Professional Documents

Culture Documents

Ar15 Parts COMPLETE LISTING

Uploaded by

Dennis Klineman0 ratings0% found this document useful (0 votes)

16 views10 pagesAR15 PARTS LISTING

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAR15 PARTS LISTING

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views10 pagesAr15 Parts COMPLETE LISTING

Uploaded by

Dennis KlinemanAR15 PARTS LISTING

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 10

This guide is is created to help put together an AR-15 lower receiver from a stripped receiver

and a lower receiver parts kit.

Tools

There are a few tools that make it easier to put together these kits, but none of them are

necessary. inimum re!uirements include a hammer and punch to drive in a couple of roll pins, a

flat-blade screwdriver for A" stock screw, and either a screwdriver or Allen key for the pistol grip

screw.

Roll Pin Punches - to drive roll pins (3/32", 1/8", 5/32"); these have a small raised

projection in the face of the punch to automaticall center the punch and prevent the roll

pin from collapsin!

Roll Pin Holders - used to hold and start roll pins""" ver convenient

Hammer - used to drive the roll pins

#10 Flat-Blade Screwdriver - used for #2 stoc$ scre% and some pistol !rips

Block of wood - &ase to support receiver %hen drivin! roll pins

Pivot Pin Installation Tool - hand tool if ou &uild a fe% lo%ers

llen !e" - used for some pistol !rips

Telesco#in$ Stock %rench - to ti!hten telescopin! stoc$ loc$ rin!

The Parts

The lower receiver parts kit consists of #$ parts not counting the stock assembly, the receiver, or

the pistol grip. %t is a good idea to lay all your parts out on a flat, light-colored surface so that you

can verify all your parts are there, and find them easily when you need them.

ost parts kits come covered in oil to prevent rust& wipe all the e'cess oil off before assembly.

(ecause of tight tolerances, some of these parts will be a tight fit. )ith the e'ception of the roll

pins, no part should need to be hammered into place.

SPRI&'S

Bolt (atch S#rin$ - easil confused %ith the disconnector sprin!; disconnector sprin! is

tapered thou!h"

Buffer Retainer S#rin$ - second lar!est sprin! in the $it"

)isconnector S#rin$ - similar to &olt-catch sprin!, &ut identifia&le &ecause one end is

%ide than the other"

Hammer S#rin$ - lar!er of the t%o similar sprin!s"

*a$a+ine (atch S#rin$ - this is the lar!est sprin! in the $it"

Pivot )etent S#rin$ - same as the ta$edo%n detent sprin!, so there are t%o in a $it"

Selector S#rin$ - similar to the ta$edo%n and pivot detent sprin!s, &ut there %ill onl &e

one of these"

Takedown )etent S#rin$ - same as the pivot detent sprin!, so there are t%o in a $it"

Tri$$er S#rin$ - the smaller of the t%o similar sprin!s"

PI&S

Bolt (atch Buffer

Bolt (atch Roll Pin - smaller of the t%o roll pins"

Hammer Pin - same as tri!!er pin; can &e inserted from either side"

Pivot )etent - same as ta$edo%n detent; &oth sides usuall rounded"

Pivot Pin - lar!er of the t%o lar!e pins"

Selector )etent - one end is flat, the other pointed"

Takedown )etent - same as pivot detent; &oth sides usuall rounded"

Takedown Pin - smaller of the t%o lar!e pins"

Tri$$er 'uard Roll Pin - lar!er of the t%o roll pins"

Tri$$er Pin - same as hammer pin; can &e inserted from either side"

Bolt (atch

Buffer Retainer

)isconnector

Hammer - %ill have a '-pin alread installed"

*a$a+ine (atch

*a$a+ine (atch Button - some are plastic, some metal"

Pistol 'ri# ,ock %asher

Pistol 'ri# Screw - some are #llen-head, some use a slotted pan-head scre%

Selector

Tri$$er

Tri$$er 'uard - some are metal, some plastic" (ill alread have a detent installed on its

front end"

ssem-l"

The steps for assembly are presented in a se!uence which has been effective. %t is by no means

the only correct method, as it does not make any difference on the end result if the maga*ine

catch is installed before or after the bolt catch for instance. %t is important to install the selector

before the pistol grip, and a few other steps that must be performed before others. +nless you are

e'perienced, follow the se!uence presented and you will be successful.

