Professional Documents

Culture Documents

Description - Docx Valve

Uploaded by

ChusnadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Description - Docx Valve

Uploaded by

ChusnadiCopyright:

Available Formats

Description Specifications Documentation

Premium performance, direct spring operated pressure relief valves use special internals and soft seats to provide optimum, accurate performance.

Features & Benefits: Soft seat design as standard. Helps provide repeatable leak-tight performance before and after each relief cycle. Leak-tight performance near set pressure. Allows higher operating pressure, resulting in increased process throughput and system optimization. Replaceable soft seat and seals. Easy seat and seal replacement, compared to refurbishment (no expensive, time consuming lapping of metal components) results in lower long-term maintenance costs. External adjustable blowdown (Types 81/83/86). Allows for precise adjustment of reseat pressure without affecting set pressure adjustment. Adjustment does not require access to valve internal trim, blowdown can be adjusted with valve in service, helping eliminate the need for costly removal and/or system shut down. Full lift at set pressure (Types 81/83/86). No overpressure required for full lift. Minimizes possibility of freeze-up in applications involving a cryogenic or refrigerant and allows for D.O.T. applications to be set higher than Maximum Allowable Operating Pressure (MAOP). Balanced spindle design (Type 81P). Balanced against the effects of back pressure without the use of a bellows, reducing cost of both the initial valve purchase and associated long-term maintenance. Meets ASME Section VIII requirements. Provides the user third-party verification of valve capacity and performance.

Types 81, 83, 86 Safety Valves The Type 81 direct spring operated safety valve, with an inert plastic seat, is suitable for a wide range of products, pressures, and temperatures involving gas, vapor, and liquid or gas thermal relief applications. It allows maintained tightness close to set pressure, opens fully at set pressure, and provides a safe, external adjustment for short blowdown. The Type 81 valve is best suited for cryogenic, high set pressure, and chemically active applications.

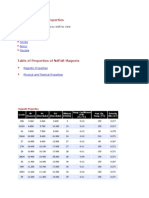

Orifice Sizes: 0.049 in [0.32 cm] and D through J Connections: 1/2 x 3/4 to 2 x 3 Inlet Flange Ratings: ANSI 150, 300, 600, 900, 1500, 2500 Maximum Temperature: 550F [288C] Minimum Pressure: 20 psig [1.4 barg] Maximum Pressure: 10,000 psig [690 barg] Type 81P Relief Valve for Liquid Service Type 81P Relief Valve The Type 81P is a soft-seated, balanced, direct spring operated pressure relief valve intended for liquid applications. This valve is rated at full capacity at 10 percent overpressure and meets the latest requirements of Section VIII, Division 1 of the ASME Unfired Pressure Vessel Code. Orifice Sizes: 0.049 in [0.32 cm] and E, G and J Connections: 3/4 x 1 to 2 x 3 Inlet Flange Ratings: ANSI 150, 300, 600, 900, 1500, 2500 Maximum Temperature: 400F [204C] Minimum Pressure: 50 psig [3.4 barg] Maximum Pressure: 6,000 psig [414 barg]

Filter By:

Document Type

Document Type

English

English 1 Last Technical Data Sheets Anderson Greenwood Series 80 Direct Spring Safety Valves (English)

Download | E-mail Document

Installation & Maintenance Instructions Anderson Greenwood Type 81P SOPRV Installation and Maintenance Instructions (English)

Download | E-mail Document

Installation & Maintenance Instructions Anderson Greenwood Type 83 SOPRV Installation and Maintenance Instructions (English)

Download | E-mail Document

Installation & Maintenance Instructions Anderson Greenwood Type 86 SOSRV Installation and Maintenance Instructions (English)

Download | E-mail Document

Installation & Maintenance Instructions Anderson Greenwood Type 89 Safety Relief Valve Maintenance Instructions (English)

Download | E-mail Document

Installation & Maintenance Instructions Anderson Greenwood Type 81 SOPRV Maintenance Instructions (English)

Download | E-mail Document

1 Last

Series 80 Direct Spring Safety Valve

Description Specifications Documentation

Premium performance, direct spring operated pressure relief valves use special internals and soft seats to provide optimum, accurate performance.

Features & Benefits: Soft seat design as standard. Helps provide repeatable leak-tight performance before and after each relief cycle. Leak-tight performance near set pressure. Allows higher operating pressure, resulting in increased process throughput and system optimization. Replaceable soft seat and seals. Easy seat and seal replacement, compared to refurbishment (no expensive, time consuming lapping of metal components) results in lower long-term maintenance costs. External adjustable blowdown (Types 81/83/86). Allows for precise adjustment of reseat pressure without affecting set pressure adjustment. Adjustment does not require access to valve internal trim, blowdown can be adjusted with valve in service, helping eliminate the need for costly removal and/or system shut down. Full lift at set pressure (Types 81/83/86). No overpressure required for full lift. Minimizes possibility of freeze-up in applications involving a cryogenic or refrigerant and allows for D.O.T. applications to be set higher than Maximum Allowable Operating Pressure (MAOP). Balanced spindle design (Type 81P). Balanced against the effects of back pressure without the use of a bellows, reducing cost of both the initial valve purchase and associated long-term maintenance. Meets ASME Section VIII requirements. Provides the user third-party verification of valve capacity and performance.

