Professional Documents

Culture Documents

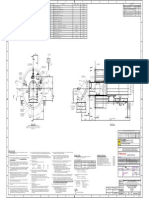

B0054829-4 Erection Arrangement DRB-XCL PC and Oil Fired Burner C.W

Uploaded by

Nanang Cesc UttaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B0054829-4 Erection Arrangement DRB-XCL PC and Oil Fired Burner C.W

Uploaded by

Nanang Cesc UttaCopyright:

Available Formats

127

5"

2

5

165

6 1/2"

2286 INSIDEWINDBOX

7'-6"

1

7

8

R

.

7

"

5

0

8

T

O

C

O

A

L

E

L

B

O

W

1

'-8

"

[23'-0"]

7010 ATOMIZERGUN REMOVAL SPACE

438 I.D.

1'-5 1/4"

546 B.C.

1'-9 1/2"

533

1'-9"

4

2

5

R

E

F

T

Y

P

1

'-4

3

/

4

"

330

1'-1"

4

0

6

1

'-4

"

686 REF TYP

2'-3"

8 10

1

5

5

6

'

1

5

3

0

'

3642'

2

5

'

2

3

5

5

'

3

4

6

'

1

4

3

0

'

OPERATION, ANDFOR SOLICITING BIDS FOR THE ERECTION OF, THE EQUIPMENT DISCLOSEDHEREIN.

8 7 6 5 4 3 2 1

A

J

I

H

G

F

E

D

C

B

J

I

H

G

F

E

D

C

B

A

1 2 3 4 5 6 7 8

B 0 0 5 4 8 2 9

- DO NOTSCALE-

N O

D W G

J 44-Customer.slddrt

11/2"=1'-0"

NO

YES

YES

563-0060-39-53

REV

J

DWG NO COA PROJ ECTNO

DISTMFG

DISTEREC

DISTCUST

SCALE

DATE

CHKD

APPVD

DWN

USERDEFINED FIELD

B0054829.slddrw

DRB-XCL PC AND OIL FIRED

ERECTION ARRANGEMENT

C.W.

4 B0054829 AC5100 0635-212F

BURNER

USEDIMENSIONSONLY

ORIG CONTRACTNO

12/11/08

D.W.DOWDELL

D.A.SMITH

C.A.IAFANO

TYPE PROJ ECT

Babcock & Wilcox Power Generation Group, Inc.

2007 BABCOCK &WILCOX POWER GENERATION GROUP, INC. ALL RIGHTS RESERVED.

THIS DRAWING IS THE PROPERTY OF BABCOCK &WILCOX POWER GENERATION GROUP, INC. (B&WPGG) ANDITS USE IS

GOVERNEDBY THE TERMS ANDCONDITIONS OF THE CONTRACT FOR WHICH IT WAS CREATED. B&WPGG GRANTS A

NON-EXCLUSIVE LICENSE TO USE, REPRODUCE ANDDISTRIBUTE THIS DRAWING SOLELY FOR THE MAINTENANCE, REPAIR AND

20 SOUTH VAN BUREN AVENUE, BARBERTON, OHIO

VIEWK

VIEWL

VIEWS

?

T

FLANGE#1

1'-9 1/2"B.C.

SECTION A-A

ON 76[3"] CENTERS

4

7

NE14

5

NE3

NE3

2 1

16 18 8

G7. ELECTRICAL DATA FORATOMIZERAIRCYLINDERPROXIMITY SWITCH:

IN

W

IN

D

B

O

X

41

21/2"O.D. TUBES

NE14 & NE27

(16) 7/8"DIA THRU

[9'-4 5/8"]

2861 RETRACTED

CL

28

STRADDLE

27

30

56

29

NE14 & NE27

LIFTING LUG

FLANGE#2

NE14 & NE27

FLANGE#2

EQ SPC'D ON

8 [5/16]

NE9,

NE10

& NE27

4

1

9

I.D

.

1

'-4

1

/

2

"

REF

1'-2 1/2"

9

1

4

3

'-0

"

I.D

. T

H

R

O

A

T

1/4"

6

1/4"

REF

4

'-5

"

IN

S

ID

E

1

3

4

6

4

'-7

"

D

IA

O

P

E

N

IN

G

1

3

9

7

8'-4 5/8"

INSERTED 2556

2'-0"

368

O.D.

