Professional Documents

Culture Documents

TS90 EV2 Datasheet

Uploaded by

Suhaimi AdananOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TS90 EV2 Datasheet

Uploaded by

Suhaimi AdananCopyright:

Available Formats

TS90-EV2 LITHIUM BATTERY BALANCING SYSTEM DATASHEET

The TS90 Battery management system is designed for Lithium Iron Phosphate cells of capacity 10180Ah. The cells may be connected in series to make a battery of any voltage. The system has two components, cell balancer modules and a master control unit (MCU). The cell modules bolt directly on top of each cell and perform the cell balancing function during charging. The MCU has simple relay outputs to control a load or alarm and a relay to control the charger. Any charger may be used that has a suitable peak voltage and charge curve for Lithium Ion batteries. The MCU can control either the charger AC supply or DC output.

Features

Modular - one small balancing module bolts directly to each cell. Simple - A one wire interface is all that is required. No birds nest. Scalable - Battery balancing from one cell up to almost any number. Fail Safe - a unique safety interlock system prevents any cell from going over/under voltage. Flexible - the master control unit can work with almost any charger. Cost Effective - low cost per cell for large format Lithium Ion batteries.

Principle of Operation

During charging the cell voltage of LiFePO4 batteries will stay relatively constant at 3.2-3.4V until near the end of charge. At this point the voltage begins to rise rapidly and if no limits are applied it will rise past 4.2V and cause permanent cell damage. The battery charger will normally limit the voltage applied to the whole battery but cannot regulate the voltage of each cell. Normally the maximum cell voltage for full charge should not exceed 3.65V. The cell modules act as regulators on each cell by bypassing some of the charge current as they reach their fully charged voltage. In this manner the battery will always be balanced if it is fully charged regularly. On discharge the cell voltage will stay relatively constant at 3.2V until near 100% depth of discharge. Under heavy loads it may sag lower than this but will always return to 3.2V while the cell still has some capacity. The cell modules monitor the voltage of each cell. If any cell falls below 2.5V for more than 2 seconds the MCU will sound an alarm and can deactivate the load to reduce danger of damage. As soon as the voltage is back in the safe range the alarm will cease. The TS90 MCU has two sets of LED outputs to indicate the state of the battery and of the charger. No battery fuel gauge or temperature measurement functions are incorporated and there are no

digital or analog outputs available to interface with external devices. The TBS E-Xpert Pro battery fuel gauge is recommended for this purpose. In combination with a suitable charger the TS90 will provide automated charging of Lithium Iron Phosphate batteries. Failure safety is integral to its design and it will protect the battery from damage under most circumstances. Cell modules can be used in standalone mode with outputs daisy chained together to interface with electronic control equipment. Output is NC when cell voltages are within safe limits and NO when outside these limits. Automatic cell balancing will still occur when the charge voltage reaches 3.63V/ cell. Most SLA chargers are suitable for use with LFP cells. EV Power also has a range of suitable charger. Using a Battery Monitor with the TS90 can provide a complete battery management system for Electric Vehicles with user feedback of battery fuel levels.

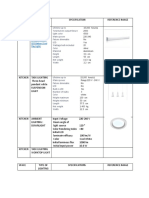

Master Control Unit Specifications

Supply Voltage 35-350VDC (HV model), 12-36VDC (LV model) Supply Power 3.5W max. @ 144VDC MCU weight: 1.5kg Size: 170 x 120 x 55mm Charger Relay (Relay is closed when system is OK and the Reset button has been pressed) Contacts NO/COM Max Voltage: 250VAC / 24VDC Max Current: 20A Load/Alarm Relay (Relay is active/closed when the system is OK) Contacts: NO/NC/COM Max Voltage: 30VDC Max Current: 10A

This document may not be reproduced without the permission of EV Power Australia.

You might also like

- 4 Design & Developing of A Microcontroller Based High-Efficient Smart Solar Charge Controller For Standalone Solar PhotovoltaicDocument9 pages4 Design & Developing of A Microcontroller Based High-Efficient Smart Solar Charge Controller For Standalone Solar PhotovoltaicPrabhu RajNo ratings yet

- TPM Prt006a0199 ch10Document10 pagesTPM Prt006a0199 ch10Thomas A. EDISSONNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Battery Alarm 300Document8 pagesBattery Alarm 300Tomuta StefanNo ratings yet

- Turnigy Accucell-8150, Cargador / Balanceador / Descargador, Manual EnglishDocument23 pagesTurnigy Accucell-8150, Cargador / Balanceador / Descargador, Manual EnglishTICTRONICA Ltda.100% (2)

