agrario di San Michele all'Adige (IASMA), Centro Sperimentale-Dipartimento Qualit Agro-Alimentare, Unit Microbiologia e Tecnologie Alimentari, V. E. Mach 1, 38010 San Michele a/A (TN), Italy. 0168-1605/$ - see front matter 2007 Elsevier B.V. All rights reserved. doi:10.1016/j.ijfoodmicro.2007.09.001

124

L. Settanni, A. Corsetti / International Journal of Food Microbiology 121 (2008) 123138

Non-fermented vegetables . . . . . . . . . . . . . . . . 5.2.1. Mashed potatoes . . . . . . . . . . . . . . . . 5.2.2. Soy milk . . . . . . . . . . . . . . . . . . . . 5.2.3. Fruit and vegetable juice . . . . . . . . . . . . 5.2.4. Canned vegetables . . . . . . . . . . . . . . . 5.2.5. Fresh-cut products. . . . . . . . . . . . . . . . 5.2.6. Zucchini pure . . . . . . . . . . . . . . . . . 6. Combined effect of pure bacteriocins and bacteriocin-producing 7. Application of non-LAB bacteriocinogenic strains . . . . . . . 8. Future prospects . . . . . . . . . . . . . . . . . . . . . . . . . 9. Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . Acknowledgement . . . . . . . . . . . . . . . . . . . . . . . . . . References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Further reading . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . strains . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

130 130 130 131 131 132 132 133 133 133 134 134 134 137

1. Introduction Nowadays, consumers are particularly aware of the health concerns regarding food additives; the health benefits of natural and traditional foods, processed with no added chemical preservatives, are becoming more and more attractive. Thus, in the last decades, due to consumer demand for higher quality and naturalness of foods, as well as strict government requirements for guarantees of food safety, food producers have faced conflicting challenges. Chemical additives have generally been used to combat specific microorganisms. Historically, the birth of modern microbiology is dated back to 1929 when Alexander Fleming discovered the antibiotic properties of penicillin, but the need of controlling pathogenic and spoilage microorganisms is dated back to the previous century since the studies of Louis Pasteur. In the case of fermented foods, lactic acid bacteria (LAB) have been essential for millennia. Thanks to some of their metabolic properties, LAB are generally employed because they significantly contribute to the flavour, texture, and, in many cases, to the nutritional value of the food products (McKay and Baldwin, 1990). LAB play a defining role in the preservation and microbial safety of fermented foods (Caplice and Fitzgerald, 1999), thus promoting the microbial stability of the final products of fermentation (Mensah et al., 1991). Protection of foods is due to the production of organic acids, carbon dioxide, ethanol, hydrogen peroxide and diacetyl (Atrih et al., 2001; De Vuyst and Vandamme, 1994), antifungal compounds such as fatty acids (Corsetti et al., 1998) or phenyllactic acid (Lavermicocca et al., 2000), bacteriocins (De Vuyst and Vandamme, 1994) and antibiotics such as reutericyclin (Hltzel et al., 2000). However, growth of LAB has been also found to show positive effects in non-fermented foods, e.g. vacuum-packaged meat products (Castellano et al., 2004; Vold et al., 2000). Actually, in that specific case, LAB such as Carnobacterium spp., Lactobacillus spp. and Leuconostoc spp. are the main spoilage organisms (Borch et al., 1996; Korkeala and Bjrkroth, 1997; Nychas and Drosinos, 2000), but a selective growth promotion of LAB capitalising on their ability to control meatborne pathogens with a preferential growth of benign strains would minimise their spoilage effects.

Biopreservation refers to the extension of the shelf-life and improvement of the safety of foods using microorganisms and/ or their metabolites (Ross et al., 2002). The term bacteriocin was coined in 1953 to define colicin produced by Escherichia coli. Like LAB, also bacteriocins have been consumed for millennia by mankind as products of LAB and, for this reason, they may be considered as natural food ingredients. As reported by Cotter et al. (2005) bacteriocins can be used to confer a rudimentary form of innate immunity to foodstuffs. Bacteriocins are ribosomally synthesized, extracellularly released lowmolecular-mass peptides or proteins (usually 3060 amino acids) which have a bactericidal or bacteriostatic effect on other bacteria (Klaenhammer, 1988; Tagg et al., 1976), either in the same species (narrow spectrum) or across genera (broad spectrum) (Cotter et al., 2005). Thanks to their typical characteristics, bacteriocins, although showing antibiotic properties, are not termed antibiotics in order to avoid confusion and concern with therapeutic antibiotics that can determine allergic reactions in humans (Cleveland et al., 2001). Since the discovery of the first bacteriocin by Gratia in 1925 (Garneau et al., 2002), bacteriocin production has been found in numerous species of bacteria, among which, due to their generally recognised as safe (GRAS) status, LAB have attracted great interest in terms of food safety. In fact, LAB bacteriocins enjoy a food-grade and this offers food scientists the possibility of allowing the development of desirable flora in fermented foods or preventing the development of specific unwanted (spoilage and pathogenic) bacteria in both fermented and non-fermented foods by using broad- and narrow-host-range bacteriocins, respectively. De Vuyst and Vandamme reported in 1994 that the majority of bacteriocins described at the time of writing were those produced by Lactobacillus spp., followed by Enterococcus, Pediococcus and Leuconostoc spp.; nowadays, other bacteriocins from the group of LAB, such as those produced by Lactococcus, Streptococcus and Carnobacterium have been described. However, the only bacteriocin approved for utilization as a preservative in many foods by the US Food and Drug Administration is nisin (Federal Register, 1988), commercially available as Nisaplin (Danisco, Copenhagen, Denmark). Nisin is the first antibacterial polypeptide found in LAB (Rogers, 1928); at the time of discovery, the producer strains were identified as Streptococcus lactis [later classified as

L. Settanni, A. Corsetti / International Journal of Food Microbiology 121 (2008) 123138

125

Lactococcus lactis (Schleifer et al., 1985)]. Another commercially produced bacteriocin is pediocin PA-1 produced by Pediococcus acidilactici and marketed as ALTA 2431 (Kerry Bioscience, Carrigaline, Co. Cork, Ireland). Regarding the application of bacteriocin-producing starter strains in food fermentation, the major problem is related to the in situ antimicrobial efficacy which can be negatively influenced by various factors, such as binding of the bacteriocins to food components (fat or protein particles) and food additives (e.g. triglyceride oils), inactivation by proteases or other inhibitors, changes in solubility and charge, changes in the cell envelope of the target bacteria (Aesen et al., 2003; Degnan and Luchansky, 1992; Gnzle et al., 1999; Jung et al., 1992; Leroy and De Vuyst, 1999). Furthermore, unlike their general behaviour represented by being active against closely related species, some LAB bacteriocins have also been found to be active against Gram-negative bacteria (Abriouel et al., 2001; Caridi, 2002; Ko and Ahn, 2000; Messi et al., 2001; Todorov and Dicks, 2005a), hence the interest in their application is also forwarded to the gastrointestinal tract. Regarding food safety, bacteriocin-producing LAB cultures that are not effective against Gram-negative bacteria, protected by an outer membrane, should not be used as the primary processing step or barrier to prevent the growth or survival of pathogens, but rather they can be used in hurdle technology strategies to reduce the likelihood of food-borne disease (Deegan et al., 2006). The most recent food application of bacteriocins encompass their binding to polymeric packaging, a technology referred to as active packaging. This kind of packaging, defined as an intelligent or smart system involving interactions between package or package components and food or internal gas atmosphere, fully encounters consumer demand for prolonged shelf-life of foods (Labuza and Breene, 1989). Due to this proposal, some patents have been issued (Daeschel and McGuire, 1995; Ming et al., 1997; Siragusa et al., 1999; Wilhoit, 1996, 1997). Up to date, numerous recent review articles focused on the classification (basically based on three classes), biochemical and genetic characterisation and the mode of action of LAB bacteriocins, as well as on some of their (mainly of animal origin) food applications (Breukink, 2006; Chen and Hoover, 2003; Cleveland et al., 2001; Cotter et al., 2005; Deegan et al., 2006; Drider et al., 2006; Ennahar et al., 1999; Garneau et al., 2002; Guinane et al., 2005; Messens and De Vuyst, 2002; Rodgers, 2001, 2004; Ross et al., 2002; Saito, 2004; Typpnen et al., 2003; Zhu et al., 2005), but literature lacks of updated reviews dealing with the use of bacteriocins or bacteriocinproducing strains for the protection of vegetable food products. Bacteriocin potential for enhancing food safety and prolonging the shelf-life of final products is routinely investigated and is still under study. In general, the focus of studies on food safety using bacteriocins as preservatives follows this scheme: isolation of bacteria from raw materials or final products; screening for bacteriocin production; characterisation of bacteriocins; production of bacteriocins in food model systems; in situ application. In this review, the application of bacteriocins as agents of food biopreservation is analysed in the context of