6

610

914

3'-0"

457

1'-6"

J

J AB

AB

AC

AC

IN

L

E

T

F

L

A

N

G

E

FRONTVIEW

27

(NE10& NE12)

UNIT#2R.W. - 2A-1

UNIT#1R.W. - 1A-1

B&WHIGH

ENERGY

EXCITER

9

THISBURNERARRANGEMENTFORBURNERS:

NE18

G1 &

RATCHETDRIVE

AIRZONEDISK

J UNCTION BOX

THERMOCOUPLE

DOOR

OBSERVATION

MOUNT

SCANNER

IGNITOR

MOUNT

SCANNER

IGNITOR

CONNECTION

AIRMONITOR

LOWPRESSURE

CONNECTION

AIRMONITOR

HIGHPRESSURE

HANDLE

VANEPULL

OUTERAIR

HANDLE

W.P.

W.P.

6

10

CFSOIL

INNERAIR

VANEPULL

32

T

T

H

H

F

F

G

G

E E

D

D

C

C

B

B

A

A

2

17 1/4"CONICAL DIFFUSER(SILICON CARBIDE)

NIPPLE, 3/4"X4 1/2"XSTBENPTSA106BHF/CF 2316409

58 2 ELBOW, 3/4"NPT3000#90 DEG SA105 3018110

B0054897

59 2

6420532

ASSEMBLY FLEXIBLEHOSE1"X59"LG 6254690

60 4 NIP TBE1"SCHXSX3"LG STL 3017884

61 2 TEETHRD 1"3000#SA105 3017949

62 2 BSHG HEXHD SCRD 1"X1/4"SA105 8004376

63 4 NUTHEX1/2"13UNC-2BA563A 4546572

2729173

3 2 RETAINERBAR 2345650A 2345650

4 1

FILL HOLESIN COAL NOZZLEFORDEFLECTORRETAINERBARSWITHRTV SEALER.

NE11. APPLY RTV SEALERTO LEADING EDGEOF DEFLECTORAND COAL NOZZLE.

MATCHPAINTLINEOF COAL NOZZLEWITHMOUNTING PLATE.

SEEGENERAL ARRANGEMENTFORCORRECTORIENTATION. FORALIGNMENT

DIFFUSER(INSIDENOZZLE) IN LINEWITHCENTERLINEOF COAL ELBOWINLET.

IN COAL ELBOW. ERECTORTO ROTATECENTERLINEOF DEFLECTORAND

NE10. ERECTORTO ROTATENOZZLEIF NECESSARY TO LINEUP WITHBOLTHOLES

NE9. FORWELDING CERAMIC LINED COMPONENTS, SEEDRAWING 275065A.

ISCOMPLETE.

NE8. ERECTORTO INSUREPROPERDISK MOVEMENTAFTERBURNERINSTALLATION

THEERECTORUNLESSOTHERWISESPECIFIED.

NE7. THEFIELD INSTALLED INSULATION AND LAGGING ISTHERESPONSIBILITY OF

PACKING IN PLACE.

PLATE. INSTALL ROPEPACKING AND BEND SLIP SEAL TABSOVERTO HOLD

THEBURNER. THEN COMPLETETHEWELDING OF THESLIP SEAL TO THEFRONT

TOLERANCE. ALL SUPPORTBRACKETSMUSTBECARRYING THELOAD OF

POSSIBLEWITHOUTINFRINGING ON THE13[1/2"] +6[1/4"] -0"GAP

NE6. BURNERSARETO BEASLEVEL AND PERPENDICULARTO THEWALL TUBESAS

BURNERWEIGHTON SLIP SEAL.)

AIRSLEEVEWITHRESPECTTO THETHROATOPENING. (DO NOTSUPPORT

+/- 1/8". SLIP SEAL WILL SERVEASA GUIDEFORPOSITIONING THEBURNER

NE5. TACK WELD SLIP SEAL TO FRONTPLATECONCENTRIC WITHTHROATOPENING

DIMENSIONSATSUPPORTBRACKETS.

BEFOREWELDING SUPPORTCHANNELS, ERECTORTO INSURECLEARANCE

CENTERLINEOF BURNERAND RESTING ON SUPPORTCHANNELSIN WINDBOX.

NE4. SUPPORTCHANNELSTO BEPARALLEL TO TUBEWALL, PERPENDICULARTO

BY AIRSLEEVESUPPORTBARS.)

(DO NOTLIFTBURNER IN LIFTING LUG ON COVERPLATEAND AIRSLEEVE.

