Professional Documents

Culture Documents

Autobody Materials - Lecture 4

Uploaded by

Siddharth Narayanan Chidambareswaran0 ratings0% found this document useful (0 votes)

36 views6 pagesThe document discusses two types of automotive body materials: interstitial free (IF) steel and transformation induced plasticity (TRIP) steel. IF steel contains very low amounts of carbon and interstitial elements, achieving high ductility. Additions of titanium and niobium form carbides and nitrides, removing carbon from the steel. IF steel has a yield strength of 140-180 MPa and tensile strength of 290-340 MPa. TRIP steel contains 10-15% retained austenite at room temperature that transforms to martensite during plastic deformation or impact, enhancing strength and formability. The microstructure of TRIP steel consists of ferrite, bainite, and retained

Original Description:

materials

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses two types of automotive body materials: interstitial free (IF) steel and transformation induced plasticity (TRIP) steel. IF steel contains very low amounts of carbon and interstitial elements, achieving high ductility. Additions of titanium and niobium form carbides and nitrides, removing carbon from the steel. IF steel has a yield strength of 140-180 MPa and tensile strength of 290-340 MPa. TRIP steel contains 10-15% retained austenite at room temperature that transforms to martensite during plastic deformation or impact, enhancing strength and formability. The microstructure of TRIP steel consists of ferrite, bainite, and retained

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

36 views6 pagesAutobody Materials - Lecture 4

Uploaded by

Siddharth Narayanan ChidambareswaranThe document discusses two types of automotive body materials: interstitial free (IF) steel and transformation induced plasticity (TRIP) steel. IF steel contains very low amounts of carbon and interstitial elements, achieving high ductility. Additions of titanium and niobium form carbides and nitrides, removing carbon from the steel. IF steel has a yield strength of 140-180 MPa and tensile strength of 290-340 MPa. TRIP steel contains 10-15% retained austenite at room temperature that transforms to martensite during plastic deformation or impact, enhancing strength and formability. The microstructure of TRIP steel consists of ferrite, bainite, and retained

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 6

Automotive Materials

Autobody Materials IF : Interstitial Free steel

Interstitial-free (IF) steels, also referred to as ultra-low carbon (ULC) or extra-low carbon (ELC) very low carbon and nitrogen contents The processing and chemistry of IF steels produce very high ductility and formability, albeit at low strength

Automotive Materials

Autobody Materials IF : Interstitial Free steel

Despite such low levels of interstitials, further alloying, by additions of titanium and/or niobium, are made to remove carbon and nitrogen from solid solution by the precipitation of carbides, nitrides, and other compounds IF steels border on being almost pure iron ( almost ZERO PERCENTAGE of Carbon)

Automotive Materials

Autobody Materials IF : Interstitial Free steel - Product

Niobium is considered only to combine with carbon Nb + C NbC Cold-rolled and annealed sheet steels annealed at 650 C Two strengthening approaches are used: solid-solution strengthening and bake hardening Bake hardening refers to the increment of strength that develops in cold formed sheet steel during baking of automotive panels. Bake-hardening at 175 C for 20 minutes Steels with very low interstitial contents exhibit excellent formability with low yield strength, high elongation, and good deep drawability Yield strengths typically range between 140 and 180 MPa (20 and 26 ksi) and Tensile strengths range between 290 and 340 MPa (42 and 49 ksi)

Automotive Materials

Autobody Materials TRIP : Transformation Induced Plasticity Steels Basic Concept

Similar to dual-phase steels, trip steels have emerged as an energy-absorbing high-strength steel for the automobile. The term trip is derived from the mechanism of transformation induced plasticity. These steels contain a high percentage of retained austenite (1015%). ( austenitic structure @ RT). The austenite transforms to martensite during the forming of the part (PLASTIC DEFORMATION During Crash), thus providing enhanced formability or transforms upon impact in a crash.