foods (including drinks and beverages) of vegetable origin, thus providing a complete and updated overview of this topic. 2. Classification, determination of activity, mode of action and vegetable matrices of isolation of bacteriocins Bacteriocins most frequently studied are those from LAB. They have been classified in three classes on the basis of common, mainly structural, characteristics (Nes et al., 1996). Many review articles have dealt with the classification of LAB bacteriocins as well as their main characteristics (please see Introduction section for references cited). In general, bacteriocins target the cell envelope, and with the exception of the larger proteins (N 20 kDa) that degrade the murein layer (e.g. lysins and muramidases), use non-enzymatic mechanisms to cause the depolarization of the target cell membrane and/or inhibit cell wall synthesis (Abee et al., 1995). When the presumptive bacteriocins are under study they should be referred to as bacteriocin-like inhibitory substances (BLIS) until their amino acid sequence determination. The traditional determination of the antagonism of a bacteriocin-producing strain against a sensitive strain, generally indicated as producer and indicator, respectively, can be performed in different ways (see Parente and Ricciardi, 1999 for a review). In general, the methods most frequently used are the agar-spot deferred test and the well diffusion assay (Schillinger and Lcke, 1989). In the first method, colonies of the strains to be tested for bacteriocin production are allowed to grow, generally overnight, on the surface of the optimal agar medium. The indicator strain is inoculated into the optimal soft agar medium and poured on the plate where growth of the producers occurred. After incubation, inhibition is scored positive in the presence of a detectable clearing zone around the colony of the producer strain. For the well diffusion assay, the agar base medium is overlaid with soft agar medium containing the indicator strain, as above. Thereafter, wells are cut into the agar and the cell-free supernatant of the potential producer strains is placed into each well. In the latter test, the inhibitory effect of lactic acid and/or H2O2, is eliminated by the adjustment of supernatants to neutral pH and treatment with catalase, respectively. In general, prior to incubation, plates are refrigerated for a while to allow the radial diffusion of the compounds contained in the supernatant. Bacteriocin activity of the supernatants is commonly evaluated by the critical dilution assay of Barefoot and Klaenhammer (1983) defined as the reciprocal of the highest dilution showing clear inhibition of the indicator strains and is expressed as activity units per millilitre (AU/ml). Agar based antagonistic assays may be replaced by quicker tools for bacteriocin detection: Rose et al. (1999) developed a rapid method to examine culture supernatants for the presence of some bacteriocins, such as brochocins A and B, enterocins A and B, nisin and pediocin, by means of the matrixassisted laser desorption/ionization time-of-flight mass spectrometry (MALDI-TOF MS). Furthermore, PCR methods have also been used to detect genes coding for bacteriocins in pure cultures (Bennik et al., 1997; Foulqui Moreno et al., 2003; Garde et al., 2001; Moreno et al., 2002) and fermentation broth (Mugochi et al., 2001).

126

L. Settanni, A. Corsetti / International Journal of Food Microbiology 121 (2008) 123138

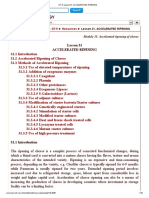

Fig. 1. Bactericidal effect of BLIS WGJ28.1 () and bacteriostatic effect of BLIS WGJ36.1 (), WGJ6.1 (), WGW33.2 (), WGJ5.1 () and WGJ1.2 () produced by E. faecium WGJ28.1, P. pentosaceus WGJ36.1 and WGJ6.1, E. faecium WGW33.2 and P. pentosaceus WGJ5.1 and WGJ1.2, respectively, isolated from wheat (Triticum durum) kernels and non-conventional flours against L. monocytogenes ATCC 19114T as determined in BHI for 72 h by means of Bioscreen C MBR (Growth Curves AB Ltd., Piscataway, NJ, USA) (from Corsetti et al., in press). Control (broken line) is represented by growth of L. monocytogenes ATCC 19114T in BHI added with concentrated supernatant of strain Enterococcus casseliflavus WGW22.1 (which does not produce any antimicrobial compound).

Bacteriocins have generally a cationic character and easily interact with Gram-positive bacteria that have a high content of anionic lipids in the membrane determining the formation of pores (see Cleveland et al., 2001 and Chen and Hoover, 2003 for reviews). Pores in the cytoplasmic membrane clearly affect the energetic status of the cell, i.e. dissipation of proton motive force causes an arrest of pH and (transmembrane electrical potential) dependent (e.g. transport) processes while certain bacteriocins cause ATP efflux (Moll et al., 1999). A bacteriocin producer protects itself against its own antimicrobial compound by means of a system referred to as immunity, which is expressed concomitantly with the antimicrobial peptide (Nes et al., 1996). The mode of action of bacteriocins can be bactericidal or bacteriostatic determining death or extension of lag phase, respectively (Fig. 1). Bacteriocins or BLIS from LAB associated to or found in vegetable food matrices are reported in Table 1. 3. Application of bacteriocinogenic LAB strains as co-culture, protective or starter cultures 3.1. Fermented vegetables In general, starter cultures for fermented foods are mainly selected on the basis of their technological potential, such as acid and exopolysaccharides production and contribution to flavour development. Moreover, other features are being taken into account, e.g. the ability to improve nutritional quality and to reduce anti-nutritional and/or toxic compounds of raw materials and probiotic attitude. The production of antimicrobial activities may constitute a secondary effect of starter cultures while it represents the unique characteristic requested for protective cultures or co-cultures which must not alter or negatively interfere

with the wanted fermentation process and should not affect the final product's sensorial properties. Applications of protective cultures and co-cultures are considered as additional safety factors warranting the microbiological stability of the resulting foods reducing risks of growth and survival of food-borne pathogens and food spoilage organisms (Holzapfel et al., 1995). 3.1.1. Table olives In the process of selection of starter cultures for olive fermentation, antimicrobial production is a desired character. Jimnez-Daz et al. (1993) and Franz et al. (1996) approached the selection of potential starter cultures focusing on the screening of table olive-associated LAB for bacteriocin production: the most interesting bacteriocin-producing strains were Enterococcus faecium BFE 900 (Franz et al., 1996) and Lactobacillus plantarum LPCO10 (Jimnez-Daz et al., 1993). L. plantarum LPCO10 was then included in a project aimed at optimizing the fermentation of green olives (Leal et al., 1998; Leal-Snchez et al., 2003; Ruiz-Barba et al., 1994). Firstly, the authors evaluated the ability of strain LPCO10 to dominate the epiphytic microflora of fermented olives and they assumed that such a dominance was due to the production of bacteriocin (Ruiz-Barba et al., 1994). L. plantarum LPCO10 and its non-bacteriocin-producing, bacteriocin-immune derivative, L. plantarum 55-1 were evaluated separately for growth and persistence in natural green olive fermentations. Spontaneously occurring lactobacilli and lactic acid bacterial cocci of brines were sensitive to L. plantarum LPCO10 bacteriocin. The final concentration of lactic acid in brines inoculated with L. plantarum LPCO10 was higher than that of brines inoculated with L. plantarum 55-1 or non-inoculated, indicating that L. plantarum LPCO10 could be a good starter culture for the lactic acid fermentation of Spanish-style green olives.