NE3. TO AVOID DAMAGETO BURNERS, USE38[11/2"] DIA HOLESPROVIDED

NE2. DISSIMILARWELD SST TO CARBON. SEEFIELD WELD SCHEDULEDRAWING.

GOOD INDUSTRY PRACTICE.

NE1. UNLESSOTHERWISENOTED: ALL NPP TO NPP WELDSSHALL CONFORM TO

ERECTION NOTES:

THREADS. (NO ADJ USTMENTSTO BEMADEBY TWISTING HOSE.)

NE20. TO PREVENTDAMAGETO HOSE, ALL ADJ USTMENTSMUSTBEMADEIN PIPE

TWISTING HOSEDURING INSTALLATION.

TWISTING. NO TORSIONAL FORCESMAY BEAPPLIED TO HOSEBY

PARALLEL TO THEVERTICAL CENTERLINEOF BURNERTO PREVENT

NE19. LOOP OF HOSETO BEINSTALLED IN A VERTICAL POSITION AND

NOTMOUNTHIGHENERGY EXCITERON WINDBOXCASING.

NE18. LOCATEHIGHENERGY EXCITERWITHIN 3048[10'-0"] OF LIGHTER. DO

COVERPLATE.

TO INSURECLEARANCETHRUAIRVANES. THEN WELD LIGHTERPIPEAT

WELDING INSTRUCTIONSFORCERAMIC COMPONENTS. . . . . . .275065A

FIELD WELD SCHEDULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B0054841

INDICATESBURNERTERMINAL

REFERENCEDRAWINGS:

R

SYMBOL:

ERECTION ARRANGEMENTDIFFERENTIAL PRESSUREGAGE. . . . .B0054842

ARRANGEMENTRECOMMENDED SPAREPARTS. . . . . . . . . . . . . .B0054840

ERECTION ARRANGEMENTTHERMOCOUPLES. . . . . . . . . . . . . . . B0054839

ERECTION ARRANGEMENTSECTIONS& VIEWS4. . . . . . . . . . . . . B0054856

ERECTION ARRANGEMENTSECTIONS& VIEWS2. . . . . . . . . . . . . B0054838

ERECTION ARRANGEMENTSECTIONS& VIEWS1. . . . . . . . . . . . . .B0054837

GENERAL ARRANGEMENTREARWALL . . . . . . . . . . . . . . . . . . . . . B0054793

GENERAL ARRANGEMENTFRONTWALL . . . . . . . . . . . . . . . . . . . . B0054792

TUBEWALL. TACK WELD LIGHTERASSEMBLY THEN STROKEAIRCYLINDER

NE17. INSUREPROPERLOCATION FROM LIGHTERSHIELD TO CENTERLINEOF

REVERSETHISPROCEDURETO ATTAIN THEFULLY CLOSED POSITION.

E) EXTEND RATCHETJ ACK BACK TO MECHANICALLY OPENED POSITION.

D) RETIGHTEN U-BOLTS

C) RETRACTRATCHETJ ACK 102[4"]

B) LOOSEN U-BOLTS

A) ASSURETHATRATCHETJ ACK ISMECHANICALLY OPEN

POSITION YOUMUST:

CLOSED TO 102[4"] FROM FULLY OPENED. TO ACHIEVETHEFULLY OPENED

RATCHETJ ACK WILL ALLOWFOR203[8"] OF TRAVEL: FROM FULLY

FULLY CLOSED POSITION. IN IT'SCURRENTPOSITION THE

NE16. BURNERSARESHIPPED WITHTHERATCHETJ ACK DRIVESIN THE

FORLIFTING BURNER.)

AFTERINSTALLATION ISCOMPLETE. (DO NOTUSETHESEMEMBERS

NE15. ERECTORTO REMOVEALL SUPPORTMEMBERSPAINTED YELLOW

ELBOWCOVER 3/4"DIA BOLTAND NUT 100 14.8

63 1/2"NUT 30 4.1

16& 18 1"DIA BOLT& NUT 245 33.9

1

17 3/8"SCREW 15 2

FIND NO. DESCRIPTION FT-LBS KG/M

17 1/4"DEFLECTOR(SILICON CARBIDE)

NE14. TORQUEREQUIREMENTS:

BURNERELEMENTASSEMBLY: 1590KG [3503LBS.]

NE13. ESTIMATED WEIGHTS:

BY MANUFACTURING.

