Professional Documents

Culture Documents

Why Stainless Steel

Uploaded by

aladinsane0 ratings0% found this document useful (0 votes)

44 views2 pagesChromium content of the steel allows the formation of a tough, adherent, invisible, corrosion-resisting chrotniwn oxide film on the steel surface. There arc more than 60 grades of stainless steel.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentChromium content of the steel allows the formation of a tough, adherent, invisible, corrosion-resisting chrotniwn oxide film on the steel surface. There arc more than 60 grades of stainless steel.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

44 views2 pagesWhy Stainless Steel

Uploaded by

aladinsaneChromium content of the steel allows the formation of a tough, adherent, invisible, corrosion-resisting chrotniwn oxide film on the steel surface. There arc more than 60 grades of stainless steel.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

he rrumy unique values provided by stainless steel

nud<e it t1 powerful ettndidate in mtJteritds

selection. Engineers, specifiers tJnd designers often

underestimrJte or overlook these 1)(1/ues because of'

whtJt is viewed as the higher initial cost of'

str1inless steel However, over the total fiji.: of'a

project; stainless is often the !Jest 1)(1lue option.

WHAT IS STAINLESS STEEL?

Stainless steel is essentially a low carbon steel which contains

chromium at lO'Yc' or more by weight. 1t is this addition of

chromium that gives the steel its unique stainless, corrosion

resisting properties.

The chromium content of the steel allows the formation of a

tough, adherent, invisible, corrosion-resisting chrotniwn oxide

film on the steel surface. lf damaged mechanically or chemically,

this film is provided that oxygen, even in very small

amounts, is present. The corrosion resistance and other useful

properties of the steel arc enhanced by increased chromium con-

tent and the addition of other dements such as molybdenum,

nickel and nitrogen.

There arc more than 60 grades of stainless steel. However, the

entire group can be divided into five classes. Each is idemificd by

the alloying clements which affect their microstructure and for

which each is named.

BENEFITS OF STAINLESS STEEL

Corrosion resistance

-lower alloyed grades resist corrosion in atmospheric and

pure water environments, while high-alloyed grades can resist

corrosion in most acids, alkaline solutions, and chlorine bear-

ing environments, properties which are utilized in process

plants.

Fire & heat resistance

-special high chromium and nickel-alloyed grades resist

scaling and retain strength at high temperatures.

Hygiene

-the easy cleaning ability of stainless makes it the first

choice for strict hygiene conditions, such as hospitals,

kitchens, abattoirs and other food processing plants.

Aesthetic appearance

- the bright, easily maintained surface of stainless steel pro-

vides a modern and attractive appearance.

GRADES/APPLICATIONS OF STAINLESS STEEL

400 Series Martensitic- Typical grade: 410

Straight chromium (12-1 R'Yc,), magnetic and can be hardened by

heat treatmem. 'lypicaluse: Fasteners, pump shafts

400 Series Ferritic - Typical grade: 430

Straight chromium (12-1 R%), "low" carbon, magnetic, but nor

heat treatable. 'lypicaluse: Appliance trim, cooking utensils

200/300 Series Austenitic- Typical grade: 304

Chromium (17-25%)/Nickd (8-25%), non-magnetic, not hear

treatable. Can develop high strength by cold work. Additions of

molybdenum (up to 7%) can inCI'case the corrosion resistance.

'lypicaluse: equipment, chemical equipment, architectural

applications

Precipitation Hardening- '(ypical grade: 17-4

C:hrornium ( 12-28%)/Nickcl (3-9%), martensitic or austenitic.

Develop strength by precipitation hardening reaction during heat

treatment. 'l);picaluse: Valves, gears, pcr:u chemica! l.:quipmcnt

Duplex- 'fjpical grade: 2205

Chromium (18-25/t,)/Nickcl (IJ-7%) and up to 4% tnolyhdc-

nurn. More resistant to stress corrosion cracking than austenitic,

yet tougher than htlly fcrritic alloys. 'lypicaluse: Pipelines, pres-

sure vessels, shafting

Strength-to-weight advantage

-the workhardening property of austenitic grades, that

results in a significant strengthening of the material from cold-

working alone, and the high strength duplex grades, allow

reduced material thickness over conventional grades, there-

fore cost savings.