L. Settanni, A. Corsetti / International Journal of Food Microbiology 121 (2008) 123138

127

Subsequently, a medium resembling the natural environment of L. plantarum LPCO10, named olive juice broth (OJB), was obtained from green olives and it was optimal for bacteriocin production by the above strain (Leal et al., 1998). In that work, unlike L. plantarum 55-1, L. plantarum LPCO10 was able to dominate over a L. plantarum strain (128/2) of olive origin used as indicator. On the basis of those results, the authors suggested that the OJB could be a valuable substitute for the olive fermentation brine for successful Spanish-style olive fermentations with strain LPCO10. A third piece of work was aimed to better investigate on the fermentation profile of green olives obtained with L. plantarum LPCO10 by means of a factorial study (Leal-Snchez et al., 2003). In all different conditions, including different salt concentration, inoculum size (CFU/ml), inoculum carrier, inoculation time, homogenization, type of acid used to decrease the basic pH of brines, and initial pH, L. plantarum LPCO10 was able to dominate over the natural population of LAB and led to a faster decrease of pH and a faster acidification than the spontaneous process during the first 25 days after brining. The authors determined that, in order to have the best final product, L. plantarum LPCO10 should be suspended at 107 CFU/ml in brine and the brine should contain 4% w/v of NaCl and be adjusted for its initial pH with acetic acid. 3.1.2. Sourdough Corsetti and Settanni (2007) have reviewed the contribution of bacteriocins from LAB to the stability of sourdoughs over consecutive refreshments, reporting on the in situ activity of BLIS 2MF8 from L. pentosus 2MF8 (Corsetti et al., 2004), lacticin 3147-like bacteriocin from L. lactis M30 (Settanni et al., 2005) and amylovorin L471 from Lactobacillus amylovorus DCE 471 (De Vuyst et al., 2004). In addition, Mente et al. (2007) recently published a paper dealing with the effect of sourdoughs produced with L. plantarum LMO25 and Lactobacillus alimentarius LMO7, previously characterised for their inhibitory activity against rope-forming Bacillus strains, in wheat bread. The addition of 15% or 20% low pH (pH 3.54.0) sourdough to bread dough prevented the generation of visual rope caused by Bacillus subtilis and Bacillus licheniformis while sourdoughs with a higher pH (N 4) were not effective in preventing rope caused by both B. subtilis and B. licheniformis at concentrations lower than 20%. According to the authors, production of bacteriocins by the starter strains may explain the rope inhibition in breads with final pH values above 4.8 and they discussed their results as consistent with prior data showing that the bacteriocins produced by Lactobacillus strains have optimal activities at pH 3.04.0 (Mente et al., 2005). 3.1.3. Miso Miso, a fermented soybean paste, is a very important seasoning for Japanese and Asian cooking (Fukushima, 1981). Rice-koji miso is prepared using a certain percentage of ricekoji fermented by Aspergillus oryzae (Yamabe et al., 2007). Rice miso has presented a big concern regarding the growth of Bacillus spp. during koji fermentation which prevents the

development of the fermenting aspergilli and produces offflavours, thus, causing quality defects of the resulting rice miso (Ebine, 1984) and the persistence of alive Bacillus spores. The spores cause spoilage of processed foods seasoned with miso. Kato et al. (1999) investigated on the inhibition of growth of B. subtilis by nisin-producing lactococci in fermented soybeans. From this proposal, nisin-producing L. lactis ssp. lactis IFO12007, a strain that does not tolerate the presence of NaCl, was used. Strain IFO12007 rapidly proliferated to more than 109 cells/g in cooked soybeans, but it did not determine an excessive pH decrease. However, the growth of B. subtilis, inoculated at a concentration of 106 cells/g, was inhibited till 72 h. Thus, L. lactis ssp. lactis IFO12007, whose nisin activity was determined to be 1.28 105 AU/g in cooked soybean, was used as a starter culture to produce soybean miso. The problem regarding over-acidification of miso by L. lactis was solved by adding salt. Later, Kato et al. (2001) focused on the growth of nisin-producing lactococci in cooked rice supplemented with soybean extract to inhibit B. subtilis in rice miso. LAB growth in cooked rice supplemented with soybean extract was not negatively affected and no off-flavour or undesirable coloration were generated. L. lactis ssp. lactis IFO12007 proliferated till 109 cells/g showing in situ nisin activity inhibiting bacilli, including B. subtilis and it did not inhibit the growth of A. oryzae during koji fermentation. The resulting rice miso, obtained after 12 weeks of ageing, was characterised by favourable acidity, taste and colour. 3.1.4. Sauerkrauts The most common among the fermented Brassica (e.g. cabbage) products is sauerkraut, which is manufactured either by natural or controlled fermentation (Fleming et al., 1995) in the presence of NaCl. The correct sequence of organisms is essential in achieving a stable product with flavour and aroma typical of sauerkraut (Pederson and Albury, 1969). Harris et al. (1992) developed a paired starter culture system for sauerkraut, consisting of the nisin-resistant Leuconostoc mesenteroides NCK293 and the nisin-producing L. lactis NCK401. The authors used a filter-sterilized cabbage juice broth (CJB), previously demonstrated (Stamer et al., 1971) to be a satisfactory experimental substitute for shredded cabbage. The two strains were first evaluated separately and in combination for growth and nisin production in a model sauerkraut fermentation. The growth and survival of L. mesenteroides were similar in the presence and absence of L. lactis. The growth of L. lactis was reduced and the population decline was more pronounced in the presence of L. mesenteroides. Nisin level was almost constant over the 12-day test period. However, the maximum cell populations and nisin levels achieved could be altered by changing the initial cell ratios of L. mesenteroides and L. lactis. Nisin level produced in mixed culture was sufficient to delay the growth of the L. plantarum strain used as an indicator. Although in a model system, the above work represents the first application of a bacteriocin-producing strain as a coculture/protective culture to a vegetable food fermentation. Furthermore, as highlighted by the authors themselves, that research, from a microbiological point of view, offered an

128

L. Settanni, A. Corsetti / International Journal of Food Microbiology 121 (2008) 123138

Table 1 Bacteriocin-producing bacteria isolated from vegetable raw materials or foods

L. Settanni, A. Corsetti / International Journal of Food Microbiology 121 (2008) 123138 Table 1 (continued )

129

N.R., not reported.

excellent model system for the study of mixed culture ecology. They concluded that, at the time of writing, the lack of literature available on the application of starter cultures for sauerkraut production was, in part, due to the difficulties involved in studying a natural mixed culture fermentation. 3.2. Non-fermented vegetables When no fermentation is required, preservation with live (protective) cultures provides the unique temperature-responsive protection. 3.2.1. Refrigerated pickles Refrigerated pickles are made from cucumbers packed into brine with appropriate spices and salt. The product is not heat processed. The shelf-life depends on the refrigeration temperature and the presence of vinegar and preservatives such as sodium benzoate: in general, about 3 weeks without any addition to three months with vinegar and preservatives added to the brine (Reina et al., 2005). Reina et al. (2005), in order to characterise spontaneous LAB for their biopreservation potential, subjected refrigerated pickles to various thermal abuse (16, 25 and 30 C) after storage for three weeks at 5 C. A total of 10 isolates were found to be bacteriocin-producers, among which three showed anti-Listeria activities. At the time of writing, the authors showed the willingness to perform future trials of minimally processed pickle products co-inoculated with Listeria monocytogenes and LAB cultures producing bacteriocins. 3.2.2. Mungbean sprouts Mungbean sprouts are commonly sold in modified atmosphere packaging (MAP). As minimally processed food, the shelf-life of this product mainly counts on the refrigeration at which it is stored. However, the growth of L. monocytogenes may occur. Bacteriocinogenic strains of LAB (Enterococcus mundtii ATO6 and Pediococcus parvulus ATO34 and ATO77) were investigated for their ability to inhibit L. monocytogenes MAP mungbean sprouts (Bennik et al., 1999). Firstly, E. mundtii ATO6 and P. parvulus ATO34 and ATO77 were evaluated for their growth and acid and bacteriocin production in APT broth and vegetable agar medium at different temperatures and CO2 concentrations.