BY BURNERNUMBERAND NOZZLESROTATED TO THEIRAPPROXIMATELOCATIONS

BURNERNUMBERPERTHEGENERALARRANGEMENTS. BURNERSARESTENCILED

NE12. ERECTORMUSTINSERTBURNERSIN THEIRAPPROPRIATELOCATIONSBY

5

c) ALL REMAINING BOLTS.

USERDEFINED FIELD UNIT#2 UNIT#1

563-0061-39-53

ORIG CONTRACTNO

PROJ ECTNO

0635-212G

D) CARESHOULD BETAKEN TO AVOID CONTACTWITHANY OTHER

b) FOUR(4) COVERBOLTSFORFLANGES#2.

a) FOUR(4) COVERBOLTSFORFLANGES#1.

C) REBOLTFLANGESSEQUENTIALLY ASFOLLOWS:

B) CLEAN FLANGESAND APPLY HIGHTEMPERATURERTV.

A) UNBOLTAND REMOVECOVER.

NE28. FIELD PROCEDUREFORREMOVAL AND INSTALLATION OF COAL ELBOWCOVER:

NE27. TRIM VANESASNEEDED TO MAINTAIN TOLERANCES.

PRIORTO INSERTING THECOAL NOZZLEINTO THEBURNER.

THECOAL NOZZLETHERMOCOUPLESARETO BEINSTALLED ON THECOAL NOZZLE

SEEBURNERGENERAL ARRANGEMENTDRAWINGSFORCORRECTORIENTATIONS.

MOUNTING HOLESAREINLINEWITHTHECENTERLINEOF THECOAL ELBOWINLET.

NE26. ORIENTATECOAL NOZZLESO THECENTERLINEBETWEEN THEDEFLECTOR

6 & 9 O'CLOCK PATTERN TO FORM A COMPLETEWELD.

ELBOW. WELD PROCEDURETO BE16 [5/8"] LG. SEAL WELD IN A 12, 3,

REG. ROD SUPPORTPIPEAND REG. ROD SUPPORTPIPETO COAL

TO REG. ROD SUPPORTPIPE, ROD & PORTSEAL ASSEMBLY TO

TRAVEL OF REGULATING ROD, THEN WELD SUPPORTBRACKET

HOLESATEACHEND OF STROKEAND INSUREUNRESTRICTED

AND VERIFY ALIGNMENTBY CHECKING CONCENTRICITY OF

FIND NO. 43 AND AIRCYLINDERFIND NO. 44 TO THEBURNER

NO. 41, DRIVEBRACKETFIND NO. 42, MOUNTING BRACKET

NE25. ASSEMBLEEXISTING COAL ELBOW, ROD SUPPORTPIPEFIND

FROM AIRCYLINDERTO CONTROL TRAVEL SPEED.

NE24. ASSEMBLEFLOWCONTROL VALVESFIND NO. 55 WITHARROWPOINTING AWAY

NE23. INDEXREGULATING ROD ATNORMAL FIRING POSITION, WITHSCRIBELINE.

TO BEFLUSHWITHCLAMPSWHEN PROBETIP ISFLUSHWITHOIL IGNITORSHIELD.

NE22. ERECTORTO FILEMARK SPARK TCD WITH(4) 6 [1/4"] INCREMENTS. FIRSTMARK

OBJ ECTS, ANY IMPACTCAN DAMAGETHECERAMIC.

G6. AIRREQUIREMENTSFORATOMIZERAIRCYLINDER:

PERSTROKE

3

: .0025M

2

5.6-7.0 KG/CM

80-100 PSIG: .089 CF PERSTROKE

T

<10V @25 MA AC

VOLTAGEDROP . . . . . . . <8V @25 MA DC

2.5 MA @121-250 VAC/ DC

LEAKAGECURRENT. . . . .1.7 MA @120 VAC/DC

LOAC CURRENT. . . . . . . .2-25 MA

VOLTAGERANGE. . . . . . 20-250 VAC/DC

G5. ELECTRICAL DATA FOROIL IGNITORPROXIMITY SWITCH:

PERSTROKE

3

: .0025M

2

5.6-8.4 KG/CM

80-120 PSIG: .017 CF PERSTROKE

CYLINDER:

G4. AIRREQUIREMENTSFOROIL IGNITORPROBEDRIVE

PERSTROKE

3

: .0025M

2

5.6-8.4 KG/CM

80-120 PSIG: .087 CF PERSTROKE

G3. AIRREQUIREMENTSFOROIL IGNITORDRIVECYLINDER:

G2. SEAL AIRREQUIREMENTS:

85-250 VAC, 50-60 HZ, 1 PHASE, 100VA

G1. ELECTRICAL REQUIREMENTSFORHIGHENERGY SPARK IGNITOR:

GENERALNOTES:

CERAMIC PARTFORLIFTING.

