Professional Documents

Culture Documents

G300LS Black White Lap Sealants TDB-Oct10

G300LS Black White Lap Sealants TDB-Oct10

Uploaded by

scribd_login2010Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

G300LS Black White Lap Sealants TDB-Oct10

G300LS Black White Lap Sealants TDB-Oct10

Uploaded by

scribd_login2010Copyright:

Available Formats

T E C H N I C A L

D A T A

B U L L E T I N

VERSICOS G300LS BLACK LAP SEALANT AND WHITE LAP SEALANT

Application **

1. 2. All surfaces to be sealed with Lap Sealant must be rm, dry and free of oil, talc dust and other foreign materials. After seams are cemented together with the proper splicing materials, clean the rubber to remove all foreign materials by wiping with a Splice Wipe (or equivalent) dampened with Weathered Membrane Cleaner. (Note: Protective gloves MUST be worn while using cleaner.) Apply a 5/16" (8 mm) bead of Lap Sealant (22' [6.7 m] per cartridge) along the exposed edge of the membrane. Using the feathering tool supplied with the sealant, feather the sealant bead so the high point is above the offset of the splice and the edges are feathered onto the deck. Lap Sealant must be applied and feathered on all splice edges by the end of the working day. Curedto-cured membrane eld splices must be allowed to age at least two hours before Lap Sealant is applied. Uncured EPDM Flashing eld seams and splices between cured membrane and Uncured EPDM Flashing may be sealed immediately. General properties. Typical properties and characteristics are based on samples tested and are not guaranteed for all samples of this product. This data and information is intended as a guide and does not reect the specication or specication range for any particular property of this product. REVIEW CURRENT VERSICO SPECIFICATIONS AND DETAILS FOR SPECIFIC APPLICATION REQUIREMENTS.

3.

4.

Overview

Let Versico simplify your next VersiGard EPDM installation with their G300LS Black or White Lap Sealants. Versicos Lap Sealants are heavy-bodied trowel- or gun-consistency materials used in conjunction with roong system materials. Its primary use is to seal the exposed edges of EPDM membrane splices. Lap Sealants are extremely durable. The cured rubber consistency enables them to expand and contract with the membrane. G300LS Lap Sealant is to be used to seal splice edges of cured VersiGard EPDM and uncured EPDM Flashing. White Lap Sealant seals the splice edges of cured White EPDM and uncured White EPDM Flashing. 5.

Intended Uses

Versicos Lap Sealants are primarily used to seal the exposed edges of EPDM membrane splices.

**

Features and Benets

Various application methods - trowel, caulk gun, etc. Cured rubber consistency

Able to expand and contract with EPDM membrane Seals exposed edges of EPDM and provides a durable barrier to weather extremes

A S I N G L E S O U R C E F O R S I N G L E - P LY R O O F I N G Ve r s i c o , P O B o x 12 8 9, C a r l i s l e , PA 17013 Te l : 8 0 0 .9 9 2 . 76 6 3 F a x : 717.9 6 0 . 4 0 3 6 We b : w w w.ve r s i c o . c o m

T E C H N I C A L

D A T A

B U L L E T I N

Precautions

1. 2. Review the applicable Material Safety Data Sheet for complete safety information prior to use. Lap Sealant is EXTREMELY FLAMMABLE - it contains solvents that are dangerous re and explosion hazards when exposed to heat, ame or sparks. Store and use away from all sources of heat, ame or sparks. Do not smoke while applying. Do not use in a conned or unventilated area. Vapors are heavier than air and may travel along ground to a distant ignition source and ash back. A red caution label is required when shipping. Avoid breathing vapors. Keep container closed when not in use. Use with adequate ventilation. If inhaled, remove to fresh air. If not breathing, perform articial respiration. If breathing is difcult, give oxygen. Call a physician immediately If swallowed, DO NOT INDUCE VOMITING. Call a physician immediately. Avoid contact with eyes. Safety glasses or goggles are recommended. If splashed in eyes, immediately ush eyes with plenty of clean water for at least 15 minutes. Contact a physician immediately. Avoid contact with skin. Wash hands thoroughly after handling. In case of contact with skin, thoroughly wash affected area with soap and water. NOTE: SOLVENT-RESISTANT GLOVES ARE TO BE WORN WHEN USING THIS PRODUCT TO PROTECT HANDS FROM IRRITATING INGREDIENTS. 7. 8. Follow Versicos recommended splice instructions. DO NOT USE as Splice Adhesive between rubber membranes. Jobsite storage temperatures in excess of 90F (32C) may affect product shelf life. Should the Lap Sealant be stored at temperatures below 60F (15C), restore to room temperature prior to use. If using an excessively wet solvent cloth while cleaning the splice edge, solvent may be left in the offset of the membrane sheets. To avoid causing this problem, use a damp rag and make sure the Weathered Membrane Cleaner is completely ashed off the area before Lap Sealant application.

Coverage Rates

22' (6.7 m) per tube using a 5/16" (8 mm) bead.

TYPICAL PROPERTIES AND CHARACTERISTICS

Property

Color Solids Flash Point Service Temperature Specic Gravity Cold Weather Flex. Resistance to: Staining General Weathering Ozone Ultraviolet Radiation Slump Water Acid Alkali VOC Average Net Weight/gallon Packaging Shelf Life

Value

G300LS black White white G300LS 63% White 55% G300LS 40F (4C) Tag Open Cup White 52F (11C) Closed Cup -60F to 180F (-51C to 82C) G300LS 1.03 White 1.16 Excellent Excellent Excellent Excellent Excellent Very Good Excellent Good Good G300LS 395 grams/liter White 448 grams/liter G300LS 8.58 lbs (1.03 Kg/l) White 9.94 lbs (1.19 Kg/l) 25 Tubes/Carton 1 year

3.

4. 5.

6.

9.

10. If applied during periods of cold, dampness or high humidity, it is possible that evaporation of solvents will be substantially reduced, resulting in some slight membrane swelling. This would be further aggravated should the sealant be applied in an unusually heavy coat. 11. Coverage rates are average and may vary due to conditions on the jobsite. 12. KEEP OUT OF THE REACH OF CHILDREN.

2010 Versico. Printed in U.S.A. 10/10

Versico and the Versico logo are trademarks of Versico.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Cemcolift IM ManualDocument1,044 pagesCemcolift IM Manualscribd_login2010100% (2)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Miele DishwasherDocument48 pagesMiele Dishwasherscribd_login20100% (1)

- Sanyo PLV-Z2000 ProjectorDocument60 pagesSanyo PLV-Z2000 Projectorscribd_login2010No ratings yet

- Maths Key Notes Coordinate GeometryDocument2 pagesMaths Key Notes Coordinate Geometryscribd_login2010No ratings yet

- Instruction Manual Digital Sixteen/Nine Channel Video RecorderDocument77 pagesInstruction Manual Digital Sixteen/Nine Channel Video Recorderscribd_login2010No ratings yet

- Key Notes: Heron's FormulaDocument2 pagesKey Notes: Heron's Formulascribd_login2010No ratings yet

- Stealing Cthulhu PDFDocument94 pagesStealing Cthulhu PDFscribd_login2010100% (2)

- Nassim Taleb 5% P-ValuesDocument4 pagesNassim Taleb 5% P-Valuesscribd_login2010No ratings yet

- 19East82ndStreet SetupDocument4 pages19East82ndStreet Setupscribd_login2010No ratings yet

- Catalogo Rhein ChemieDocument23 pagesCatalogo Rhein ChemiejorgeNo ratings yet

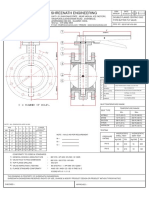

- Necon Double Flange Centric DiscDocument2 pagesNecon Double Flange Centric DiscMeet JaniNo ratings yet

- Firestone EPDM Geomembrane: General Installation Guidelines For Water ReservoirsDocument6 pagesFirestone EPDM Geomembrane: General Installation Guidelines For Water Reservoirssatuempat2010No ratings yet

- Vc-90200.01.03-En Ecoline DJDocument6 pagesVc-90200.01.03-En Ecoline DJGary IrawanNo ratings yet

- AY e BSDocument156 pagesAY e BSJosias BorgesNo ratings yet

- Group 6 - Roofing MaterialsDocument102 pagesGroup 6 - Roofing MaterialsPercival ArcherNo ratings yet

- Straub Manual Tehnic LQ E - 12Document64 pagesStraub Manual Tehnic LQ E - 12zenogredinaNo ratings yet

- 1 EN - Solutions For The Metal Industry - Machined SealsDocument20 pages1 EN - Solutions For The Metal Industry - Machined Sealswilliams vasquezNo ratings yet

- Rubber CuringDocument132 pagesRubber CuringDuc Nguyen100% (1)

- Gate Valves Data SheetDocument3 pagesGate Valves Data SheetRaied AyeshNo ratings yet

- Shelf Life ISO 2230 2002Document1 pageShelf Life ISO 2230 2002Pahe DriveNo ratings yet

- Pipes and UnionDocument8 pagesPipes and UnionSuraj Mahendra RamrajNo ratings yet

- Rubber Shelf Life WJ14Document1 pageRubber Shelf Life WJ14ankit7588No ratings yet

- Specification, Purchase, Installation and Maintenance of Poured-In-Place Playground SurfacingDocument7 pagesSpecification, Purchase, Installation and Maintenance of Poured-In-Place Playground SurfacingAhmad Zubair RasulyNo ratings yet

- Eriks Sealing Elements Precision O-Ring Technical Manual PDFDocument221 pagesEriks Sealing Elements Precision O-Ring Technical Manual PDFCarlos Eduardo Flores TorresNo ratings yet

- TricosalDocument12 pagesTricosal12378aNo ratings yet

- Xelsis SS E74144 Rev 00 PDFDocument11 pagesXelsis SS E74144 Rev 00 PDFDenis Fernando MariucioNo ratings yet

- Grundfosliterature 1073112Document120 pagesGrundfosliterature 1073112Suhas JadhavNo ratings yet

- BurgmannDocument16 pagesBurgmannRonaldo CostaNo ratings yet

- Fti Air Aodd Models Ft10A & Ft10S: Assembly, Installation, & Operation ManualDocument26 pagesFti Air Aodd Models Ft10A & Ft10S: Assembly, Installation, & Operation ManualEUGENIO CAÑAVERANo ratings yet

- Bins Am Suri 2010Document32 pagesBins Am Suri 2010FarahNo ratings yet

- Jainson CatalogueDocument18 pagesJainson CatalogueSeanNo ratings yet

- M 3031 (2013-06)Document16 pagesM 3031 (2013-06)Hatada FelipeNo ratings yet

- RSD/RCD/RCT Series: Coarse/Fine Bubble Aeration DiffuserDocument8 pagesRSD/RCD/RCT Series: Coarse/Fine Bubble Aeration DiffuserArgie AdduruNo ratings yet

- B-1050 Resilient-Valves 2020 08 1 1Document5 pagesB-1050 Resilient-Valves 2020 08 1 1satphoenixNo ratings yet

- Kind David Final E-Thesis (Master Copy)Document226 pagesKind David Final E-Thesis (Master Copy)Clint FosterNo ratings yet

- Pentair-Sudmo Components Catalog PDFDocument572 pagesPentair-Sudmo Components Catalog PDFJohnny PaloozaNo ratings yet

- ARLANXEO Keltan EPDM APAC ENDocument5 pagesARLANXEO Keltan EPDM APAC ENkarthibenNo ratings yet

- FNW Fig.340Document4 pagesFNW Fig.340Imtinan MohsinNo ratings yet

- Ficha Técnica Bomba PeristálticaDocument12 pagesFicha Técnica Bomba PeristálticaKEIRNENo ratings yet