E. mundtii ATO6 was selected, since it showed a significantly higher maximum specific growth rate than P. parvulus strains at concentrations of CO2 relevant for storage of vegetables under MAP. The latter strain was then evaluated for its potential to in situ control the growth of L. monocytogenes LDCD861 and LDCD1087. The interactions between the mundticin producer E. mundtii ATO6 and L. monocytogenes strains, after spraying 10 ml of approximately 106108 CFU/ml cell suspension per kg of produce, was studied in fresh mungbean sprouts under 1.5% O2/20% CO2/78.5% N2 at 8 C. The treatment did not show the same defining effect of the selected lactic acid bacterium on the pathogen as observed on vegetable agar. However, the application of pure mundticin (200 AU/ml) to the vegetables during a washing step or a coating procedure with an alginate film was successful against L. monocytogenes. 4. Interactions between bacteriocins and undesired bacteria in model systems Food model systems are artificial media that mimic the composition of natural food complex matrices or sterile food matrices useful to study the basic interactions between microorganisms. Foods are not sterile, thus the results that are retrieved by antagonistic assays can be influenced by a mixed microbial population. Furthermore, it has to be noted that the heat-treatments necessary to kill any microbial form in foods might modify the chemical composition of the matrices used for bacterial inhibition test and that the results can also be influenced by a different substrate availability and/or a different interaction between antimicrobials and food chemicals. However, since model systems have the advantage of being sterile, it is easy to evidence any reciprocal effect of the different species inoculated or the effect of antimicrobials on the undesired microorganisms. Jamuna et al. (2005) evaluated the antibacterial efficacy of bacteriocin LABB and LABP from appam batter and vegetable pickles Lactobacillus isolates, respectively, and nisin individually and in combination against several Gram-positive and Gram-negative food spoilage and pathogenic organisms in a liquid medium. The authors found that when employed individually, nisin was a potent inhibitor of Clostridium sporogenes while bacteriocins LABB and LABP were effective

130

L. Settanni, A. Corsetti / International Journal of Food Microbiology 121 (2008) 123138

against L. monocytogenes and Staphylococcus aureus. Bacteriocins LABB and LABP in combination with nisin were more potent than alone and these dual bacteriocin combinations were also able to inhibit Gram-negative E. coli and Pseudomonas spp. On the basis of these results, the authors addressed their attention towards the inhibition of L. monocytogenes and S. aureus in a vegetarian food model system represented by a partially cooked vegetable pulav, prepared using rice, vegetable and spices, packed in paper aluminium foil and polypropylene pouches and autoclaved. The bacteriocin LABB was found to be more effective as there was considerable inhibition of both L. monocytogenes and S. aureus as compared to either nisin or LABP, whereas the combination of LABB with nisin proved to be better as there was maximum inhibition of both organisms and no bloating of the sealed pouches was observed up to 14 days. The authors concluded that combinations of bacteriocins may improve microbial quality, safety and shelf-life of vegetarian foods. 5. Application of bacteriocins from LAB as food additives Bacteriocins can be incorporated into foods as a concentrated, though not purified, preparation made with food-grade techniques. 5.1. Fermented vegetables 5.1.1. Kimchi Kimchi is a generic term indicating a group of traditional lactic acid-fermented vegetable foods in Korea (Lee et al., 2005). The major raw material (oriental cabbage or radish) is salted after pre-brining, blended with various spices (red pepper, garlic, green onion, ginger, etc.) and other minor ingredients (seasonings, salted seafoods, fruits and vegetables, cereals, fish and meats, etc.), and then fermented. Its fermentation is extremely difficult to control because of the unique characteristics of the fermenting microflora, among which are mainly species of LAB. Choi and Park (2000) reported on the use of nisin to control the lactobacilli responsible for the over-ripening of kimchi. L. mesenteroides represents the main species during kimchi fermentation at temperatures under 10 C, producing kimchi with a better organoleptic quality than that made at higher temperatures at which L. plantarum is dominant and kimchi becomes too acidic for consumption ([Lee et al., 1992]). With this in mind, Choi and Park (2000) tested pure nisin against 40 lactobacilli, including L. plantarum (n = 28), L. brevis (n = 7), Lactobacillus malefermentans (n = 4) and an unidentified Lactobacillus spp. Most of lactobacilli were sensitive to nisin at a concentration of 100 AU/ml, while two strains appeared to be resistant. Thus, the concentration of 100 AU/ml of nisin was chosen for evaluation in kimchi. In those experimental conditions, the growth of Lactobacillus spp. was inhibited more than the growth of Leuconostoc spp., as evaluated by plate counts and confirmed by scanning electron micrograph observations. The predominance of cocci in kimchi containing nisin suggested that, at recommended levels, nisin can be used

to preserve kimchi by inhibiting lactobacilli more effectively than LAB positively involved in kimchi fermentation. 5.1.2. Cider Cider can be spoiled by the growth of exopolysaccharideproducing bacteria, e.g. B. licheniformis, which are responsible for the formation of slime, giving the resulting drink a ropy appearance (Larpin et al., 2002). In order to preserve their characteristic organoleptic properties, raw materials that cannot be heat-treated need alternative methods to inactivate undesirable bacteria. Grande et al. (2006) proposed the use of enterocin AS-48, whose stability in vegetable juice was prior determined (Grande et al., 2005a), to inhibit the endospore-forming B. licheniformis LMG 19409. The bacteriocin, produced by Enterococcus faecalis A-48-32 (formerly Streptococcus faecalis subsp. liquefaciens S-48) isolated from a human wound exudate (Glvez et al., 1989) was tested in glucoseMRS broth, fresh-made apple juice and two commercial apple ciders. The authors found that a concentration of 0.5 g/ml of enterocin AS-48 was enough to inactivate B. licheniformis LMG 19409 in glucoseMRS broth, while 3 g/ml was necessary to obtain the inhibition in fresh apple juice. Furthermore, enterocin AS48 was able to increase the heat sensitivity of spores and the combination of heat-treatment and enterocin AS-48 was demonstrated to determine a reduction of the complete inactivation time of intact spores in cider. 5.2. Non-fermented vegetables 5.2.1. Mashed potatoes Potatoes represent the main ingredient of many convenience foods. The cooking process does not inactivate heat-resistant bacterial spores and, consequently, endospore-forming Bacillus spp. and Clostridum spp. can be found in the final products, even during storage at low temperature ( 5 C) (Gould, 1995). Clostridium botulinum and Bacillus cereus belong to this genera that are reported as the cause of several food-borne outbreaks (Angulo et al., 1998; Doan and Davidson, 2000), thus, their inhibition by bacteriocins has a relevant significance. Nisin has been tested for its useful contribution to control Bacillus and Clostridium growth in potato-based products by Thomas et al. (2002). Addition of 6.25 g of nisin per g of cooked mashed potatoes retarded the growth of B. cereus and B. subtilis, previously inoculated in the product not vacuum packaged, for at least 27 days at 8 C and the growth of C. sporogenes and Clostridium tyrobutiricum, added as spores in the product and then vacuum packaged, for at least 58 days at 25 C. Nisin remained at active levels after pasteurization, but the authors highlighted that, in order to be effective against temperature abuse and in extending shelf-life of final products, nisin must be well mixed to the various ingredients. 5.2.2. Soy milk Soy powder milk is one of the product of soybean that is becoming very popular among consumers, not only among those intolerant to animal milk. Similarly to milk products, in general, the etiological agents of concern in soy milk are mainly

L. Settanni, A. Corsetti / International Journal of Food Microbiology 121 (2008) 123138

131

represented by L. monocytogenes and S. aureus. In order to prevent the possible contamination and/or to determine their elimination, Laukov and Czikkov (1999) tested enterocin CCM 4231 for controlling the growth of the above two species in soy milk. The addition of enterocin CCM 4231 at 3200 AU/ ml inhibited the L. monocytogenes indicator strain for 24 h, while concentration of S. aureus was reduced of 3.55 log cycles. The mode of action of the bacteriocin was presumptively bactericidal against L. monocytogenes, whereas it was proven to be bacteriostatic against S. aureus. Since enterocin CCM 4231 did not affect pH of soy milk, it was suggested as a valid candidate to preserve its stability. Furthermore, the authors also verified the ability of E. faecium CCM 4231 to grow and to produce bacteriocin in soy milk. It was found to be an in situ bacteriocin-producing strain: after 2 h from inoculation, bacteriocin was detected at 100 AU/ml. 5.2.3. Fruit and vegetable juice Growth of unwanted bacteria in fruit and vegetable juices during storage may cause spoilage due, in particular, to the formation of ropiness and off-flavours. In order to face this problem, Grande et al. (2005a) evaluated the stability of enterocin AS-48 in fruit and vegetable juices as a preliminary step for its food applications. Enterocin AS-48 was first concentrated and then applied 10-fold diluted in juices. It showed different interactions with the juices tested, from complete to negligible activity losses. Under refrigeration storage, the bacteriocin was stable within the first 2448 h in vegetable juices (avocado, cabbage, cauliflower, celery, green beans and lettuce), while its stability was longer (at least 15 days) in fresh fruit juices (apple, grapefruit, kiwi, orange, pear and pineapple) and mixed juices. In the latter, bacteriocin activity was detectable after 30 days. Stability of enterocin AS-48 did not change for up to 120 days in case of refrigerated commercial fruit juices (apple, orange, peach and pineapple) whereas its inactivation increased with temperature. However, at 15 C, in case of lettuce juice, enterocin AS-48 reduced viable counts of L. monocytogenes, B. cereus and S. aureus. Moreover, loss of activity of enterocin AS-48 was reduced by increasing its concentration, diluting the juices or heatpretreatment of juices. The results of the study also indicated compatibility of the bacteriocin with food-grade dyes and thickening agents, making it suitable for food bioprotection. Alicyclobacillus acidoterrestris is a spore-forming bacterium known to cause problems in fruit juices and fruit juice-based drinks either not heat-treated or pasteurized (Pettipher et al., 1997). Komitopoulou et al. (1999) studied the growth of A. acidoterrestris in fruit juice and its sensitivity to heattreatment and nisin. The spores were confirmed to be heatresistant after 10 min at 80 C, 2 min at 90 C and l min at 95 C in orange, grapefruit and apple juice. The resistance was reduced with decrement of pH of juices, although the effect was less marked at higher temperatures. Nisin addition (100 AU/ml) completely prevented A. acidoterrestris under all temperature and time of storage conditions. In particular, the presence of nisin during heating decreased the decimal reduction time up to 40% and its minimal inhibition concentration against A. acidoterrestris spores was only 5 AU/ml at 25 C.

