Professional Documents

Culture Documents

Router8000 5axis

Uploaded by

Daniel AustinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Router8000 5axis

Uploaded by

Daniel AustinCopyright:

Available Formats

8000-R Series Feature and Specification Guide

MultiCam 8000 Series Five-Axis CNC Router

The Ultimate in HeavyDuty, High-Performance Five-Axis CNC Routing

MultiCam 8000 Series Five-Axis Routers offer the ultimate in high-performance CNC machining. Choose from a broad range of standard table sizes and Z-axis open-height configurations. Designed for highspeed, heavy-duty routing, 8000 Series five-axis machines are easy to configure to meet demanding application requirements in woodworking, plastics, nonferrous metals and composites industries. Heavy-duty, structural-steel, tubularframe construction coupled with a spacesaving, moving-gantry design make the 8000 Series five-axis a robust, commercialgrade machine designed for todays competitive manufacturing environment. MultiCam, Inc. 1025 West Royal Lane DFW Airport, TX 75261 972-929-4070 Fax: 972-929-4071 www.multicam.com sales@multicam.com

All specifications subject to change. 2012 MultiCam, Inc. All Rights Reserved.

Feature and Specification Guide

Ideal for Cutting:

Wood Plastics Non-Ferrous Metals Composite Materials And More

Innovation. Quality. Performance.

8000-R Series Feature and Specification Guide

No machine in its class offers more standard features than the MultiCam 8000 Series Five-Axis Router.

High-performance OSAI five-axis control/drive package Stress-relieved, precision-machined, all-steel frame Unique RAM-Z axis assembly 35-mm linear ball-bearing profile rails 2700-IPM rapid traverse Standard automatic tool calibration

Thermoformed Plastic Parts

Molded Plywood Furniture Structural Aluminum Components

Five-Axis Applications

Five-axis CNC routing opens up a world of new applications for the end user including edge trimming thermoformed and molded plastic plus composite parts. Often featuring interior cutouts on an angled plane, they require simultaneous five-axis machining. Other applications include deep-cavity mold making that requires short tools. Molded plywood chair and decorative furniture parts require simultaneous five-axis machining many times. Remember that a MultiCam five-axis CNC router can rotate in 90% increments and machine horizontally on all four sides of a part plus perform simple vertical machining from the top. Shops that dont think they have five-axis work may in fact benefit because this table allows machining on five separate sides of a part. Many years ago, shops wondered why they should switch from manual mills to CNC. The scenario for investing in five-axis machining technology is similar. Those who didnt switch to CNC were left behind eventually. With any business, investing in the latest technology is a requirement to stay on top and compete effectively. Five-axis machining reduces overall setup time, increases accuracy and can expand your shops capabilities for future work.

Composite Wind Turbine Parts

8000-R Series Feature and Specification Guide

Automatic Tool Changer (ATC)

The 8000 Series Five-Axis Router is available with an optional 12-position rotary tool changer. It optimizes the system for bidirectional rotation and takes the shortest route to help reduce tool-changing time. All ATC systems come standard with automatic tool length calibration, and the tool change routines built into the controls simplify integration with your favorite CAM software. An Automatic Tool Changer solution helps reduce job times, improve accuracy and reduce setup errors.

Standard Working Surface

Our standard working surface is 1" thick 80-82 Durometer phenolic with a grid pattern to utilize 0.5 x 0.25 foam gasket tape. We mount the phenolic on top of the steel base frame and machine it in place. This ensures a flat cutting surface normal to the spindle. Phenolic makes an excellent work surface because of its dependable mechanical strength and dimensional stability. In addition, phenolic has low-moisture absorption, resists heat and wear and is easy to repair as needed.

Gantry

The gantry is a 0.5" thick, 20" x 12" internally-ribbed rectangular structural steel tube mounted on machined pads on the top of each box frame support. We weld, stress relieve and precision machine the gantry that features internal ribbing, ensuring a smooth, vibration-free cut. Dual 35-mm linear bearings spaced on 18" centers provide maximum RAM-Z axis assembly rigidity.

Gantry Supports

Two heavy box-frame steel weldments support the gantry. Each gantry support rides on four 35-mm bearing blocks on both sides of the machine for eight bearings total. We space each bearing 31" center to center, giving extraordinary rigidity and vibration-free movement of the gantry in the X axis. The result is over 76,800 pounds of bearing support capability on a gantry/Ram-Z axis assembly weighing approximately 7000 pounds. Thats over a 10-1 safety ratio, which assures durability, smooth movement and accuracy over the life of the machine.

8000-R Series Feature and Specification Guide

Base Frame

The MultiCam 8000 Series five-axis base is a onepiece steel frame that we weld, stress relieve and precision machine. It features 0.5" thick structural steel tubes to support the X-axis linear bearings. One-piece construction allows for a very accurate and smooth cutting system while greatly reducing installation time. It also removes the possibility for installation errors that could affect the systems performance and accuracy.

RAM-Z Axis

MultiCam pioneered a unique design concept in its RAM-Z axis. Instead of driving a spindle-mounting plate up and down via a ball screw, a 12" x 12" structural-steel tube with internal ribbing rides up and down on six 35-mm bearing blocks to form the Z axis. A high-tolerance, precision-ground helical rack-and-pinion system drives the tube that forms the Z axis. We mount the spindle with its integrated fourth and fifth axes at the base of the tube. The result is extraordinary rigidity in the Z axis and the ability to deal with gantry clearances from 24" to 48" easily. Our RAM-Z design far outperforms a conventional Z-axis ball-screw-driven assembly especially in typical five-axis gantry configurations.

Linear Bearings

The 35-mm ball linear-bearing profile rails with stainless spring-steel strip covers are standard in all axes. Linear bearings feature: High rigidity and top-load capacities in all load directions Lowest possible noise level and best running characteristics High-torque load capacity 9600-pound load capacity per bearing

8000-R Series Feature and Specification Guide

Precision Planetary Gearboxes

Alpha Precision Planetary Gearboxes are the top of the line in the industry. Case-hardened and finished ground high-carbon alloy steel gears guarantee the lowest backlash and highest service life available. These gearboxes are among the many components that make the MultiCam 8000 Series Five-Axis Router a smooth, accurate and long-lasting cutting system. Single Stage: 10:1 Efficiency: > 97% Low noise level Integrated thermal length compensation Designed for continuous operation

High-Speed Helical Rack System

A high-speed helical rack drive system is standard on the MultiCam 8000 Series Five-Axis CNC Router. With speeds of 2700 IPM, this system can get to a full-speed move in less than half a second. The helical rack achieves fast acceleration and accuracy because it engages a greater number of teeth than straight racks. Distributing the load over several teeth also reduces wear and increases the life of the rack-and-pinion system. The Helical Rack System is important to companies wanting to cut smoother, faster and more accurately.

OSAI Control

MultiCam chose the OSAI 10/Series high-performance compact CNC control and digital ac servo drive system for the 8000 RAM-Z Five-Axis CNC Router. This OSAI product utilizes a state-of-theart PC technology hardware platform that runs an easy-to-use, multitasking operating system. We feel that its ability to control the tool center point (TCP) in programming is the best in the industry, and the control/drive/drive motor package has many years of market-proven trouble-free performance. This system uses standard M- and G-codes. The operator can program it easily using five-axis AlphaCam, MasterCam or similar PC-based CAD/CAM software packages.

8000-R Series Feature and Specification Guide

Standard Features

Leveling Feet

Tool Box

Operation Manual

Electrical Schematics

8000-R Series Feature and Specification Guide

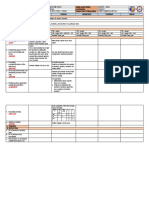

8000-R Series Specifications

(Z): 20.3 MPM (Z): 800 IPM

Frame Machining Tolerance: 0.0005"

Max. Rapid Traverse (Inches): (X, Y): 2700 IPM

Max. Rapid Traverse (Metric): (X, Y): 68.6 MPM

Power: 7 kW: 9.45 hp, 100% Duty Cycle Max RPM: 20,000

8.7 kW: 11.75 hp, 60% Duty Cycle

Automatic Tool Length Sensor: 0.0009" ( 0.023 mm)

Tool Holder: HSK F63/ER-40 Collet

C B TABLE LENGTH Top

Front

B TABLE LENGTH D TABLE HEIGHT

A TABLE WIDTH

Model

8-204-R

Size Chart (Inches) B 121 C 150

8-205-R

60

8-206-R

60

8-207-R

60

145

8-208-R

60

169

174

34

8-303-R

60

193

198

34

176

Model

8-304-R

80

241

222

34

176 176 176 176 196

8-204-R

Size Chart (Metric) B 3073 3683 4293 4902 6121 2540 3073 3683 4293 4902 6121 C 3810 4420 5029 5639 6858 3277 3810 4420 5029 5639 6858

8-205-R 8-206-R 8-207-R 8-208-R 8-303-R 8-304-R 8-305-R 8-306-R 8-307-R 8-308-R

1524 1524 1524 1524 1524 2032 2032 2032 2032 2032 2032

864 864 864 864 864 864 864 864 864 864 864

4470 4470 4470 4470 4470 4978 4978 4978 4978 4978 4978

8-305-R

80

100

270

34

8-306-R

80

121

129

34

8-307-R

80

145

150

34

8-308-R

80

169

174

34

80

193

198

34

196 196 196

241

222

34

270

34

34

196 196

Specifications subject to change.

8000-R Series Feature and Specification Guide

Spindle Rotation

C-Axis Rotation: 220

A-Axis Rotation: + 100/- 40

A Axis

220

C Axis

220

Z-Axis Stroke/Clearance

Spindle - Horizontal Position

X/Y Clearance

Work Area

Z-Stroke/ Clearance 24 36 48

Size Chart (Inches) F 125 137 149 G 21 33 45 H 15 27 39 I 4 4 4

11 X-Axis

Z-Stroke/ Clearance 610 914

Size Chart (Metric) F 3175 3480 3785 G 533 1143 838 H 381 686 I 102 102 102

Specifications subject to change.

Y-Axis

1219

991

You might also like

- Belin Tools PDFDocument40 pagesBelin Tools PDFdoc_nebulaNo ratings yet

- Milling MachinesDocument48 pagesMilling MachinesAliah IzzahNo ratings yet

- Rev I Stage ArdsDocument92 pagesRev I Stage ArdsSebastián D. GómezNo ratings yet

- 2022.9.23 FM3015C 1.5KW Fiber Laser Cutting MachineDocument11 pages2022.9.23 FM3015C 1.5KW Fiber Laser Cutting Machinesatq illNo ratings yet

- MultiCam 3000-Series CNC RouterDocument8 pagesMultiCam 3000-Series CNC RouterDaniel Austin100% (1)

- LMT Onsrud Polaris Compression BrochureDocument2 pagesLMT Onsrud Polaris Compression BrochureDaniel AustinNo ratings yet

- Trumpf Parts Service Manual - January 2004Document28 pagesTrumpf Parts Service Manual - January 2004Orlando Humberto Altamirano ArceNo ratings yet

- TaegoTech - PG BroshureDocument11 pagesTaegoTech - PG Broshurealexl5892No ratings yet

- Heidenhain TNC 640Document24 pagesHeidenhain TNC 640WalkerMachineryNo ratings yet

- C 2920 35 PDFDocument140 pagesC 2920 35 PDFHarish ChandrashekarNo ratings yet

- MultiCam 6000-Series CNC PlasmaDocument10 pagesMultiCam 6000-Series CNC PlasmaDaniel AustinNo ratings yet

- Leadwell NV-Serie 2015 PDFDocument8 pagesLeadwell NV-Serie 2015 PDFLevi BriceñoNo ratings yet

- ByStar Fiber Datasheet Eng Original 14278Document2 pagesByStar Fiber Datasheet Eng Original 14278Trần Ngọc ThànhNo ratings yet

- Laser SalesbookDocument34 pagesLaser SalesbookManuel GonzalezNo ratings yet

- Multicam Plastics BrochureDocument2 pagesMulticam Plastics BrochureMoe KimoNo ratings yet

- Ewag RS 15 en PDFDocument16 pagesEwag RS 15 en PDFMARCO.S.X7952No ratings yet

- 96ENSIS AJ 3kW - Fibre Laser Cutting MachineDocument8 pages96ENSIS AJ 3kW - Fibre Laser Cutting MachineXuan Phuong HuynhNo ratings yet

- Tool Holder CatalogDocument1,691 pagesTool Holder CatalogVladNo ratings yet

- SenFeng Series CNC Users ManualDocument11 pagesSenFeng Series CNC Users ManualJuanjo AcvdoNo ratings yet

- Neon Genesis Evangelion ANIMA Vol. 4Document262 pagesNeon Genesis Evangelion ANIMA Vol. 4jojo100% (2)

- CNC WOOD ROUTER BY MosesDocument6 pagesCNC WOOD ROUTER BY MosesNashon MutuaNo ratings yet

- Quotation For Fiber Laser Cutting Machines 4 KW: NF - PRO 315 VentoDocument25 pagesQuotation For Fiber Laser Cutting Machines 4 KW: NF - PRO 315 VentobeemasundarNo ratings yet

