Professional Documents

Culture Documents

Interactive Form U-1A

Uploaded by

Dimas AnugrahOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Interactive Form U-1A

Uploaded by

Dimas AnugrahCopyright:

Available Formats

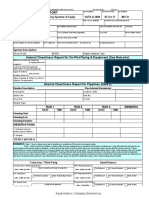

FORM U-1A MANUFACTURER’S DATA REPORT FOR PRESSURE VESSELS

(Alternative Form for Single Chamber, Completely Shop or Field Fabricated Vessels Only)

As Required by the Provisions of the ASME Boiler and Pressure Vessel Code Rules, Section VIII, Division 1

1. Manufactured and certified by:

(Name and address of Manufacturer)

2. Manufactured for:

(Name and address of Purchaser)

3. Location of installation

(Name and address)

4. Type:

(Horizontal or vertical, tank) (Manufacturer’s serial number) (CRN) (Drawing number) (National Board number) (Year built)

5. The chemical and physical properties of all parts meet the requirements of material specifications of the ASME BOILER AND PRESSURE VESSEL

CODE. The design, construction, and workmanship conform to ASME Rules, Section VIII, Division 1

Year

to

Addenda (date) (Code Case numbers) [Special Service per UG-120 (d)]

6. Shell

Material spec. number. grade) Nominal thickness (Corr. allow) (Inner diameter) [Length (overall)]

7. Seams:

[R.T.(spot or

[Long (welded, dbl. singl., lap, butt)] [R.T. (spot or full)] (Eff. %) (H.T. temp. ) (Time, hr) [Girth (welded, dbl. singl., lap, butt)] (Eff. %) (No. of courses)

full)]

8. Heads: (a) Material (b) Material

(Spec. no., grade) (Spec. no., grade)

Location (Top, Minimum Corrosion Crown Knuckle Elliptical Conical Hemispherical Flat Side to Pressure

Bottom, Ends) Thickness Allowance Radius Radius Ratio Apex Angle Radius Diameter (Convex or Concave)

(a)

(b)

If removable, bolts used (describe other fastenings)

(Material spec. number, grade, size, number)

9. MAWP at max. temp.

(Internal) (External) (Internal) (External)

Min. design metal temp. at Hydro. pneu., or comb. test press.

10. Nozzles, inspection, and safety valve openings:

Purpose Diameter Nominal Reinforcement How

(Inlet, Outlet, Drain) Number or Size Type Material Thickness Material Attached Location

11. Supports: Skirt Lugs Legs Other Attached

(Yes or no) (Number) (Number) (Describe) (Where and How)

12. Remarks: Manufacturer’s Partial Data Reports properly identified and signed by Commissioned Inspectors have been furnished for the following

items of the report:

(Name of part, item number, Manufacturer’s name and identifying stamp)

CERTIFICATE OF SHOP/FIELD COMPLIANCE

We certify that the statements made in this report are correct and that all details of design, material, construction and workmanship of this vessel

conform to the ASME BOILER AND PRESSURE VESSEL CODE, Section VIII, Division 1. “U” Certificate of Authorization Number

expires

Date Co. Name Signed

(Manufacturer) (Representative)

CERTIFICATE OF SHOP/FIELD INSPECTION

Vessel constructed by at

I, the undersigned, holding a valid commission issued by the National Board of Boiler and Pressure Vessel Inspectors and/or the State or Province of

and employed by

have inspected the component described in this Manufacturer’s Data Report on , and state that,

to the best of my knowledge and belief, the Manufacturer has constructed this pressure vessel in accordance with ASME BOILER AND PRESSURE

VESSEL CODE, Section VIII, Division 1. By signing this certificate neither the Inspector nor his/her employer makes any warranty, expressed or

implied, concerning the pressure vessel this described in this Manufacturer’s Data Report. Furthermore, neither the Inspector nor his/her employer shall

be liable in any manner for any personal injury or property damage or a loss of any kind arising from or connected with this inspection.

Date Signed Commissions

(Authorized Inspector) [National Board (incl endorsements) State, Province and number]

You might also like

- U1a - 735834Document2 pagesU1a - 735834Alex SimonNo ratings yet

- Body Flanges On ShellsDocument2 pagesBody Flanges On ShellsPadmanabhan VenkateshNo ratings yet

- Nde Plan: Joint Number / Parts Before PWHT After PWHT RT Paut UT MT PT PMI RT MTDocument2 pagesNde Plan: Joint Number / Parts Before PWHT After PWHT RT Paut UT MT PT PMI RT MTfizanlaminNo ratings yet

- Qap For Steam TurbineDocument3 pagesQap For Steam TurbinedgmprabhakarNo ratings yet