Control of A. acidoterrestris in fruit juice was also approached with enterocin AS-48 (Grande et al., 2005b). Vegetative cells of A. acidoterrestris DSMZ 2498 were inactivated by 2.5 g/ml of this bacteriocin in natural orange and apple juices incubated at 37 C. No growth was detected in both juices until the 15th day of observation. Commercial orange, apple, pineapple, peach and grapefruit juices were then added to the same concentration of enterocin AS-48 and inoculated with vegetative cells or endospores of strain DSMZ 2498 and maintained at different incubation temperatures (4, 15 and 37 C) for three months. In this cases, no viable cells were observed during the whole incubation, except for apple, peach and grapefruit juices at 37 C containing vegetative cells which, however, were stable for up to 60 days. Treatment with enterocin AS-48, as revealed by electron microscopy, determined cell damage and bacterial lysis and disorganization of endospore structure in all fruit juices object of the study. These findings showed that enterocin AS-48 can be a valid substitute of the intense heattreatments necessary for inactivation of A. acidoterrestris endospores without altering chemical composition of fruit juices. 5.2.4. Canned vegetables Canned foods represent a continuous supply of seasonal vegetables which are preserved by acidification and thermal treatments. Bacteria that tolerate these conditions can proliferate during storage and may cause spoilage; for this reason, endospore-forming bacteria (e.g. Bacillus spp.) are a major problem because the endospores require more intense treatments for inactivation than vegetative cells. Bacillus coagulans is the microorganism most frequently associated to spoilage of canned vegetables with pH between 4 and 4.5 (Mallidis et al., 1990). A big concern with the presence of B. coagulans in low pH foods is represented by the increment of food pH to values allowing germination of the food pathogen C. botulinum spores (Anderson, 1984). The purpose of the work published by Lucas et al. (2006) was to test the efficacy of enterocin AS-48 in canned vegetable foods at different final pH [tomato paste (pH 4.64), syrup from canned peaches (pH 3.97) and juice from canned pineapple (pH 3.65)] against B. coagulans. Enterocin As-48 was added at concentrations of 3 and 6 g/ml. At the highest bacteriocin concentration, no viable cells were recovered from any sample after 15 days. Actually, a strain of B. coagulans (CECT 561) showed a poor survival in tomato paste, but AS-48 inhibit the growth of surviving cells. The bacteriocin was effective against vegetative cells of another B. coagulans strain (CECT 12), even though it did not show significant inhibition of its spores. Furthermore, addition of lactic acid (1,5%), glucose (10%) and sucrose (20%) increased bacteriocin activity against vegetative cells and the combination of bacteriocin and heat-treatment (8095 C for 5 min) enhanced the effect of thermal treatments on spore inactivation. The results of that work showed that enterocin AS-48 can reduce the concentration of vegetative cells of B. coagulans until levels at which they do not represent any risk of spoilage. Since the efficacy of bacteriocin AS-48 is enhanced by other additives, it has been proposed as an additional hurdle in order to protect canned vegetables by B. coagulans damages.

132

L. Settanni, A. Corsetti / International Journal of Food Microbiology 121 (2008) 123138

5.2.5. Fresh-cut products Vegetables, during growth in field, are frequently in contact with soil (Beuchat, 1995) and their surfaces can be contaminated. In order to eliminate or reduce the presence of pathogenic and spoilage microorganism, physical and chemical treatments are used in food processing (Ukuku and Fett, 2002a; Ukuku and Sapers, 2001; Ukuku et al., 2004). Bacteriocins, in combination with other food additives, are being commonly employed as protective agents in this kind of products. In particular, Ukuku and Fett (2002a) first studied the effectiveness of chlorine and nisinEDTA treatments on whole melons and fresh-cut pieces in reducing native microflora and then the combined effect of nisin, EDTA, sodium lactate and potassium sorbate in reducing Salmonella on fresh-cut cantaloupe (Ukuku and Fett, 2004), while Bari et al. (2005) focused on the combination of nisin, pediocin, sodium lactate, citric acid, phytic acid, potassium sorbate and EDTA to L. monocytogenes on fresh-cut cabbage, broccoli and mungbean sprouts. Furthermore, the use of H2O2 in combination with nisin, sodium lactate and citric acid to reduce the transfer of bacterial pathogens from whole melon surfaces to fresh-cut pieces was also reported (Ukuku et al., 2005). In the first study (Ukuku and Fett, 2002b), the attachment and survival of L. monocytogenes on cantaloupe, their resistance to chlorine and H2O2 treatments, were investigated and their transfer from unsanitised and sanitised rinds to fresh-cut tissues during cutting. The authors concluded that sanitising with chlorine and H2O2 has the potential to reduce or eliminate the transfer of L. monocytogenes on melon surfaces to fresh-cut pieces. In a second work of the same authors (Ukuku and Fett, 2004), whole melons and fresh-cut pieces were inoculated with five Salmonella strains (Salmonella Poona RM2350, Salmonella Stanley H0558, Salmonella Newport H1275, Salmonella Anatum F4317 and Salmonella Infantis F4319) and stored at 5 C for 7 days. All combinations of nisin and chemicals included in the experiment resulted in the reduction of approximately 3 log cycles for whole melon, whereas when tested alone, all compounds, along with water washes, were ineffective. None of the five combinations completely avoided the transfer of pathogen survivors to fresh-cut pieces. However, washing with the combination nisinsodium lactatepotassium sorbate was significantly more effective in inhibiting salmonellas than the other mixed solutions, but it was less acceptable in terms of appearance, odour and overall acceptability. A similar approach was used, a year later (Bari et al., 2005), to inhibit L. monocytogenes. Also in this case study, a five-strain cocktail of the pathogen object of study (L. monocytogenes ATCC 43256, ATCC 49594, JCM 7676, JCM 7672 and JCM 7671) was inoculated in fresh-cut vegetables and left at 25 C for 4 h before antimicrobial (individual or combined) treatments were applied. When tested alone, all compounds determined a reduction of about 24 log cycles. The combinations nisinphytic acid and nisinpediocinphytic acid caused significant reductions of L. monocytogenes on cabbage and broccoli, but not on mungbean sprouts. Furthermore, pediocin treatment alone or in combination with organic acids showed a stronger effect than nisin treatment alone. Although none of the treatments tested in the