Types 81, 83, 86 Safety Valves The Type 81 direct spring operated safety valve, with an inert plastic seat, is suitable for a wide range of products, pressures, and temperatures involving gas, vapor, and liquid or gas thermal relief applications. It allows maintained tightness close to set pressure, opens fully at set pressure, and provides a safe, external adjustment for short blowdown. The Type 81 valve is best suited for cryogenic, high set pressure, and chemically active applications. Orifice Sizes: 0.049 in [0.32 cm] and D through J Connections: 1/2 x 3/4 to 2 x 3 Inlet Flange Ratings: ANSI 150, 300, 600, 900, 1500, 2500 Maximum Temperature: 550F [288C] Minimum Pressure: 20 psig [1.4 barg] Maximum Pressure: 10,000 psig [690 barg] Type 81P Relief Valve for Liquid Service Type 81P Relief Valve The Type 81P is a soft-seated, balanced, direct spring operated pressure relief valve intended for liquid applications. This valve is rated at full capacity at 10 percent overpressure and meets the latest requirements of Section VIII, Division 1 of the ASME Unfired Pressure Vessel Code. Orifice Sizes: 0.049 in [0.32 cm] and E, G and J Connections: 3/4 x 1 to 2 x 3 Inlet Flange Ratings: ANSI 150, 300, 600, 900, 1500, 2500 Maximum Temperature: 400F [204C] Minimum Pressure: 50 psig [3.4 barg] Maximum Pressure: 6,000 psig [414 barg]

Series 60 Direct Spring Safety Valve

Description Specifications Documentation

The Types 61 and 63B are direct spring operated safety valves suitable for medium set pressure gas, vapor, and liquid or gas thermal relief applications. Brass construction offers an economical valve for carbon dioxide, natural gas, and general gas or vapor services. The Type 61 is also suitable for cryogenic and chemically active applications.

Features & Benefits: Soft seat design as standard. Helps provide repeatable leak-tight performance before and after each relief cycle. Leak-tight performance near set pressure. Allows higher operating pressure, resulting in increased process throughput and system optimization. Replaceable soft seat and seals. Easy seat and seal replacement, compared to refurbishment (no expensive, time consuming lapping of metal components) results in lower long-term maintenance costs. Meets ASME Section VIII requirements. Provides the user third-party verification of valve capacity and performance.

Sizes: 1/2" x 1" to 3/4" x 1" Orifices: 0.077 to 0.150 in2 [0.497 to 0.968 cm2] Connections: NPT Temperature Range: -320 to 400F [-196 to +205C] Set Pressures: 30 to 531 psig [2.07 to 36.6 barg] Code: ASME VIII

Filter By:

Document Type

Document Type

English

English

Last Technical Data Sheets Anderson Greenwood Series 60 Direct Spring Safety Valves (English)

Download | E-mail Document

Installation & Maintenance Instructions Anderson Greenwood Type 63 SOPRVs Maintenance Instructions For Type 63 Spring Operated Pressure Relief Valves (English)

Download | E-mail Document

Installation & Maintenance Instructions Anderson Greenwood Type 61 SOPRVs Maintenance Instructions For Type 61 Spring Operated Pressure Relief Valves (English)

Download | E-mail Document

Last

Description Specifications Documentation

The Types 61 and 63B are direct spring operated safety valves suitable for medium set pressure gas, vapor, and liquid or gas thermal relief applications. Brass construction offers an economical valve for carbon dioxide, natural gas, and general gas or vapor services. The Type 61 is also suitable for cryogenic and chemically active applications.

Features & Benefits: Soft seat design as standard. Helps provide repeatable leak-tight performance before and after each relief cycle. Leak-tight performance near set pressure. Allows higher operating pressure, resulting in increased process throughput and system optimization. Replaceable soft seat and seals. Easy seat and seal replacement, compared to refurbishment (no expensive, time consuming lapping of metal components) results in lower long-term maintenance costs. Meets ASME Section VIII requirements. Provides the user third-party verification of valve capacity and performance.