Always work in a well-lit area, and it is helpful to work on a flat, hard surface. There are many

small pins and springs, and they have a tendency to roll or fly away and disappear forever... %n

addition, look over the lower receiver before you begin the assembly. any of the small holes can

have debris in them from the forging process& a small drill bit, turned by hand, will clean these out

nicely.

aga*ine ,atch Assembly

Trigger -uard Assembly

(olt ,atch Assembly

.ivot .in Assembly

Trigger Assembly

/ammer

0elector

.istol -rip Assembly

A" 0tock

Telescoping 0tock

*'.I&/ (T(H SS/*B,0

.ART01 ma!a)ine catch, ma!a)ine catch sprin!, ma!a)ine &utton

T22301 5/32" roll pin punch

%nstall maga*ine catch into recess on left of receiver.

%nstall spring onto threaded portion of maga*ine catch from the right side of receiver.

0crew button onto threaded portion of maga*ine catch # or 4 turns.

+se a punch 5larger than hole in maga*ine button6 or wooden dowel to push in the

maga*ine button so you can turn the maga*ine catch clockwise until the end of the catch

is flush with the maga*ine button head. 7ou can hold the receiver and press the punch

against the table to do this, but put something between the punch and the maga*ine

catch button to prevent marking it. 8o this step first, as it will prevent the bolt catch from

getting in the way as you turn the maga*ine catch into place.

(1TI2&3

%T %0 .200%(39 T2 0,RAT,/ T/9 R9,9%:9R 2; T/%0 0T9.<

Take special care when turning the maga*ine catch to avoid rubbing against the hump

around the bolt catch.

F1&(TI2& (H/(!

,heck that depressing the maga*ine release button will push the maga*ine catch out of

the maga*ine well in the lower receiver.

0pring will return maga*ine catch to engage in maga*ine well.

TRI''/R '1R) SS/*B,0

.ART01 tri!!er !uard assem&l, roll pin

T22301 1/8" roll pin punch, hammer

Attach front of trigger guard assembly to the receiver using the detent.

3ay receiver on a block of wood, and drive roll pin into receiver and rear of trigger guard

using drive pin punch.

ake sure that the small block of wood is supporting the bottom flange and that the

trigger guard is in position supporting the top flange otherwise you risk bending or

breaking off one of the flanges.

Also watch as you put in the roll pin that it is going through the hole in the trigger guard

correctly.

F1&(TI2& (H/(!

,heck that by depressing the detent on trigger guard you are able to pivot the trigger

guard open.

B2,T (T(H SS/*B,0

.ART01 &olt catch, &olt catch &uffer, &olt catch sprin!, roll pin

T22301 3/32" roll pin punch, 5/32" (or lar!er) punch

(1TI2&3

IT IS 4/R0 /S0 T2 S(RT(H TH/ R/(/I4/R 2& THIS ST/P<

Take special care to make sure pin in in place before driving it, and ensure that it is held

securely in place when striking the punch. =iberglass packing tape - " layers thick - taped

over the receiver >ust between the receiver and the punch can help avoid scratching.

)hen installing the bolt catch, first drive the roll pin about halfway into the rear hump

from the rear of the receiver using roll pin holder. %t can be very difficult to get this pin

started& you might want to try s!uee*ing the roll pin on one end with pliers or the vise

before starting. %f you don?t have a roll pin holder, then try holding it in place with a pair of

needle nose pliers while you drive using a 5@#"A punch.

%nstall spring in hole on left side of receiver.

%nstall bolt catch plunger on top of spring with round portion on top and small end into

receiver. ake sure it moves freely in its hole.

%nstall bolt catch in receiver& it only fits on one way.

