Professional Documents

Culture Documents

Magic Bow

Uploaded by

Steve DowellOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Magic Bow

Uploaded by

Steve DowellCopyright:

Available Formats

s

ctions and Parts List

w" Tyer

een" and "Decorette" Brand Ribbon

Litho in U.S.A. g" 9 Systems Division/3M ~g 220-8E. 3M Center innesota 55144-1000

.J~

c:" ~.

3M

911 1250mml

5\4 [135 mini 9\4 [235 mml

f - -I I I

,

---t=lk'

/

'" ---r~

"

[465 mmJ

'"

'

-l

-l

\ _----Ly'

/

UPPER SPINDLE ARM (P)

"

'

/

TYING RIBBON BRACKET IC)

/---~-

4 (1l10 mm]

I I

,

N

16% [420 mm]

", --I--/--n--,

'~ ~

CALIBRATED SCALE BAR IG)

___ P

L/lJ

./

"------ T

/

L

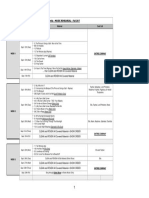

-,FIGURE 1 5-13

\-:/

------- -LEFT SIDE VIEW

------------

------ --- -- --- ----------FRONT VIEW

"MAGIC BOW" ITER

OVERALL DIMENSIONS

AND SET-UP.

II

RECEIVING AND HANDLING Examine the S-13 "Magic Bow" Tyer for damage that might have occurred during transit. If damage is evident, file a damage claim immediately with the transportation company and also your 3M Representative. WARRANTY IMPORT~~ NOTICE TO PURCHASER: The following is made in lieu of all warranties, expressed or implied, including the implied warranties of merchantability and fitness for purpose; The only obligation of the seller and manufacturer of "Sasheen" Brand equipment shall be to repair or replace any mechanical part proved to be defective, provided the defect occurs within 90 days after date of purchase, and the so-purchased item is returned immediately to the 3M factory or to an authorized service station designated by the manufacturer. NEITHER SELLER NOR MANUFACTURER SHALL BE LIABLE EITHER IN TORT OR IN CONTRACT FOR ANY LOSS OR DAMAGE, DIRECT, INCIDENTAL, OR CONSEQUENTIAL, ARISING OUT OF THE USE OF OR THE INABILITY TO USE THE "Sasheen" BRAND EQUIPMENT. :;'0 statement or recoIlllllendation contained not herein shall have any force or effect unless in an agreement signed by officers of seller and manufacturer. "Sasheen" and "Decorette" are registered trademarks of 3M, St. Paul, Minnesota 55144. SPECIFICATIONS Ribbon - "Sasheen" and "Decorette" Brand Rihbon.

~

I I I I I

Ribbon Width - 5/8 inch [15.8 mm] minimum to 1 1/4 inches [31.7 mm] maximum Ribbon Roll Diameter - Up to 8 1/2 inches [215 mm] maximum (250 yds. [228 m]) with 9/16 inch [15 mm] diameter core hole. Overall Dimensions Length 22 Height 16 Width 15 Weight 1/4 inches [565 rom] 1/2 inches [420 mm] inches (380 mm) 18 Ihs. [8.2 kg] 13 3/4 lbs. [6.2 kg]

Packaged Unpackaged

SET-UP INSTRUCTIONS FOLLOW THESE INSTRUCTIONS TO READY YOUR S-13 FOR OPERATION. 1) 2) 3) Remove and discard two retaining fasteners and plywood base from under side of unit. Remove and discard rubber band from calibrated scale bar (G). Loosen wing nut and position tying ribbon bracket (C) as shown in figure 1. Tighten wing nut to secure bracket position Loosen wing nut and position upper spindle arm (P) as shown in figure 1. Tighten wing nut to secure arm position. To make bows, change ribbon or bow size, refer to the following procedures in this manual.

- 3 -

4) 5)

The first step is to mount the tying ribbon on the Tving Ribbon Bracket provided (C) and thread the ribbon through the hole in the back stand as shown. Your tying ribbon is now ready for

operation.

