Professional Documents

Culture Documents

TTT

Uploaded by

Taufanbenz0 ratings0% found this document useful (0 votes)

20 views7 pagestabel TTT

Original Title

Ttt

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenttabel TTT

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views7 pagesTTT

Uploaded by

Taufanbenztabel TTT

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

1

436-221/223/281 Unit 2: Engineering Materials Dr. K. Xia

Phase Transformations in Fe-C System

Fe-C system is chosen to

illustrate some typical

transformations and resulting

microstructures, not to mention its

importance in engineering

applications of steels

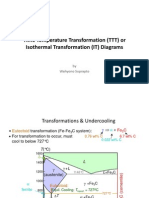

Isothermal Transformation

Diagrams

Such a diagram plots the fraction

of transformation versus time

when the alloy is held

isothermally (i. e. at a constant

temperature) at various

temperatures

Example: formation of pearlite in

a eutectoid alloy (0.76C) from the

eutectoid reaction

= + Fe

3

C (at T = T

i

)

fraction of transformation vs time

curves at various temperatures

Reading: 10.5-10.9 (5th & 6th ed)

y = 1 exp( kt

n

) Avrami equation

start time: t

0

completion time: t

100

half time:

t

50

Corresponding to each temperature,

we can find t

0

, t

50

and t

100

.

436-221/223/281 Unit 2: Engineering Materials Dr. K. Xia

Phase Transformations in Fe-C System (2)

plot temperature versus

log t

0

, t

50

and t

100

,

respectively

connecting all the

points for t

0

= the

start curve

connecting all the

points for t

50

= the

half curve

connecting all the

points for t

100

= the

completion curve

these curves are also

called TTT curves or C

curves

the rate of transformation

is the fastest at an

intermediate temperature

(the nose)

675

650

no reaction above Te

t

50

= ~28 h

at ~720C

t

50

< 5 s

at 600C

2

436-221/223/281 Unit 2: Engineering Materials Dr. K. Xia

Phase Transformations in Fe-C System (3)

ABCD = a real heat treatment route

due to high

diffusion rate

due to low

diffusion rate

436-221/223/281 Unit 2: Engineering Materials Dr. K. Xia

Phase Transformations in Fe-C System (4)

Coarse

pearlite

Fine

pearlite

Micro-

structures

3

436-221/223/281 Unit 2: Engineering Materials Dr. K. Xia

Phase Transformations in Fe-C System (5)

Extended (down to ~215C) TTT diagram for the eutectoid steel

at T < ~540C, a new microstructure - bainite - forms as a result of

phase transformation

Bainite takes a needle or a plate shape and consists of elongated

cementite in a matrix of ferrite

cementite

ferrite

bainite

~540C

pearlite

austenite

nose -

fastest

trans-

formation

436-221/223/281 Unit 2: Engineering Materials Dr. K. Xia

Phase Transformations in Fe-C System (6)

Complete TTT diagram

for the eutectoid steel

when cooled so fast

that no C diffusion is

possible, a new

phase - martensite -

forms (at even lower

temperatures) from

the austenite phase

the martensite (M)

transformation is

diffusionless, and

thus takes virtully no

time (the amount of M

depends on T only,

NOT on time)

Above M(start),

no M forms

At M(90%), 90% of A

transforms into M

4

436-221/223/281 Unit 2: Engineering Materials Dr. K. Xia

Phase Transformations in Fe-C System (7)

martensite

Fe forms a body-centred

tetragonal (BCT) unit cell

C atoms remain in the

interstitial sites (no formation of

cementite)

a non-equilibrium phase (not

present in the phase diagram)

Austenite

(FCC)

Martensite

(BCT)

c > a

Dark phase: martensite of needle shape

Light phase: untransformed austenite

hard

and

brittle

further

transfor-

mation

possible

436-221/223/281 Unit 2: Engineering Materials Dr. K. Xia

Phase Transformations in Fe-C System (8)