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportDocument4 pagesProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarNo ratings yet

- Double Pipe and Multitube IP 6-2-1 Hairpin Heat Exchangers: Section 1 - GeneralDocument7 pagesDouble Pipe and Multitube IP 6-2-1 Hairpin Heat Exchangers: Section 1 - Generalhcsharma1967No ratings yet

- ITP For Piping SystemsDocument6 pagesITP For Piping SystemsGia Minh Tieu TuNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSathish Kumar SelvarajNo ratings yet

- Inspection Report For Pipeline Route Survey Sign Copy and Blank FormatDocument1 pageInspection Report For Pipeline Route Survey Sign Copy and Blank FormatVishvjeet Prakash TiwariNo ratings yet

- 0.hydro Test Package Index - 2Document13 pages0.hydro Test Package Index - 2VISHNUPRASAD ARAKKAL MOHANDASNo ratings yet

- EIL - Formats - PMI PDFDocument53 pagesEIL - Formats - PMI PDFABHISHEK SINGHNo ratings yet

- SAIC-W-2077 Weld Joint Identification SystemDocument1 pageSAIC-W-2077 Weld Joint Identification Systemkarioke mohaNo ratings yet

- Cable Tray InstallationDocument1 pageCable Tray InstallationNaeemNo ratings yet

- Sl-Elt-Pr-Wps1-4107-C2-S1-Welder QualificationDocument15 pagesSl-Elt-Pr-Wps1-4107-C2-S1-Welder Qualificationsaeed ghafooriNo ratings yet

- 2G & 5GDocument2 pages2G & 5GRahul MoottolikandyNo ratings yet

- EQUIPMENT: Tube Bundle For Shell &tube HX Titile: Inspection Test Plan Item: 6112-E-02Document6 pagesEQUIPMENT: Tube Bundle For Shell &tube HX Titile: Inspection Test Plan Item: 6112-E-02Khalilahmad KhatriNo ratings yet

- TP-01Hydrostatic Test Cover SheetDocument4 pagesTP-01Hydrostatic Test Cover SheetAnonymous GaMb5H52100% (1)

- 024 Itp For Grouting Works PDFDocument8 pages024 Itp For Grouting Works PDFHarshvardhan PathakNo ratings yet

- 2021.12.13 ITP - Concreting (5244.009) V.0Document4 pages2021.12.13 ITP - Concreting (5244.009) V.0huot phirunNo ratings yet

- Field Hydrotest Manual UndergroundDocument8 pagesField Hydrotest Manual UndergroundPhuoc PhuNo ratings yet

- QAP For Conical StrainerDocument2 pagesQAP For Conical StrainersatishchidrewarNo ratings yet

- Cold Tap Coating Report 2Document1 pageCold Tap Coating Report 2Jamal BakhtNo ratings yet

- Electrode Test Record E6010Document9 pagesElectrode Test Record E6010Veeraraghavan GuruNo ratings yet

- Hydrostatic Test Procedure For Ug Non-Metallic Piping SystemDocument16 pagesHydrostatic Test Procedure For Ug Non-Metallic Piping SystemabrayalamNo ratings yet

- Project Document No.: VD-MR-007-01-037: Document Title: Site Acceptance Test ProcedureDocument9 pagesProject Document No.: VD-MR-007-01-037: Document Title: Site Acceptance Test ProcedureshahimulkNo ratings yet

- Office: Printout Sample - ASME WPSDocument2 pagesOffice: Printout Sample - ASME WPSDanem HalasNo ratings yet

- Inspection Log Book PLMB - 040915Document42 pagesInspection Log Book PLMB - 040915Rahmad DesmanNo ratings yet

- Inspection and Test Paln For LSAWDocument4 pagesInspection and Test Paln For LSAWkbpatel123No ratings yet

- Materials System SpecificationDocument13 pagesMaterials System SpecificationJeck MaquitedNo ratings yet

- A F E S: Process Piping 670.200Document17 pagesA F E S: Process Piping 670.200puwarin najaNo ratings yet

- Steel Wedge Gate Valves (Flanged and Butt-Welding Ends) For The Petroleum, Petrochemical and Allied IndustriesDocument28 pagesSteel Wedge Gate Valves (Flanged and Butt-Welding Ends) For The Petroleum, Petrochemical and Allied IndustriesImed BenNo ratings yet

- Sensitization of Inconel 625Document9 pagesSensitization of Inconel 625nantha kumarNo ratings yet

- Expansion Tank (Et) : Rabigh II Project Interconnecting Package (UO1)Document14 pagesExpansion Tank (Et) : Rabigh II Project Interconnecting Package (UO1)dodonggNo ratings yet

- Schematic Diagram For Hydrotest.Document1 pageSchematic Diagram For Hydrotest.vsNo ratings yet

- ITP - Erection Instalation and Testing of Site Erected Storage TANKDocument11 pagesITP - Erection Instalation and Testing of Site Erected Storage TANKVasilica BArbarasaNo ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechJagdishNo ratings yet

- Package 2s E0001 - Jupiter DCR 30-10-2021Document96 pagesPackage 2s E0001 - Jupiter DCR 30-10-2021senthilNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- 32 Samss 008Document26 pages32 Samss 008naruto256100% (1)

- Technical Doc 1 - Technical Scope of Work Drs Eac181Document25 pagesTechnical Doc 1 - Technical Scope of Work Drs Eac181bhargavpansuria09No ratings yet

- P7512TS2000P0009 (Purchase Spec) .Document37 pagesP7512TS2000P0009 (Purchase Spec) .Jibin Reji KoshyNo ratings yet

- Inspection of Test Plan Pressure Vessel: LOCATION: Isi Sesuai Lokasi Peralatan Akan Di InspeksiDocument3 pagesInspection of Test Plan Pressure Vessel: LOCATION: Isi Sesuai Lokasi Peralatan Akan Di Inspeksizvlcar nainNo ratings yet

- Equipment Delivery Erection Schedule-PCB Project 1Document1 pageEquipment Delivery Erection Schedule-PCB Project 1K.praveenNo ratings yet

- 6001F Rev 07 Material, Fabrication and Installation StructureDocument83 pages6001F Rev 07 Material, Fabrication and Installation StructurePatrickioNo ratings yet

- Proposed WPS For API 5LDocument1 pageProposed WPS For API 5LMecon HyderabadNo ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282: Visual Inspection Test Procedure B-QAC-PRO-210-39162Document14 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282: Visual Inspection Test Procedure B-QAC-PRO-210-39162ZaidiNo ratings yet

- Off Shore Piping Design, Layout and Stress Analysis (Project Standards and Specifications)Document5 pagesOff Shore Piping Design, Layout and Stress Analysis (Project Standards and Specifications)sachin nagavkarNo ratings yet

- Arcelormittal APIDocument4 pagesArcelormittal APIBaskara Surya WidagdoNo ratings yet

- Working ITPDocument4 pagesWorking ITPStephen BoodooNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- 4.1 - ANX-1 Definition of Mechanical Completion PDFDocument18 pages4.1 - ANX-1 Definition of Mechanical Completion PDFLegend AnbuNo ratings yet

- ITP For Piping SystemsDocument6 pagesITP For Piping SystemssojeckNo ratings yet

- G. Std. ITP For Pipeline Job PDFDocument4 pagesG. Std. ITP For Pipeline Job PDFAnonymous 4e7GNjzGWNo ratings yet

- GMCo - WPSDocument8 pagesGMCo - WPSMohamed AtefNo ratings yet

- 13427-01weekly QAQC ReportDocument1 page13427-01weekly QAQC ReportShyam SinghNo ratings yet

- A05 004 Inspection Test Plan Shell Tube Heat Exchangers 5 210D HA 01 A B C D PDFDocument14 pagesA05 004 Inspection Test Plan Shell Tube Heat Exchangers 5 210D HA 01 A B C D PDFfdfazfzNo ratings yet

- Form T-1B Manufacturer'S Data Report For Class 2 Transport Tanks As Required by The Provisions of The ASME Code Rules, Section XIIDocument1 pageForm T-1B Manufacturer'S Data Report For Class 2 Transport Tanks As Required by The Provisions of The ASME Code Rules, Section XIIEmma DNo ratings yet

- BPVC Viii-1 U-1a PDFDocument2 pagesBPVC Viii-1 U-1a PDFabdesselam00No ratings yet

- Form A-1P Manufacturer'S Data Report For Plate Heat Exchangers As Required by The Provisions of The ASME Code Rules, Section VIII, Division 2Document2 pagesForm A-1P Manufacturer'S Data Report For Plate Heat Exchangers As Required by The Provisions of The ASME Code Rules, Section VIII, Division 2Emma DNo ratings yet

- Asme Interactive Form U 1aDocument1 pageAsme Interactive Form U 1aJleemax OctaNo ratings yet

- Alloying Elements and Their EffectsDocument5 pagesAlloying Elements and Their EffectsDimas Anugrah100% (2)

- Influence of PWHT To Steel Phase & PropertiesDocument6 pagesInfluence of PWHT To Steel Phase & PropertiesDimas AnugrahNo ratings yet

- Principles of DrawingDocument6 pagesPrinciples of DrawingSudesh Gubale BNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Drain A Tank CalculationDocument743 pagesDrain A Tank CalculationDimas AnugrahNo ratings yet