C) DO NOTUSEA CABLEORCHAIN THROUGHORAROUND ANY

B) FORPARTSWITHOUTLIFTING LUGS, USENYLON SLING FORLIFTING.

A) ALWAYSUSELIFTING LUGS, IF PROVIDED, TO LIFTPART.

TO AVOID BREAKING, CRACKING AND CHIPPING:

CERAMIC ISA VERY BRITTLEPRODUCTAND REQUIRESSPECIAL HANDLING

NE21. GENERAL HANDLING FORCERAMIC COMPONENTS:

2343811D 2343811

6 4 FLANGESEGMENT 2763817A 2763817

7 1 DIFFUSERMOUNTING BRACKET 299350B 2174414

8 1 GASKET 356104C 4688613

9 1 EXCITERHIGHENERGY 348822C 4688147

10 1 IGNITORCFSOIL L.H. "L"=10'-0" "LS"=8'-0 5/16" 2269078E 6419309

11 4 BURNERSUPPORTBRACKETRETAINER 162770A 4539895

12 4 C6 X10.5 X1'-4"LG. A36 4678009

13 .5 TUBE SEALER, RED SILICONERUBBER 0330146

14 31 FT PACKING ROUND ROPEFIBERFRAX2300 5/8" 4591668

15 4 WASHERPLN 3/8"TYPEB(W) F844 0458702

16 16 NUTHEX1"A563B(GR5) 4685586

17 4 SCREWCAP HEX3/8"-16UNC-2A X1 1/4"A307A 8004289

18 16 BOLTHEX1"X3 1/4"LG. A449TP1 (GR5) 4695347

19 2 ASSEMBLY FLEXIBLEHOSE3/8"X50"LG 6253420

20 2 TEETHRD 1/2"3000#STL 3017087

21 2 BSHG HEXHD SCRD 1/2"X3/8"SA105 0350068

22 4 PLUG THRD SQ HD 1/4"3000#SA105 3026365

23 2 BSHG HEXHD SCRD 1/2"X1/4"STL 3014711

24 2 BALL VALVE1/2"SHARPE54574N 4688127

25

DESCRIPTION FLOW PRESSURE

a OIL IGNITORCONN.

5 SCFM

8.5 NM

3

/HR

2"WC ABOVEWINDBOX

5 CM WC ABOVEWINDBOX

b OIL IGNITORCONN.

10 SCFM

17 NM

3

/HR

2"WC ABOVEFURNACE

5 CM WC ABOVEFURNACE

c ATOMIZERASPIRATOR

10 SCFM

4688148 ASSEMBLY CABLE15'-0" 1 32

4688667 BALL VALVE1"SHARPE54574N 2 31

6423304 B0054895 COAL NOZZLEMOUNTING PLATE 1 30

6425088 B0054905 ASSEMBLY MOUNTING PLATE 1 29

6426580 B0054913

5 250 -- --

5 125 5 480

1 48 2 240

2 24 4 120

AMPS DC VOLTS AMPS AC VOLTS

ASSEMBLY 16 1/2"CERAMIC LINED COAL NOZZLE 1 28

6436076 B0054932 ASSEMBLY 17 1/4"I.D. CERAMIC LINED COAL ELBOW 1 27

6441549 GO SWITCHLIMITSWITCH73-13527DCA 1 26

2233574 NIPPLE1/2' X3"LG TBENPTSA106B 2

10 CM WC ABOVEFURNACE

4"WC ABOVEFURNACE

/HR

3

7.8 NM

4 SCFM

ROD & PORTSEAL d

5 CM WC ABOVEFURNACE

2"WC ABOVEFURNACE

/HR

3

17 NM

ITEM NO QTY DESCRIPTION DRAWING NUMBER PARTNUMBER

1 1 ASSEMBLY BURNERELEMENTC.W. B0054848 6420992

2 1 ASSEMBLY SLIP SEAL 2729173C

ITEM NO QTY DESCRIPTION DRAWING NUMBER PARTNUMBER

33 1 HIGHENERGY SPARK ROD PL-12' =9'-11 9/16" 188723B 2226783

34 1 HIGHENERGY SPARK PROBETIP 188722B 8804376

35

36

37 1 TARGETMAGNET 6441550

38 1 SWITCHPLATE B0055213 6441512

39 1 SWITCHPLATE B0055214 6441532

40 1 ASSEMBLY ATOMIZERMF "L"=15'-6" 146577D 6421158

41 1 ASSEMBLY SUPPORTPIPE B0054849 6421162

42 1 ASSEMBLY DRIVEBRACKET 6255238B 6255238

43 1 ASSEMBLY MOUNTING BRACKET 2324955B 2324955

44 1 AIRCYLINDERYATESW/PROXY SWITCHES4"BOREMODEL NO. L4-N-B4.0V12.00N1.00V4S11 4703920

45 1 ROD EYEYATES#13-MSRE-0750 2324916

46 1 CLEVISPIN YATES#12-YP-9004-3-G-CBS-A 2324917

47 1 CLEVISBRACKETYATES#14-YCB-133-05-CBS-A 2324914

48 2 U-BOLT3/8"X2"W/ 4 NUTSCARBON STEEL 4677637

49 2 PROXIMITY SWITCHCABLE30'-0"LG. 6441548

50 4 BOLTHEX1/2"-13UNC-2A X2"LG A563A 4661082

51 4 NUTHVY HEX3/8"24UNF-2B 4700049

52 4 WASHERSPRING LOCK 1/2"STL 0493478

53 4 WASHERLOCK 3/8"STL 0493475

54 2 NIP HEXRED CAJ ON B-8-HRN-6 6041159

55 2 VALVEFLOWCONTROL 3/8"N.P.T. PNEU-TROL F-25BK 3087733

56 1 RETAINERSTRAP B0054912 6426486

57

REVISIONS

REV DESCRIPTION DATE APPROVED

1 ADDED CUSTOMERTITLEBLOCK. CAI/ DAS 2/ 2/ 2009 DWD

2

CHG'D DESC. OF ITEM NO. 26, 27, 28, 29, 30, 38, 39, 49 AND

56. ADDED ITEM NO. 37. UPDATED GRAPHICSIN FRONTVIEW

AND SECTION A-A. ADDED SECTIONSAB-ABAND AC-AC.

REVISED NE14. ADDED NE26-28. REVISED CUSTOMERTITLE

BLOCK FROM YYY TO BNR. CAI/ DAS

6/ 2/ 2009 DWD

3

REVISED DRAWING REVISION NUMBERSIN TITLE BLOCK.

DAS

6/ 16/ 2009 DWD

4

CHG'D DESC AND P/ N FORITEM NO. 9. ADDED ITEM

NOs. 32-34.REVISED CUSTOMERTITLE BLOCK. CAI/ DAS

3/ 1/ 2010 DWD

EMPLOYERS DOCUMENT REVIEWANDSTATUS

LOG

IN

DATE 08/09/09 REVIEW BY REVISION STATUS DISTRIBUTION 1

COMM NO : 0312 MECHANICA

L

A : ACCEPTED X CONTRACTOR X

LOG

OUT

DATE 16/10/09 ELECTRICAL B : ACCEPTED AS NOTED RECORD 1

COMM NO: 0233 I &C C : NOT ACCEPTED PIKITRING J BN 1

RELEASED BY : DATE: 16/10/09 SUPPORT I : INFORMATION ONLY PROJ ECT 1

Owner :

PT. PLN (PERSERO)

SURALAYA STEAM POWER PLANT UNIT 1- 4 ( 4 X 400 MW)

LOT 1 : BOILER UNIT 1 & 2

REHABILITATION PROJECT Contract No. 255.PJ/041/DIR/2008

PT PLN (PERSERO) JASA ENJINIRING

DRAWING TITLE :

PLN DRAWINGNo. REV

0 1 0 4 1 L 1 - 0 2 - M - 5 1 - H J A - 0 0 6

Contractor :

MARUBENI CORPORATION

Revision History

Rev. Rev. Date Created by Checked

by

Approved by Description

01 2/03/2009 C.A. IAFANO D. SMITH D.W. DOWDELL ADDED CUSTOMER TITLE BLOCK.

02 6/02/2009 C.A. IAFANO D. SMTIH D.W. DOWDELL ADDED COAL NOZZLE ANDREALATEDPARTS.

