Professional Documents

Culture Documents

58205-mt - Advanced Chemical Engineering Plant Design

Uploaded by

SRINIVASA RAO GANTA0 ratings0% found this document useful (0 votes)

616 views2 pagesA) explain the following in the design of heat exchanger. B) discuss the classification of vaporizing exchangers. C) Give the methods to Calculate pressure drop through a given packing.

Original Description:

Original Title

58205-mt----advanced chemical engineering plant design

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA) explain the following in the design of heat exchanger. B) discuss the classification of vaporizing exchangers. C) Give the methods to Calculate pressure drop through a given packing.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

616 views2 pages58205-mt - Advanced Chemical Engineering Plant Design

Uploaded by

SRINIVASA RAO GANTAA) explain the following in the design of heat exchanger. B) discuss the classification of vaporizing exchangers. C) Give the methods to Calculate pressure drop through a given packing.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

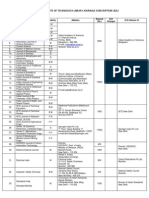

Code No: 58205/MT

NR

M.Tech. – II Semester Regular Examinations, September, 2008

ADVANCED CHEMICAL ENGINEERING PLANT DESIGN

(Chemical Engineering)

Time: 3hours Max. Marks:60

Answer any FIVE questions

All questions carry equal marks

---

1. a) Explain the following in the design of heat exchanger.

i) Heat exchanger tube arrangement.

ii) Shell and Baffles.

b) Compare with neat diagrams.

i) Fixed – head 1, 2 heat exchanger.

ii) Pull through – head 1, 2 heat exchanger.

iii) Floating head 1, 2 heat exchanger.

2. It is desired to concentrate 23,000 kg/hr of a chemical solution at

380C and 10 percent solids to a product which contains 50 percent

solids. Steam is available at 82.74 × 103 Pa, and the last effect of a

triple effect evaporator with equal heat transfer surfaces in each

effect will be assumed to operate at a vacuum of a 66 cm Hg

referred to a 76 cm barometer. Water is available at 29.440C for

use in Barometric Condenser.

Assume a negligible BPE, an average specific heat of 1.0 in all

effects, the condensate from each effect leaves at its saturation

temperature and that there are negligible radiation losses.

Calculate

a) Steam consumption

b) Heating surface required for each body

c) Condenser water requirement.

The overall coefficients of heat transfer for the different effects will

be

U1 = 3413 w/m2 0C

U2 = 1422 w/m2 0C

U3 = 711 w/m2 0C

3. a) Explain the classification of vaporizing exchangers.

b) Discuss heat flux and temperature difference limitations.

Contd…2

Code No: 58205/MT :2:

4. a) Discuss about the flooding in packed towers.

b) Give the methods for calculating pressure drop through a given

packing.

5. Write about the following design factors for value trays.

a) Flooding and Entrainment.

b) Tray spacing.

c) Tray types.

d) Tray diameter & layout.

6. a) Write about the mechanical design of coloumn and discuss

about the vessel internals.

b) With neat diagrams explain different downcomer types.

7. Explain the concept of practical rules of thumb and how this

influences the design of the following.

a) Operating temperature in heat exchanger.

b) Heat transfer area.

c) Power required to drive a centrifugal pump for a given duty.

8. a) Discuss about the scale – up of tubular flow reactor.

b) Discuss about the scale – up of liquid mixing systems.

You might also like

- JNTUH MCA Syllabus 2013Document107 pagesJNTUH MCA Syllabus 2013SRINIVASA RAO GANTANo ratings yet

- JNTUH Syllabus 2013 M.tech Communication SysDocument26 pagesJNTUH Syllabus 2013 M.tech Communication SysSRINIVASA RAO GANTANo ratings yet

- JNTUH MBA Course Structure and Syllabus 2013Document80 pagesJNTUH MBA Course Structure and Syllabus 2013SRINIVASA RAO GANTANo ratings yet

- JNTUH M.TECH PEDS 2013 SyllabusDocument24 pagesJNTUH M.TECH PEDS 2013 SyllabusSRINIVASA RAO GANTA100% (1)