- Pengantar NDT 2003Document27 pagesPengantar NDT 2003Dimas AnugrahNo ratings yet

- Itinerary KigaliDocument2 pagesItinerary KigaliDaniel Kyeyune Muwanga100% (1)

- Introduction To Cybersecurity: Nanodegree Program SyllabusDocument15 pagesIntroduction To Cybersecurity: Nanodegree Program SyllabusaamirNo ratings yet

- Final Test 1 Grade 10Document4 pagesFinal Test 1 Grade 10Hường NgôNo ratings yet

- Shes Gotta Have It EssayDocument4 pagesShes Gotta Have It EssayTimothy LeeNo ratings yet

- Reaserch ProstitutionDocument221 pagesReaserch ProstitutionAron ChuaNo ratings yet

- ACR Format Assisstant and ClerkDocument3 pagesACR Format Assisstant and ClerkJalil badnasebNo ratings yet

- Questionnaires in Two-Way Video and TeleconferencingDocument3 pagesQuestionnaires in Two-Way Video and TeleconferencingRichel Grace PeraltaNo ratings yet

- CCC Guideline - General Requirements - Feb-2022Document8 pagesCCC Guideline - General Requirements - Feb-2022Saudi MindNo ratings yet

- From "Politics, Governance and The Philippine Constitution" of Rivas and NaelDocument2 pagesFrom "Politics, Governance and The Philippine Constitution" of Rivas and NaelKESHNo ratings yet

- Are You ... Already?: BIM ReadyDocument8 pagesAre You ... Already?: BIM ReadyShakti NagrareNo ratings yet

- Lesson Agreement Pronoun Antecedent PDFDocument2 pagesLesson Agreement Pronoun Antecedent PDFAndrea SNo ratings yet

- I.T. Past Papers Section IDocument3 pagesI.T. Past Papers Section IMarcia ClarkeNo ratings yet

- UntitledDocument9 pagesUntitledRexi Chynna Maning - AlcalaNo ratings yet

- Coral Dos Adolescentes 2021 - Ônibus 1: Num Nome RG / Passaporte CPF Estado Data de NascDocument1 pageCoral Dos Adolescentes 2021 - Ônibus 1: Num Nome RG / Passaporte CPF Estado Data de NascGabriel Kuhs da RosaNo ratings yet

- Invoice 961Document1 pageInvoice 961Imran KhanNo ratings yet

- Upsc 1 Year Study Plan 12Document3 pagesUpsc 1 Year Study Plan 12siboNo ratings yet

- Just Design Healthy Prisons and The Architecture of Hope (Y.Jewkes, 2012)Document20 pagesJust Design Healthy Prisons and The Architecture of Hope (Y.Jewkes, 2012)Razi MahriNo ratings yet

- Securities and Exchange Board of India Vs Kishore SC20162402161639501COM692642Document14 pagesSecurities and Exchange Board of India Vs Kishore SC20162402161639501COM692642Prabhat SinghNo ratings yet

- ECONOMÍA UNIT 5 NDocument6 pagesECONOMÍA UNIT 5 NANDREA SERRANO GARCÍANo ratings yet

- Session - 30 Sept Choosing Brand Elements To Build Brand EquityDocument12 pagesSession - 30 Sept Choosing Brand Elements To Build Brand EquityUmang ShahNo ratings yet

- Ciplaqcil Qcil ProfileDocument8 pagesCiplaqcil Qcil ProfileJohn R. MungeNo ratings yet

- Gillette vs. EnergizerDocument5 pagesGillette vs. EnergizerAshish Singh RainuNo ratings yet

- Region 12Document75 pagesRegion 12Jezreel DucsaNo ratings yet

- Biopolitics and The Spectacle in Classic Hollywood CinemaDocument19 pagesBiopolitics and The Spectacle in Classic Hollywood CinemaAnastasiia SoloveiNo ratings yet

- Enrollment DatesDocument28 pagesEnrollment DatesEdsel Ray VallinasNo ratings yet

- Dua AdzkarDocument5 pagesDua AdzkarIrHam 45roriNo ratings yet

- People V GGGDocument7 pagesPeople V GGGRodney AtibulaNo ratings yet

- Case2-Forbidden CItyDocument10 pagesCase2-Forbidden CItyqzbtbq7y6dNo ratings yet

- Economic Question PaperDocument3 pagesEconomic Question PaperAMIN BUHARI ABDUL KHADERNo ratings yet

- Hedge Fund Ranking 1yr 2012Document53 pagesHedge Fund Ranking 1yr 2012Finser GroupNo ratings yet