Automotive Materials

Autobody Materials TRIP : Microstructure, Composition & Properties

Microstructure: austenite remains in the ferritic-bainitic basic matrix, The bainitic structure consists of acicular ferrite and retained austenite Acicular ferrite is a microstructure of ferrite that is characterized by needle shaped crystallites or grains when viewed in two dimensions

Composition:

Automotive Materials

Autobody Materials TRIP : Microstructure, Composition & Properties

Mechanical Property: TRIP steels are intercritically annealed and isothermally transformed. The microstructure after heat-treatment consists of ferrite, bainite, retained austenite Manganese is used for hardenability and strength Silicon plays an important role on the stabilisation of the retained austenite 590- 780 Mpa high strength steel sheet superior formability

The excellent mechanical properties exhibited by the TRansformation Induced Plasticity steels are mainly due to the martensitic transformation of the metastable retained austenite induced by strain

You might also like

- E 3134 - 17Document12 pagesE 3134 - 17Jacky LeongNo ratings yet

- Interpretation of The Microstructure of SteelsDocument61 pagesInterpretation of The Microstructure of SteelsCiresica Sanda Cocindau100% (1)

- Chetan Bhagat - Three Mistakes of My LifeDocument144 pagesChetan Bhagat - Three Mistakes of My LifeGayathri ParthasarathyNo ratings yet

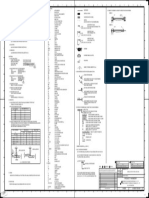

- Australian Steel Detailing ChartDocument1 pageAustralian Steel Detailing Chartvinodh100% (1)

- Astm A653 15 PDFDocument13 pagesAstm A653 15 PDFDaniel Vasquez100% (2)

- Lecture 13 - HEAT FLOW AND HEAT BALANCE IN WELDINGDocument10 pagesLecture 13 - HEAT FLOW AND HEAT BALANCE IN WELDINGVINAYAK SHARMANo ratings yet

- Final MT-4 & 5Document31 pagesFinal MT-4 & 5RajasekharKosuruNo ratings yet

- Amatconrep PPT 5Document31 pagesAmatconrep PPT 5Raymark SazonNo ratings yet

- Civil Engineering Materials 1st Edition Sivakugan Solutions ManualDocument7 pagesCivil Engineering Materials 1st Edition Sivakugan Solutions Manualbinhlinhh9ih100% (32)

- Ebook Civil Engineering Materials 1St Edition Sivakugan Solutions Manual Full Chapter PDFDocument28 pagesEbook Civil Engineering Materials 1St Edition Sivakugan Solutions Manual Full Chapter PDFtironcolossald30y100% (10)

- Transformation Induced PlasticityDocument6 pagesTransformation Induced PlasticityKarthick RamNo ratings yet

- National Institute of TransportDocument9 pagesNational Institute of Transportfahad khalefNo ratings yet

- Engine Bearing MaterialsDocument12 pagesEngine Bearing MaterialsADNo ratings yet

- 2.2 Steel Making: Figure 2.2-1Document4 pages2.2 Steel Making: Figure 2.2-1yaswanth1992No ratings yet

- Composite Material For Drive ShaftDocument22 pagesComposite Material For Drive ShaftRavi ParkheNo ratings yet

- Ferrous Alloys - Group 05Document36 pagesFerrous Alloys - Group 05Nipun HarshaNo ratings yet

- Submitted in Partial Fulfillment of The Requirements For The Award ofDocument25 pagesSubmitted in Partial Fulfillment of The Requirements For The Award ofAnuj TripathiNo ratings yet

- Difference Between Carbon Steel and Alloy SteelDocument3 pagesDifference Between Carbon Steel and Alloy SteelhaharameshNo ratings yet

- Structure and PropertiedDocument43 pagesStructure and PropertiedJalaj GaurNo ratings yet

- Week 1 Lecture Material - WatermarkDocument88 pagesWeek 1 Lecture Material - Watermarkchristi SNo ratings yet