2)

Place roll or rolls of ribbon on the Ribbon Spindles (D) by pushing the spindle through the center gro=cet on the ribbon roll and then locking it in place by replacing the Stock Roll Retainer (B) on the ribbon spindle.

3)

read the ribbon through the Ribbon Guide (L). Slot #1 for 1/4" ribbon, Slot #2 for 3/4" and 7/8" ribbons, Slot 113 for 5/8" ribbon and Slot 114 not used.

Adjust Winding Arms (F) on the Scale Bar (G) one at a time. Move Winding Arm toward end of scale bar to proper setting with even pull. Move winding arm toward center of scale bar by lifting slightly with left hand and pushing with right hand. This releases the tension spring allowing

easier movement of arms.

:OTE: For proper operation both winding arms should be set in the same position. For example, 4-4, 5-5, etc. This will center the notch properly in the bow.

- 4 -

OPERATING INSTRUCTIONS (Continued) 5) Place ribbon in slot in winding arm. (Be sure ribbon is centered properly on winding arm.) Pull ribbon through slot and slightly over half the distance between the winding arms. This assures proper notching of the bow hank.

6) Turn winding arms required number of turns with Winding Handle (A). (See Quick Reference Chart.) Be sure to stop winding arms in the position shown in the photo. Note: Winding arm is shown in neutral position. Each time the Scale Bar is turned past this point, a click will be heard and can be used for counting the turns.

7) Clasp the ribbon with the left hand and release with right hand the Slide Release (N). With both hands, push the Slide (K) into the cutting jaws. Be sure to push back until it contacts the rubber pad at rear of slide holder. NOTE: It is extremely important that you hold the ribbon hank with your left hand.

8) With left hand on ribbon hank, reach over with right hand and pull the Cutting Press Handle (M) all the way down. Return Cutting Press Handle to original position. This removes Cutting Blades (I) from ribbon hank.

- 5 -

I .STRUCTIONS (Continued) 9) With left hand still on ribbon hank, place right hand on the Slide Release (N) and pull slide back to original position. Once the slide reaches its original position, it will lock in place.

.I

I

10) Now pull and cut off approximately 6 to 8 inches or 155 to 200 mm of tying ribbon as shown.

11) Thread the tying ribbon through the notch on the ribbon hank and tie in a double knot as shown in the photo. (This is now known as a pre-fab bow.)

12) Remove pre-fab bow from the winding arms and cut off on the Bow Ribbon Cut-off Blade (J) as shown.

- 6 -

OPERATING INSTRUCTIONS (Continued) Pulling the Bow: 1) Hold the pre-fab bow (A) firmly in your left hand, just below the knot and on the bottom half of the notch (B). Pull the inside loop out and up above the left thumb, unlocking the notches so they won't slip back into the pre-bow position (C). Repeat, arranging loops above and to the side to fill in the half bow. 2) Turn the bow around and repeat on the other half of the bow (D). It is most important to hold the prebow notches firmly, so when pulled, they will open completely.

3)

Tie the bow (E) on the package and finish arranging the loops as

necessary.

"Magic Bow" Quick Reference Chart

SET ARMS RIBBON WIDTH NO.OF TURNS NO.OF LOOPS APPROX. RIBBON YARDAGE APPROX. DIA.OF BOW

3.3 3.3 4.4 4-4 4-4 4-4 5-5 5.5 5-5 6-6 6-6 7.7

~~tfk(?-7

518" 3/4"

5/8"

3/4"

10 8 13 10 9 7 15 12 10 16 15 20 17 20

19 13 25 19 17 13 29 23 19 31 29 39 33 39

1%yd. 1%yd. 3yd. 2% yd. 2yd. 1 V2 yd. 4yd. 3yd. 2,yd. 5% yd. 43;" yd. 8yd.

6V2 yd.

2V2"

2V2"

33;" " 33/4'

33/4"

33,4" 43,4" 43,4" 43.4"

718"

11/4 "

3/4"

I I I

7/8" 11/4 " 7/8" 1114 "

5V2" 5V2" 6112" 6112" 7V2"

7/8"

1 V4"

8-8

1""'''

83;" yd.

NOTE: When winding two ribbons, use half the number of turns as noted on chart.