Ease of fabrication

-modem steel-making techniques mean that stainless can

be cut, welded, formed, machined, and fabricated as readily

as traditional steels.

Impact resistance

- the austenitic microstructure of the 300 series provides

high toughness, from elevated temperatures to far below

freezing, making these steels particularly suited to cryogenic

applications.

Long term value

-when the total life cycle costs are considered, stainless is

often the least expensive material option.

SPECIALTY STEEL INDUSTRY

OF NORTH AMERICA

3050 K Street, N.W.

Washington, D.C. 20007

TEL: (202) 342-8630 or (BOO) 982-0355

FAX: (202) 338-5534

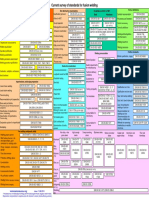

CLASSIFICATION OF STAINLESS STEEL PRODUCT FORMS*

Dimensions

Item Description Thickness Width Diameter or Size

Sheet Coils and cut lengths:

Mill finishes Nos. 1, 2]) & 2B under (4.7Gmm) 24" & over (609.6mm) -

PoL finishes Nos. 3, 4, 6, 7 & H

""It

all widths

Strip Cold finished, coils or cut lengths under (4.76mm) under 24" (G09.Gmm)

Pol. finishes Nos. 3, 4, 6, 7 & 8

""It

all widrhs

Plate Flat rolled or forged

& over (4.76mm) over I 0" (254mm) -

Bar Hot finished rounds, squares,

tKtagtlllS and hexagons - - \cj" & over (6.35mm)

Hot tlnishcd Hats & over (3.l8mtn) (6.35mm) to -

I 0" incl. (254mm)

Cold finished rounds, squares

octagons and hexagons -

(12.7mm)

Cold finished flats - & over (953mm) -

Wire Cold finishes only:

Round, square, octagon, hexagon (254mm)

flat win:' 0.010" to (0.254mm)

to (1. 59mm) Y;." & under (12.7mm)

under (4.76mm) under%" (9.53mm)

Pipe & 'lirbing Several different classifications, with differing specifications, arc available. For information on standard sizes consult your local Steel Service Center

or the SSTUS.

FxtrusioJlS Not considered "standard" shapes, hut of potentially wide interest.

or structurals.

t1ngots, Slabs and l-lot Bands aho available

STANDARD MECHANICAL SHEET FINISHES

Unpolished or Rolled Finishes:

No. 1 /\ rough, dull surf::-.cc which rcsu!cs from hot rolling to the spcci!lcd

thickness followed by annealing and dcscaling.

No. 2D A dull !lnish which results from cold rolling followed hy annealing and

(kscaling, and may perhaps get a final light roll pass through t!llpoli.shed

rolls. A 2D finish is used where appearance i.s or no concern.

No. 2n J\ bright, cold rolled finish resulting in the same manner as No. 2D

1-lnish, except that the annealed and descaled sheet receives a final light

roll pass through polished rolls. This is the general purpose, cold rolled

finish that can he used as mas a preliminary step to polishing.

Polished Finishes:

No.3 An intermediate polish surhce obtained by finishing with a 100-gtit

abrasive. CcneraJly used where a semiflnished polished surface is

required. A No. finish usually receives additional polishing

during f:tbrication.

CONDITIONS & FINISHES FOR BAR

Conditions Surface Finishes*

L Hot worked only (a) Scale not removed (excluding spot conditioning)

(b) Rough turned**

(c) Pickled or blast cleaned and pickled

2. Annealed or other- (a) Scale not reJnoved (excluding spot conditioning)

wise hear treated (b) Rough turned

(c) Pickled or blast cleaned and pickled

(d) Cold drawn or cold rolled

(e) Centerless gJound

(f) Polished

3. Annealed and cold (d) Cold drawn or cold rolled

worked to high (e) Centerless ground

tensile strength*** (f) Polished

* Surface finishes (h), (e) and (f) are applicable to round bars only.

'* Bars of the 4xx series stainless steels which arc highly hardcnable, such as

'lypcs 414,420, 420F, 431, 440A, 440B and 440C, are annealed before

rough turning. Other hardenable grades, such as 'l}rpcs 403, 410, 416 and

416Se, may also require annealing depending on their composition and size.

