Professional Documents

Culture Documents

Pipe Flanges and Flanged Fittings ASME B16.5-2003

Uploaded by

Panchal ShaileshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Flanges and Flanged Fittings ASME B16.5-2003

Uploaded by

Panchal ShaileshCopyright:

Available Formats

375

395

485

585

675

112

2

212

3

4

5

6

8

10

12

97

133.4

146.1

162.0

177.8

203.2

73.1

82.6

92.1

108.0

123.9

495

552

597

641

762

197

229

292

368

451

70

105

124

133

162

Diameter

of Hub,

X

355.6

406.4

457.0

508.0

610.0

141.3

168.3

219.1

273.0

323.8

48.3

60.3

73.0

88.9

114.3

Hub Diameter

Beginning of

Chamfer

Welding Neck,

A

[Note (2)]

...

...

...

...

...

...

...

...

...

...

44

57

64

...

...

Threaded/

Slip-on/

Socket

Welding,

Y

241

260

276

292

330

105

119

143

178

219

44

57

64

73

90

Lapped,

Y

298

311

327

356

406

156

171

213

254

283

83

102

105

117

124

Welding

Neck,

Y

Length Through Hub

...

...

...

...

...

...

...

...

...

...

32

39

48

...

...

Thread Length

Threaded

Flange

Min.,

T

[Note (3)]

...

...

...

...

...

...

...

...

...

...

49.5

61.9

74.6

...

...

Slip-on/

Socket

Welding

Min.,

B

10

Bore

11

360.2

411.2

462.3

514.4

616.0

144.4

171.4

222.2

277.4

328.2

50.0

62.5

75.4

91.4

116.8

Lapped

Min.,

B

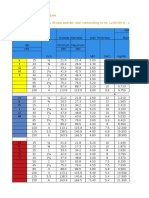

Dimensions of Class 1500 Flanges (Contd)

GENERAL NOTES:

(a) Dimensions of Table 20 are in millimeters. For dimensions in inch units, refer to Annex F, Table F20.

(b) For tolerances, see para. 7.

(c) For facings, see para. 6.4.

(d) For flange bolt holes, see para. 6.5 and Table 19.

(e) For spot facing, see para 6.6.

(f) For reducing threaded and slip-on flanges, see Table 6.

(g) Blind flanges may be made with or without hubs at the manufacturers option.

(h) For reducing welding neck flanges, see para 6.8.

NOTES:

(1) This dimension is for large end of hub, which may be straight or tapered. Taper shall not exceed 7 deg on threaded,

slip-on, socket-welding, and lapped flanges. This dimension is defined as the diameter at the intersection between the

hub taper and the back face of the flange.

(2) For welding end bevel, see para. 6.7.

(3) For thread of threaded flanges, see para. 6.9.

750

825

915

985

1 170

180

215

245

265

310

Nominal

Pipe Size,

NPS

14

16

18

20

24

Thickness

of Flange

Min.,

tf

Outside

Diameter

of

Flange,

O

31.8

38.1

41.3

47.7

54.0

Table 20

Welding

Neck/

Socket

Welding,

B

12

13

13

13

13

13

11

13

13

13

13

6

8

8

10

11

Corner Radius

of Bore of

Lapped Flange

and Pipe,

r

13

...

...

...

...

...

...

...

...

...

...

50.6

63.5

76.2

...

...

Counter

bore

Threaded

Flange

Min.,

Q

14

...

...

...

...

...

...

...

...

...

16

17

19

...

...

Depth of

Socket,

D

15

PIPE FLANGES AND FLANGED FITTINGS

ASME B16.5-2003

You might also like

- Pipe Flanges and Flanged Fittings ASME B16.5-2003Document1 pagePipe Flanges and Flanged Fittings ASME B16.5-2003Panchal ShaileshNo ratings yet

- RTJ Flanges Dimensions ASME B 16.5Document6 pagesRTJ Flanges Dimensions ASME B 16.5Em JoeNo ratings yet

- ASME B16.5-2003 Annex FDocument1 pageASME B16.5-2003 Annex FPanchal ShaileshNo ratings yet

- Cadena 140 LinbrltDocument1 pageCadena 140 LinbrltIsabel GonzalezNo ratings yet

- Annex F ASME B16.5-2003Document1 pageAnnex F ASME B16.5-2003Panchal ShaileshNo ratings yet

- Structural Steel Channel Section PropertiesDocument18 pagesStructural Steel Channel Section PropertiesSudath KularathnaNo ratings yet

- Dsi Usa Dywidag Strand Anchor PropertiesDocument1 pageDsi Usa Dywidag Strand Anchor PropertiesFachri BahrakNo ratings yet

- 300 LB WELDING NECK FLANGE DIMENSIONSDocument2 pages300 LB WELDING NECK FLANGE DIMENSIONSemre ozdemirNo ratings yet

- American Wire Gauge (AWG) Sizes and SpecificationsDocument2 pagesAmerican Wire Gauge (AWG) Sizes and SpecificationsRommell BacosNo ratings yet