- 7 -

1. Remove wing nut and bolt.

2. Tip bracket to position shown above.

3. Move blade holder to upright position. WAR N I N G

Use care when replacing blade as it is sharp. TO INSTALL NEW BLADES REVERSE PROCEDURE.

Loosen screws (one on each side).

5. Remove blades with thumb and forefinger.

CUTIING PAD REPLACEMENT

1. Loosen wing nut.

2. Remove cutting pad assembly.

3. Loosen and remove the two screws that hold the pad on the holder

TO INSTALL THE NEW CUTTING PAD, REVERSE THE PROCEDURE.

4. Remove the cutting pad from the holder and discard. - 8 -

HOW TO ORDER REPLACEMENT PARTS

1)

Refer to Parts Illustration to determine individual part and reference number. Refer to replacement parts list for the part number and part name.

NOTE: The complete description has been included for the standard fasteners and ~ercially available components. This has been done to allow the customer to obtain these standard parts locally, should they elect to do so. 2) Order parts by PART NUMBER, DESCRIPTION, DISPENSER NAME and part quantity required. (Order form attached to back cover of manual.) ~: Parts identified by (*) are not available as a replacement stock item.

Minimum billing on parts orders will be $10.00. Replacement part prices available on request.

3)

Replacement parts available direct from:

Dispenser Parts Route 4, Box 5B Amery, WI 54001

RECONDITIONING SERVICE For complete reconditioning send your machine to: Tape Equipment Repair Services 241 Venture Drive Amery, WI 54001

The cost to recondition your machine is based on time-and-material, with an invoice following completion. If an estimate is desired before work is started, please indicate so when machine is returned. Allow 2 - 6 weeks for the reconditioning service.

- 9 -

J u J I

I I I I

II I I I I

~

I

S-13 "MAGIC BOW" TVER PARTS ILLUSTRATION )

--~

- 10 -

REPLACEMENT PARTS LIST S-13 ''MAGIC BOW" TYER REF. NO.

1

2

PART NUMBER 78-8018-7976-4 18-1745-2845-7 78-8018-7977-2 78-8018-7978-0 78-8032-0102-5 78-8018-7979-8 78-8005-2700-0 78-8018-7980-6 78-8161-4221-6 78-8018-7981-4 18-9260-8403-1 78-8011-6522-2 78-8011-6523-0 78-8018-7982-2 78-8018-7983-0 78-8011-6526-3 78-8023-2178-2 12-7997-1396-6 78-8018-7984-8 78-8023-2186-5 78-8023-2180-8 78-8018-7985-5 78-8018-7986-3 78-8018-7987-1 78-8018-7988-9 78-8018-7989-7 78-8018-7990-5 78-8023-2179-0 78-8018-7991-3 18-1745-2745-9 78-8018-7992-1 78-8018-7993-9 18-4004-7603-4 78-8018-7994-7 83-9260-8130-4 78-8018-7995-4 78-8000-5292-6 78-8018-7996-2 78-8018-7997-0 12-7994-5930-5 12-7997-9639-1 78-8018-7998-8 78-8018-7999-6 78-8656-4003-7 78-8023-2181-6

DESCRIPTION Crank Handle Assy. Nut-Cap, Hex, 1/4-28 UNF Flange - Crank Washer - Detent Nut - Mach. Hex 8-32 UNC Spring-Clicker Ball-Steel, for Bearings 1/4 Dia. Winding Arm Assy. Bearing-Flange, "OILlTE" I/FF-520-15 Spacer - Winding Arm Pin-Spring, 1/8 Dia. x 3/8 Lg. Stock Roll Retainer Stock Roll Brake Spring Shaft - Stock Roll Spring - Collar Spring - Latch Screw-Mach. Fi1 Hd, Slot Dr, C/StI. UNC, 1/4-20 Dia. x 3 Lg. Bracket - Stock Roll Blade Head - Stripper Stop-Slide Spring - Slide, Leaf Gauge Slide Plate - Ram, Side Rod - Connecting Pin Eccentric Nut - Cap, Hex, 1/4-20 UNC Plate - Side Plate - Back Screw - Mach. Slot Truss Hd, 1/4-20 UNC x 1 1/2 Lg. Mount - Blade Screw-Mach. Slot Truss Hd, 6-32 UNC x 3/16 Lg. Clamp - Blade Bumper - Grey 3M No. SJ-5023 Frame Bracket - Stop Nut - Wing, Type A, 1/4-20 UNC Screw-Mach. Slot Truss Hd, 1/4-20 UNC x 1 3/4 Lg. Carriage Latch Ring-Retaining Waldes "TRUARC" 1/5133-37 Shaft - Idle stock item.