- Engineering Materials & Metallurgy: Unit IiiDocument14 pagesEngineering Materials & Metallurgy: Unit IiiKandasamy VenkatachalamNo ratings yet

- Steel - Material of Choice For Automotive Lightweight ApplicationsDocument7 pagesSteel - Material of Choice For Automotive Lightweight ApplicationsÖzge uyanıkNo ratings yet

- Protective CoatingsDocument203 pagesProtective CoatingsGopalakrishnan KuppuswamyNo ratings yet

- Interstitial Free SteelsDocument3 pagesInterstitial Free SteelsVishalNo ratings yet

- Steel - Macaraeg, Edward Joseph M.Document31 pagesSteel - Macaraeg, Edward Joseph M.Mark Lester LualhatiNo ratings yet

- Sheet Metal Stamping in Automotive Industry IgnoreDocument48 pagesSheet Metal Stamping in Automotive Industry IgnoreSalil GhateNo ratings yet

- Test 2 Material SelectionDocument6 pagesTest 2 Material Selectionsilent spritsNo ratings yet

- Sadique Pro If SteelDocument12 pagesSadique Pro If Steelsatish_trivediNo ratings yet

- 9b... 2b To 5bDocument7 pages9b... 2b To 5bCubillan, Kenneth M.No ratings yet

- MicrostructuresDocument10 pagesMicrostructuresErin BarryNo ratings yet

- Ferrous Metallurgy: The Chemistry and Structure of Iron and SteelDocument37 pagesFerrous Metallurgy: The Chemistry and Structure of Iron and SteelTeknik PemesinanNo ratings yet

- FC-06-Engineering Material & Metallurgy PDFDocument431 pagesFC-06-Engineering Material & Metallurgy PDFsomnath ghosh100% (1)

- Ferrous and Non Ferrous MetalsDocument31 pagesFerrous and Non Ferrous MetalsadinamdarNo ratings yet

- Carbon Steel and Mild Steel DifferenceDocument8 pagesCarbon Steel and Mild Steel DifferenceSteinol SolutionsNo ratings yet

- Asm - Metalografia de Aço Baixo CarbonoDocument20 pagesAsm - Metalografia de Aço Baixo CarbonoengetarcioNo ratings yet

- Weldability of High Strength Low Alloy SteelDocument34 pagesWeldability of High Strength Low Alloy SteelGanesan Veerasamy100% (1)

- Tech Information From Mahle Clevite IncDocument2 pagesTech Information From Mahle Clevite Inceng_ebrahim_2000No ratings yet

- Processingand Applicationof IFGradesteeel Prospectsin SAIL3Document19 pagesProcessingand Applicationof IFGradesteeel Prospectsin SAIL3Chhatramani SinghNo ratings yet

- Write The Various Classification of Engineering MaterialsDocument7 pagesWrite The Various Classification of Engineering Materialsashok pradhanNo ratings yet

- Automotive Materials-Current Trends and Futuristic PerspectivesDocument60 pagesAutomotive Materials-Current Trends and Futuristic Perspectivesphap thuNo ratings yet

- Design of Leaf SpringsDocument27 pagesDesign of Leaf Springsmic50% (2)

- Steel MakingDocument38 pagesSteel Makings.samNo ratings yet

- Steel: Module I. Introduction and Basic ConceptsDocument21 pagesSteel: Module I. Introduction and Basic ConceptsKris dNo ratings yet

- Handbook On Stainless Steel WeldingDocument71 pagesHandbook On Stainless Steel Weldinganunay kumarNo ratings yet

- Modern Metallic MaterialsDocument6 pagesModern Metallic MaterialsRajaganapathy GanaNo ratings yet

- 10-Low Alloy Steel PDFDocument32 pages10-Low Alloy Steel PDFIdes Trian100% (1)

- Materials NotesDocument15 pagesMaterials NotesShermar BerkleyNo ratings yet

- Automotive Engine Block PDFDocument14 pagesAutomotive Engine Block PDFNico ViciNo ratings yet