Sizes: 1/2" x 1" to 3/4" x 1" Orifices: 0.077 to 0.150 in2 [0.497 to 0.968 cm2] Connections: NPT Temperature Range: -320 to 400F [-196 to +205C] Set Pressures: 30 to 531 psig [2.07 to 36.6 barg] Code: ASME VIII

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Behavior Theory ABC Model by Thomas KrausDocument28 pagesBehavior Theory ABC Model by Thomas KrausChusnadiNo ratings yet

- 09 - ROMVEC HSE Management System ManualDocument11 pages09 - ROMVEC HSE Management System ManualBebe Bucătaru100% (1)

- I. MANUAL PURPOSE (Revision 2)Document21 pagesI. MANUAL PURPOSE (Revision 2)VyacheslavNo ratings yet

- Tank Farm OperationsDocument13 pagesTank Farm OperationsRahul KumarNo ratings yet

- Gas Detector Bump Test Record Log Sheet: Bump Test Result Test Date Time Pass Fail Retest Pass Retest Fail Tester NameDocument2 pagesGas Detector Bump Test Record Log Sheet: Bump Test Result Test Date Time Pass Fail Retest Pass Retest Fail Tester NameAndry Kurnia100% (2)

- Catalogo 2010 en PDFDocument278 pagesCatalogo 2010 en PDFTuấn QuáchNo ratings yet

- Design of Pressure VesselDocument137 pagesDesign of Pressure VesselAnand Bhandarkar75% (4)

- Desarmado de La Transmision de Motoniveladora SERIE HDocument221 pagesDesarmado de La Transmision de Motoniveladora SERIE Hluisitolokitod100% (1)

- API 2000 Spread SheetDocument43 pagesAPI 2000 Spread Sheetjagan100% (3)

- Problem, Failure and Safety Analysis of Ammonia Plant-A ReviewDocument16 pagesProblem, Failure and Safety Analysis of Ammonia Plant-A ReviewATUL SONAWANE67% (3)

- Buku PUIL Keselamatan Dan Pemasangan Instalasi Listrik Voltase RendahDocument240 pagesBuku PUIL Keselamatan Dan Pemasangan Instalasi Listrik Voltase Rendahlamenty55100% (1)

- Handbooks Alternatif Dari PriyatnoDocument1 pageHandbooks Alternatif Dari PriyatnoChusnadiNo ratings yet

- Civil Engineering BooksDocument1 pageCivil Engineering BooksChusnadiNo ratings yet

- How To Use A Wire MeasuringDocument2 pagesHow To Use A Wire MeasuringChusnadiNo ratings yet

- Safety Engineering IIDocument2 pagesSafety Engineering IIChusnadiNo ratings yet

- 1 Inspection Report Dump Truck Da 1038 LaDocument2 pages1 Inspection Report Dump Truck Da 1038 LaChusnadiNo ratings yet

- Automotive Ebooks YahoooDocument2 pagesAutomotive Ebooks YahoooChusnadiNo ratings yet

- 21 Juli 2014 Sub Sea Construction TestDocument1 page21 Juli 2014 Sub Sea Construction TestChusnadiNo ratings yet

- 15 Juli 2014 InspectorDocument3 pages15 Juli 2014 InspectorChusnadiNo ratings yet

- Welding Standard For Formula StudentDocument1 pageWelding Standard For Formula StudentChusnadiNo ratings yet

- Design GuideDocument29 pagesDesign GuideChusnadiNo ratings yet

- Magnet Materials PropertiesDocument6 pagesMagnet Materials PropertiesChusnadiNo ratings yet

- Marine Safety Guidance Marine Engineering Practice Series Vol 1 Part 5Document1 pageMarine Safety Guidance Marine Engineering Practice Series Vol 1 Part 5ChusnadiNo ratings yet

- Mechanical Inspector Course e LearningDocument1 pageMechanical Inspector Course e LearningChusnadiNo ratings yet

- Fatality Assessment and Control EvaluationDocument2 pagesFatality Assessment and Control EvaluationChusnadiNo ratings yet

- Safety Health and Environmental EbookDocument1 pageSafety Health and Environmental EbookChusnadiNo ratings yet

- MSA American Eagle V-Gard Freedom Series Hard Cap With Fas-Trac SuspensionDocument2 pagesMSA American Eagle V-Gard Freedom Series Hard Cap With Fas-Trac SuspensionChusnadiNo ratings yet

- Mechanical Engineering Books 29 April 2014Document1 pageMechanical Engineering Books 29 April 2014ChusnadiNo ratings yet

- Code Buckling PlateDocument6 pagesCode Buckling PlateChusnadiNo ratings yet

- Construction Risk Strategist ConferenceDocument2 pagesConstruction Risk Strategist ConferenceChusnadiNo ratings yet

- Oq &gs - L : Orleans, LA. Cincinnati, OH: U.S. Department of Health, Education, and Welfare, Public Health ServiceDocument3 pagesOq &gs - L : Orleans, LA. Cincinnati, OH: U.S. Department of Health, Education, and Welfare, Public Health ServiceChusnadiNo ratings yet