***Produced in T}rpes 302, 303Sc, 304 and 316.

Currently limited in size to approximately 6 Y/ (l65.lmm) diameter circle,

No.1

No. G

No.7

No.8

J\ polished surface obtained by finishing with a 120-150 rned\

abrasive, following initial grinding with coarser abrasives. This is a

general-purpose bright finish with a visible "grain" which prevents

mirror rcAection.

A dull satin llnish having lower rdkctivity than No, 4 It is

produced hy 'Eunpico brushing rhe No. ;j finish in a medium of

abrasive and oil. It is used for architectural applications and

ornamentation where a high luster is undesirable, and to contrast

with brighter finishes.

A highly rd-lcctive finish that is obrained by buHlng flndy ground

surfaces, but not to the extenr of completely removing the "grit" lines.

lt is used chiefly for architr.:ctural and ornamental purpmes.

The most reflective surface obtained by polishing with successively

finer abrasives and buffing extensively until all grit lines hom

preliminary grinding operations arc removed. lr is used f(u

applications such as mirrors and reAectors.

CONDITIONS & FINISHES FOR PLATE

Condition and Finish Description and Remarks

Hot rolled Scale not removed. Not heat treated. Plates not

recommended for final usc in this condition.*

Hot rolled, annealed Scale not removed. Use of plates in this condition

or heat treated is generally confined to heat resisting applications.

Scale impairs corrosion n:sisran.ce. *

HM rolled, annealed Condition and finish commonly preferred fOr

or heat treated, blast corrosion resisting and most heat resisting

cleaned or pickled applications.

Hot rolled, annealed Smoother finish for specialized application.s.

dcscalcd and temper

passed

Hot rolled, annealed Smooth finish with greater freedom hom surface

descaled cold rolled, imperfections than the above.

annealed, descaled,

optionally temper

Hot rolled, annealed or Polished finishes: refer to sheet finishes.

heat treated, surface

cleaned and polished

*Surface inspection is not practical on plates which have not been pickled or

You might also like

- Heat, The Mechanical UniverseDocument2 pagesHeat, The Mechanical UniversealadinsaneNo ratings yet

- Research Notes On Sulfide Stress CrackingDocument5 pagesResearch Notes On Sulfide Stress CrackingaladinsaneNo ratings yet

- Research Notes On Sulfide Stress CrackingDocument5 pagesResearch Notes On Sulfide Stress CrackingaladinsaneNo ratings yet

- TTC - Dark Matter, Dark Energy, Dark Side of The UniverseDocument6 pagesTTC - Dark Matter, Dark Energy, Dark Side of The UniversealadinsaneNo ratings yet

- Grigull, Ulrich - Fahrenheit, A Pioneer of Exact Thermometry (Article)Document10 pagesGrigull, Ulrich - Fahrenheit, A Pioneer of Exact Thermometry (Article)aladinsaneNo ratings yet

- Foma NDT System PDFDocument16 pagesFoma NDT System PDFaladinsaneNo ratings yet

- Comparisons of Steel Water Storage Tanks (Tim Guishard Enterprises)Document11 pagesComparisons of Steel Water Storage Tanks (Tim Guishard Enterprises)aladinsaneNo ratings yet

- A Fracture Mechanics Approach For Analyzing Spiral Weld Pipes Containing CracksDocument9 pagesA Fracture Mechanics Approach For Analyzing Spiral Weld Pipes Containing CracksaladinsaneNo ratings yet

- XRF Analytical TechniquesDocument83 pagesXRF Analytical Techniquesaladinsane100% (1)

- Plate A516 and A387 - Pressure Vessel SteelsDocument16 pagesPlate A516 and A387 - Pressure Vessel SteelsaladinsaneNo ratings yet

- Met Preparation of Zinc Coatings (Struers)Document6 pagesMet Preparation of Zinc Coatings (Struers)aladinsaneNo ratings yet

- Moment Redistribution - Principles and Practice Using Aci 318-02Document19 pagesMoment Redistribution - Principles and Practice Using Aci 318-02aladinsaneNo ratings yet

- Pub BDC Codeti2014 Div3 GB x2xDocument4 pagesPub BDC Codeti2014 Div3 GB x2xaladinsaneNo ratings yet