- Course Prepared by M.Jayaprasad Materials, Manufacturing and Testing of EngineDocument63 pagesCourse Prepared by M.Jayaprasad Materials, Manufacturing and Testing of EngineGopi GopinathNo ratings yet

- Design and Structural Analysis of Alloy Wheels For Light Weight VehiclesDocument10 pagesDesign and Structural Analysis of Alloy Wheels For Light Weight VehiclesIOSRjournalNo ratings yet

- Mechanical Properties of Aluminium Alloy6061-B C Reinforced Metal Matrix CompositesDocument1 pageMechanical Properties of Aluminium Alloy6061-B C Reinforced Metal Matrix CompositesAlagar SamyNo ratings yet

- Aluminium Rail CoachDocument7 pagesAluminium Rail CoachdselvakuuNo ratings yet

- Metals For Construction - FROSIODocument8 pagesMetals For Construction - FROSIOAdityaNo ratings yet

- STEELDocument24 pagesSTEELDino LimNo ratings yet

- SteelDocument14 pagesSteelgodwinirabor4850% (2)

- Engineering MaterialsDocument32 pagesEngineering MaterialsAdhanom G.No ratings yet

- Chapter 4 SteelDocument28 pagesChapter 4 SteelDiyar NezarNo ratings yet

- 17-4 PH Stainless SteelDocument21 pages17-4 PH Stainless Steelmavis16100% (1)

- Railway Heat TreatmentDocument16 pagesRailway Heat TreatmentEr Vishal Divya JagadaleNo ratings yet

- LV04 - Vehicle Construction - Issue 1Document45 pagesLV04 - Vehicle Construction - Issue 1Phil HicksNo ratings yet

- Mechanics of Materials: Balaji Y SDocument32 pagesMechanics of Materials: Balaji Y SSubhashree PanigrahyNo ratings yet

- EEE Final Syllabus 160708Document78 pagesEEE Final Syllabus 160708Siddharth Narayanan ChidambareswaranNo ratings yet

- Classified 2014 05 23 GTDocument2 pagesClassified 2014 05 23 GTSiddharth Narayanan ChidambareswaranNo ratings yet

- Classified 2014 05 22 GTDocument3 pagesClassified 2014 05 22 GTSiddharth Narayanan ChidambareswaranNo ratings yet

- Love Your Job Not OrganisationDocument3 pagesLove Your Job Not OrganisationSiddharth Narayanan ChidambareswaranNo ratings yet

- Amet University: Grade Statement DetailsDocument2 pagesAmet University: Grade Statement DetailsSiddharth Narayanan ChidambareswaranNo ratings yet

- Hues and MoodsDocument1 pageHues and MoodsSiddharth Narayanan ChidambareswaranNo ratings yet

- PSG College of TechnologyDocument43 pagesPSG College of TechnologySiddharth Narayanan ChidambareswaranNo ratings yet

- Formula Sae WestDocument6 pagesFormula Sae WestSiddharth Narayanan ChidambareswaranNo ratings yet

- Student Reg FormDocument2 pagesStudent Reg FormSiddharth Narayanan ChidambareswaranNo ratings yet

- ME LM SyllabusDocument5 pagesME LM SyllabusSiddharth Narayanan ChidambareswaranNo ratings yet

- By Gautam Janardhan (09A207) Ahmadullah M (10A202) Ashwin A (10A206) Jayanth R (10A215) Ramki A (10A238) Gowtham Kumar (11A434)Document12 pagesBy Gautam Janardhan (09A207) Ahmadullah M (10A202) Ashwin A (10A206) Jayanth R (10A215) Ramki A (10A238) Gowtham Kumar (11A434)Siddharth Narayanan ChidambareswaranNo ratings yet

- Skateboard TruckDocument14 pagesSkateboard TruckSiddharth Narayanan ChidambareswaranNo ratings yet