- Battery Charger SolutionsDocument32 pagesBattery Charger SolutionsGeorges MeindersNo ratings yet

- Ower Upply: Functional DescriptionDocument6 pagesOwer Upply: Functional DescriptionThomas A. EDISSONNo ratings yet

- Gkt-Battery System-0709Document5 pagesGkt-Battery System-0709rajan25No ratings yet

- GP Power System OverviewDocument36 pagesGP Power System OverviewMd.Bellal HossainNo ratings yet

- General EscalatorDocument65 pagesGeneral EscalatorMạnh HùngNo ratings yet

- Battery Charger Termination Issues With System Load Applied Across Battery While ChargingDocument5 pagesBattery Charger Termination Issues With System Load Applied Across Battery While ChargingBOLFRANo ratings yet

- Manual Td2310tu, Td2410tuDocument12 pagesManual Td2310tu, Td2410tujnsosa3No ratings yet

- Galaxy PW Muti Module Technical SpecsDocument30 pagesGalaxy PW Muti Module Technical SpecsRUBEN LOZANONo ratings yet

- BCU PEV 2.x ManualDocument19 pagesBCU PEV 2.x ManualcristiNo ratings yet

- Introduction To Electric Vehicle Battery Systems - Technical ArticlesDocument5 pagesIntroduction To Electric Vehicle Battery Systems - Technical ArticlesMoorthy subramanianNo ratings yet

- Charge ControllersDocument10 pagesCharge Controllersfr33mumiaNo ratings yet

- Capacitor 2Document4 pagesCapacitor 2karthikdote100% (1)

- Battery System at 220Kv Substation Punnapra: Anakha.MDocument20 pagesBattery System at 220Kv Substation Punnapra: Anakha.MManu JosephNo ratings yet

- Li-Ion Battery Charging Basics, Featuring The FAN5400 / FAN5420 Family of PWM Battery ChargersDocument0 pagesLi-Ion Battery Charging Basics, Featuring The FAN5400 / FAN5420 Family of PWM Battery Chargersziko23No ratings yet

- Thyrotronic 07-02Document8 pagesThyrotronic 07-02Hillary Mcgowan100% (1)

- Charge ControllerDocument3 pagesCharge ControllerSumon ShariarNo ratings yet

- O&m - Manual - 220V - 187 Ah Plante Battery PDFDocument16 pagesO&m - Manual - 220V - 187 Ah Plante Battery PDFrukmagoud100% (1)

- DC BattryDocument36 pagesDC Battryelsayed abdemagiedNo ratings yet

- BQ24196 TexasInstrumentsDocument41 pagesBQ24196 TexasInstrumentsNoel Alejandro Cordova RangelNo ratings yet

- NTPC Thermal Power Plant Training ReportDocument63 pagesNTPC Thermal Power Plant Training ReportTARUN KUMARNo ratings yet

- Solar Charge ControllerDocument11 pagesSolar Charge Controllerayirp89No ratings yet

- Charge ControllerDocument19 pagesCharge ControllerHina KadevalNo ratings yet

- B6AC V2 ManualDocument28 pagesB6AC V2 ManualFrancisco Russo100% (1)

- Victron Battery Balancer: Energy Unlimited'Document2 pagesVictron Battery Balancer: Energy Unlimited'Vasile SilvioNo ratings yet

- B6 ManualDocument28 pagesB6 ManualHelder Chaves100% (1)

- ELOSDocument14 pagesELOSMostafa MohmmedNo ratings yet

- Introduction To Portable Charger Circuits For Electronic Appliances and Uninterruptible Power Supply.Document3 pagesIntroduction To Portable Charger Circuits For Electronic Appliances and Uninterruptible Power Supply.Omor Hasan Al BoshirNo ratings yet

- Ups TraingDocument63 pagesUps Traingyirga shitahunNo ratings yet

- Battery Balancer ENDocument2 pagesBattery Balancer ENtrnNo ratings yet

- Operating and Maintenance Manual For Charger UnitDocument16 pagesOperating and Maintenance Manual For Charger UnitUrsula Johnson100% (4)

- Juntek - 4300 Wireless Meter - User GuideDocument6 pagesJuntek - 4300 Wireless Meter - User GuideadyhansoloNo ratings yet

- FCBC PDFDocument3 pagesFCBC PDFsaurabhjerps231221No ratings yet

- BCSW ChargerDocument12 pagesBCSW ChargermatoyNo ratings yet

- 20A 30A 40A MPPT Solar Charge Controller ManualDocument32 pages20A 30A 40A MPPT Solar Charge Controller ManualreneNo ratings yet

