Professional Documents

Culture Documents

5S - Daily Checklist Da

Uploaded by

Anonymous zXWxWmgZEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5S - Daily Checklist Da

Uploaded by

Anonymous zXWxWmgZECopyright:

Available Formats

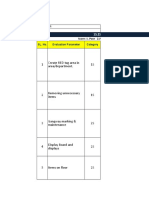

5S Daily Checklist- WORK AREA

Items 1 2 3 4 5

( 5S- SORT, SET, SHINE, STANDARDISE, SUSTAIN)

6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27

Month:

28 29 30 31

1. Team leader's table clean, no unnecessary things present 2. All cells clean, waste bins empty & located in designated spot. 3. All packing tables clean as per photo displayed

4. Brooms present on every table 5. All unused fans/heaters & lights turned OFF 6. All cardboard waste dumped in master bin outside 7. Drilling machine table & surrounding area clean 8. All pallets/trolleys sitting in designated area

9. All aisles are clean 10. Bins & bin lifter sits on green designated spot 11. Check if electric connection for ANDON lights, sealer, weigh balance are swithced off at the end of shift. 12. Bins to be refilled by warehouse dropped off at warehouse pick up point 13. No items on EXIT way and near power line

Date Opened

5S needs and requirements

Select Code: M= Machine, E= Equipment, T= Tools, C= Consumables, R= Raw Material, I= Information

Actions Taken

Responsibility

Date Closed

Status

Instruction: This Daily 5 S Checklist has to be done by area team leader or designate. Tick box if all good else put a cross X in the respective box. Mention any needs or requirements in the space provided. CODE: Machine: Any mechanical device used to manufacture product Equipment: Tables, benches etc Consumable: Any item, other than raw materials, consumed in the job Raw material: Items that make up in the finished product. Information: Information required to perform tasks.

You might also like

- BF Area - 5S Check ListDocument30 pagesBF Area - 5S Check ListVi KraNo ratings yet

- 6S in HealthcareDocument13 pages6S in HealthcareChannel MedicalNo ratings yet

- 5S For OfficesDocument3 pages5S For OfficesckopoletoNo ratings yet

- 5S (Methodology) - WikipediaDocument4 pages5S (Methodology) - WikipediaBORRELNo ratings yet

- 5S Productivity ManagementDocument28 pages5S Productivity Managementloryn_dungca2031No ratings yet

- 5S Implementation Manual Part 2Document63 pages5S Implementation Manual Part 2jgprasadNo ratings yet

- Lesson 1 - From Waste To Wealth - Session 2 WorksheetDocument1 pageLesson 1 - From Waste To Wealth - Session 2 WorksheetNicole Angela NavarroNo ratings yet

- Incentive Scheme: Muzzammil Sheriff M App SSE/Electrical/General Service GOC Workshop, Ponmalai, TrichyDocument31 pagesIncentive Scheme: Muzzammil Sheriff M App SSE/Electrical/General Service GOC Workshop, Ponmalai, TrichyMUZZAMMILSHERIFFNo ratings yet

- Basic Concepts On 5s Kaizen TQMDocument19 pagesBasic Concepts On 5s Kaizen TQMRodj Eli Mikael Viernes-IncognitoNo ratings yet

- Office 5S ChecklistDocument15 pagesOffice 5S ChecklistAkhilesh Yadav100% (1)

- Quality CircleDocument33 pagesQuality CircleveenapeterNo ratings yet

- Quiz Answers Standard WorkDocument4 pagesQuiz Answers Standard WorkJose OrtegaNo ratings yet

- Ciencia Y Virtud: The 7SDocument11 pagesCiencia Y Virtud: The 7SElle DyNo ratings yet

- 5s Basic TrainingDocument14 pages5s Basic Trainingsachin_bharti92% (13)

- Great Place To WorkDocument18 pagesGreat Place To WorkRamakant SuroliaNo ratings yet

- KaizenDocument18 pagesKaizenshazin_s100% (2)

- 5s Basic Training PPT 204Document15 pages5s Basic Training PPT 204Sheila Ibay VillanuevaNo ratings yet

- CANDO Pillar Audit Check SheetDocument2 pagesCANDO Pillar Audit Check SheetharpreetmuditNo ratings yet

- TPM OverviewDocument13 pagesTPM OverviewjesusmemNo ratings yet

- Key HR Audit TemplateDocument4 pagesKey HR Audit Templatezahoor80No ratings yet

- 4a Quiz StraightenDocument2 pages4a Quiz StraightenJose Ortega0% (1)

- 5S - Levels of ExcellenceDocument2 pages5S - Levels of ExcellenceHartoyo SwiNo ratings yet

- What Is The 5S MethodologyDocument8 pagesWhat Is The 5S MethodologydwaNo ratings yet

- World Class Manufacturing ManagementDocument2 pagesWorld Class Manufacturing ManagementShashank BurdeNo ratings yet