+se a #@#"A punch to hold the assembly by placing it through the front hump.

The pin can be driven the rest of the way from the rear as the punch will be pushed out

and while holding the bolt catch in correct alignment. 5function check as you do it to make

sure it?s going in correctly6

Avoid marring@scratching lower by covering receiver with tape, cloth, or other material

while you do this.

F1&(TI2& (H/(!

:erify that the bolt catch functions smoothly and is under tension from the spring.

PI42T PI& SS/*B,0

.ART01 pivot pin, pivot pin detent, pivot pin detent sprin!

T22301 pivot pin installation tool, 3/32" drive pin punch

This is perhaps the hardest part of the lower assembly, so if available, install the

installation tool.

%nsert spring and detent into receiver.

,ompress detent in recess using #@#"A punch and rotate tool.

.ush out tool with pivot pin and rotate until detent is in groove of pivot pin.

F1&(TI2& (H/(!

:erify that the pivot pin detent prevents the pivot pin from coming off the receiver.

;ote1 %f you do not have an installation tool, it can be difficult to get the pivot pin inserted

without losing the detent and@or detent spring& if these parts do fly out, they can be very

hard to find. The idea is to insert the spring and detent, and then compress them as you

insert the pivot pin. A pair of needle-nose pliers can be helpful. %t is difficult to remove the

pivot pin once installed, so make sure you do it right the first time and make sure you?ve

cleaned out the detent@spring hole with a drill bit before inserting the spring.

TRI''/R SS/*B,0

.ART01 *ri!!er, *ri!!er +in, *ri!!er ,prin!, -isconnector, -isconnector ,prin!

T22301 5/32" drive pin punch

0houlder trigger spring onto trigger with ends of spring forward and under.

%nstall disconnector spring with the wider portion of spring down towards trigger and push

until it locks in there.

.osition disconnector on top of trigger, where trigger pin will hold both in place.

%nsert trigger assembly into receiver.

%nsert trigger retaining pin through receiver, trigger, and disconnector. The trigger pin has

" grooves in it& one in the middle of the pin and one off to one side. %t does not matter

which way it is inserted, though common practice is to insert from left to right, with the

groove to the left.

%nsert hammer pin from opposite side to help align things as you push the trigger pin in

and the hammer pin out. 7ou will have to push down on trigger assembly to align the

holes and get the pin in all the way.

F1&(TI2& (H/(!

ake sure that the trigger pivots smoothly when depressed.

:erify that the disconnector pivots when pushed.

H**/R SS/*B,0

.ART01 hammer (%ith '-pin installed), hammer sprin!, hammer retainin! pin

T22301 5/32" drive pin punch

%nstall spring onto hammer, ends of spring to rear and shoulder on back of hammer.

%nstall hammer in receiver with feet pointing rearward away from hammer

+se 5@#"A punch to retain hammer in place as you insert hammer retaining pin.

3ike the trigger pin, you may have to push down and align the holes perfectly in order to

push the pin in all the way.

9nds of the hammer spring will rest on top of the trigger pin, with one end in the groove

on the trigger pin.

%nserting the hammer pin may re!uire some effort, as the B-pin in the hammer will catch

the grooves in the pin.

F1&(TI2& (H/(!

:erify that hammer locks to the rear when pushed back.

:erify that hammer pivots forward when trigger is pressed.

)ithout releasing the trigger, push the hammer back again and verify that it locks 5caught

by disconnector6.

Releasing the trigger should not cause the hammer to pivot fully forward 5caught by

trigger6.

/ammer will fall when trigger is pressed.

S/,/(T2R SS/*B,0

.ART01 safet selector

T22301

)ith hammer cocked back, insert from left side of receiver, selector pointing up in the

?fire? position.

F1&(TI2& (H/(!

ake sure selector rotates freely.

PIST2, 'RIP SS/*B,0

.ART01 selector detent, selector detent sprin!, pistol !rip, pistol !rip scre%, loc$ %asher

T22301 #llen $e or flat-&lade scre%driver (depends on our scre% tpe)

%nstall detent, pointed end towards the selector, and the spring into the receiver from the

bottom.