- DSP Sine Wave InverterDocument8 pagesDSP Sine Wave InverterBhushan H Deshpande57% (7)

- Stable Power Supplies in Power Station: Rectifier/ Charger Battery Rectifier/ Charger (Spare)Document6 pagesStable Power Supplies in Power Station: Rectifier/ Charger Battery Rectifier/ Charger (Spare)Santosh MondalNo ratings yet

- 301 DX2 EnglishDocument18 pages301 DX2 EnglishNingaidenNo ratings yet

- MSRX Charge Controller: Product ManualDocument48 pagesMSRX Charge Controller: Product Manualrevle100% (1)

- Automatic External DefibrillatorDocument18 pagesAutomatic External Defibrillatormohamed ghedanyNo ratings yet

- Technical Note On Integrated Power Supply System IPS For Indian RailwaysDocument70 pagesTechnical Note On Integrated Power Supply System IPS For Indian Railwaysrkr_123No ratings yet

- Enatel Rectifier CommisioningDocument12 pagesEnatel Rectifier Commisioningadramat1085No ratings yet

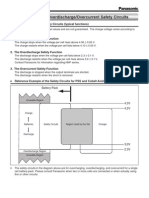

- Overcharge/Overdischarge/Overcurrent Safety Circuits: - The Functions of The Safety Circuits (Typical Functions)Document4 pagesOvercharge/Overdischarge/Overcurrent Safety Circuits: - The Functions of The Safety Circuits (Typical Functions)Mahir MahmoodNo ratings yet

- Laptop 3Document2 pagesLaptop 3أحمد الأمينNo ratings yet

- Laptop Battery Charging Circuit DiagramDocument2 pagesLaptop Battery Charging Circuit Diagrammax100% (1)

- An137 - Lithium Ion Battery Charger Using c8051f300Document36 pagesAn137 - Lithium Ion Battery Charger Using c8051f300oakkar7No ratings yet

- Tracer An Sms El v1.0Document44 pagesTracer An Sms El v1.0Jason KettleNo ratings yet

- Problems of Li-Ion Battery and Production of Battery Management SystemDocument7 pagesProblems of Li-Ion Battery and Production of Battery Management SystemTrung Đức NguyễnNo ratings yet

- SRNE Specification of SR-MT4860Document16 pagesSRNE Specification of SR-MT4860Carlos LehmanNo ratings yet

- Photovoltic Battery Charge ControllerDocument2 pagesPhotovoltic Battery Charge ControllerDipak GayakwadNo ratings yet

- Protection System of Hybrid Insulated Sub-StationDocument8 pagesProtection System of Hybrid Insulated Sub-Stationshoaib faseehNo ratings yet

- Application Note Abstract: Implementation of MPPT Solar Charge Controller With PowerpsocDocument14 pagesApplication Note Abstract: Implementation of MPPT Solar Charge Controller With PowerpsocRon HuangNo ratings yet

- Battery Charger - DC RectifierDocument8 pagesBattery Charger - DC Rectifierghribiabdelwadoud4131No ratings yet

- Babelan - Charger Training - Overall - 27Document27 pagesBabelan - Charger Training - Overall - 27dimasrimantiktoNo ratings yet

- ZipGrade User Guide JPDocument6 pagesZipGrade User Guide JPJinsen Paul MartinNo ratings yet

- Testing Method For SuspensionDocument131 pagesTesting Method For SuspensionAliNo ratings yet

- ZbirkicaDocument520 pagesZbirkicaVladimir MilovanovicNo ratings yet

- Apache MyFaces Trinidad - Skin SelectorsDocument25 pagesApache MyFaces Trinidad - Skin SelectorsJorge LavadoNo ratings yet

- Intel® System Identification UtilityDocument2 pagesIntel® System Identification UtilityPatel NikhilNo ratings yet

- Manual V100-V30-70 ENGDocument38 pagesManual V100-V30-70 ENGAzeddine LANo ratings yet

- Aircraft Refuelling HoseDocument4 pagesAircraft Refuelling HoseBimo IndroNo ratings yet

- Modelling of Short Duration Isopluvial Map For Raichur District KarnatakaDocument4 pagesModelling of Short Duration Isopluvial Map For Raichur District KarnatakaMohammed Badiuddin ParvezNo ratings yet

- WPT PresentationDocument23 pagesWPT PresentationSyed Safiur RahmanNo ratings yet

- Paccar PX 8 Spec SheetDocument6 pagesPaccar PX 8 Spec SheetCarlos Alberto Gutierrez Lopez0% (1)

