Professional Documents

Culture Documents

Special Purpose Basic Switch

Uploaded by

ng_viet_cuong_groupCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Special Purpose Basic Switch

Uploaded by

ng_viet_cuong_groupCopyright:

Available Formats

CSM_DZ_DS_E_2_2

1

Special-purpose Basic Switch

DZ

DPDT Basic Switch for Two

Independent Circuit Control

Ideal for switching the circuits operating on two

different voltages, and for controlling two independent

circuits.

Interchangeable with OMRON Z Basic Switches, as

both switches are identical in mounting hole

dimensions, mounting pitch and pin plunger position.

Be sure to read Safety Precautions on page 4 and Safety

Precautions for All Basic Switches.

Model Number Structure

Model Number Legend

Ordering Information

Specifications

Terminal Solder terminal (-1A) Screw terminal (-B)

Actuator Model Model

Pin plunger DZ-10G-1A DZ-10G-1B

Hinge lever

High OT DZ-10GW-1A DZ-10GW-1B

Low OT DZ-10GV-1A DZ-10GV-1B

Short hinge roller lever

High OT DZ-10GW22-1A DZ-10GW22-1B

Low OT DZ-10GV22-1A DZ-10GV22-1B

Hinge roller lever

High OT DZ-10GW2-1A DZ-10GW2-1B

Low OT DZ-10GV2-1A DZ-10GV2-1B

(1) Ratings

10 : 10 A (250 VAC)

(2) Contact Gap

G : 0.5 mm

(3) Actuator

None : Pin plunger

V : Hinge lever

V22 : Short hinge roller lever

V2 : Hinge roller lever

W : Hinge lever

W22 : Short hinge roller lever

W2 : Hinge roller lever

(4) Contact Form

1 : DPDT

(5) Terminals

A : Solder terminal

B : Screw terminal

DZ-10G@-1@

(1) (2)(3) (4)(5)

Ratings

Note: 1. The above values are for steady-state current.

2. Inductive load has a power factor of 0.4 min. (AC) and a time constant of 7 ms max. (DC).

3. Lamp load has an inrush current of 10 times the steady-state current.

4. Motor load has an inrush current of 6 times the steady-state current.

5. The ratings values apply under the following test conditions:

(1) Ambient temperature: 202C

(2) Ambient humidity: 655%RH

(3) Operating frequency: 20 operations/min

Rated voltage

Non-inductive load (A) Inductive load (A)

Resistive load Lamp load Inductive load Motor load

NC NO NC NO NC NO NC NO

125 VAC

250 VAC

10

10

2

1.5

1

0.7

6

4

3

2

1.5

1

8 VDC

14 VDC

30 VDC

125 VAC

250 VDC

10

10

10

0.5

0.25

3

3

3

1.5

1.5

1.5

6

6

4

0.05

0.03

5

5

3

2.5

2.5

1.5

0.5

0.25

0.05

0.03

Certified Standard Ratings

Ask your OMRON representative for

information on certified models.

UL/CSA

Rated voltage DZ-10G

125 VAC 10 A 1/8 HP

250 VAC 10 A 1/4 HP

480 VAC 2 A

125 VDC 0.5 A

250 VDC 0.25 A

Accessories (Terminal Covers, Actuators, and Separators): Refer to Z/A/X/DZ Common Accessories and Z/X/DZ Common Accessories.

2

DZ

Structure

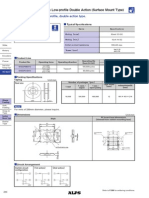

Contact Form (DPDT)

Dimensions (Unit: mm)

Terminals

Solder Terminals (-1A) Screw Terminals (-1B)

Dimensions and Operating Characteristics

The solder terminal model has a suffix "-1A" in its model number and its omitted dimensions are the same as the corresponding dimensions of the pin plunger model.

Characteristics

*1. The values are for pin plunger models. (Contact your OMRON representative for other models.)

*2. Malfunction: 1 ms max.