- Finite Element Analysis of Steel CordDocument6 pagesFinite Element Analysis of Steel CordSanjiv Kumar SinghNo ratings yet

- D800 BrochureDocument4 pagesD800 BrochurefrankNo ratings yet

- T316Document5 pagesT316ANKIT SHARMA100% (1)

- En 132011 3 2015 2019 PDFDocument68 pagesEn 132011 3 2015 2019 PDFPrem Anand100% (2)

- 1000 PDocument8 pages1000 PDaniel AustinNo ratings yet

- Hmaxseries DRDSFSDDocument6 pagesHmaxseries DRDSFSDMarius UrzicăNo ratings yet

- MultiCam 3000-Series CNC WaterjetDocument12 pagesMultiCam 3000-Series CNC WaterjetDaniel AustinNo ratings yet

- Comagrav MT Profi enDocument2 pagesComagrav MT Profi enNiki CiuteanuNo ratings yet

- Accessories For Tools CNCDocument16 pagesAccessories For Tools CNCIonutNo ratings yet

- XYZ Probe Modification - CNCzoneDocument17 pagesXYZ Probe Modification - CNCzonejdk3dNo ratings yet

- 5 Axis Lesson 2 SampleDocument20 pages5 Axis Lesson 2 SampledizorientedNo ratings yet

- Onsrud CatalogDocument104 pagesOnsrud CatalogDaniel AustinNo ratings yet

- Cartridge Dust CollectorsDocument2 pagesCartridge Dust CollectorsDaniel AustinNo ratings yet

- Silent Tools: Productivity With Slender ToolsDocument12 pagesSilent Tools: Productivity With Slender Toolsxmen norNo ratings yet

- CNC Stands For Computer Numerical Control, And: G-Code. CNC Was Developed inDocument4 pagesCNC Stands For Computer Numerical Control, And: G-Code. CNC Was Developed inKhateeb Ul Islam QadriNo ratings yet

- H - Additional MachiningDocument51 pagesH - Additional MachiningedsaregNo ratings yet

- Recommendations For Thread Milling Cutters: Materials and Application RecommendationsDocument1 pageRecommendations For Thread Milling Cutters: Materials and Application RecommendationsHaizmeer BonzieNo ratings yet

- Davi-MCA - FOUR ROLLDocument8 pagesDavi-MCA - FOUR ROLLبازرگانی راهیان کار و دانشNo ratings yet

- Comparative Study of CNC Controllers Used in CNC Milling MachineDocument9 pagesComparative Study of CNC Controllers Used in CNC Milling MachineAJER JOURNALNo ratings yet

- Invo MillingDocument8 pagesInvo MillingOvidiu StoianNo ratings yet

- MTM Lab PresentationDocument26 pagesMTM Lab PresentationMuhammad WaseemNo ratings yet

- Milling PDFDocument282 pagesMilling PDFDulis DulisNo ratings yet

- Unit-II-Capstan & Turret LatheDocument101 pagesUnit-II-Capstan & Turret LatheRavichandran GNo ratings yet

- CNCDocument98 pagesCNCRohit SinghNo ratings yet

- 2050 Panther LatheDocument2 pages2050 Panther Lathepramod_tryNo ratings yet

- CNC Mill ProgrammingDocument24 pagesCNC Mill ProgrammingZahidah AmaninaNo ratings yet

- CNC Common Terms PDFDocument2 pagesCNC Common Terms PDFShaival JhaNo ratings yet

- Sitecollectiondocuments Downloads Global Brochures En-Gb C-2940-131Document24 pagesSitecollectiondocuments Downloads Global Brochures En-Gb C-2940-131Rudra DasNo ratings yet

- Bystar Datasheet Eng OriginalDocument2 pagesBystar Datasheet Eng OriginalAmer FatićNo ratings yet

- Assingment 2: Manufacturing TechnologyDocument29 pagesAssingment 2: Manufacturing TechnologySarweshNarayanParbatNo ratings yet

- CNC Programmer Job Description PostingDocument2 pagesCNC Programmer Job Description Postingsmith9krNo ratings yet

- Horizontal Machining CenterDocument18 pagesHorizontal Machining CenterShashankNo ratings yet

- Apostila PowerMILL 5.5 - 5 EixosDocument126 pagesApostila PowerMILL 5.5 - 5 EixosRoberto SilvaNo ratings yet