4

5 6

7

9

10 11

12 13

14

15 16 17 18 19

20 23

24 25 26 27

28

29 30 31

32

33 34

35

36

37

38 39

* *

40

41

42

43

44

45 46

47

48

NOTE:

Parts identified by (*) are not available as a replacement

- 11 -

. rlS

REPLACEMENT PARTS LIST S-13 "MAGIC BOW" TYER

REF, NO,

J

DESCRIPTION Screw-Se1f-Tap, Phil Flat Hd, Type BT, 6-20 x 3/8 Lg. Stop Assy. Screw-Mach, Slot Truss Hd., 8-32 UNC x 3/8 Lg. Pin - Shoulder Spreader Mount - Blade Blade Clamp - Blade Stripper Cutting Pad Plate Bolster Screw-Mach. Slot Flat Hd., 1/4-20 UNC x 1/2 Lg. Label - Identification Label - Reference Chart Track Front End Plate Assy. Screw- Mach. Slot Truss Hd., 10-32 UNF x 1/4 Lg. Adapter Rear End Plate Assy. Mount - Press Screw-Mach. Slot Truss Hd., 1/4-20 UNC x 3/8 Lg. Spreader Guide - Ribbon Washer - Plain, 1/4 Narrow Type A Knob - Plastic Davies #44 Lever Bracket - Tie Ribbon Arm - Two Color Washer - Lock, 1/4 Ext. Tooth, Flat, Type A Screw-Mach, Slot Truss Hd, 8-32 UNC x 5/16 Lg. Washer Bumper - Grey 3M No. SJ-5017 Pin - Spring, 1/8 Dia x 1/2 Lg. Label - Caution Screw-Mach. Slot Flat Hd., 10-32 x 3/8 Lg. Nut - Mach. Hex 10-32 Winding Arm and Slide Assy.

~

PART NUMBER 78-8000-0796-1 78-8023-2161-8 18-4002-7803-4 78-8023-2162-6 78-8023-2163-4 78-8023-2164-2 78-8015-7201-3 78-8023-2165-9 78-8023-2166-7 78-8015-7199-9 78-8023-2168-3 12-7997-0933-7 78-8018-7945-9 78-8023-2188-1 78-8023-2169-1 78-8023-2170-9 18-4003-2703-9 78-8023-2171-7 78-8023-2172-5 78-8023-2173-3 18-4004-5403-1 78-8023-2174-1 78-8023-2175-8 18-9813-1403-4 26-1002-4542-7 78-8023-2183-2 78-8023-2176-6 78-8023-2177-4 18-9851-1403-4 83-9260-8164-3 78-8023-2167-5 78-8033-1303-6 18-9260-8503-8 70-8000-4519-0 70-7023-2400-8 70-7023-4520-3 78-8052-6286-8

49 50 51 52 53 54 55 56 57 58 59 60 *61 *62 *63 *64 65 66 *67 68 69 *70 71 72 73 74 *75 76 77 78 79 80 81 82 83 84 87

NOTE:

I I I I I I

til

Parts identified by (*) are not available as a replacement stock item. S-13 "MAGIC BOW" TYER Tune-Up Kit 78-8015-6871-4 (This kit is not stocked at the parts location referenced on page 9. Contact your 3M Representative for kit price and ordering information.)