- Product CatalogDocument84 pagesProduct CatalogZied JEMMALINo ratings yet

- Fruit Recognition Deep LearningDocument53 pagesFruit Recognition Deep Learningsaran20099No ratings yet

- MYG Varistors Data SheetDocument4 pagesMYG Varistors Data SheetPedro Giménez100% (1)

- OBIEE 11g Training Details: Contact Name: Rao Contact No: 919948713895Document7 pagesOBIEE 11g Training Details: Contact Name: Rao Contact No: 919948713895SwapnasaritNo ratings yet

- 18CrNiMo7-6 Chromium-Nickel-Molybdenum Case Hardening Steel - Hillfoot Multi MetalsDocument1 page18CrNiMo7-6 Chromium-Nickel-Molybdenum Case Hardening Steel - Hillfoot Multi MetalsKunal KoreNo ratings yet

- Advanced Database - Chap 5Document84 pagesAdvanced Database - Chap 5Anhtho LeeNo ratings yet

- C Basic ExercisesDocument7 pagesC Basic ExercisesAngelo MartinNo ratings yet

- AnalysisofUnder reamedPilesSubjectedtoDifferentTypesofLoadinClayeySoil 1 8 PDFDocument9 pagesAnalysisofUnder reamedPilesSubjectedtoDifferentTypesofLoadinClayeySoil 1 8 PDFAkhilesh Kumar SinghNo ratings yet

- 8 - Field Inspectors (CQA) Certification ProgramDocument7 pages8 - Field Inspectors (CQA) Certification Program齐左No ratings yet

- OpenSolver ChangeLogDocument24 pagesOpenSolver ChangeLogSantaCruzStoreroomNo ratings yet

- Exp't 61: 1,4-Di-T-Butylbenzene Via Friedel-Crafts AlkylationDocument6 pagesExp't 61: 1,4-Di-T-Butylbenzene Via Friedel-Crafts AlkylationlovehopeNo ratings yet

- Nse Past Questions and AnswersDocument10 pagesNse Past Questions and Answersadesloop85% (13)

- The Wire and Cable Technical Information HandbookDocument313 pagesThe Wire and Cable Technical Information Handbookdannyalarconm64718100% (5)

- SSA 716 StudentGuide 20150211Document551 pagesSSA 716 StudentGuide 20150211Ashok Kumaresan100% (1)

- Philips Slimline Compact 20w/2000lm 2ft LED Batten (Cool Day Light)Document4 pagesPhilips Slimline Compact 20w/2000lm 2ft LED Batten (Cool Day Light)Shrutie PatilNo ratings yet

- 04Document2 pages04Vishesh negiNo ratings yet

- PowerLogic ION 8600 Product Part Number Guide 052006Document2 pagesPowerLogic ION 8600 Product Part Number Guide 052006Magistra AkbarNo ratings yet

- Science 6 Special - Properties of MatterDocument9 pagesScience 6 Special - Properties of MatterAxcyl Volleybolista PremaylonNo ratings yet

- Chapter 9 PondsDocument65 pagesChapter 9 Pondssheil.cogayNo ratings yet

- Sintech Pumps For Sugar Processing PlantDocument18 pagesSintech Pumps For Sugar Processing Plantsahildhingra100% (2)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsFrom EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsRating: 4 out of 5 stars4/5 (4)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Heavy and Extra-heavy Oil Upgrading TechnologiesFrom EverandHeavy and Extra-heavy Oil Upgrading TechnologiesRating: 4 out of 5 stars4/5 (2)

- The Petroleum Engineering Handbook: Sustainable OperationsFrom EverandThe Petroleum Engineering Handbook: Sustainable OperationsRating: 3.5 out of 5 stars3.5/5 (5)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Guide to the Practical Use of Chemicals in Refineries and PipelinesFrom EverandGuide to the Practical Use of Chemicals in Refineries and PipelinesRating: 5 out of 5 stars5/5 (1)

- Petroleum Production Engineering, A Computer-Assisted ApproachFrom EverandPetroleum Production Engineering, A Computer-Assisted ApproachRating: 4.5 out of 5 stars4.5/5 (11)

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityFrom EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityRating: 3 out of 5 stars3/5 (2)

- Gas and Oil Reliability Engineering: Modeling and AnalysisFrom EverandGas and Oil Reliability Engineering: Modeling and AnalysisRating: 4.5 out of 5 stars4.5/5 (6)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesFrom EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesRating: 5 out of 5 stars5/5 (5)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Reservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesFrom EverandReservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesRating: 5 out of 5 stars5/5 (7)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet