Professional Documents

Culture Documents

Bouiler

Uploaded by

Assem ElhajjOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bouiler

Uploaded by

Assem ElhajjCopyright:

Available Formats

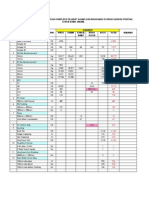

Boiler Mechanical Works Item Description Qty Unit Rate (SAR) Amount (SAR)

BOILER HOUSE INSTALLATION Supply, installation and commissioning of complete steam and hot water generation syst-ems. steam and condensate piping networks c/w all piping, supports, valves, fittings, insul-ation, safety and operating controls as herein specified. All steam and condensate piping shall be heat insulated and cladded as specified. Steam and hot water generation installation shall comprise:

Supply and installation of steam boiler, capacity = 150 HP dry saturated steam at 10 bar working pressure C/W burner, measuring instruments, safety and operating controls, insulation and cladding and in general all necessary accessorise . Supply and installation of boiler feed water pumps c/w all piping, valves, fittings, controls and in general all parts required for safe and proper operation. Capacity: 66 GPM at 120 m head ( two stand by ) Supply and installation of boiler chimney c/w dampers, heat insulation and.; cladding up to roof of boiler house, access doors, supports etc. and in general all parts, work required for safe and proper operation

Size 16

M U

50 1

Supply and installation of automatic blow down system for boilers c/w pneumatic solenoid valve. analyzer, sensor, control unit. c/w all piping, fittings. etc. and in general all parts, required for safe/proper operation . Bottom Blow Down System

Carried to Collection

Bakry Consulting Engineers

Page 1 of 6

Jan., 2010

Boiler Mechanical Works Item Description Qty Unit Rate (SAR) Amount (SAR)

Supply and installation of high pressure steam header c/w insulation, cladding, valves, steam traps, instruments as herein specified and shown on drawings Supply and installation of pressure reducing set from 10 bar to 2.4 bar 2" for A/C heaters Ditto but 1 1/4" for storage heaters

U NO.

1 1

Supply and installation of Spray master dearator tank unit c/w steam supply unit, make-up, gauges. Pump suction headers, base, vents. etc. and in general all parts required for safe and proper operation Capacity = 15000 IB

Supply and installation of duplex water softener system, capacity 66 GPM continuous flow of soft water form 1300 to 4 PPM hardness c/w brine tank, control, resin and test kit. Price shall include all required piping, fittings and connections as specified.

ENS

Supply & installation of hot water Storage heater serving domestic hot water capacity 1200 gallon, and the heating capacity 416500 BTU/Hr as specified. Price shall include all steam, condensate and cold water piping, fittings valves, traps, control insulation metal cladding ... etc. inside boiler house steam 35 psi

Carried to Collection

Bakry Consulting Engineers

Page 2 of 6

Jan., 2010

Boiler Mechanical Works Item Description Qty Unit Rate (SAR) Amount (SAR)

10

INSTANTEOUSE HEATERS Supply and Installation of instanteouse heat exchanger shell and tube type complete with self acting thermostatic control valve controller , high limit valve control , anti vacuum valve , pressure gauge thermometer and safety valve, difference temp. of secondary circuit = 20 C A- Main Building, North & South Heating Capacity 2,700,000 BTU/H ( 790 KW ) steam 35 Psi B- Conference Building Heating Capacity 1,600,000 BTU/H ( 470 KW ) steam 35 Psi C- Spa Building Heating Capacity 1,000,000 BTU/H ( 293 KW ) steam 35 Psi

NR

11

pumps Supply And Installation Of Variable speed vertical Pumps , Complete With Gate Valves , Globe Valve , Strainer , Check Valve , Flexible Connection , Pressure Gauges Electrical Connection And All Fittings And Accessories A/ C hot water pumps a- Main Building, North & South Flow Rate 270 GPM Head 70 Ft Speed 1450 RPM (one stand by)

Carried to Collection

Bakry Consulting Engineers

Page 3 of 6

Jan., 2010

Boiler Mechanical Works Item Description Qty Unit Rate (SAR) Amount (SAR)

b- Conference Building Flow Rate 160 GPM Head 75 Ft Speed 1450 RPM (one stand by) c- SPA Building Flow Rate 100 GPM Head 70 Ft Speed 1450 RPM (one stand by)

12

Supply and installation of hot water circulating pumps for guest room & villas : 60 GPM at: 70 FT . head c/w all valves, piping, fittings, connections to hot water generators ..etc. as herein specified. ( one stand by )

13

Supply and installation of hot water circulating pumps for main building , conference & SPA 60GPM at: 70 FT . head c/w all valves, piping, fittings, connections to hot water generators ..etc. as herein specified. ( one stand by ) Supply& installation pressure reducing station laundry for

14 a

Supply & installation pressure reducing station 1" as

specified on drawings for laundry ( 10-5 bar ) b 15

Ditto but 3/4" ( 10-3 bar ) For laundry Supply & installation chemical feed unit complete with mixer & piston pump simplex type.

Carried to Collection

U U

1 2

Bakry Consulting Engineers

Page 4 of 6

Jan., 2010

Boiler Mechanical Works Item Description Qty Unit Rate (SAR) Amount (SAR)

16 a b

Soft Water Tank Soft Water Tank Connections Soft Water Pump Set 2*(75 GPM & 80 FT ) Condensate Work Condensate Tank 100 Lit Condensate Pumps

650 L/hr

L.S 1

L.S NO.