NOTE: 13

55

The Tune-Up Kit consists of the following standard S-13 Parts: 78-8011-6522-2 78-8015-7201-3 78-8015-7199-9 78-8033-1303-6 Stock Roll Retainer Blade Cutting Pad Bumper - Gray, 3M No. SJ-5017 - 12 -

58

80

'1

I I I I I I I

You might also like

- Audition Form (REPURPOSED)Document2 pagesAudition Form (REPURPOSED)Kris Dave Villarubia AusteroNo ratings yet

- Possible Audition 2016Document2 pagesPossible Audition 2016Jay MellmanNo ratings yet

- But She Loves MeDocument2 pagesBut She Loves MeRon PassNo ratings yet

- Highway Miles: Briskly, With SingerDocument9 pagesHighway Miles: Briskly, With Singertheatrelover125No ratings yet

- Maddie & Tae - Shut Up and Fish Guitar ChartDocument1 pageMaddie & Tae - Shut Up and Fish Guitar ChartZach Sicherman100% (1)

- Mama Who Bore Me ChordsDocument2 pagesMama Who Bore Me ChordsRuby KieftNo ratings yet

- Zombie Prom Auditon FormDocument2 pagesZombie Prom Auditon Formktbaby_20109948No ratings yet

- Scenes and props list for play productionDocument5 pagesScenes and props list for play productionAndrew BartleNo ratings yet

- Shoop Vocal OnlyDocument2 pagesShoop Vocal OnlyEleanor StruttNo ratings yet

- The Way Old Friends Do PDFDocument1 pageThe Way Old Friends Do PDFEdvárd Pink0% (1)

- We Belong (Live) : A Intro Moderate Ballad 142Document6 pagesWe Belong (Live) : A Intro Moderate Ballad 142Toni AholaNo ratings yet

- Order 339770 for Jacqueline Burroughs from Total Sheet MusicDocument8 pagesOrder 339770 for Jacqueline Burroughs from Total Sheet MusicKaleigh HuserNo ratings yet

- Jekyll and Hyde Medley AnalysisDocument15 pagesJekyll and Hyde Medley Analysisrichaaarddd100% (2)

- Remote by Stef Smith: ThemesDocument3 pagesRemote by Stef Smith: ThemesJosh UreNo ratings yet

- Folsom Prison Blues PDFDocument1 pageFolsom Prison Blues PDFAntonio LajaraNo ratings yet

- Cinderella - Music RehearsalDocument1 pageCinderella - Music Rehearsalcompos24No ratings yet

- The Little Foxes, Alexandra MonologueDocument1 pageThe Little Foxes, Alexandra MonologueKatherine J.No ratings yet

- Damn It, Janet Musical ArrangementDocument3 pagesDamn It, Janet Musical ArrangementDaniel AbrahamsonNo ratings yet

- FineDocument4 pagesFineLillie RicciardiNo ratings yet

- WHATEVER I WANT IT TO BE - LyricsDocument3 pagesWHATEVER I WANT IT TO BE - LyricsMeg BarbeauNo ratings yet

- Stage West Past ProductionsDocument3 pagesStage West Past ProductionsSamuel Martin McCallNo ratings yet

- Rosies Monologue - Most Likely ToDocument2 pagesRosies Monologue - Most Likely ToLillianNo ratings yet

- A Gentleman's Guide To Love & Murder!Document9 pagesA Gentleman's Guide To Love & Murder!Juan Ignacio HervasNo ratings yet

- Spitfire Grill Audition Info 090317Document4 pagesSpitfire Grill Audition Info 090317Anna KopsickNo ratings yet

- Into The UnknownDocument2 pagesInto The UnknownbensteersNo ratings yet

- HOME - BeetleJuiceDocument3 pagesHOME - BeetleJuiceÉrikaNo ratings yet

- Musical Theatre Revision Guide - Rodgers and HammersteinDocument3 pagesMusical Theatre Revision Guide - Rodgers and HammersteinChris Powell0% (1)

- HOME CHORDS by Michael Bublé @Document3 pagesHOME CHORDS by Michael Bublé @Luca Sabella100% (1)

- Pennys Song Piano VocalDocument3 pagesPennys Song Piano VocalPandarenLokiNo ratings yet

- When I Was Your Man Chords by Bruno Mars @Document2 pagesWhen I Was Your Man Chords by Bruno Mars @Pudyasto Adi WibowoNo ratings yet