Contact Specifications

Operating speed 0.1 mm to 1 m/s *1

Operating

frequency

Mechanical 240 operations/min

Electrical 20 operations/min

Insulation resistance 100 M min. (at 500 VDC)

Contact resistance 15 m max. (initial value)

Dielectric strength

1,000 VAC, 50/60 Hz for 1 min between non-continuous terminals

1,500 VAC, 50/60 Hz for 1 min between current-carrying

metal parts and non-current-carrying metal part, and between

current-carrying metal part and ground and between switches

Vibration

resistance

Malfunction 10 to 55 Hz, 1.5-mm double amplitude *2

Shock

resistance

Destruction 1,000 m/s

2

max.

Malfunction 300 m/s

2

max. *1 *2

Durability

Mechanical 1,000,000 operations min.

Electrical 500,000 operations min.

Degree of protection IP00

Degree of protection

against electric shock

Class I

Proof tracking index (PTI) 175

Ambient operating temperature 25C to 80C (with no icing)

Ambient operating humidity 35% to 85%RH

Weight Approx. 30 to 50 g

Contacts

Material Silver alloy

Gap (standard value) 0.5 mm

Inrush current

NC 30 A max.

NO 15 A max.

Engineering Data

Mechanical Durability (DZ-10G-1B)

Electrical Durability (DZ-10G-1B)

10,000

7,000

5,000

3,000

1,000

700

500

300

100

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

Overtravel (mm)

D

u

r

a

b

i

l

i

t

y

(

x

1

0

4

o

p

e

r

a

t

i

o

n

s

)

Ambient temperature: 202C

Ambient humidity: 655%RH

Without load

Operating frequency: 240 operations/min

1,000

700

500

300

100

70

50

30

10

0 5 10 15

Switching current (A)

250 VAC

125 VAC

D

u

r

a

b

i

l

i

t

y

(

x

1

0

4

o

p

e

r

a

t

i

o

n

s

)

Ambient temperature: 202C

Ambient humidity: 655%RH

Operating frequency: 20 operations/min

cos1

COM2 NC2

NO2

COM1 NC1

NO1

NC NO COM

NC NO COM

17.450.2

25.40.1

11.9

49.2

8.2

14.5

23.5 16.8

COM NC NO

COM NC NO

17.450.2

25.40.1

11.9

49.2

8.2

14.5

23.5 16.8

Six M3 pan head screws

(with toothed washer)

4.2 dia. hole

+0.075

-0.025

4.36 dia.

+0.1

-0.05

4.2

+0.075

-0.025

23.30.25

25.40.1

11.9

49.2

17.450.2

PT

OP

3 dia. 2.5SR *

0.4

14.5

8.2

* Stainless-steel pin plunger

Pin Plunger

DZ-10G-1B

Operating force OF max.

Release force RF min.

Pretravel PT max.

Overtravel OT min.

Movement Differential MD max.

5.59 N

0.56 N

1.7 mm

0.13 mm

0.4 mm

Operating Position OP 15.60.4 mm

3

DZ

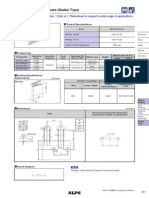

Note: Unless otherwise specified, a tolerance of 0.4 mm applies to all dimensions.

28.4

25.40.1

11.9

49.2

17.450.2

17.7

19.7

14.5

FP

8.2

OP

4.9

* Stainless-steel lever

t = 1 *

6

3

.5

R

4.2 dia. hole

+0.075

-0.025

4.36 dia.

+0.1

-0.05

4.2

+0.075

-0.025

Hinge Lever

DZ-10GW-1B

OF max.

RF min.

OT min.

MD max.

1.67 N

0.27 N

1.6 mm

4 mm

FP max.

OP

46.3 mm

21.81 mm

17.450.2

4.9

* Stainless-steel lever

25.40.1

11.9

49.2

17.7

4.2 dia. hole

+0.075

-0.025

4.36 dia.

+0.1

-0.05

4.2

+0.075

-0.025

19.7

14.5

8.2

OP

PT

t = 1 *

63.5R

1.1

DZ-10GV-1B

OF max.

RF min.

PT max.

OT min.

MD max.

1.96 N

0.13 N

6 mm

0.4 mm

1.7 mm

OP 18.31 mm

4.2 dia. hole

+0.075

-0.025

4.36 dia.

+0.1

-0.05

4.2

+0.075

-0.025

28.4

25.40.1

11.9

49.2

17.450.2

17.7

19.7

14.5

FP

8.2

OP

9.5 dia. 4

(plastic roller)

* Stainless-steel lever

t = 1 *

2

6

.

2

R

Short Hinge Roller Lever

DZ-10GW22-1B

OF max.

RF min.

OT min.

MD max.

3.92 N

0.83 N

0.9 mm

2.4 mm

FP max.

OP

39.7 mm

30.20.8 mm

17.450.2

* Stainless-steel lever

4.2 dia. hole

+0.075

-0.025

4.36 dia.

+0.1

-0.05

25.40.1

11.9

49.2

17.7

19.7

14.5

8.2

OP

PT

4.2

+0.075

-0.025

t = 1 *

1.1

9.5 dia. 4

(plastic roller)

3

0

.

2

R

DZ-10GV22-1B

OF max.

RF min.

PT max.

OT min.

MD max.

4.22 N

0.41 N

3 mm

0.13 mm

0.6 mm

OP 29.40.8 mm

28.4

25.40.1

11.9

49.2

17.450.2

17.7

19.7

14.5

FP

8.2

OP

9.5 dia. 4

(plastic roller)

* Stainless-steel lever

t = 1 *

4

8

.4

R

4.2 dia. hole

+0.075

-0.025

4.36 dia.

+0.1

-0.05

4.2

+0.075

-0.025

17.450.2

* Stainless-steel lever

4.2 dia. hole

+0.075

-0.025

4.36 dia.

+0.1

-0.05

25.40.1

11.9

49.2

17.7

19.7

14.5

8.2

OP

PT t = 1 *

1.1

9.5 dia. 4

(plastic roller)

4

8

.4

R

4.2

+0.075

-0.025

OF max.

RF min.

PT max.

OT min.

MD max.

2.65 N

0.33 N

4 mm

0.26 mm

1.1 mm

OP 29.40.8 mm

Hinge Roller Lever

DZ-10GW2-1B

OF max.

RF min.

OT min.

MD max.

2.09 N

0.41 N

1.2 mm

3.3 mm

FP max.

OP

47.6 mm

31.80.8 mm

DZ-10GV2-1B

4

DZ

Safety Precautions

Refer to Safety Precautions for All Basic Switches.

Terminal Connection

When soldering lead wires to the Switch, make sure that the capacity

of the soldering iron is 60 W maximum. Do not take more than 5 s to

solder any part of the Switch. The characteristics of the Switch will

deteriorate if a soldering iron with a capacity of more than 60 W is

applied to any part of the Switch for 5 s or more.

Operation

Make sure that the switching frequency or speed is within the

specified range.

1.If the switching speed is extremely slow, the contact may not be

switched smoothly, which may result in a contact failure or

contact welding.

2.If the switching speed is extremely fast, switching shock may

damage the Switch soon. If the switching frequency is too high,

the contact may not catch up with the speed.

The rated permissible switching speed and frequency indicate the

switching reliability of the Switch.

The life of a Switch is determined at the specified switching speed.

The life varies with the switching speed and frequency even when

they are within the permissible ranges. In order to determine the

life of a Switch model to be applied to a particular use, it is best to

conduct an appropriate durability test on some samples of the

model under actual conditions.

Make sure that the actuator travel does not exceed the permissible

OT position. The operating stroke must be set to 70% to 100% of

the rated OT.

Mounting Location

Do not use the switch alone in atmospheres such as flammable or

explosive gases. Arcing and heat generation associated with

switching may cause fires or explosions.

Switches are generally not constructed with resistance against

water. Use a protective cover to prevent direct spraying if the switch

is used in locations subject to splashing or spurting oil or water, dust

adhering.

Install the switch in a location that is not directly subject to debris

and dust from cutting. The actuator and the switch body must be

protected from accumulated cutting debris and dirt.

Do not use the switch in locations subject to hot water (greater than

60C) or in water vapor.

Do not use the switch outside the specified temperature and

atmospheric conditions.

The permissible ambient temperature depends on the model.

(Refer to the specifications in this catalog.) Sudden thermal

changes may cause thermal shock to distort the switch and result

in faults.

Mount a cover if the switch is to be installed in a location where

worker inattention could result in incorrect operation or accidents.

Subjecting the switch to continuous vibration or shock may result in

contact failure or faulty operation due to abrasion powder and in

reduced durability. Excessive vibration or shock will cause the

contacts to operate malfunction or become damaged. Mount the

switch in a location that is not subject to vibration or shock and in a

direction that does not subject the switch to resonance.

If silver contacts are used with relatively low frequency for a long

time or are used with microloads, the sulfide coating produced on

the contact surface will not be broken down and contact faults will

result. Use a microload switch that uses gold contacts.

Do not use the switch in atmospheres with high humidity or heat or

in harmful gases, such as sulfide gas (H2S, SO2), ammonia gas

(NH3), nitric acid gas (HNO3), or chlorine gas (Cl2). Doing so may

impair functionality, such as with damage due to contacting faults

or corrosion.

The switch includes contacts. If the switch is used in an atmosphere

with silicon gas, arc energy may cause silicon oxide (SiO2) to

accumulate on the contacts and result in contact failure. If there is

silicon oil, silicon filling, silicon wiring, or other silicon products in the

vicinity of the switch, use a contact protection circuit to limit arcing

and remove the source of the silicon gas.

Mounting

Use M4 mounting screws with plane washers or spring washers to

securely mount the Switch. Tighten the screws to a torque of 1.18 to

1.47 Nm.

Mounting Holes

Accessories (Order separately)

Refer to Z/A/X/DZ Common Accessories for details about Terminal Covers, Separators, and Actuators.

Precautions for Safe Use

Precautions for Correct Use

Terminal box

Terminal box

Incorrect Correct

Incorrect Correct

Incorrect

Separate the

installation lo-

cation from

heat sources.

Correct

Correct

(preventing malfunctions)

Incorrect

25.40.1

Two, 4.2 dia. mounting holes or

M4 screw holes

Read and Understand This Catalog

Please read and understand this catalog before purchasing the products. Please consult your OMRON representative if you have any questions or

comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or other period if specified)

from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT, MERCHANTABILITY, OR

FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS

IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE PRODUCTS UNLESS

OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT

SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of products in the customer's

application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying ratings and limitations of use that apply to the

products. This information by itself is not sufficient for a complete determination of the suitability of the products in combination with the end product,

machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not intended to be an exhaustive list of all possible

uses of the products, nor is it intended to imply that the uses listed may be suitable for the products:

Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or uses not described in this catalog.

Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical equipment, amusement machines, vehicles,

safety equipment, and installations subject to separate industry or government regulations.

Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE

SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any consequence thereof.

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons.

It is our practice to change model numbers when published ratings or features are changed, or when significant construction changes are made.

However, some specifications of the products may be changed without any notice. When in doubt, special model numbers may be assigned to fix or

establish key specifications for your application on your request. Please consult with your OMRON representative at any time to confirm actual

specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

PERFORMANCE DATA

Performance data given in this catalog is provided as a guide for the user in determining suitability and does not constitute a warranty. It may represent the

result of OMRONs test conditions, and the users must correlate it to actual application requirements. Actual performance is subject to the OMRON

Warranty and Limitations of Liability.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however, no responsibility is assumed for clerical,

typographical, or proofreading errors, or omissions.

2011.7

In the interest of product improvement, specifications are subject to change without notice.

OMRON Corporation

Industrial Automation Company

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2011 All Right Reserved.

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- cmt1 Sampleques BookbDocument25 pagescmt1 Sampleques Bookbng_viet_cuong_groupNo ratings yet

- PLC Solution BookDocument49 pagesPLC Solution BookJagadeesh Rajamanickam71% (14)

- 120k Active Code 668-2Document4 pages120k Active Code 668-2selviantobilmon78No ratings yet

- C1070 - NDE RequirementsDocument7 pagesC1070 - NDE RequirementsWill SmithNo ratings yet

- DPDT Basic Switch For Two Independent Circuit ControlDocument5 pagesDPDT Basic Switch For Two Independent Circuit ControlShubham GuptaNo ratings yet

- Ordering Information: Sealed Snap Action SwitchDocument6 pagesOrdering Information: Sealed Snap Action SwitchG Sandeep KumarNo ratings yet

- Model Number Structure: High-Temperature Basic SwitchDocument4 pagesModel Number Structure: High-Temperature Basic Switchblackbeast8No ratings yet

- Economical, Miniature Limit Switch Boasting Rigid ConstructionDocument5 pagesEconomical, Miniature Limit Switch Boasting Rigid ConstructionRajeev Saini100% (1)

- Model Number Structure: Enclosed SwitchDocument10 pagesModel Number Structure: Enclosed SwitchJavierNo ratings yet

- G5Q PCB Relay: Ordering InformationDocument4 pagesG5Q PCB Relay: Ordering InformationLAU_CBrNo ratings yet

- HF2100 enDocument4 pagesHF2100 enBhakti PermanaNo ratings yet

- Brochure Mercotac PDFDocument8 pagesBrochure Mercotac PDFRoderikus Rendy MNo ratings yet

- Quick-Connect Terminals Simplify Wiring and Reduce Production StepsDocument5 pagesQuick-Connect Terminals Simplify Wiring and Reduce Production StepsStephen GreeneNo ratings yet

- Sddje: 10A 250V AC Qualified TypeDocument6 pagesSddje: 10A 250V AC Qualified TypeshyhuNo ratings yet

- Cf-Relays: New Dual Power Automotive RelayDocument3 pagesCf-Relays: New Dual Power Automotive Relaytotovasi50% (2)

- Omron Master GuideDocument14 pagesOmron Master GuidemasakpNo ratings yet

- 5.2mm Square Low-Profile (Surface Mount Type)Document4 pages5.2mm Square Low-Profile (Surface Mount Type)shyhuNo ratings yet

- TQ-SMD Relays: Low-Profile Surface-Mount RelayDocument5 pagesTQ-SMD Relays: Low-Profile Surface-Mount RelayTomas Perez GNo ratings yet

- SKEGDocument4 pagesSKEGshyhuNo ratings yet

- Silicon 5 Watt Zener Diodes: 1N5333B Thru 1N5388BDocument5 pagesSilicon 5 Watt Zener Diodes: 1N5333B Thru 1N5388Bwilburroberts20034852No ratings yet

- High Operation Force, Low Contact Resistance Type (Surface Mount Type)Document3 pagesHigh Operation Force, Low Contact Resistance Type (Surface Mount Type)shyhuNo ratings yet

- E6f-C Ds csm499Document5 pagesE6f-C Ds csm499Achmad RamadhaniNo ratings yet

- HS25 Incremental EncoderDocument4 pagesHS25 Incremental Encoderoswaldo58No ratings yet

- Omron Z-15GW2-Omron PDFDocument18 pagesOmron Z-15GW2-Omron PDFCorne WolfaardtNo ratings yet

- Model Number Structure: General-Purpose Limit SwitchDocument9 pagesModel Number Structure: General-Purpose Limit SwitchHung LeNo ratings yet

- Datasheet Techman OMIT SS 124LMDocument2 pagesDatasheet Techman OMIT SS 124LMSteve MurphyNo ratings yet

- Safety Limit Switch: Model Number StructureDocument16 pagesSafety Limit Switch: Model Number StructureEgoitz Arruti BarrenetxeaNo ratings yet

- OMRONDocument14 pagesOMRONwirawansatriaNo ratings yet

- 0.6mm Low-Profile, Double Action TypeDocument3 pages0.6mm Low-Profile, Double Action TypeshyhuNo ratings yet

- Hollow-Shaft Type That Enables Output Covering The Whole 360-Degree Angle Due To Adoption of 2-Phase OutputDocument4 pagesHollow-Shaft Type That Enables Output Covering The Whole 360-Degree Angle Due To Adoption of 2-Phase OutputshyhuNo ratings yet

- Datasheet Relay 12 V PDFDocument7 pagesDatasheet Relay 12 V PDFturkceNo ratings yet

- Magnetrol Model Tk1Document4 pagesMagnetrol Model Tk1Billy Isea DenaroNo ratings yet

- 18mm Size Insulated Shaft Type: Absolute Type Achieving High Water Resistance and Heavy TorqueDocument4 pages18mm Size Insulated Shaft Type: Absolute Type Achieving High Water Resistance and Heavy TorqueshyhuNo ratings yet

- Rf1v RelaysDocument8 pagesRf1v RelaysbansalrNo ratings yet

- Ordering Information: Snap Action SwitchDocument10 pagesOrdering Information: Snap Action Switchconti51No ratings yet

- Ultra-Miniature, Highly SensitiveDocument4 pagesUltra-Miniature, Highly SensitivemariotexmNo ratings yet

- Allen Bradley PulsadoresDocument76 pagesAllen Bradley PulsadoresetorinNo ratings yet

- Water-Proof Type With Built-In Detector SwitchesDocument3 pagesWater-Proof Type With Built-In Detector SwitchesshyhuNo ratings yet

- 3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)Document3 pages3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)shyhuNo ratings yet

- 7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsDocument3 pages7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsshyhuNo ratings yet

- G2RSDocument14 pagesG2RSMisaelRodriguezNo ratings yet

- Tesys Contactors: CharacteristicsDocument12 pagesTesys Contactors: CharacteristicsArquidarkNo ratings yet

- 12mm Square (Snap-In Type) : Joint Stem & Flat Stem With Stable Operation FeelingDocument4 pages12mm Square (Snap-In Type) : Joint Stem & Flat Stem With Stable Operation FeelingshyhuNo ratings yet

- En g8nbDocument3 pagesEn g8nbAnonymous 3hUDn2No ratings yet

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDocument4 pages6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuNo ratings yet

- 10mm Square Water-Proof (Snap-In Type)Document5 pages10mm Square Water-Proof (Snap-In Type)shyhuNo ratings yet

- 24V - D3427 and 5V D3423Document14 pages24V - D3427 and 5V D3423Pradeeban NNo ratings yet

- OnkyoC701A JP SMDocument21 pagesOnkyoC701A JP SMHelder MartinsNo ratings yet

- Subminiature Models Capable of Large-Capacity Load of 7A: Ultra Subminiature Basic SwitchDocument4 pagesSubminiature Models Capable of Large-Capacity Load of 7A: Ultra Subminiature Basic SwitchLuthie SinghNo ratings yet

- Sanitary TurbinaDocument4 pagesSanitary TurbinaCindy MateusNo ratings yet

- Selladora de Cajas de Carton - EXC-103TBDocument26 pagesSelladora de Cajas de Carton - EXC-103TBMarco Antonio Pereira BustosNo ratings yet

- Thuc Hanh 1Document7 pagesThuc Hanh 1tuantu007100% (1)

- Terazaki TZS-68 - Earth Leakage RelayDocument2 pagesTerazaki TZS-68 - Earth Leakage RelayJon Carlo DelmarNo ratings yet

- Relay 5vDocument2 pagesRelay 5vNgoc Loi Nguyen HoNo ratings yet

- G5A 237P DC5 OmronDocument8 pagesG5A 237P DC5 OmronGhilang TriputraNo ratings yet

- Mechanical Pressure Switch S4130: Description FeaturesDocument2 pagesMechanical Pressure Switch S4130: Description FeaturesRolando Jara Young100% (1)

- Omron G3MC 202P DC5 DatasheetDocument6 pagesOmron G3MC 202P DC5 DatasheetArief MuhammadNo ratings yet

- Datasheet Final de CarreraDocument3 pagesDatasheet Final de CarreraLucas PisitelloNo ratings yet

- Data Sheet: HLMP-RL20, HLMP-SL20Document9 pagesData Sheet: HLMP-RL20, HLMP-SL20Anonymous pMVR77x1No ratings yet

- Catálogo General Medidor para Agua WoltmanDocument8 pagesCatálogo General Medidor para Agua WoltmanLuis David LopezNo ratings yet

- Project 10: Frequency Measurement Using Input CaptureDocument18 pagesProject 10: Frequency Measurement Using Input Captureng_viet_cuong_groupNo ratings yet

- Servo ConnectDocument1 pageServo Connectng_viet_cuong_groupNo ratings yet

- Junior Design PIC Microprocessor Demo 2Document2 pagesJunior Design PIC Microprocessor Demo 2ng_viet_cuong_groupNo ratings yet

- Cmt2 Reading Spr12Document4 pagesCmt2 Reading Spr12ng_viet_cuong_groupNo ratings yet

- MCP3909 3-Phase Energy Meter Reference DesignDocument88 pagesMCP3909 3-Phase Energy Meter Reference Designng_viet_cuong_groupNo ratings yet