two above works completely eliminated the pathogens arbitrarily added to the vegetables, the authors suggested that some treatments could be useful to improve the microbiological safety of fresh-cut vegetables. Regarding the use of mixed chemicals and nisin for reducing transfer of bacterial pathogens from whole melon surfaces to fresh-cut pieces, Ukuku et al. (2005) inoculated whole cantaloupes and honeydew melons with E. coli O157:H7 and L. monocytogenes at concentrations of approximately 35 log CFU/cm2 and incubated them at 5 C for 7 days. Whole melons at day 0 and 7 were subjected to antimicrobial [H2O2 (2.5%) alone or H2O2 (1%) in combination with nisin (25 g/ml), sodium lactate (1%), and citric acid (0.5%)] washing treatments and surviving bacterial populations and the numbers transferred to fresh-cut pieces were determined: the combination of inhibitors significantly reduced the numbers of both pathogens by 3 to 4 log CFU/cm2 on both types of whole melon and it was also found to be significantly more effective than treatment with 2.5% H2O2. The authors proposed the above mixture as a washing treatment to decontaminate whole melon surfaces and, thus, improve the microbial safety and quality of fresh-cut melons. Recently, Molinos et al. (2005) tested the effectiveness of immersion solutions containing enterocin AS-48 for decontamination of raw vegetables. In particular, the authors focused on the application of immersion solutions alone or in combination with chemical preservatives to inhibit L. monocytogenes CECT 4032 growth on fresh green asparagus and alfalfa and soybean sprouts. L. monocytogenes CECT 4032 was inoculated onto fresh vegetables at a concentration ranging from 4.69 to 4.72 log CFU/g. Each produce was immersed for 5 min at room temperature in solutions containing 25 g/ml of enterocin AS-48. In case of alfalfa and soybean sprouts, L. monocytogenes counts were reduced of 2.02.4 log CFU/g compared to a control immersion treatment in distilled water, while the treatment showed a limited effect when applied on green asparagus. However, during storage, L. monocytogenes viable counts were reduced below the detection limits at days 1 to 7 not only for alfalfa and soybean sprouts at 6 and 15 C, but also for green asparagus at 15 C. At 22 C the inhibition of L. monocytogenes CECT 4032 on alfalfa sprouts and green asparagus was not significant. Treatment with solutions containing enterocin AS-48 and chemicals such as lactic acid, sodium lactate, sodium nitrite, sodium nitrate, trisodium phosphate, trisodium trimetaphosphate, sodium thiosulphate, n-propyl p-hydroxybenzoate, p-hydoxybenzoic acid methyl ester, hexadecylpyridinium chloride, peracetic acid, or sodium hypochlorite reduced L. monocytogenes viable counts below the detection limits and significant increases of antimicrobial activity were found for AS-48 in some combination with potassium permanganate, acetic acid, citric acid, sodium propionate, and potassium sorbate. 5.2.6. Zucchini pure Endospore-forming bacteria, especially Bacillus spp., represent the main bacterial population of vegetable pures (Carlin et al., 2000). On the basis of a study reporting on Bacillus macroides/Bacillus maroccanus as being favoured in zucchini pure stored at 4 C (Guinebretiere et al., 2001), Garca et al.

L. Settanni, A. Corsetti / International Journal of Food Microbiology 121 (2008) 123138

133

(2004) studied the effectiveness of enterocin EJ97 to inhibit strains (INRA P51-5 and INRA P53-2) of zucchini pure origin belonging to the above species. The bacteriocin had a bactericidal effect on strain INRA P53-2 (chosen as test organism on the basis of its higher sensitivity to enterocin EJ97 with respect to strain INRA P51-5) after several incubation conditions (4 h at 37 C, 24 h at 15 C and 48 h at 4 C); its activity was reduced at pH 5.0 and 9.0 and enhanced by sodium nitrite, sodium benzoate, sodium lactate and sodium tripolyphosphate. The in situ efficacy of pure enterocin EJ97 was obtained with a 10-fold higher concentration, whereas no inhibition of strain INRA P532 was detected with the application of E. faecalis EJ97 as a developing bacterium in pure, although it was able to produce the bacteriocin in situ. Thus, the enterocin EJ97 has a potential to preserve food spoiled by B. macroides/B. maroccanus if used in concentrated pure form. 6. Combined effect of pure bacteriocins and bacteriocin-producing strains Schillinger et al. (2001) studied the potential of nisin in combination with bacteriocinogenic LAB (E. faecium BFE 9006a, Lactobacillus sakei Lb 706-1a and L. lactis BFE 902) in the preservation of highly perishable food products, in order to confirm their previous observation of the enhancement of the anti-listerial efficacy of nisin by combination with a bacteriocinogenic protective culture in a laboratory medium at 30 C (Schillinger et al., 1998). Tofu, a non-fermented soybean product consumed in Far-Eastern countries which may allow the growth of L. monocytogenes at refrigeration temperatures, was chosen as the test food system. The efficacy of nisin against Listeria spp. may be compromised by the emergence of spontaneous nisin-resistant mutants. Tests performed in vitro demonstrated that E. faecium BFE 900-6a, L. sakei Lb 706-1a and L. lactis BFE 902 used as protective cultures in combination with nisin were able to suppress the proliferation of L. monocytogenes cells not killed by nisin at 10 C. Furthermore, when used in combination with live strains, lower amounts of nisin were required for an effective inhibition of L. monocytogenes Scott A. In particular, the combination nisin/E. faecium BFE 900-6a or nisin/L. lactis BFE 902 resulted in a complete suppression of L. monocytogenes growth in homemade tofu stored at 10 C for 1 week, whereas the combination nisin/L. sakei Lb 706-1a was found to be less effective and it did not prevent a slight increase of L. monocytogenes Scott A numbers during storage. In conclusion, the author found that when the protective culture is used in combination with nisin, L. monocytogenes is kept at a low level by nisin for several days, during which the protective culture can proliferate until reaching concentrations sufficient to suppress growth of survivors of nisin. 7. Application of non-LAB bacteriocinogenic strains In the last few years, the potential of starter cultures for controlling and safeguarding the fermentation of traditional fermented foods has been emphasised also with regard to nonLAB species (Beaumont, 2002). In particular, the benefits

through the use of non-LAB bacteriocinogenic starter cultures or co-cultures for the production of traditional fermented products, such as condiments, are mainly represented by improved safety, as compared to spontaneous and uncontrolled traditional fermentations; this assumes a basic significance in case of countries with poor hygienic conditions (Beaumont, 2002). Unlike majority of fermented foods in which LAB dominates, okpehe, a traditional Nigerian soup condiment produced from Prosopis africana seeds (Guill, Perr) Taub. (Sanni and Onilude, 1999), is mainly fermented by Bacillus spp., with B. subtilis being commonly isolated (Oguntoyinbo et al., 2007). Some strains of the species B. subtilis are, indeed, known as spoilage agents, e.g. wheat bread due to rope formation (Kirschner and Von Holy, 1989), or as cause of food-borne illness if present at levels over 105 CFU/g (Kramer and Gilbert, 1989). However, B. subtilis has been recently proposed as a starter culture for this kind of product (Oguntoyinbo et al., 2007). In that study, the selection of starter cultures for fermentation of P. africana seeds started from Bacillus and Enterococcus strains isolated from traditional okpehe. The choice of starter strains was then narrowed to two B. subtilis strains (BFE 5301 and BFE 5372), determined to be the best starter combination because of rapid growth, high amylolytic and proteolytic activities, high levels of polyglutamic acid production by strain BFE 5372, bacteriocin production by strain BFE 5301, as well as non-virulent characteristics. The employment of B. subtilis BFE 5372 alone produced okpehe with very good sensory characteristics, but it did not prevent the growth of B. cereus, hence the subtilisinproducing B. subtilis BFE 5301, which was able to delay B. cereus growth and showing poor proteinase activity and polyglutamic acid production, was used as a co-culture. Another example of the use of a non-LAB bacteriocin in food biopreservation is represented by variacin from Kocuria varians to control the growth of B. cereus in chilled dairy products (O'Mahony et al., 2001). 8. Future prospects With the growing consumer refusal of chemical additives to combat undesired bacterial growth in foods and beverages, there is a growing demand for alternative antimicrobial treatments and bacteriocins are well accepted natural means of selective microbial inhibition. Moreover, the increasing demand of minimal food processing is providing an opportunity for their widespread application. However, although many bacteriocins, such as lacticin 3147, pediocin PA-1, and enterocin AS-48, have been shown to exhibit a large spectrum of food applications, due to legal restrictions, nisin is still the sole bacteriocin permitted as biopreservative in the food industries of about 50 countries. The incidence of nisin-resistant mutants is determining novel strategies for the inhibition of nisin non-sensitive strains, basically represented by the combination of more bacteriocins or bacteriocins and bacteriocinogenic strains. In the latter strategy, in case of non-fermented foods, bacteriocinogenic strains have to be used as protective cultures. In the past, there had been a great attraction of food scientists towards the creation of bacterial strains exhibiting over expression