- If It Wasn't For The Irish And The JewsDocument2 pagesIf It Wasn't For The Irish And The Jewsbill desaillyNo ratings yet

- You've Lost That Loving FeelingDocument6 pagesYou've Lost That Loving Feelinghornob2No ratings yet

- Jule StyneDocument3 pagesJule Stynegritchard4No ratings yet

- The Civil War Study GuideDocument16 pagesThe Civil War Study GuideFord's Theatre100% (6)

- SHe Loves MeDocument5 pagesSHe Loves MeJ.R. Bloomer0% (1)

- Back To DecemberDocument3 pagesBack To DecemberPopescu Patricia100% (1)

- Sylvias Lullaby PDFDocument2 pagesSylvias Lullaby PDFMariana Guadarrama0% (1)

- Apples and OrangesDocument12 pagesApples and OrangesKate GouldNo ratings yet

- Really Don't CareDocument2 pagesReally Don't CareMiguel GranadaNo ratings yet

- Come Sail Away - Styx Chords and LyricsDocument2 pagesCome Sail Away - Styx Chords and LyricsCameron TragesserNo ratings yet

- Audition for 'The Fantasticks' MusicalDocument4 pagesAudition for 'The Fantasticks' MusicaljamesoperamanNo ratings yet

- Epk - All Shook UpDocument7 pagesEpk - All Shook UpEthanFelizzariNo ratings yet

- Bloody Bloody Andrew Jackson Ten Little IndiansDocument10 pagesBloody Bloody Andrew Jackson Ten Little IndiansEmily AnneNo ratings yet

- "Tom" From Hello AgainDocument1 page"Tom" From Hello AgainannaNo ratings yet

- Fun Home - MapsDocument10 pagesFun Home - MapsFebe Pardaens100% (2)

- Roar - Katy PerryDocument2 pagesRoar - Katy Perryturaks_15No ratings yet

- Born This WayDocument28 pagesBorn This WayOsmanFer33% (3)

- Spies Are ForeverDocument13 pagesSpies Are ForeverMarta KosiorekNo ratings yet

- Act 1 Characters and SongsDocument4 pagesAct 1 Characters and SongsJGNo ratings yet

- FD-FE 1500 Maint Manual Rev 2 11-08Document28 pagesFD-FE 1500 Maint Manual Rev 2 11-08ddeppenjrNo ratings yet

- Gto Montaje de AlastraDocument88 pagesGto Montaje de AlastraTecnico Artes GraficasNo ratings yet

- AO 820 Microtome PDFDocument8 pagesAO 820 Microtome PDFalmutazimNo ratings yet

- 7 CP 06Document12 pages7 CP 06JackNo ratings yet

- Assembly and Operating Instructions for METTLER TOLEDO Model 4182-A Portable Beam ScaleDocument12 pagesAssembly and Operating Instructions for METTLER TOLEDO Model 4182-A Portable Beam ScaleKadson AmaralNo ratings yet

- (Filmmaking Technique) - CAMERA STABILIZER PLANS, STEADY, STEADI, STEADICAM, STEDYDocument81 pages(Filmmaking Technique) - CAMERA STABILIZER PLANS, STEADY, STEADI, STEADICAM, STEDYTaproot Photog100% (1)

- WheelHorse Lawn Sweeper Manual 7-2513Document6 pagesWheelHorse Lawn Sweeper Manual 7-2513Kevins Small Engine and Tractor Service100% (1)

- Service Manual: VCR Mechanism UnitDocument34 pagesService Manual: VCR Mechanism UnitcobrabrNo ratings yet

- Adjust Horizontal Bandsaw Blade & Guide for Accurate CutsDocument16 pagesAdjust Horizontal Bandsaw Blade & Guide for Accurate CutsKelvin TyhNo ratings yet

- Parts: RoebuckDocument6 pagesParts: RoebuckCary BriefNo ratings yet

- New Microsoft Office Word DocumentDocument50 pagesNew Microsoft Office Word DocumentSusavan MandalNo ratings yet

- Lipke Second EditionDocument194 pagesLipke Second EditionDavid Wrobel100% (7)

- ITRS 02 Force Eqn AnalysisDocument7 pagesITRS 02 Force Eqn AnalysisEzgi DalNo ratings yet