- CS9803GPDocument2 pagesCS9803GPng_viet_cuong_groupNo ratings yet

- OrCad TutorialDocument62 pagesOrCad Tutorialng_viet_cuong_groupNo ratings yet

- De 1 211Document6 pagesDe 1 211ng_viet_cuong_groupNo ratings yet

- 70 Test B 8955Document503 pages70 Test B 8955ng_viet_cuong_groupNo ratings yet

- 1 Soil MechanicsDocument113 pages1 Soil MechanicsAysheshim BahruNo ratings yet

- Spirit Man JinnDocument198 pagesSpirit Man JinnM JNo ratings yet

- Rigidity Modulus - Torsional PendulumDocument4 pagesRigidity Modulus - Torsional PendulumGAMES TECHNo ratings yet

- Exp 2 Series DC CircuitsDocument4 pagesExp 2 Series DC Circuitsmaskrasheed777No ratings yet

- GR 7 Skill Builder 5Document3 pagesGR 7 Skill Builder 5mulashyam81No ratings yet

- Double Scatter or Ghost ScatterDocument3 pagesDouble Scatter or Ghost ScatterTrần Văn BìnhNo ratings yet

- Engineers Handbooks As 17Document140 pagesEngineers Handbooks As 17Rakesh TiwariNo ratings yet

- Leica Zoom 2000Document6 pagesLeica Zoom 2000HaienasrNo ratings yet

- Gemini VII 2390 Operator Manual V3.03Document426 pagesGemini VII 2390 Operator Manual V3.03PablosNo ratings yet

- Model Answer Winter 2014Document21 pagesModel Answer Winter 2014Prashant KasarNo ratings yet

- Unified Council Results NSTSE ResultsDocument1 pageUnified Council Results NSTSE ResultsDevashish RaiNo ratings yet

- Matched FilterssDocument8 pagesMatched FilterssPaidamoyo MuzvidziwaNo ratings yet

- CSEC Physics June 1999 P1Document10 pagesCSEC Physics June 1999 P1Laimen ReveskiNo ratings yet

- Kongu Engineering College, Perundurai, Erode - 638060, IndiaDocument2 pagesKongu Engineering College, Perundurai, Erode - 638060, IndiaraviciviltNo ratings yet

- Maths Deleted SyllabusDocument7 pagesMaths Deleted SyllabusHazardicNo ratings yet

- Grade 10 Math in 1 Hour Questions-1Document16 pagesGrade 10 Math in 1 Hour Questions-1ArnoldNo ratings yet

- Me101 HW 1Document2 pagesMe101 HW 1Saqib JabbarNo ratings yet

- 64Document18 pages64Rana Sabouni TabariNo ratings yet

- LOCALIZED INDIGENIZED INSTRUCTIONAL MATERIALS Science 8Document6 pagesLOCALIZED INDIGENIZED INSTRUCTIONAL MATERIALS Science 8joyce kris AlmacinNo ratings yet

- Process Control and Instrumentation CB308: BarometersDocument8 pagesProcess Control and Instrumentation CB308: BarometersDevesh Pratap SinghNo ratings yet

- The Development of Geometry: Euclidean Geometry To Non-Euclidean GeometryDocument5 pagesThe Development of Geometry: Euclidean Geometry To Non-Euclidean GeometryAntonio CruzNo ratings yet

- Analysis of Modelling Methods of Quadruple Tank SystemDocument15 pagesAnalysis of Modelling Methods of Quadruple Tank Systemcosmos35No ratings yet

- Skyrealms DemoDocument16 pagesSkyrealms DemoAlexGamer12100100% (1)

- Determining SIMS Relative Sensitivity Factors From Ion Implanted External StandardsDocument3 pagesDetermining SIMS Relative Sensitivity Factors From Ion Implanted External StandardsLuigi HernándezNo ratings yet

- Applied Finite Element Analysis, 2/e: Book Information Sheet Book Information SheetDocument2 pagesApplied Finite Element Analysis, 2/e: Book Information Sheet Book Information SheetKAUSTUV LAHIRINo ratings yet

- Topological InsulatorsDocument9 pagesTopological InsulatorsRiturajNo ratings yet

- Fluid Mechanics: TA. Igor SepulvedaDocument20 pagesFluid Mechanics: TA. Igor SepulvedaIgor SepNo ratings yet

- Crossbows EnglishDocument30 pagesCrossbows EnglishÁlvaro AlcaláNo ratings yet