134

L. Settanni, A. Corsetti / International Journal of Food Microbiology 121 (2008) 123138

of bacteriocins by genetic manipulation (Horn et al., 1999) or the introduction of this character into eukaryotic organisms (Van Reenen et al., 2003). This branch of research is still on the increase. However, although particularly interesting, this strategy cannot represent an applicative future direction of research because of the restrictive legal regulations and the skeptical behaviour of consumers with regards to genetically modified organisms. In addition to the three approaches identified by Schillinger et al. (1996) as commonly used in the application of bacteriocins for biopreservation of foods (inoculation with bacteriocinogenic bacteria, adjunct in purified form and use of a product previously fermented with bacteriocinogenic bacteria as ingredient in food processing), a fourth recent food application of bacteriocins is represented by their binding to polymeric packaging. Up to date, this kind of bacteriocin application has been reported only for preserving foods of animal origin such as meat and poultry (Ming et al., 1997), frankfurters (Ercolini et al., 2006) and raw and pasteurized milk (Mauriello et al., 2005); from our perspective, it has a great potential as a biopreservation technology for vegetable origin foods as well. Lysozyme and nisin are both antimicrobial proteins effective against Gram-positive bacteria and their use in combination with chelating agents (e.g. EDTA) displays increased effectiveness against Gram-negative bacteria (Padgett et al., 1998). Furthermore, bacteriocins often have synergies with other treatments (Cleveland et al., 2001). Thus, bacteriocin-activated packaging films alone or in a hurdle technology program represent one of the most attractive directions of future research on vegetable food protection. 9. Conclusions The application of bacteriocins as biopreservatives for vegetable food matrices started approximately 20 years ago. In these years, a lot of studies have focused on the inhibition of spoilage and/or human pathogen bacteria vehiculated with vegetable foods and beverages by bacteriocins and their application appeared as a good alternative to chemical compounds and antibiotics. Whether deliberately added or produced in situ, bacteriocins have been found to play a defining role in the control of undesirable flora, as well as in the establishment of beneficial bacterial populations. However, the effect of bacteriocins, bacteriocinogenic strains or their combinations would not alleviate the practical food safety issues associated with a large variety of vegetable foods, e.g. they may be efficient only in a narrow pH range, which excludes their utilization in many food products. Thus, a single bacteriocin-based technique could fit with a single food matrix and its application should be tested on a product by product basis. Furthermore, it can be concluded that in addition to the traditional hurdle technology represented by low temperature and vacuum packaging or MAP, the exploitation of bacteriocinogenic cultures, as well as their pure bacteriocins holds a great potential for extension of shelf-life and improvement of microbiological safety of vegetable raw materials and final products.

Acknowledgement The authors wish to thank Dr. Elena Critaro (Library of the Agricultural Faculty-University of Teramo, Italy) for her valuable help in retrieving the bibliographic material. References

Abee, T., Krockel, L., Hill, C., 1995. Bacteriocins: modes of action and potentials in food preservation and control of food poisoning. International Journal of Food Microbiology 28, 169185. Abriouel, H., Valdivia, E., Glvez, A., Maqueda, M., 2001. Influence of physicochemical factors on the oligomerization and biological activity of bacteriocin AS-48. Current Microbiology 42, 8995. Aesen, I.M., Markussen, S., Mretr, T., Katla, T., Axelsson, L., Naterstad, K., 2003. Interactions of the bacteriocins sakacin P and nisin with food constituents. International Journal of Food Microbiology 87, 3543. Anderson, R.E., 1984. Growth and corresponding elevation of tomato juice pH by Bacillus coagulans. Journal of Food Science 49, 647649. Angulo, F.J., Getz, J., Taylor, J.P., Hendricks, K.A., Hatheway, C.L., Barth, S.S., Solomon, H.M., Larson, A.E., Johnson, E.A., Nickey, L.N., Reis, A.A., 1998. A large outbreak of botulism: the hazardous baked potato. Journal of Infective Disease 178, 172177. Atrih, A., Rekhif, N., Moir, A.J.G., Lebrihi, A., Lefebvre, G., 2001. Mode of action, purification and amino acid sequence of plantaricin C19, an antiListeria bacteriocin produced by Lactobacillus plantarum C19. International Journal of Food Microbiology 68, 93104. Barefoot, S.F., Klaenhammer, T.R., 1983. Detection and activity of lactacin B, a bacteriocin produced by Lactobacillus acidophilus. Applied and Environmental Microbiology 45, 18081815. Bari, M.L., Ukuku, D.O., Kawasaki, T., Inatsu, Y., Isshiki, K., Kawamoto, S., 2005. Combined efficacy of nisin and pediocin with sodium lactate, citric acid, phytic acid, and potassium sorbate and EDTA in reducing the Listeria monocytogenes population of inoculated fresh-cut produce. Journal of Food Protection 68, 13811387. Beaumont, M., 2002. Flavouring composition prepared by fermentation with Bacillus spp. International Journal of Food Microbiology 75, 189196. Bennik, M.H.J., Smid, E.J., Gorris, L.G.M., 1997. Vegetable-associated Pediococcus parvulus produces pediocin PA-1. Applied and Environmental Microbiology 63, 20742076. Bennik, M.H.J., van Overbeek, W., Smid, E.J., Gorris, L.G.M., 1999. Biopreservation in modified atmosphere stored mungbean sprouts: the use of vegetable-associated bacteriocinogenic lactic acid bacteria to control the growth of Listeria monocytogenes. Letters in Applied Microbiology 28, 226232. Beuchat, L.R., 1995. Pathogenic microorganisms associated with fresh produce. Journal of Food Protection 59, 204216. Borch, E., Kant-Muermans, M., Blixt, Y., 1996. Bacterial spoilage of meat and cured meat products. A review. International Journal of Food Microbiology 33, 103120. Breukink, E., 2006. A lesson in efficient killing from two-component lantibiotics. Molecular Microbiology 61, 271273. Caplice, E., Fitzgerald, G.F., 1999. Food fermentattions: role of microorganisms in food production and preservation. International Journal of Food Microbiology 50, 131149. Caridi, A., 2002. Selection of Escherichia coli-inhibiting strains of Lactobacillus paracasei subsp. paracasei. Journal of Industrial Microbiology and Biotechnology 29, 303308. Carlin, F., Guinebretiere, M.H., Choma, C., Pasqualini, R., Branconier, A., Nguyen-The, C., 2000. Spore-forming bacteria in commercial cooked, pasteurized and chilled vegetable pures. Food Microbiology 17, 153165. Castellano, P.H., Holzapfel, W.H., Vignolo, G.M., 2004. The control of Listeria innocua and Lactobacillus sakei in broth and meat slurry with the bacteriocinogenic strain Lactobacillus casei CRL705. Food Microbiology 21, 291298. Chen, H., Hoover, D.G., 2003. Bacteriocins and their food applications. Comprehensive Reviews in Food Science and Food Safety 2, 82100.