Example 10.1

Fe-C of eutectoid composition

starting microstructure: at

760C

Find: microstructures and

percentages of each

microconstituent after the

following heat treatments

(a) rapid cooling to 350C,

holding for 10000 s, and

quenching to RT

(b) rapid cooling to 250C,

holding for 100 s, and

quenching to RT

(c) rapid cooling to 650C,

holding for 20 s, rapid

cooling to 400C, holding

for 1000 s, and quenching

to RT

No M

forms as

the starting

phase is B

or P

50%B 100%B 100%A A to B

starts

100%A

100%A

A to M starts

50%M

90%M

100%A

A to P

starts 50%P

50%A

no more

transformation

A to B

starts

A to B

completes

These phases

and structures

cannot be

read from the

equilibrium

phase

diagram!!

5

436-221/223/281 Unit 2: Engineering Materials Dr. K. Xia

Phase Transformations in Fe-C System (9)

Effect of composition

C: non-eutectoid compositions

e. g. a hypereutectoid alloy (C

o

)

proeutectoid cementite may

appear

C

o

T'

T'

Proeutectoid

Fe

3

C

A to C

starts

A & C coexist

C

C +

A to C

starts

A to C

completes

A to P

starts

A to P

completes

436-221/223/281 Unit 2: Engineering Materials Dr. K. Xia

Phase Transformations in Fe-C System (10)

other alloying elements

shape and position

of the starting, half

and completion lines

may be different

Fe-0.76C

4340 alloy steel: Fe-0.4C-1.8Ni-

0.7Mn-0.8Cr-0.2Si-0.25Mo

proeutectoid

ferrite

HW: follow isothermal phase transformations

of alloy steel 4340 at 350, 550, 650 and 750C

6

436-221/223/281 Unit 2: Engineering Materials Dr. K. Xia

Phase Transformations in Fe-C System (11)

Continuous cooling

transformation (CCT)

diagrams

In practice, the cooling is often

continuously carried out at a

certain rate to room

temperature, rather than rapid

cooling to a certain temperature

and holding at the temperature

for a period of time when the

isothermal transformation

diagrams are applicable.

For continuous cooling, the

transformation diagrams are

different: various curves are

usually shifted to lower

temperatures and longer times.

Also, some phases may not

appear at all.

continuous

cooling

isothermal

holding

436-221/223/281 Unit 2: Engineering Materials Dr. K. Xia

Phase Transformations in Fe-C System (12)

Example: continuous cooling of a

eutectoid steel

A

P

P + M

M

A to P

starts

A to P

finishes:

100% P

A to P stops:

P +

remaining A

remaining

A to M

starts

A to M

starts

A to P

transfor-

mation

stops at

line AB

Cooling rate determines what

microstructures will be present

following heat treatment

7

436-221/223/281 Unit 2: Engineering Materials Dr. K. Xia

Phase Transformations in Fe-C System (13)

Things can certainly get

much more complicated

with alloying, but the

diagram can be read in

the same way.

4340 alloy steel

HW: Try to reach the

final microstructures

following cooling at

different rates

You might also like

- Chap 6 TTT Diagram (New)Document26 pagesChap 6 TTT Diagram (New)eeit_nizamNo ratings yet

- Review MetalDocument38 pagesReview MetalnisannisaNo ratings yet

- TTT 11Document55 pagesTTT 11MrDOTNo ratings yet

- TTT N AvramiDocument40 pagesTTT N AvramiAmirul AminNo ratings yet

- TTT Phase DiagramDocument9 pagesTTT Phase Diagramhari krishnaNo ratings yet

- Publication 4 11889 199Document9 pagesPublication 4 11889 199Mulia AridhoNo ratings yet

- Diagram Fasa Fe-CDocument12 pagesDiagram Fasa Fe-CRudi HirarkiNo ratings yet

- 3 Fe-Fe3C Phase DiagramDocument33 pages3 Fe-Fe3C Phase DiagramRajat Mishra100% (1)

- FALLSEM2019-20 MEE1005 ETH VL2019201001078 Reference Material I 29-Aug-2019 Fe-Fe3C Phase DiagramDocument33 pagesFALLSEM2019-20 MEE1005 ETH VL2019201001078 Reference Material I 29-Aug-2019 Fe-Fe3C Phase DiagramFazal KhanNo ratings yet

- Ch-8 Compatibility ModeDocument58 pagesCh-8 Compatibility Modedreamgurl9011No ratings yet

- Closed-Book Practice-Ch 10 (2017!08!08)Document12 pagesClosed-Book Practice-Ch 10 (2017!08!08)Juan0% (1)

- Time Temperature Transformation (TTT) or IsothermalDocument26 pagesTime Temperature Transformation (TTT) or IsothermalAfredo TrilasetyaNo ratings yet

- Fe CDocument34 pagesFe CZaza ArifinNo ratings yet

- Iron-Carbon Phase Diagram (A Review) See Callister Chapter 9Document34 pagesIron-Carbon Phase Diagram (A Review) See Callister Chapter 9Zefa Erliana YullahNo ratings yet

- Sudipta Nath: Materials EngineeringDocument19 pagesSudipta Nath: Materials EngineeringSudipta NathNo ratings yet

- Homework 14 Solutions Spring 2001Document2 pagesHomework 14 Solutions Spring 2001Ikhwan Wf Miscellaneous AveroesNo ratings yet

- Fe C Phase DiagramDocument12 pagesFe C Phase DiagramDwi Cahyo NugrohoNo ratings yet

- Chapter Outline: Phase Transformations. KineticsDocument23 pagesChapter Outline: Phase Transformations. Kineticsmpcd07No ratings yet

- Kuliah Diagram TTT Dan CCTDocument35 pagesKuliah Diagram TTT Dan CCTAlmanFikriyansyahNo ratings yet

- Time Temperature Transformation (TTT) Diagrams PDFDocument108 pagesTime Temperature Transformation (TTT) Diagrams PDFSerkan Apay100% (1)

- Hypoeutectiod Steel Alloys - SteelDocument52 pagesHypoeutectiod Steel Alloys - SteelnotsofarNo ratings yet

- TTT and CCT DiagramDocument24 pagesTTT and CCT DiagramArun Raj A C100% (2)

- BG2802 Heat Treatment and Mechanical Properties of SteelsDocument11 pagesBG2802 Heat Treatment and Mechanical Properties of SteelsVenus LimNo ratings yet

- TTT CurvesDocument4 pagesTTT Curvesmanas310jntuhNo ratings yet

- Phase Transformation PDFDocument5 pagesPhase Transformation PDFmehdidalNo ratings yet

- Chapter 10Document4 pagesChapter 10Izzat NasrullahNo ratings yet

- Hypoeutectoid Carbon SteelsDocument12 pagesHypoeutectoid Carbon SteelsCho BhoNo ratings yet

- Cast Iron Phase DiagramDocument97 pagesCast Iron Phase DiagramBhargav Suvagiya100% (1)

- E45 Laboratory4Document7 pagesE45 Laboratory4nickNo ratings yet

- EMAT 10 (2k21)Document41 pagesEMAT 10 (2k21)Kumail AbbasNo ratings yet

- What Is The Difference Between CCT and TTT Curve by An Easy Example? How They Are Plotted?Document5 pagesWhat Is The Difference Between CCT and TTT Curve by An Easy Example? How They Are Plotted?nareshNo ratings yet

- Fe-C Phase Diagram Lecture 33Document15 pagesFe-C Phase Diagram Lecture 33Manish GuptaNo ratings yet

- Phase TransformationsDocument27 pagesPhase TransformationsCatweazle999No ratings yet

- 5-Phase Transformation 3 - Fe-CDocument7 pages5-Phase Transformation 3 - Fe-ChamalNo ratings yet

- Principles of Heat Treating of SteelsDocument30 pagesPrinciples of Heat Treating of Steelssatish_trivediNo ratings yet

- Carbon Steels: ME 215/205:materials Science LaboratoryDocument9 pagesCarbon Steels: ME 215/205:materials Science Laboratoryfaizan997No ratings yet

- Lecture Chapter 4 Phase Transformation and Metal AlloysDocument79 pagesLecture Chapter 4 Phase Transformation and Metal AlloysWinni TanNo ratings yet

- 8.heat TreatmentDocument7 pages8.heat Treatmentrohan_n_desai100% (2)

- Rohini 88980349004Document3 pagesRohini 88980349004shubhadipmondal2000No ratings yet

- Phase Transformations During Cooling in A+b Titanium Alloys: T. Ahmed, H. J. RackDocument6 pagesPhase Transformations During Cooling in A+b Titanium Alloys: T. Ahmed, H. J. RackAli RafiqueNo ratings yet

- TTT NotesDocument41 pagesTTT NotesshivanigopiNo ratings yet

- Engineering Material-II: Iron Carbide Phase DiagramDocument16 pagesEngineering Material-II: Iron Carbide Phase DiagramAla ZiNo ratings yet

- Phase Transformations in Ti-6Al-4V-x H Alloys: ItaniumDocument11 pagesPhase Transformations in Ti-6Al-4V-x H Alloys: ItaniumAli RafiqueNo ratings yet

- A 1033 - 04 Qtewmzm - PDFDocument14 pagesA 1033 - 04 Qtewmzm - PDFTiến Lượng NguyễnNo ratings yet

- Callister7E - pp290 301 (The Iron Carbon System)Document12 pagesCallister7E - pp290 301 (The Iron Carbon System)iglumacNo ratings yet

- IpmmmmDocument6 pagesIpmmmmAshok PradhanNo ratings yet

- E45 Lab 6 Heat Treatment of SteelDocument8 pagesE45 Lab 6 Heat Treatment of SteelAlisha PowerNo ratings yet

- Fe-C Phase DiagramDocument34 pagesFe-C Phase DiagramYoung-long Choi100% (1)

- Heat Treatment Part 1Document32 pagesHeat Treatment Part 1Naman DaveNo ratings yet

- MEC 414 - TTT Experiment 2Document4 pagesMEC 414 - TTT Experiment 2boatcomNo ratings yet

- Week 5 Phase DiagramDocument51 pagesWeek 5 Phase DiagramMohaiminul Islam TalhaNo ratings yet

- Chapter Outline:: Heat Treatment (And Temperature)Document24 pagesChapter Outline:: Heat Treatment (And Temperature)DSGNo ratings yet

- 05 - MetE 414-Phase Transformations-Microstructures of Steels-Fall 2023Document70 pages05 - MetE 414-Phase Transformations-Microstructures of Steels-Fall 2023egesenturk2000No ratings yet

- Iron-Carbon DiagramDocument3 pagesIron-Carbon DiagramnaniNo ratings yet

- Fundamentals of Electrocatalyst Materials and Interfacial Characterization: Energy Producing Devices and Environmental ProtectionFrom EverandFundamentals of Electrocatalyst Materials and Interfacial Characterization: Energy Producing Devices and Environmental ProtectionNo ratings yet

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014From EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014No ratings yet

- NTSE Question Bank & Solutions (Complete Syllabus) PDFDocument7 pagesNTSE Question Bank & Solutions (Complete Syllabus) PDFSaksham50% (2)

- Manual CAT4000Document36 pagesManual CAT4000windrider56No ratings yet

- Problemas de Espectroscopia Organica IDocument5 pagesProblemas de Espectroscopia Organica IGabriel Alejandro Socias EsquivelNo ratings yet

- Introduction To Plasma Physics and Contr PDFDocument10 pagesIntroduction To Plasma Physics and Contr PDFshamsudeenNo ratings yet

- Atomic Structure QuizDocument7 pagesAtomic Structure QuizJohanna Martin LipioNo ratings yet