- Regulation & Syllabus - BE 2012Document19 pagesRegulation & Syllabus - BE 2012Siddharth Narayanan ChidambareswaranNo ratings yet

- ME IE SyllabusDocument9 pagesME IE SyllabusSiddharth Narayanan ChidambareswaranNo ratings yet

- Stop Bollard Safety Road DeviceDocument19 pagesStop Bollard Safety Road DeviceIhsan MokhtarNo ratings yet

- Ringo - Control ValvesDocument36 pagesRingo - Control ValvesPatricio Acuña100% (1)

- SAE Designation UNS Designation % CR % Ni % C % MN AusteniticDocument4 pagesSAE Designation UNS Designation % CR % Ni % C % MN AusteniticKemal ArthurNo ratings yet

- CR ProjectDocument23 pagesCR Projectneelang2002No ratings yet

- List of EN StandardsDocument22 pagesList of EN StandardsVinay ShrivastavaNo ratings yet

- A314-15 Standard Specification For Stainless Steel Billets and Bars For ForgingDocument3 pagesA314-15 Standard Specification For Stainless Steel Billets and Bars For Forgingtjt4779No ratings yet

- AgromechDocument4 pagesAgromechsunintheheartNo ratings yet

- C - LA Steel Market Analysis - 2011Mar10-FINALDocument14 pagesC - LA Steel Market Analysis - 2011Mar10-FINALSaurabhShrivastavaNo ratings yet

- China StahlDocument8 pagesChina StahldstifterNo ratings yet

- Astm A182 2015Document16 pagesAstm A182 2015Lėo GuimarãesNo ratings yet

- Stafford - Presentation - PDFDocument21 pagesStafford - Presentation - PDFdeepak kumarNo ratings yet

- Asme Section II A Sa-387 Sa-387mDocument8 pagesAsme Section II A Sa-387 Sa-387mAnonymous GhPzn1xNo ratings yet

- Types of Carbon Steel and Their PropertiesDocument4 pagesTypes of Carbon Steel and Their Propertiesahmed ezwaiNo ratings yet

- PitampurDocument68 pagesPitampurUday kumar100% (1)

- Iso 11970 2016 en PDFDocument8 pagesIso 11970 2016 en PDFKamal ThummarNo ratings yet

- Weld Inspection Check ListDocument3 pagesWeld Inspection Check ListBGRLNo ratings yet

- Review of The Green Ammonia ProcessDocument5 pagesReview of The Green Ammonia ProcessBrendan JonesNo ratings yet

- Hard Rock: CatalogueDocument96 pagesHard Rock: CatalogueAngarEnkhzayaNo ratings yet

- Ecet - Welding, Forging and Foundry1Document13 pagesEcet - Welding, Forging and Foundry1GENESIS ENGINEERS ACADEMYNo ratings yet

- SAIC-W-2031 In-Process Welding Inspection of Hot TapDocument2 pagesSAIC-W-2031 In-Process Welding Inspection of Hot TapAnonymous S9qBDVkyNo ratings yet

- BS en 10113 2 PDFDocument15 pagesBS en 10113 2 PDF9245126694No ratings yet

- F07-Visual Inspection Report NEWDocument1 pageF07-Visual Inspection Report NEWmohd as shahiddin jafriNo ratings yet

- J-DMS: Project HarmonyDocument1 pageJ-DMS: Project HarmonyMary DenizeNo ratings yet

- Effect of Alloying Elements On Microstructure and Mechanical Properties of Ductile IronDocument5 pagesEffect of Alloying Elements On Microstructure and Mechanical Properties of Ductile IronIjabiNo ratings yet

- Thermally Insulated Balcony Connectors PDFDocument36 pagesThermally Insulated Balcony Connectors PDFAlok MehtaNo ratings yet

- Trav L Cutter - CATALOGO PDFDocument2 pagesTrav L Cutter - CATALOGO PDFJorgeNo ratings yet