- 95 Members: Kegiatan para Alumni SMA TRIMURTI..Document1 page95 Members: Kegiatan para Alumni SMA TRIMURTI..ChusnadiNo ratings yet

- Chassis Stiffness CalculationDocument1 pageChassis Stiffness CalculationChusnadiNo ratings yet

- Modern Safety Management 2 Juli 2014Document2 pagesModern Safety Management 2 Juli 2014ChusnadiNo ratings yet

- Below Hooks 19 June 2014Document4 pagesBelow Hooks 19 June 2014ChusnadiNo ratings yet

- Crystal Growth Technology: K. Byrappa T. Ohachi (Eds.)Document8 pagesCrystal Growth Technology: K. Byrappa T. Ohachi (Eds.)ChusnadiNo ratings yet

- Index of Materials Science and Engineering HandbookDocument1 pageIndex of Materials Science and Engineering HandbookChusnadiNo ratings yet

- Popov E P, Mechanical of Material, Prentice Hall, Inc. 1952 Mechanical of Material by Popov E.P, Prentice Hall Inc 1952Document1 pagePopov E P, Mechanical of Material, Prentice Hall, Inc. 1952 Mechanical of Material by Popov E.P, Prentice Hall Inc 1952ChusnadiNo ratings yet

- PR LC Lfa e PDFDocument68 pagesPR LC Lfa e PDFmanjappahNo ratings yet

- Centrifugal Pump ScriptDocument2 pagesCentrifugal Pump Scriptcgjp120391No ratings yet

- AKV Valvulas Expansion ElectronicaDocument16 pagesAKV Valvulas Expansion ElectronicaWilder VilcaNo ratings yet

- Pump Characteristic Curves .Document3 pagesPump Characteristic Curves .sgrsthNo ratings yet

- D 3154 - 91 R95 - RdmxntqtukveDocument15 pagesD 3154 - 91 R95 - RdmxntqtukveAnilNo ratings yet

- Cargo Ballast Pumps - HTMLDocument5 pagesCargo Ballast Pumps - HTMLstamatisNo ratings yet

- Evaporators - Agitated Thin Film Evaporators Manufacturer From Faridabad - 2018Document11 pagesEvaporators - Agitated Thin Film Evaporators Manufacturer From Faridabad - 2018Viviana E. MesaNo ratings yet

- Vdocuments - MX - Api 612 Latest Edition 612 Latest Editionpdf Free Download Here Api Standard PDFDocument2 pagesVdocuments - MX - Api 612 Latest Edition 612 Latest Editionpdf Free Download Here Api Standard PDFNeeraj JangidNo ratings yet

- Midea 10 HP CatalogueDocument10 pagesMidea 10 HP Cataloguethanh longNo ratings yet

- ''atlantis'' Type: Submersible Pumps / ''ατλαντίς'' Υποβρύχιες ΑντλίεςDocument23 pages''atlantis'' Type: Submersible Pumps / ''ατλαντίς'' Υποβρύχιες ΑντλίεςStefanos GrammenosNo ratings yet

- Lab 2 HydraulicDocument7 pagesLab 2 Hydraulicohoodalfowdaie123No ratings yet

- TE's DescriptionDocument10 pagesTE's DescriptionsadiqNo ratings yet

- Rectisol - LindeDocument5 pagesRectisol - Lindevenkatr1No ratings yet

- Gas StoichiometryDocument17 pagesGas StoichiometryJamless ChimChimNo ratings yet

- Vitodens 200-b2hb SM TDMDocument52 pagesVitodens 200-b2hb SM TDMMartin GarciaNo ratings yet

- Fleet Vessels CKP Questionnaire Data Base For 1st AE in 2012Document6 pagesFleet Vessels CKP Questionnaire Data Base For 1st AE in 2012IgorNo ratings yet

- CHAPTER 14 Cabin Atmosphere Control PDFDocument47 pagesCHAPTER 14 Cabin Atmosphere Control PDFchris laskyNo ratings yet

- Chapter 27: Physical Properties Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocument23 pagesChapter 27: Physical Properties Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HalljnmanivannanNo ratings yet

- UNIT 8 - Natural Gas BusinessDocument10 pagesUNIT 8 - Natural Gas BusinessJay JaniNo ratings yet

- 3-Gas Hydrate: P GE 403 Natural Gas EngineeringDocument12 pages3-Gas Hydrate: P GE 403 Natural Gas Engineeringabu0ali095.aaNo ratings yet

- Rebreather Design Optimizing Pendulum TypesDocument7 pagesRebreather Design Optimizing Pendulum TypesSusan ColemanNo ratings yet

- An Introduction To Pressure Surge AnalysisDocument6 pagesAn Introduction To Pressure Surge AnalysisReld DavidNo ratings yet