,arefully compress the spring with the grip and make sure spring fits into hole in grip.

,heck the function of the selector with the grip held in place& if too tight 5unable to rotate6

you may need to either cut the spring, or clean out the hole in the grip.

2nce feel is acceptable, secure the grip in place with the screw and lock washer.

F1&(TI2& (H/(!

:erify selector is able to move from safe to fire and clicks in place. %t should not move

past the ?safe? or ?fire? positions.

)ith selector on ?safe?, verify cocked hammer is not released when trigger is pressed.

)ith selector on ?semi?, verify hammer is released when trigger is pressed.

;2T91 0elector cannot be rotated to ?safe? unless hammer is cocked.

5 ST2(!

.ART01 ta$edo%n pin, ta$edo%n pin sprin!, ta$edo%n pin detent, stoc$, &uffer e.tension,

retainer, retainer sprin!, &uffer, &uffer sprin!

T22301 /10 (or lar!er) flat-&lade scre%driver

%nsert retainer spring and retainer into recess in lower.

%nstall buffer e'tension, 5buffer tube6& press detent when necessary& tor!ue to #5-#C ft-lbs

add spacer onto stock tube, and insert stock.

%nstall takedown pin with groove to the rear and install detent and spring from the rear of

the receiver.

,arefully compress the spring with the stock and secure the stock in place with the self-

locking screw.

%nsert stock screw from rear into stock.

)ith hammer down, insert buffer spring and buffer into buffer tube until retainer snaps up

to lock it in place.

=unction check on takedown pin and buffer retainer.

T/,/S(2PI&' ST2(!

.ART01 ta$edo%n pin, ta$edo%n pin sprin!, ta$edo%n pin detent, telescopin! stoc$, &uffer

e.tension, &ac$plate, loc$in! rin!, retainer, retainer sprin!, &uffer sprin!, &uffer

T22301 *elescopin! ,toc$ (rench

%nsert retainer spring and retainer into recess in lower.

%nstall buffer tube, backplate, and locking ring onto receiver and depress retainer when

necessary to get it to rest under the e'tension tube. Turn tube until it is about 1@4 turn

past the correct location.

%nstall takedown pin with groove to the rear and install detent and spring from the rear of

the receiver.

(ackplate will now hold spring in place when you turn the e'tension tube back 1@4 turn.

Tighten locking ring using telestock wrench for a snug fit.

)ith the hammer down, insert buffer spring and buffer into buffer tube until retainer snaps

up to lock it in place.

=unction check takedown pin, stock, and buffer retainer.

You might also like

- Elminster's Forgetten RealmsDocument194 pagesElminster's Forgetten RealmsJosh N Oregonia100% (29)

- A Beginner's Guide To SuppressorsDocument46 pagesA Beginner's Guide To SuppressorsDavidArcher100% (2)

- The Underground Assault Rifle SystemDocument33 pagesThe Underground Assault Rifle SystemAaronJay Jimankge100% (2)

- Selecting An AR15 For Defense A Preppers Manual: Written By: Randy WilsonDocument23 pagesSelecting An AR15 For Defense A Preppers Manual: Written By: Randy WilsonRandy Wilson100% (5)

- 2011 PWC Service Repair Manual PDFDocument968 pages2011 PWC Service Repair Manual PDFNaoufel Sousse50% (2)

- The Underground Assault Rifle SystemDocument33 pagesThe Underground Assault Rifle SystemAaronJay Jimankge100% (2)

- Threading A Barrel For A Muzzle Brake or orDocument4 pagesThreading A Barrel For A Muzzle Brake or orJohnn Schroeder100% (1)

- Building a Home Defense Remington 870 ShotgunFrom EverandBuilding a Home Defense Remington 870 ShotgunRating: 3.5 out of 5 stars3.5/5 (5)

- Dremeling A GLOCKDocument18 pagesDremeling A GLOCKBillyGlock100% (1)