03 6/16/2009 D.SMITH D.SMITH D.W.DOWDELL REVISED DRAWINGREVISION NUMBERS

04 3/1/2010 C.A.IAFANO D.SMITH D.W.DOWDELL CHGD DESC ANDP/NFOR ITEM9. ADDEDITEMS

32-34. REVISED CUSTOMER TITLE BLOCK.

Contractors (Partner, Subcontractor)

Babcock&WilcoxPower GenerationGroup

Scale

1 1/2"=1-0

Contractors Document/ Drawing No

SRLSPP12-1-255-BNR-A-004-04

Responsible dept.

ISP

Created by

C.A. IAFANO

Checkedby

D.A. SMITH

Approvedby

D.W. DOWDELL

Size

J

Originator

B&W

Document Title(Subtitle)

ERECTION ARRANGEMENT

DRB-XCL PC ANDOIL FIRED

BURNER C.W.

DocumentType

For FINAL

Identification number

B0054829

Rev.

04

Date

3/1/2010

Sheet

1/1

You might also like

- NEMA Premium Efficiency Electric Motor (600V or Less)Document12 pagesNEMA Premium Efficiency Electric Motor (600V or Less)Nanang Cesc Utta100% (1)

- Application of A High-Order Asymptotic Expansion Scheme To Long-Term Currency OptionsDocument14 pagesApplication of A High-Order Asymptotic Expansion Scheme To Long-Term Currency OptionsNanang Cesc UttaNo ratings yet

- AWWA D100-96 TocDocument4 pagesAWWA D100-96 TocNanang Cesc UttaNo ratings yet

- Astm Specifications For Weld Fittings and FlangesDocument1 pageAstm Specifications For Weld Fittings and FlangesamitkumarkarmakarNo ratings yet

- Astm Specifications For Weld Fittings and FlangesDocument1 pageAstm Specifications For Weld Fittings and FlangesamitkumarkarmakarNo ratings yet

- Performance of CFB ErectionDocument0 pagesPerformance of CFB ErectionNanang Cesc UttaNo ratings yet

- B0054833-4 Erection Arrangement DRB-XCL PC and Oil Fired Burner C.C.WDocument1 pageB0054833-4 Erection Arrangement DRB-XCL PC and Oil Fired Burner C.C.WNanang Cesc UttaNo ratings yet

- Welding Defects Part 4Document56 pagesWelding Defects Part 4Nanang Cesc UttaNo ratings yet

- B0054827-4 Erection Arrangement DRB-XCL PC Fired Burner C.WDocument1 pageB0054827-4 Erection Arrangement DRB-XCL PC Fired Burner C.WNanang Cesc UttaNo ratings yet

- B0054831-4 Erection Arrangement DRB-XCL PC Fired Burner C.C.WDocument1 pageB0054831-4 Erection Arrangement DRB-XCL PC Fired Burner C.C.WNanang Cesc UttaNo ratings yet

- B0054832-4 Erection Arrangement DRB-XCL PC Fired Burner C.C.WDocument1 pageB0054832-4 Erection Arrangement DRB-XCL PC Fired Burner C.C.WNanang Cesc UttaNo ratings yet

- 1 - Transmittal No. R0051734-CTCDocument7 pages1 - Transmittal No. R0051734-CTCNanang Cesc UttaNo ratings yet

- Coating ProcedureDocument10 pagesCoating ProcedureNanang Cesc Utta100% (1)

- B0179073-3 Erection Arrangement Superheater Replacement Section B-B Unit 1 OnlyDocument1 pageB0179073-3 Erection Arrangement Superheater Replacement Section B-B Unit 1 OnlyNanang Cesc UttaNo ratings yet

- Performance of CFB ErectionDocument0 pagesPerformance of CFB ErectionNanang Cesc UttaNo ratings yet

- Welding Defects, Causes and CorrectionsDocument3 pagesWelding Defects, Causes and CorrectionsBinh Pham100% (2)

- Draft Surat Undangan Untuk Depnaker EnglishDocument1 pageDraft Surat Undangan Untuk Depnaker EnglishNanang Cesc UttaNo ratings yet

- Epizootic Rabbit ThyDocument13 pagesEpizootic Rabbit ThyNanang Cesc UttaNo ratings yet

- MTV - Demineralised and Potable Water Distribution SystemDocument7 pagesMTV - Demineralised and Potable Water Distribution SystemNanang Cesc UttaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Drill Pipe ProtectorsDocument11 pagesDrill Pipe ProtectorsDon BraithwaiteNo ratings yet