- PC Fapt BrochureDocument2 pagesPC Fapt Brochurebabak671No ratings yet

- MARVEL 6000 Series High Power Fiber Laser Cutting Machine - Laser Cutting Farley Laserlab, CNC Laser Cutting Machine, Plasma Cutting Machine, Fiber Laser Cutting Machine, Cutting Machine PriceDocument1 pageMARVEL 6000 Series High Power Fiber Laser Cutting Machine - Laser Cutting Farley Laserlab, CNC Laser Cutting Machine, Plasma Cutting Machine, Fiber Laser Cutting Machine, Cutting Machine PriceTradiyo ForexNo ratings yet

- Hartford Pro 1000 CNC Vertical MillDocument14 pagesHartford Pro 1000 CNC Vertical MillChuck20620% (1)

- HMC BasicDocument14 pagesHMC BasicShashankNo ratings yet

- Sodick Technology SelectorDocument14 pagesSodick Technology SelectorTrần Văn TrườngNo ratings yet

- Touch Probe Cycles: Product InformationDocument6 pagesTouch Probe Cycles: Product Informationsonnv_hcmuteNo ratings yet

- Introduction To Introduction To Computer Numerical Control: Computer Aided Manufacturing TECH 4/53350 1Document11 pagesIntroduction To Introduction To Computer Numerical Control: Computer Aided Manufacturing TECH 4/53350 1BabuRaoThellaNo ratings yet

- LT1424Document20 pagesLT1424octaviocamachoNo ratings yet

- Hyundai L2000sy L3000sy TurningcenterDocument40 pagesHyundai L2000sy L3000sy TurningcenterAndreas AnugerahNo ratings yet

- Seco ToolsDocument24 pagesSeco ToolscortelinirosaNo ratings yet

- Machine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryFrom EverandMachine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryNo ratings yet

- Eurovac High Volume Collector PackageDocument15 pagesEurovac High Volume Collector PackageDaniel AustinNo ratings yet

- Onsrud CatalogDocument104 pagesOnsrud CatalogDaniel AustinNo ratings yet

- Cartridge Dust CollectorsDocument2 pagesCartridge Dust CollectorsDaniel AustinNo ratings yet

- Versatile, Feature-Rich Production Routing!: Multicam 3000 Series CNC Router Feature and Specification GuideDocument7 pagesVersatile, Feature-Rich Production Routing!: Multicam 3000 Series CNC Router Feature and Specification GuideDaniel AustinNo ratings yet

- Kase MakeDocument1 pageKase MakeDaniel AustinNo ratings yet

- Onsrud Catalog - Milling and Drilling ToolsDocument40 pagesOnsrud Catalog - Milling and Drilling ToolsDaniel AustinNo ratings yet

- ShopData QuickPlate BuilderDocument2 pagesShopData QuickPlate BuilderDaniel AustinNo ratings yet

- KASEMAKE SoftwareDocument2 pagesKASEMAKE SoftwareDaniel AustinNo ratings yet

- MultiCam Rapid ShapeDocument2 pagesMultiCam Rapid ShapeDaniel AustinNo ratings yet

- Features of The Sideros RotoLiftDocument2 pagesFeatures of The Sideros RotoLiftDaniel AustinNo ratings yet

- ShopData Quickduct CAD 2009Document2 pagesShopData Quickduct CAD 2009Daniel AustinNo ratings yet

- MultiCam Corporate BrochureDocument32 pagesMultiCam Corporate BrochureDaniel AustinNo ratings yet

- CMTS HandoutDocument2 pagesCMTS HandoutDaniel AustinNo ratings yet

- MultiCam 7000-Series CNC RouterDocument10 pagesMultiCam 7000-Series CNC RouterDaniel AustinNo ratings yet

- Graphics HandoutDocument2 pagesGraphics HandoutDaniel AustinNo ratings yet

- MultiCam 3000-Series CNC PlasmaDocument9 pagesMultiCam 3000-Series CNC PlasmaDaniel AustinNo ratings yet

- SIDEROS - RotoliftDocument2 pagesSIDEROS - RotoliftDaniel AustinNo ratings yet

- MultiCam 2000-Series CNC LaserDocument14 pagesMultiCam 2000-Series CNC LaserDaniel Austin0% (1)

- SIDEROS Engineering - Product OfferingsDocument2 pagesSIDEROS Engineering - Product OfferingsDaniel AustinNo ratings yet

- SIDEROS - RotocleanDocument2 pagesSIDEROS - RotocleanDaniel AustinNo ratings yet