- Trigger Slap and Doubling Trouble ShootingDocument8 pagesTrigger Slap and Doubling Trouble ShootingAdam Hemsley100% (2)

- Sub Machine GunsDocument10 pagesSub Machine Gunsprinando260408No ratings yet

- Ar-10 Rifles PDFDocument12 pagesAr-10 Rifles PDFstonefirearmsNo ratings yet

- Woodworking - Basics-Shopjigs PDFDocument4 pagesWoodworking - Basics-Shopjigs PDFv00d00blues100% (1)

- AR-15 Builders Resource - Version 1 (Rev. 1)Document48 pagesAR-15 Builders Resource - Version 1 (Rev. 1)blowmeasshole1911100% (1)

- Polymer80: Phoenix Version - G150 80% Lower Receiver InstructionsDocument13 pagesPolymer80: Phoenix Version - G150 80% Lower Receiver InstructionsTimothy ScottNo ratings yet

- AR-15 Assembly TipsDocument9 pagesAR-15 Assembly TipsTrunky100% (1)

- Details - WF Wall Footing Masonry Details: CHB To Slab-On-Grade End DetailsDocument1 pageDetails - WF Wall Footing Masonry Details: CHB To Slab-On-Grade End Detailsacurvz2005No ratings yet

- Coat Hanger Machine Gun DIASDocument8 pagesCoat Hanger Machine Gun DIASRoddy Pfeiffer100% (1)

- Assemble Your Own AR15 Rifle From Parts Things I Have Not SortedDocument64 pagesAssemble Your Own AR15 Rifle From Parts Things I Have Not SortedJay GonzalezNo ratings yet

- Fire Control Pocket With A DRODocument7 pagesFire Control Pocket With A DROterrencebelles100% (1)

- Present Arms AR-15 Gunners MountDocument18 pagesPresent Arms AR-15 Gunners MountAmmoLand Shooting Sports NewsNo ratings yet

- CAT Lift Trucks Service ManualDocument349 pagesCAT Lift Trucks Service ManualJuan Carlos97% (65)

- English Layout SquareDocument2 pagesEnglish Layout Squarev00d00bluesNo ratings yet

- The Grand Illusionist's DelusionDocument15 pagesThe Grand Illusionist's Delusionv00d00bluesNo ratings yet

- Mujahadeen AR-15Document13 pagesMujahadeen AR-15Chris Leahy100% (2)

- Brooks Trigger Kit 1st Set If InstructionsDocument9 pagesBrooks Trigger Kit 1st Set If Instructionsjimmywiggles100% (3)

- Colt AR-15 Rifle Lightning LinkDocument5 pagesColt AR-15 Rifle Lightning Linkelvergonzalez1100% (2)

- AR15 Trigger ComparisonDocument16 pagesAR15 Trigger ComparisonIM_JohnnyV100% (1)

- Building A Complete AR-15 Lower RecieverDocument27 pagesBuilding A Complete AR-15 Lower RecieverDelta Exrae100% (11)

- BHP Trigger JobDocument8 pagesBHP Trigger Jobssnvet100% (3)

- Caminhão Volvo FM - Relés e FusíveisDocument5 pagesCaminhão Volvo FM - Relés e FusíveisWiterMarcosNo ratings yet

- AR15 Parts AssemblyDocument10 pagesAR15 Parts Assemblykolas hernandez100% (1)

- Lista de Gun PlansDocument2 pagesLista de Gun PlansZehBrzNo ratings yet

- Ghost Gunner Operator's ManualDocument30 pagesGhost Gunner Operator's Manualjcernuda95100% (1)

- L1 - Material List and BreakdownDocument36 pagesL1 - Material List and Breakdownmohammed100% (1)

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsFrom EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNo ratings yet

- US DIS FLMD 6 21cv1245 NOTICE by Bureau of Alcohol Tobacco Firearms and E OptDocument80 pagesUS DIS FLMD 6 21cv1245 NOTICE by Bureau of Alcohol Tobacco Firearms and E OptJohn Crump100% (1)

- Modulus Arms Heavy-Duty AR-15 Jig Instructions V1Document21 pagesModulus Arms Heavy-Duty AR-15 Jig Instructions V1Justin HeadNo ratings yet

- Gun Digest's Customize Your Revolver Concealed Carry Collection eShort: From regular pistol maintenance to sights, action, barrel and finish upgrades for your custom revolver.From EverandGun Digest's Customize Your Revolver Concealed Carry Collection eShort: From regular pistol maintenance to sights, action, barrel and finish upgrades for your custom revolver.No ratings yet

- Gun Silencer Patent 3Document7 pagesGun Silencer Patent 3Flavio Marçal100% (2)

- The SWD Lightning LinkDocument2 pagesThe SWD Lightning LinkRay Bailey100% (3)

- Bolt Together AR15 Lower ReceiverDocument0 pagesBolt Together AR15 Lower ReceiverLogicIndustriesLLC100% (1)

- Checkmate II .22lr Manual.Document2 pagesCheckmate II .22lr Manual.Griffin Armament SuppressorsNo ratings yet

- A1 To A2Document45 pagesA1 To A2leeyangseopNo ratings yet

- Gunsmithing the AR-15, Vol. 3: The Bench ManualFrom EverandGunsmithing the AR-15, Vol. 3: The Bench ManualRating: 2.5 out of 5 stars2.5/5 (4)

- Polymer80 RJ556U Build InstructionsDocument14 pagesPolymer80 RJ556U Build InstructionsAW GehrsNo ratings yet

- Carl Gustav SMGDocument18 pagesCarl Gustav SMGJorihood100% (1)

- Ti25 Advanced Composite Steel Lip Magazine For Ruger 10 - 22 byDocument3 pagesTi25 Advanced Composite Steel Lip Magazine For Ruger 10 - 22 byarizona212No ratings yet

- Homebuilt - HPDE AR15 LowerDocument15 pagesHomebuilt - HPDE AR15 LowerMike Bell100% (3)

- Ras47 Semi-Auto Rifle: Owner's ManualDocument16 pagesRas47 Semi-Auto Rifle: Owner's ManualGregoryNo ratings yet

- Drawings - 37163, 37164Document23 pagesDrawings - 37163, 37164intecNo ratings yet

- Handi Instr OneDocument9 pagesHandi Instr OnenotjustsomeoneNo ratings yet

- Build AR15 LowersDocument4 pagesBuild AR15 LowersBuildAR15Lowers67% (3)

- Assembling Your Own Stripped AR - 1Document103 pagesAssembling Your Own Stripped AR - 1bigwhiteguy100% (1)

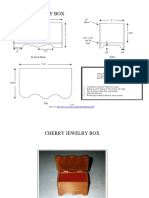

- Woodworking Plans - Cherry Jewelry BoxDocument2 pagesWoodworking Plans - Cherry Jewelry Boxv00d00bluesNo ratings yet

- Practical Guide to the Operational Use of the PPS-43 Submachine GunFrom EverandPractical Guide to the Operational Use of the PPS-43 Submachine GunNo ratings yet

- AK Accurizing TipsDocument27 pagesAK Accurizing TipsEmilio Torres EsguerraNo ratings yet

- Sample BQ For c3381 Julai2010Document76 pagesSample BQ For c3381 Julai2010Azlan LorenNo ratings yet

- Aa-12 Us4693170Document33 pagesAa-12 Us4693170TEKO - TepicKurestwoOficjal PS4 CrewNo ratings yet

- GG2 Operator's ManualDocument30 pagesGG2 Operator's ManualWerner Patric WengNo ratings yet

- KSC or KWA Glock 18C Hammer Spring InstallationDocument8 pagesKSC or KWA Glock 18C Hammer Spring Installationapi-3829577100% (1)

- Installing An External Bolt Stop/Release On A Remington 700Document10 pagesInstalling An External Bolt Stop/Release On A Remington 700M Poveda0% (1)

- ListDocument40 pagesListCarlos Ramos100% (1)

- Specific Parts For The Mil Spec Trigger GroupDocument2 pagesSpecific Parts For The Mil Spec Trigger GroupMauricio Rojas GutierrezNo ratings yet

- Silent-Sr Sound Suppressor: Instruction Manual ForDocument12 pagesSilent-Sr Sound Suppressor: Instruction Manual ForlucaNo ratings yet

- Makesupply Passport Case Template Set Rounded CornersDocument3 pagesMakesupply Passport Case Template Set Rounded Cornersv00d00blues0% (1)

- Woodworking - Jointer's MalletDocument4 pagesWoodworking - Jointer's Malletv00d00bluesNo ratings yet

- KlonbufferDocument1 pageKlonbufferv00d00bluesNo ratings yet

- Termostat (Thermostat) Siemens RAB31Document6 pagesTermostat (Thermostat) Siemens RAB31IONUT PRISECARUNo ratings yet

- Wag9hc CLWDocument93 pagesWag9hc CLWShrish ShankhdharNo ratings yet

- Diagnostic Trouble Codes For Sinotruk HOWO Engines PDFDocument4 pagesDiagnostic Trouble Codes For Sinotruk HOWO Engines PDFhektor Atkinson100% (1)

- Rn8hah7xrp8o PDFDocument140 pagesRn8hah7xrp8o PDFOliverNo ratings yet

- Lintels AutoCad Files ListDocument6 pagesLintels AutoCad Files ListAngel MurrayNo ratings yet

- Legrand CatalogueDocument356 pagesLegrand CatalogueEtienne MagriNo ratings yet

- Synchronous Machines-Part 0Document49 pagesSynchronous Machines-Part 0An00pgadzillaNo ratings yet

- Cold Cathode Fluorescent Lamp Driver General Description FeaturesDocument6 pagesCold Cathode Fluorescent Lamp Driver General Description FeaturesluisfeipezzNo ratings yet

- 3KF13060LB11 Datasheet enDocument6 pages3KF13060LB11 Datasheet enOcklen SetiadilagaNo ratings yet

- 4.chint Contactor (NXC)Document5 pages4.chint Contactor (NXC)Yamendra GurungNo ratings yet

- Typical Beam Elevation: Foundation PlanDocument1 pageTypical Beam Elevation: Foundation PlanLester John PrecillasNo ratings yet

- Industry Standard Sized Laser Sensors With Built-In AmplifiersDocument8 pagesIndustry Standard Sized Laser Sensors With Built-In AmplifiersJunaidi ArigaNo ratings yet

- Assembling The LCR T4 Mega328 Tester KitDocument7 pagesAssembling The LCR T4 Mega328 Tester Kittremelo68No ratings yet

- Catalog rt2db - (English) - Ind 4 PDFDocument8 pagesCatalog rt2db - (English) - Ind 4 PDFroyclhorNo ratings yet

- Saab 900 Convertible Owners ManualDocument60 pagesSaab 900 Convertible Owners ManualScottNo ratings yet

- LB Series: 12 D F S Lb1 NDocument4 pagesLB Series: 12 D F S Lb1 NPasindu PriyankaraNo ratings yet

- ABB Motor Starting BRDocument66 pagesABB Motor Starting BRAziz SultanNo ratings yet

- Pool Covers PDF Document Aqua Middle East FZCDocument10 pagesPool Covers PDF Document Aqua Middle East FZCAdolfsmith69No ratings yet

- Mounting Manual For 190WP PanelDocument11 pagesMounting Manual For 190WP Panelkbn5899No ratings yet

- 24-013, 24-014 Catalog Page PDFDocument2 pages24-013, 24-014 Catalog Page PDFAndres Felipe TapiaNo ratings yet

- Unijunction TransistorDocument54 pagesUnijunction TransistorPaoNo ratings yet

- 9m Pole Revised BOQDocument2 pages9m Pole Revised BOQSB Engineering, INDIANo ratings yet

- Corinthian Order RachoDocument21 pagesCorinthian Order RachoBiKi OrleansNo ratings yet