L. Settanni, A. Corsetti / International Journal of Food Microbiology 121 (2008) 123138 Choi, M.H., Park, Y.H., 2000. Selective control of lactobacilli in kimchi with nisin. Letters in Applied Microbiology 30, 173177. Cleveland, J., Montville, T.J., Nes, I.F., Chikindas, M.L., 2001. Bacteriocins: safe, natural antimicrobials for food preservation. International Journal of Food Microbiology 71, 120. Corsetti, A., Settanni, L., 2007. Lactobacilli in sourdough fermentation. Food Research International 40, 539558. Corsetti, A., Gobbetti, M., Rossi, J., Damiani, P., 1998. Antimould activity of sourdough lactic acid bacteria: identification of a mixture of organic acids produced by Lactobacillus sanfrancisco CB1. Applied Microbiology and Biotechnology 50, 253256. Corsetti, A., Settanni, L., Van Sinderen, D., 2004. Characterisation of bacteriocin-like inhibitory substances (BLIS) from sourdough lactic acid bacteria and evaluation of their in vitro and in situ activity. Journal of Applied Microbiology 96, 521534. Corsetti, A., Settanni, L., Braga, T.M., de Fatima Silva Lopes, M., Suzzi, G., in press. An investigation on the bacteriocinogenic potential of lactic acid bacteria associated with wheat (Triticum durum) kernels and non-conventional flours. LWT. Food Science and Technology. doi:10.1016/j.lwt.2007.07.022. Cotter, P.D., Hill, C., Ross, R.P., 2005. Bacteriocins: developing innate immunity for food. Nature Reviews 3, 777788. Daeschel, M.A., McGuire, J., 1995. Bactericidal surfaces and articles with attached bacteriocins. U.S. Patent No. 5,451,369. Deegan, L.H., Cotter, P.D., Hill, C., Ross, P., 2006. Bacteriocins: biological tools for bio-preservation and shelf-life extension. International Dairy Journal 16, 10581071. Degnan, A., Luchansky, J., 1992. Influence of beef tallow and muscle on the antilisterial activity of pediocin AcH and liposome-encapsulated pediocin AcH. Journal of Food Protection 55, 552554. De Vuyst, L., Vandamme, E.J., 1994. Bacteriocins of Lactic Acid Bacteria: Microbiology, Genetics and Applications. Blackie Academic and Professional, London. De Vuyst, L., Avonts, L., Neysens, P., Hoste, B., Vancanneyt, M., Swings, J., Callewaert, R., 2004. Applicability and performance of the bacteriocin producer Lactobacillus amylovorus DCE 471 in type II cereal fermentations. International Journal of Food Microbiology 90, 93106. Doan, C.H., Davidson, P.M., 2000. Microbiology of potatoes and potato products: a review. Journal of Food Protection 63, 668683. Drider, D., Fimland, G., Hchard, Y., McMullen, L.M., Prvost, H., 2006. The continuing story of class IIa bacteriocins. Microbiology and Molecular Biology Reviews 70, 564582. Ennahar, S., Sonomoto, K., Ishizaki, A., 1999. Class IIa bacteriocins from lactic acid bacteria: antibacterial activity and food preservation. Journal of Bioscience and Bioengineering 87, 705716. Ebine, H., 1984. Miso. In: Sato, S. (Ed.), Aging of Foods. Korin, Tokyo, pp. 255275. Ercolini, D., La Storia, A., Villani, F., Mauriello, G., 2006. Effect of a bacteriocin-activated polythene film on Listeria monocytogenes as evaluated by viable staining and epifluorescence microscopy. Journal of Applied Microbiology 100, 765772. Federal Register, 1988. Nisin preparation: affirmation of GRAS status as a direct human food ingredient. Federal Register 54, 1124711251. Fleming, H.P., Kyung, K.H., Breidt, F., 1995. Vegetable fermentation. In: Rehm, H.-J., Reed, G. (Eds.), Biotechnology, Enzymes, Biomass, Food and Feed. VCH Publishers, Weinheim, pp. 639659. Foulqui Moreno, M.R., Callewaert, R., Devreese, B., Van Beeumen, J., De Vuyst, L., 2003. Isolation and biochemical characterisation of enterocins produced by enterococci from different sources. Journal of Applied Microbiology 94, 214229. Franz, C.M.A.P., Schillinger, U., Holzapfel, W.H., 1996. Production and characterisation of enterocin 900, a bacteriocin produced by Enterococcus faecium BFE 900 from black olives. International Journal of Food Microbiology 29, 255270. Fukushima, D., 1981. Soy proteins for foods centering around soy sauce and tofu. Journal of American Oil Chemistry Society 58, 346354. Glvez, A., Gimnez-Gallego, G., Maqueda, M., Valdivia, E., 1989. Purification and amino acid composition of peptide antibiotic AS-48 produced by Streptococcus (Enterococcus) faecalis subsp. liquefaciens S-48. Antimicrobial Agents and Chemotherapy 33, 437441.

135

Gnzle, M., Weber, S., Hammes, W., 1999. Effect of ecological factors on the inhibitory spectrum and activity of bacteriocins. International Journal of Food Microbiology 46, 207217. Garca, M.T., Lucas, R., Abriouel, H., Ben Omar, N., Prez, R., Grande, M.J., Martnez-Caamero, M., Glvez, A., 2004. Antimicrobial activity of enterocin EJ97 against Bacillus macroides/Bacillus maroccanus isolated from zucchini pure. Journal of Applied Microbiology 97, 731737. Garde, S., Rodriguez, E., Gaya, P., Medina, M., Nunez, M., 2001. PCR detection of the structural genes of nisin Z and lacticin 481 in Lactococcus lactis subsp. lactis INIA 415, a strain isolated from raw milk Manchego cheese. Biotechnology Letters 23, 8589. Garneau, S., Martin, N.I., Vederas, J.C., 2002. Two-peptide bacteriocins produced by lactic acid bacteria. Biochimie 84, 577592. Gould, G.W., 1995. Biodeterioration of foods and an overview of preservation in the food and dairy industries. International Biodeterioration and Biodegradation 36, 267277. Grande, M.J., Lucas, R., Valvidia, E., Abriouel, H., Maqueda, M., Ben Omar, N., Martnez-Caamero, M., Glvez, A., 2005a. Stability of enterocin AS-48 in fruit and vegetable juices. Journal of Food Protection 68, 20852094. Grande, M.J., Lucas, R., Abriouel, H., Ben Omar, N., Maqueda, M., MartnezBueno, M., Martnez-Caamero, M., Valvidia, E., Glvez, A., 2005b. Control of Alicyclobacillus acidoterrestris in fruit juices by enterocin AS48. International Journal of Food Microbiology 104, 289297. Grande, M.J., Lucas, R., Abriouel, H., Valvidia, E., Ben Omar, N., Maqueda, M., Martnez-Caamero, M., Glvez, A., 2006. Inhibition of Bacillus licheniformis LMG 19409 from ropy cider by enterocin AS-48. Journal of Applied Microbiology 101, 422428. Guinane, C.M., Cotter, P.D., Hill, C., Ross, R.P., 2005. Microbial solutions to microbial problems; lactococcal bacteriocins for the control of undesirable biota in food. Journal of Applied Microbiology 98, 13161325. Guinebretiere, M.H., Berge, O., Normand, P., Morris, C., Carlin, F., NguyenThe, C., 2001. Identification of bacteria in pasteurized zucchini pures stored at different temperatures and comparison with those found in other pasteurized vegetable pures. Applied and Environmental Microbiology 76, 45204530. Harris, L.J., Fleming, H.P., Klaenhammer, T.R., 1992. Novel paired starter culture system for sauerkraut, consisting of a nisin-resistant Leuconostoc mesenteroides strain and a nisin-producing Lactococcus lactis strain. Applied and Environmental Microbiology 58, 14841489. Hltzel, A., Gnzle, M.G., Nicholson, G.J., Hammes, W.P., Jung, G., 2000. The first low-molecular-weight antibiotic from lactic acid bacteria: reutericyclin, a new tetrameric acid. Angewandte Chemie International Edition 39, 27662768. Holzapfel, W.H., Geisen, R., Schillinger, U., 1995. Biological preservation of foods with reference to protective cultures, bacteriocins and food-grade enzymes. International Journal of Food Microbiology 24, 343362. Horn, N., Martinez, M.I., Martinez, J.M., Hernandez, P.E., Gasson, M.J., Rodriguez, J.M., Dodd, H.M., 1999. Enhanced production of pediocin PA-1 and co-production of nisin and pediocin PA-1 by Lactococcus lactis ssp. lactis. Applied and Environmental Microbiology 65, 44434450. Jamuna, M., Babusha, S.T., Jeevaratnam, K., 2005. Inhibitory efficacy of nisin and bacteriocins from Lactobacillus isolates against food spoilage and pathogenic organisms in model and food systems. Food Microbiology 22, 449454. Jimnez-Daz, R., Ros-Snchez, R.M., Desmazeaud, M., Ruiz-Barba, J.L., Piard, J.-C., 1993. Plantaricin S and T, two new bacteriocins produced by Lactobacillus plantarum LPCO10 isolated from a green olive fermentation. Applied and Environmental Microbiology 59, 14161424. Jung, D.-S., Bodyfelt, F., Daeschel, M., 1992. Influence of fat and emulsifiers on the efficiency of nisin in inhibiting Listeria monocytogenes in fluid milk. Journal of Dairy Science 75, 387393. Kato, T., Maeda, K., Kasuya, H., Matsuda, T., 1999. Complete growth inhibition of Bacillus subtilis by nisin-producing lactococci in fermented soybeans. Bioscience, Biotechnology and Biochemistry 63, 642647. Kato, T., Inuzuka, L., Kondo, M., Matsuda, T., 2001. Growth of nisin-producing lactococci in cooked rice supplemented with soybean extract and its application to the inhibition of B. subtilis in rice miso. Bioscience, Biotechnology and Biochemistry 65, 330337.

136