- Sean A. Hayward Et Al - Dilatonic Wormholes: Construction, Operation, Maintenance and Collapse To Black HolesDocument9 pagesSean A. Hayward Et Al - Dilatonic Wormholes: Construction, Operation, Maintenance and Collapse To Black HolesDex30KMNo ratings yet

- Force Relations and Dynamics of Cutting Knife in A Vertical Disc Mobile Wood Chipper - Leonardo El J Pract TechnolDocument14 pagesForce Relations and Dynamics of Cutting Knife in A Vertical Disc Mobile Wood Chipper - Leonardo El J Pract TechnolNguyenHuanNo ratings yet

- Rotational Dynamics: Physics 101Document10 pagesRotational Dynamics: Physics 101learningboxNo ratings yet

- Seminar ReportDocument23 pagesSeminar ReportvinaykumaarNo ratings yet

- DLL - G8 Science - Q3 - F2FDocument2 pagesDLL - G8 Science - Q3 - F2FRAMIR BECOYNo ratings yet

- Distance DisplacementDocument4 pagesDistance DisplacementRuchi Briam James LagitnayNo ratings yet

- Drmos Specifications: November 2004 Revision 1.0Document17 pagesDrmos Specifications: November 2004 Revision 1.0Tran Xuan NamNo ratings yet

- 2013 Shear Strength of Brick Masonry Walls Assembled With Different Types of MortarDocument8 pages2013 Shear Strength of Brick Masonry Walls Assembled With Different Types of MortarCatherineNo ratings yet

- Aeroelastic Tailoring-Theory, Practice, and PromiseDocument13 pagesAeroelastic Tailoring-Theory, Practice, and Promiservramkumar78No ratings yet

- GuidelinesDocument15 pagesGuidelinesKenn Fabre0% (1)

- Cauchy Riemann EquationDocument6 pagesCauchy Riemann EquationeSinist3rNo ratings yet

- Instruction Manual PHE PDFDocument78 pagesInstruction Manual PHE PDFzniperxNo ratings yet

- (IS) Conditioner For (IS) RVDT Sensor 690210266 (IS) : SensorexDocument2 pages(IS) Conditioner For (IS) RVDT Sensor 690210266 (IS) : SensorexShakir SarvaiyaNo ratings yet

- 2015-05 Alto Motorcycle CatalogDocument97 pages2015-05 Alto Motorcycle CatalogGeorgi AleksievNo ratings yet

- ReiewDocument19 pagesReiewcullen bohannonNo ratings yet

- HILTI HST3 Brochure PDFDocument5 pagesHILTI HST3 Brochure PDFPatrick LaoNo ratings yet

- Prosprod I Casting Process (2) - Part2 PDFDocument36 pagesProsprod I Casting Process (2) - Part2 PDFPandu WibowoNo ratings yet

- MKN Hansdampf Cge12 eDocument2 pagesMKN Hansdampf Cge12 eRumen PavlovNo ratings yet

- Calculation of Wind Peak Velocity Pressure - Eurocode 1Document4 pagesCalculation of Wind Peak Velocity Pressure - Eurocode 1weipinNo ratings yet

- Seminar On Wireless Charging of Mobile DevicesDocument24 pagesSeminar On Wireless Charging of Mobile DevicesGourish Amonkar100% (1)

- Experimental and Numerical Analysis of Steel and Fiber-Reinforced Polymer Concrete Beams Under Transverse LoadDocument14 pagesExperimental and Numerical Analysis of Steel and Fiber-Reinforced Polymer Concrete Beams Under Transverse LoadErnie SitanggangNo ratings yet

- LENZE E84AVxCx - 8400 StateLine-HighLine-TopLine 0.25-45kW - v9-0 - ENDocument291 pagesLENZE E84AVxCx - 8400 StateLine-HighLine-TopLine 0.25-45kW - v9-0 - ENClaudioNo ratings yet

- 03 Combustor Dynamics Monitoring (CDM)Document9 pages03 Combustor Dynamics Monitoring (CDM)Luis Alonso Dipaz ZeaNo ratings yet

- Guidelines On Good Laboratory Practice in Pesticide Residue Analysis CAC/GL 40-1993 ContentDocument36 pagesGuidelines On Good Laboratory Practice in Pesticide Residue Analysis CAC/GL 40-1993 ContentVishal AroraNo ratings yet

- GWR As RLI For Boiler Drum LevelDocument14 pagesGWR As RLI For Boiler Drum LevelRoger SeaverNo ratings yet

- WT Chapter 6 2Document21 pagesWT Chapter 6 2kanchanabalajiNo ratings yet