17 a b

U U

1 2

Head according to supplier recommendation ( One Stand By )

B 1

FUEL OIL STORAGE INSTALLATION

Supply and installation of underground fuel tanks , 3 fabricated from 6 mm black steel , complete with all Capacity 10m Supply and installation of daily fuel tank fabricated from 6 mm thick black steel , rectangular and completed with isolating valves , float switches , drain valve , and overflow pipes , fuel sight glass of capacity 1.5 m3 Dimension (1.5 x 1.2 x 1.0 m )

Supply and installation of oil gear pumps , self priming , closed coupled , positive displacement and complete with all connections . Capacity 800 GPH. head. Head 40 FT ( one stand by) Supply and installation of black steel pipes , seamless type to complete with fitting and supports for fuel oil system

Carried to Collection

L.S

L.S

Bakry Consulting Engineers

Page 5 of 6

Jan., 2010

Boiler Mechanical Works Item Description Qty Unit Rate (SAR) Amount (SAR)

C 1

STEAM AND CONDENSATE PIPING NETWORK INSIDE BOILER HOUSE Supply, erection. Testing and handing over in a good operating condition of all equipment materials required for the steam and condensate, hot and cold, blow down and drain piping networks inside boiler house as herein specified and shown on plans. All steam, condensate & hot water piping shall be heat insulated and metal cladding as specified. Price shall include all required parts, fittings, valves, supports, insulation ..etc. Steam piping network Condensate piping network Hot water Cold water Blow down Drain

L.S L.S L.S L.S L.S M

L.S L.S L.S L.S L.S 30

Half round drain trough and grating 6 " diameter from C.I. pipes and steel coated

Any other item required for proper and safe operation of system Supply & installation electric panel for boiler room

Carried to Collection

Bakry Consulting Engineers

Page 6 of 6

Jan., 2010

You might also like

- SQL Developer User Manual enDocument44 pagesSQL Developer User Manual ensyodudeNo ratings yet

- Communications Plan ExcelDocument12 pagesCommunications Plan ExcelPedro BentoNo ratings yet

- 01 Build DeliverablesDocument7 pages01 Build DeliverablesAssem ElhajjNo ratings yet

- Danzas IT Solutions EstimatorDocument457 pagesDanzas IT Solutions EstimatorAssem Elhajj100% (1)

- Excel Gantt v4Document14 pagesExcel Gantt v4PMPNo ratings yet

- CALCULATION OF PUMP HEAD AND POWER REQUIREDDocument2 pagesCALCULATION OF PUMP HEAD AND POWER REQUIREDlutfi awn100% (1)

- Anchor BoltDocument15 pagesAnchor BoltRyan Wiratama67% (3)

- MFC Hierarchy Chart3of3Document1 pageMFC Hierarchy Chart3of3Assem ElhajjNo ratings yet

- Project Charter TemplateDocument4 pagesProject Charter TemplateAssem ElhajjNo ratings yet

- Organization Charts UNDP AODocument2 pagesOrganization Charts UNDP AOAssem ElhajjNo ratings yet

- Electrical EstimateDocument55 pagesElectrical EstimateAssem ElhajjNo ratings yet

- Kaizen Structure Rev0Document86 pagesKaizen Structure Rev0hiattolaNo ratings yet

- Area CalculationsDocument11 pagesArea Calculationsash1968No ratings yet

- Standard Org Chart & Role DescriptionsDocument15 pagesStandard Org Chart & Role DescriptionsAssem ElhajjNo ratings yet

- 0 List of Checklists ItemsDocument3 pages0 List of Checklists ItemsAssem ElhajjNo ratings yet

- Chiller Maintenance ChecklistDocument2 pagesChiller Maintenance ChecklistAssem Elhajj100% (16)

- RET Org ChartDocument2 pagesRET Org ChartAssem ElhajjNo ratings yet

- 0-Air Distribution System CHECKLISTDocument2 pages0-Air Distribution System CHECKLISTAssem ElhajjNo ratings yet

- Procurement PoliciesDocument18 pagesProcurement PoliciesAssem ElhajjNo ratings yet

- Site Inspection Check List2Document38 pagesSite Inspection Check List2Assem Elhajj100% (2)

- 0 Hvac ChecklistDocument13 pages0 Hvac ChecklistAssem Elhajj100% (1)

- 0030 Budget EstimateDocument56 pages0030 Budget EstimateAssem ElhajjNo ratings yet

- Material Takeoff SheetDocument14 pagesMaterial Takeoff SheetAssem ElhajjNo ratings yet

- Box PlotsDocument2 pagesBox PlotsAssem ElhajjNo ratings yet

- Task Start Date Duration in Days End Date: Proposed Programme of WorksDocument2 pagesTask Start Date Duration in Days End Date: Proposed Programme of WorksAssem ElhajjNo ratings yet

- Project Establishment CostDocument6 pagesProject Establishment CostAssem ElhajjNo ratings yet

- Providing and fixing glazing in aluminium doors and windowsDocument1 pageProviding and fixing glazing in aluminium doors and windowsAssem Elhajj100% (1)

- Activities: Gantt Chart - Priority Area - AgencyDocument2 pagesActivities: Gantt Chart - Priority Area - AgencyAssem ElhajjNo ratings yet

- HistogramDocument2 pagesHistogramAssem ElhajjNo ratings yet

- Gantt Chart TemplateDocument2 pagesGantt Chart TemplateAssem ElhajjNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)