- JNTUH Syllabus 2013 M.Tech CSEDocument33 pagesJNTUH Syllabus 2013 M.Tech CSESRINIVASA RAO GANTANo ratings yet

- JNTYH Syllabus 2013 M.Tech CAD CAMDocument23 pagesJNTYH Syllabus 2013 M.Tech CAD CAMSRINIVASA RAO GANTANo ratings yet

- JNTUH Syllabus 2013 M.Tech EPSDocument23 pagesJNTUH Syllabus 2013 M.Tech EPSSRINIVASA RAO GANTANo ratings yet

- JNTUH Syllabus 2013 M.tech Embedded SystemsDocument24 pagesJNTUH Syllabus 2013 M.tech Embedded SystemsSRINIVASA RAO GANTANo ratings yet

- Paper-I Set-WDocument16 pagesPaper-I Set-WKaran AggarwalNo ratings yet

- NET - 59-12 (Library & Inf Sci)Document16 pagesNET - 59-12 (Library & Inf Sci)SRINIVASA RAO GANTANo ratings yet

- J-59-12 (Library of Inf Sci)Document20 pagesJ-59-12 (Library of Inf Sci)SRINIVASA RAO GANTANo ratings yet

- JNTUH Syllabus 2013 Civil Engg Course StructureDocument2 pagesJNTUH Syllabus 2013 Civil Engg Course StructureSRINIVASA RAO GANTANo ratings yet

- Kvs Librarypolicy2012Document59 pagesKvs Librarypolicy2012SRINIVASA RAO GANTANo ratings yet

- The Ideal Library - The InformatoriumDocument1 pageThe Ideal Library - The InformatoriumSRINIVASA RAO GANTANo ratings yet

- Academic Conference and Case Chase Competition 12Document8 pagesAcademic Conference and Case Chase Competition 12SRINIVASA RAO GANTANo ratings yet

- Vbit Journals 2011-12Document6 pagesVbit Journals 2011-12SRINIVASA RAO GANTANo ratings yet

- IP Addresses and SubnettingDocument16 pagesIP Addresses and SubnettingHusnainNo ratings yet

- ISBN Manual 2012Document31 pagesISBN Manual 2012SRINIVASA RAO GANTANo ratings yet

- Guidelines For Open Educational Resources (OER) in Higher EducationDocument27 pagesGuidelines For Open Educational Resources (OER) in Higher EducationSRINIVASA RAO GANTANo ratings yet

- Library Quality Criteria For NBA AccreditationDocument3 pagesLibrary Quality Criteria For NBA AccreditationSRINIVASA RAO GANTA100% (6)

- Use Full Library TermsDocument20 pagesUse Full Library TermsSRINIVASA RAO GANTANo ratings yet

- AICTE Hand Book 2011-12Document188 pagesAICTE Hand Book 2011-12SRINIVASA RAO GANTANo ratings yet

- Librarian Is Teaching or Non TeachingDocument1 pageLibrarian Is Teaching or Non TeachingSRINIVASA RAO GANTANo ratings yet

- NET EXAM Paper 1Document27 pagesNET EXAM Paper 1shahid ahmed laskar100% (4)

- Ready Reckoner Radar EwDocument27 pagesReady Reckoner Radar EwSRINIVASA RAO GANTANo ratings yet

- Good Handling PrinciplesDocument11 pagesGood Handling PrinciplesSRINIVASA RAO GANTANo ratings yet

- Teqip IiDocument244 pagesTeqip IiSRINIVASA RAO GANTANo ratings yet

- Dspace On WindowsDocument15 pagesDspace On WindowsSRINIVASA RAO GANTANo ratings yet

- PSoC Express First Touch DocumentationDocument12 pagesPSoC Express First Touch DocumentationSRINIVASA RAO GANTANo ratings yet

- Reg Pay Degree 020110Document16 pagesReg Pay Degree 020110SRINIVASA RAO GANTANo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- DSI Valves: Forged Steel Carbon, Stainless and Alloy Gate, Globe and Check ValvesDocument32 pagesDSI Valves: Forged Steel Carbon, Stainless and Alloy Gate, Globe and Check ValvesJordan Magaña MoralesNo ratings yet