- Crochet Dream Catcher Pattern and TutorialDocument18 pagesCrochet Dream Catcher Pattern and Tutorialmariposadrift100% (1)

- Vanish Magic Magazine The Ehrlich BrothersDocument218 pagesVanish Magic Magazine The Ehrlich BrothersMarcelo Jorge Abel rossiNo ratings yet

- Instructions For The Safe Use Of: Flat Woven Webbing SlingsDocument2 pagesInstructions For The Safe Use Of: Flat Woven Webbing SlingsMontadhar SaeedNo ratings yet

- Flat Woven Webbing SlingsDocument2 pagesFlat Woven Webbing SlingsYosses Sang NahkodaNo ratings yet

- Easy Macrame Bracelet Tutorial Under 40 CharactersDocument3 pagesEasy Macrame Bracelet Tutorial Under 40 CharactersIvana Silva100% (1)

- Scout Pravesh To RajyapuraskarDocument74 pagesScout Pravesh To RajyapuraskarPARTHA PRATIM DEY0% (1)

- 3rdQ - SLM - TLE-g9g10 (PDF FOR STUDENT COPY)Document19 pages3rdQ - SLM - TLE-g9g10 (PDF FOR STUDENT COPY)Grace Mary Jao100% (2)

- Uterine Prolapse in Cattle - 2Document11 pagesUterine Prolapse in Cattle - 2frankyNo ratings yet

- Billy Pugh Complete CatalogueDocument64 pagesBilly Pugh Complete CatalogueDuong Do100% (1)

- Balloonology GuideDocument10 pagesBalloonology GuideexcellNo ratings yet

- SCOUT QUESTION BANKDocument64 pagesSCOUT QUESTION BANKsiya rajendran100% (1)

- Seamanship techniques for securing rope endsDocument6 pagesSeamanship techniques for securing rope endsMico YogoreNo ratings yet

- Physical Education and Health 4 Exam Reviewer Lesson 1: Recreational ActivitiesDocument15 pagesPhysical Education and Health 4 Exam Reviewer Lesson 1: Recreational ActivitiesJesusaNo ratings yet

- Clydeport Mooring Guidelines Jun 21Document26 pagesClydeport Mooring Guidelines Jun 21Sally AhmedNo ratings yet

- SAF Commando CourseDocument18 pagesSAF Commando CourseMcNavy PA100% (1)

- Palm Weaving:: The Story... and The ArtDocument8 pagesPalm Weaving:: The Story... and The ArtHans GommansNo ratings yet

- ST 4 TleDocument1 pageST 4 TleAngela AladanoNo ratings yet

- Camping KnotsDocument14 pagesCamping KnotsGenn ParcellanoNo ratings yet

- Crib and Tarp InstructionsDocument2 pagesCrib and Tarp InstructionsCrazyCreekProducts100% (1)

- Basic Illustrated Knots For The Outdoors PDFDocument80 pagesBasic Illustrated Knots For The Outdoors PDFJuan Luis100% (3)

- 8 MBK Kites 1 Skewer SeriesDocument273 pages8 MBK Kites 1 Skewer SeriesKonstantaras Yiannis100% (1)

- Merit Badge Application SafetyDocument5 pagesMerit Badge Application SafetyZeus RuizNo ratings yet

- The Fireman'S Coil The Sailor'S CoilDocument20 pagesThe Fireman'S Coil The Sailor'S CoilPresenti SergheiNo ratings yet

- Ikatan Dan TeknikDocument5 pagesIkatan Dan TeknikMahirah WailyNo ratings yet

- (BSA) Knotting For Scouts (1967) PDFDocument10 pages(BSA) Knotting For Scouts (1967) PDFbillludley_15No ratings yet

- ADM Q3 TLE 9 10 Week 3 Module Macrame and Basketry CAMINSIDocument10 pagesADM Q3 TLE 9 10 Week 3 Module Macrame and Basketry CAMINSIAvea RiveraNo ratings yet

- Soutache & Bead EmbroideryDocument97 pagesSoutache & Bead EmbroiderySissy1124100% (2)