- Eddy Current Array Technology For The Inspection of Aircraft and EngineDocument37 pagesEddy Current Array Technology For The Inspection of Aircraft and EnginealadinsaneNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Endurance LimitDocument13 pagesEndurance LimitOmkar Kumar Jha0% (1)

- Ten Rules of Good Manufacturing PracticeDocument2 pagesTen Rules of Good Manufacturing PracticeGeorge MarkasNo ratings yet

- Autobody Materials - Lecture 4Document6 pagesAutobody Materials - Lecture 4Siddharth Narayanan ChidambareswaranNo ratings yet

- List of Is Codes For Cement and ConcreteDocument9 pagesList of Is Codes For Cement and ConcreteamitkuknaNo ratings yet

- RBR Na Pas Tac f6 Tech Spec LbaDocument3 pagesRBR Na Pas Tac f6 Tech Spec LbaNORDBNo ratings yet

- Knives, Blades, Tools & Parts Product Listing: Knife ProductsDocument8 pagesKnives, Blades, Tools & Parts Product Listing: Knife ProductsWilberth FrancoNo ratings yet

- Bell B50DDocument1 pageBell B50DAlejandro QuiñonezNo ratings yet

- Company Profile Krona Liquatec LTD: Providing WATER SOLUTIONS ForDocument4 pagesCompany Profile Krona Liquatec LTD: Providing WATER SOLUTIONS Forkher_sumitNo ratings yet

- Example - Complete Model of Eng Management ReportDocument38 pagesExample - Complete Model of Eng Management ReportSyah RullacmarNo ratings yet

- Magnetrol O&gDocument100 pagesMagnetrol O&gesakkiraj1590No ratings yet

- Voltex MethodologyDocument3 pagesVoltex Methodologykkarukkuvelan100% (1)

- Storage Location Not Defined For Delivery ItemDocument19 pagesStorage Location Not Defined For Delivery ItembiswajitNo ratings yet

- Optimum D240x500GDocument2 pagesOptimum D240x500Gjavi_mr50% (2)

- HCC PDFDocument24 pagesHCC PDFmark mywordNo ratings yet

- Life Cycle Phases in Construction ProjectDocument10 pagesLife Cycle Phases in Construction Projectaymanmomani2111No ratings yet

- 3rd Quarter Las in TLE 6Document4 pages3rd Quarter Las in TLE 6Michael Edward De Villa100% (3)

- Survey Welding-Standards 13-09-2010Document1 pageSurvey Welding-Standards 13-09-2010Nenad MilosevicNo ratings yet

- The RMA Rubber HandbookDocument62 pagesThe RMA Rubber Handbookjonathan6657No ratings yet

- Hocut 795 Article by Hank LimperDocument4 pagesHocut 795 Article by Hank LimperLORENZO GOMEZNo ratings yet

- Port of Tacoma: Directory of Third-Party Logistic Service ProvidersDocument4 pagesPort of Tacoma: Directory of Third-Party Logistic Service ProvidersPort of TacomaNo ratings yet

- Astm Standards201706Document52 pagesAstm Standards201706KaioFernandesNo ratings yet

- Auto Comp ReportDocument167 pagesAuto Comp ReportnilekaniNo ratings yet

- Subsea Insulation SystemDocument1 pageSubsea Insulation SystemProject Sales CorpNo ratings yet

- Combustion Inspection Elimination KitDocument2 pagesCombustion Inspection Elimination KitP_DaviesNo ratings yet

- Tapping Into New and International MarketsDocument31 pagesTapping Into New and International MarketsFahim KhanNo ratings yet

- Powder Metallurgy Review Vol1 No1Document52 pagesPowder Metallurgy Review Vol1 No1SyarifNo ratings yet

- X'WELL Company Profile 2017Document35 pagesX'WELL Company Profile 2017francis pacaigueNo ratings yet

- AWS-Welding Journal-March 2014Document155 pagesAWS-Welding Journal-March 2014ran.ben.arieNo ratings yet

- TN27 Australian Standard For Precast BC and HeadwallDocument8 pagesTN27 Australian Standard For Precast BC and HeadwallgemotorresNo ratings yet

- 1.0 Introduction To Supply Chain Management (SCM)Document69 pages1.0 Introduction To Supply Chain Management (SCM)Anchal BaggaNo ratings yet