- CableDocument7 pagesCablerocketvtNo ratings yet

- Seismic Design Steps: Er.T.Rangarajan, B.E, M.SC (Struct - Engg), Consulting Structural EngineerDocument16 pagesSeismic Design Steps: Er.T.Rangarajan, B.E, M.SC (Struct - Engg), Consulting Structural EngineercivilsadiqNo ratings yet

- Internship Report On Harshit LandmarkDocument32 pagesInternship Report On Harshit LandmarkABHISHEK SINGHNo ratings yet

- Comacchio MC 1200 PDFDocument2 pagesComacchio MC 1200 PDFUpasnaNo ratings yet

- Numerical Analysis of Rail Structure Interaction and Resonance in Railway BridgesDocument11 pagesNumerical Analysis of Rail Structure Interaction and Resonance in Railway BridgesJEETENDRA PRAKASHNo ratings yet

- Diagrid, Prada Boutique AoyamaDocument4 pagesDiagrid, Prada Boutique AoyamastefanNo ratings yet

- Concept and Basic, Details Engg InfoDocument2 pagesConcept and Basic, Details Engg InfomgkvprNo ratings yet

- Cmaa 74 Deflection Criteria: Most Asked Action Alerts MHIDocument3 pagesCmaa 74 Deflection Criteria: Most Asked Action Alerts MHIboringNo ratings yet

- Leed GA Practice Questions - QuestionsDocument35 pagesLeed GA Practice Questions - QuestionsAl-Madinah Al-MunawarahNo ratings yet

- Base Isolated LNG Tanks Seismic Analyses and Comparison StudiesDocument10 pagesBase Isolated LNG Tanks Seismic Analyses and Comparison StudiesciscoNo ratings yet

- Modipur SelectorGuideDocument3 pagesModipur SelectorGuideSaidiJalelNo ratings yet

- Catalogo de Peças Scania - 2015Document433 pagesCatalogo de Peças Scania - 2015João Paulo Gonçalves100% (2)

- Design of Bolted Connections in Steel StructuresDocument4 pagesDesign of Bolted Connections in Steel StructuresHarish T S Gowda0% (1)

- A Case StudyDocument25 pagesA Case StudyJainam ShahNo ratings yet

- Hyperboloid StructureDocument7 pagesHyperboloid StructureGeorgiaNo ratings yet

- Engineering Job CV FormatDocument3 pagesEngineering Job CV FormatOjolowo OlamideNo ratings yet

- Executive Summary of The Tropicana Inspection ReportDocument18 pagesExecutive Summary of The Tropicana Inspection ReportFOX5 VegasNo ratings yet

- Beta PMDocument2 pagesBeta PMSeif el dean MamdouhNo ratings yet

- General Notes FBDocument3 pagesGeneral Notes FBEnglish for KidsNo ratings yet

- 4 Day Work Cycle 100 Walls 100 Slabs 4 SectionsDocument2 pages4 Day Work Cycle 100 Walls 100 Slabs 4 SectionsSarinNo ratings yet

- Company Profile OverviewDocument6 pagesCompany Profile OverviewrajaduraiNo ratings yet

- National Standard Taper Pipe Threads Size NPT Chart - Engineers EdgeDocument2 pagesNational Standard Taper Pipe Threads Size NPT Chart - Engineers EdgeParesh PatelNo ratings yet

- Vendor DetailsDocument2 pagesVendor DetailsMohan BabuNo ratings yet

- Shear Wall Modelling Techniques: A ReviewDocument9 pagesShear Wall Modelling Techniques: A ReviewAmanulla MullaNo ratings yet

- 940 U S Face Permeability Monitoring For Gibe III RCC Dam and Resin Injection Works, Pittalis, Cagiano, Pietrangeli, BianDocument8 pages940 U S Face Permeability Monitoring For Gibe III RCC Dam and Resin Injection Works, Pittalis, Cagiano, Pietrangeli, BianDataniel RosarioNo ratings yet

- (3D) API ValvesDocument76 pages(3D) API ValvesTrần Trung DũngNo ratings yet

- Product BrochureDocument2 pagesProduct BrochureAnonymous JTPnBgnMxINo ratings yet

- Lab 2 - Tensile Testing of MetalsDocument8 pagesLab 2 - Tensile Testing of MetalsMoey RenNo ratings yet

- Build Up RateDocument10 pagesBuild Up RateNurul Farhanah100% (2)