- Blue Bells Public School SESSION 2022-23 Summer Holiday Homework Class ViiiDocument16 pagesBlue Bells Public School SESSION 2022-23 Summer Holiday Homework Class ViiiGyanav ChauhanNo ratings yet

- Smoothies and BeyondDocument14 pagesSmoothies and BeyondWeldon Owen Publishing80% (5)

- PD 953Document4 pagesPD 953Lloyl MonteroNo ratings yet

- Science 2nd Quarter w6Document6 pagesScience 2nd Quarter w6vernaNo ratings yet

- Etiología Del Chile HabaneroDocument12 pagesEtiología Del Chile Habaneronadia landeroNo ratings yet

- Lesson 11 BPPDocument20 pagesLesson 11 BPPMa LeslynneNo ratings yet

- How The Plant SurviveDocument16 pagesHow The Plant SurvivedhonaNo ratings yet

- Deficiency Symptoms in AvocadosDocument8 pagesDeficiency Symptoms in AvocadosJoshua YiNo ratings yet

- Test BaruDocument4 pagesTest BaruDonnie AlulNo ratings yet

- Sexual Reproduction in Flowering PlantsDocument18 pagesSexual Reproduction in Flowering PlantsBħuvi ÀnthaRaNo ratings yet

- Liquid Soap Making TechniqueDocument4 pagesLiquid Soap Making Techniqueluchoosorio100% (3)

- Elementary Statistics 9th Edition Weiss Solutions ManualDocument24 pagesElementary Statistics 9th Edition Weiss Solutions ManualDustinMahoneyidbj100% (27)

- B.SC - Agricuture 4 Year Code A PCBDocument16 pagesB.SC - Agricuture 4 Year Code A PCBsachin sharmaNo ratings yet

- Century Dinner MenuDocument1 pageCentury Dinner Menusupport_local_flavorNo ratings yet

- Diallel Analysis of Soluble Protein in Root Nodules and Seeds in Blackgram (Vigna Mungo (L.) Hepper)Document9 pagesDiallel Analysis of Soluble Protein in Root Nodules and Seeds in Blackgram (Vigna Mungo (L.) Hepper)Openaccess Research paperNo ratings yet

- Testbank Chapter 10Document44 pagesTestbank Chapter 10Fiona SimeonNo ratings yet

- Taiz & Zaiger. Plant PhysiolDocument16 pagesTaiz & Zaiger. Plant PhysiolJoana Gasparotto KuhnNo ratings yet

- Bioreactor InnovaciónDocument15 pagesBioreactor InnovaciónRenato Rojas DominguezNo ratings yet

- Lesson PlanDocument2 pagesLesson PlanCaisar Teano100% (2)

- Roles and Responsibilities of Plant Commissioning Rev 3Document10 pagesRoles and Responsibilities of Plant Commissioning Rev 3gst ajahNo ratings yet

- 19092016095638PM - File - Info (Done Excel, Done CC)Document12 pages19092016095638PM - File - Info (Done Excel, Done CC)CK AngNo ratings yet

- Fire BrochureDocument9 pagesFire BrochureherikNo ratings yet

- Chilli PestsDocument11 pagesChilli PestsSouvik Roy ChowdhuryNo ratings yet

- Volcanic SoilsDocument14 pagesVolcanic SoilsVictor Hugo BarbosaNo ratings yet

- CS 414 - Weed Science: Section 2 Basic Weed BiologyDocument15 pagesCS 414 - Weed Science: Section 2 Basic Weed BiologyKimeu EstherNo ratings yet

- Cover Page: Describe The Male and Female Reproductive Parts of A Flowering PlantsDocument19 pagesCover Page: Describe The Male and Female Reproductive Parts of A Flowering PlantsRowena DahiligNo ratings yet

- Flora &faunaDocument2 pagesFlora &faunarajesh0005No ratings yet

- Percubaan Biologi Kertas 1 Melaka 2016Document29 pagesPercubaan Biologi Kertas 1 Melaka 2016Siti Norliana JohariNo ratings yet

- Mint OilDocument4 pagesMint OilPreeti SinghNo ratings yet