- SMC SilencersDocument6 pagesSMC SilencersZachary NgNo ratings yet

- Matter Sphere For Mage The AscensionDocument2 pagesMatter Sphere For Mage The AscensionBeth100% (3)

- Advances and Challenges in Alkaline Anion Exchange Membrane Fuel CellsDocument35 pagesAdvances and Challenges in Alkaline Anion Exchange Membrane Fuel CellsJosePPMolinaNo ratings yet

- Fluid Power CircuitsDocument176 pagesFluid Power CircuitsMike Fredskilde97% (29)

- Chapter 7 Kinetics StudentsDocument137 pagesChapter 7 Kinetics Studentsnur hashimahNo ratings yet

- Standard Specifications For Road Works SERIES 4000-Bituminous Layers and SealsDocument51 pagesStandard Specifications For Road Works SERIES 4000-Bituminous Layers and SealsKisali SarakikyaNo ratings yet

- Chapter 5: Analytic Techniques: by Julia C. Drees, Matthew S. Petrie, Alan H.B. WuDocument15 pagesChapter 5: Analytic Techniques: by Julia C. Drees, Matthew S. Petrie, Alan H.B. WuTanveerNo ratings yet

- Plant Movement Bio ProjectDocument16 pagesPlant Movement Bio ProjectShahab AkhtarNo ratings yet

- Lettre MotivationDocument2 pagesLettre MotivationSalhi SiwarNo ratings yet

- Marine Enginnering SyllabusDocument3 pagesMarine Enginnering SyllabusRam Prasad YadavNo ratings yet

- Algorithms For Chemical Computations (Acs Symposium Series No 46)Document157 pagesAlgorithms For Chemical Computations (Acs Symposium Series No 46)sairama786No ratings yet

- Fuelless GeneratorDocument20 pagesFuelless GeneratorazoubraNo ratings yet

- Indonesian Mineral Deposits - IntroductoryDocument11 pagesIndonesian Mineral Deposits - IntroductoryridofambudiNo ratings yet

- 047-Itp For Oxygen Lines Fabrication and Installation PDFDocument28 pages047-Itp For Oxygen Lines Fabrication and Installation PDFKöksal PatanNo ratings yet

- (PDF) a General LC-MS - MS Method for Monitoring Potential Β-Lactam Contamination in Drugs and Drug-Manufacturing SurfacesDocument16 pages(PDF) a General LC-MS - MS Method for Monitoring Potential Β-Lactam Contamination in Drugs and Drug-Manufacturing SurfacessppNo ratings yet

- Angeles Mark P. Assignment No. 2Document2 pagesAngeles Mark P. Assignment No. 2MARK ANGELESNo ratings yet

- Monel K500 PDFDocument6 pagesMonel K500 PDFOZAIRTRADELINKNo ratings yet

- ATR MRFDocument24 pagesATR MRFnasser ondilloNo ratings yet

- Guide To The Construction Installation Operation and Maintenance of Air ReceiversDocument34 pagesGuide To The Construction Installation Operation and Maintenance of Air Receiversjosh100% (1)

- Msds - Sealxpert At222 Threadlocker Rev 4Document3 pagesMsds - Sealxpert At222 Threadlocker Rev 4dirayNo ratings yet

- Chromium Coated Piston Head Liner RingDocument56 pagesChromium Coated Piston Head Liner RingtechfiNo ratings yet

- Microsoft Office Project - Snag List v1Document1 pageMicrosoft Office Project - Snag List v1Necdet KayıkcıNo ratings yet

- Saudi Aramco Steam Turbine Training CourseDocument45 pagesSaudi Aramco Steam Turbine Training CourseDhananjay B K100% (2)

- Factors That Allow Life To Exist On Earth 2015Document4 pagesFactors That Allow Life To Exist On Earth 2015api-288682437No ratings yet

- Separating Mixtures Particulate NatureDocument5 pagesSeparating Mixtures Particulate NatureStruggl1ngNo ratings yet