- The Lean Stack - Part 1Document15 pagesThe Lean Stack - Part 1iNFuT™ - Institute for Future TechnologyNo ratings yet

- Manufacturing Team Leader Generic JDDocument4 pagesManufacturing Team Leader Generic JDTaufiq KimasNo ratings yet

- 5 SDocument7 pages5 SLokesh DahiyaNo ratings yet

- 7QC Tools - Training WorkshopDocument10 pages7QC Tools - Training Workshopb-consultant960No ratings yet

- 20170927090928talent Management W2Document19 pages20170927090928talent Management W2Bum MieNo ratings yet

- Yamazumi Process Modeling Tool by ISDDocument4 pagesYamazumi Process Modeling Tool by ISDIndra SetiawanNo ratings yet

- Eronomics and Flexible WorkingDocument23 pagesEronomics and Flexible WorkingSohaib KhanNo ratings yet

- 5S Audit Checklist Template1Document4 pages5S Audit Checklist Template1Mohamed Ali SalemNo ratings yet

- WAAREE Energies PVT Ltd-LatestDocument40 pagesWAAREE Energies PVT Ltd-LatestJp Gupta100% (2)

- Lean Six Sigma: DMAIC Model By: Manufacturing Practice LabDocument17 pagesLean Six Sigma: DMAIC Model By: Manufacturing Practice LabLean Six Sigma TrainingNo ratings yet

- Enterprise Dynamics TutorialDocument66 pagesEnterprise Dynamics TutorialBaracNo ratings yet

- NA NA NA: 4.08 Days AnnualizedDocument8 pagesNA NA NA: 4.08 Days AnnualizeddarulilmNo ratings yet

- 5S PresentationDocument31 pages5S PresentationManoj Pandey100% (2)

- 20 Steps For Manufacturing ExcellenceDocument2 pages20 Steps For Manufacturing ExcellenceDharmvir UppalNo ratings yet

- Five S Implementation: SORT (Clearing Up Space) OrganizationDocument8 pagesFive S Implementation: SORT (Clearing Up Space) OrganizationDONNo ratings yet

- 5S MethodologyDocument2 pages5S MethodologyEmeth TeoNo ratings yet

- Presentation On House Keeping TechniquesDocument82 pagesPresentation On House Keeping TechniquesJanak DoshiNo ratings yet

- 5sevaluation Radar ChartDocument2 pages5sevaluation Radar ChartMichelle Morgan LongstrethNo ratings yet

- Maintain Training Facilities: Submitted By: Aeron M. LumbaDocument10 pagesMaintain Training Facilities: Submitted By: Aeron M. LumbaAeron LumbaNo ratings yet

- 5s Evaluation Form - EnglishDocument5 pages5s Evaluation Form - Englisharun7sharma78No ratings yet

- 5s Check List MakeDocument30 pages5s Check List MakeAl Arafat Rumman100% (2)

- Equipment Type Equipment Code Location Operation ProcedureDocument18 pagesEquipment Type Equipment Code Location Operation ProcedureAnonymous qXvorZGdNo ratings yet

- Presentation 6 S STARTER TrainingDocument96 pagesPresentation 6 S STARTER Trainingm_ramas2001No ratings yet

- Contact Center Services Housekeeping ScheduleDocument2 pagesContact Center Services Housekeeping ScheduleJoy Celestial50% (2)

- March Week 1Document60 pagesMarch Week 1Agnes AnggitNo ratings yet

- Maintain Training FacilitiesDocument11 pagesMaintain Training FacilitiesRichard Jumalon100% (3)

- 1s, 2s & 5S Audit SheetDocument5 pages1s, 2s & 5S Audit SheetKhushboo Gupta100% (5)

- 5S Audit FormDocument2 pages5S Audit Formsigmasundar100% (1)

- 5s Audit PlanDocument3 pages5s Audit PlansomuanindianNo ratings yet

- 5 S Presentation Basic TrainingDocument82 pages5 S Presentation Basic TrainingEmman Bosito100% (1)

- 5 S Check ListDocument6 pages5 S Check ListWaqar LatifNo ratings yet

- 5s Audit ChecklistDocument22 pages5s Audit ChecklistJeevaAJAnanthanNo ratings yet

- Shopfloor 5S Evaluation Checklist: Observations Check ItemsDocument3 pagesShopfloor 5S Evaluation Checklist: Observations Check Itemsmuthuswamy77No ratings yet

- Maintain Training FacilitiesDocument14 pagesMaintain Training FacilitiesGlenna Camat TomasNo ratings yet

- Maintain - Training - Facilities Muah MuahDocument19 pagesMaintain - Training - Facilities Muah MuahSalvador MiraNo ratings yet

- MTF AssessmentDocument3 pagesMTF AssessmentGaygo GaygoNo ratings yet