- Annex F ASME B16.5-2003Document1 pageAnnex F ASME B16.5-2003Panchal ShaileshNo ratings yet

- Awwa c153 (Dimension Details)Document7 pagesAwwa c153 (Dimension Details)aroratsNo ratings yet

- N.B. Wall Mass Identification Inches KG/M STD XS, Xxs Schedule NumberDocument4 pagesN.B. Wall Mass Identification Inches KG/M STD XS, Xxs Schedule NumberOmkar JoshiNo ratings yet

- Max Safe Working Pressure PipesDocument1 pageMax Safe Working Pressure Pipesjok1974No ratings yet

- Steel reinforcement data chartDocument2 pagesSteel reinforcement data chartnicotrucNo ratings yet

- Annex F ASME B16.5-2003Document1 pageAnnex F ASME B16.5-2003Panchal ShaileshNo ratings yet

- Camperfiladas Asme 16 47Document16 pagesCamperfiladas Asme 16 47EllenNo ratings yet

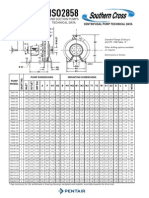

- Centrifugal Pump Technical Data SheetDocument8 pagesCentrifugal Pump Technical Data SheetKatibi VanhasNo ratings yet

- Profile Laminate-CornierDocument7 pagesProfile Laminate-CornierdarabafloNo ratings yet

- PT. KENCANA AMAL TANI STOCK UPDATEDocument32 pagesPT. KENCANA AMAL TANI STOCK UPDATEAlif AlifNo ratings yet

- Stainless Steel Square Pipe Price ListDocument7 pagesStainless Steel Square Pipe Price ListKamlendra SinghNo ratings yet

- WeldoletDocument7 pagesWeldoletMdshaffiSiddu Hina2019No ratings yet

- Sri Ganapathi Industries Kushaiguda Title: Scale Size DRWG No: Sheet NoDocument2 pagesSri Ganapathi Industries Kushaiguda Title: Scale Size DRWG No: Sheet Noanmol6237No ratings yet

- ACSR - Aluminum Conductor Steel ReinforcedDocument2 pagesACSR - Aluminum Conductor Steel ReinforcedjeanecefNo ratings yet

- Tubular SectionsDocument10 pagesTubular Sectionsvenkatesh19701No ratings yet

- H-BEAM dimensions properties gradesDocument1 pageH-BEAM dimensions properties gradesUnnikrishnan RajanNo ratings yet

- H-BEAM dimensions properties gradesDocument1 pageH-BEAM dimensions properties gradesKaung Myat HtunNo ratings yet

- IS 1239 and IS 3589 pipe standardsDocument4 pagesIS 1239 and IS 3589 pipe standardsPrem SharmaNo ratings yet

- Working PressureDocument11 pagesWorking Pressureshojaee1063No ratings yet

- ERW Pipe ChartDocument2 pagesERW Pipe ChartAlok MehtaNo ratings yet

- Euro-Bearings LTD: Combined Roller Bearings & Mating Steel ProfilesDocument24 pagesEuro-Bearings LTD: Combined Roller Bearings & Mating Steel Profilessajay_suryaNo ratings yet

- Sizes and Properties Tis/Jis Standards Structure Tees (Cut From H - Sections)Document3 pagesSizes and Properties Tis/Jis Standards Structure Tees (Cut From H - Sections)fahadfiazNo ratings yet

- Z-Section Dimensions & Properties - MetsecDocument3 pagesZ-Section Dimensions & Properties - Metsecadil_khan648No ratings yet

- RBL Precision Ansi RollerDocument8 pagesRBL Precision Ansi RollerRingball_GusNo ratings yet

- Upe, Upn, PFCDocument27 pagesUpe, Upn, PFCCédric ConreuxNo ratings yet

- Pipe Size For Phased ArrayDocument3 pagesPipe Size For Phased ArrayAnang Telah DihianatiNo ratings yet

- Hollow Bar ChartDocument1 pageHollow Bar Charthornet121No ratings yet

- ANSI 600LB RF-SO FLANGE DIMENSIONSDocument1 pageANSI 600LB RF-SO FLANGE DIMENSIONSdtoxidNo ratings yet

- Welding Neck Orifice Class 600Document1 pageWelding Neck Orifice Class 600Nguyen Thanh NguyenNo ratings yet

- JSPL Range HbeamsDocument6 pagesJSPL Range HbeamsAditya KshireNo ratings yet

- Número de Varillas: Area (CM)Document2 pagesNúmero de Varillas: Area (CM)Johnny Cecy GarciaNo ratings yet

- Series A: Welding Neck Flanges: 127 Park Street, N. E., Vienna, Virginia 22180 USADocument11 pagesSeries A: Welding Neck Flanges: 127 Park Street, N. E., Vienna, Virginia 22180 USAMANo ratings yet

- L I G H TDocument4 pagesL I G H TPrem SharmaNo ratings yet

- 868 WDocument120 pages868 WalanparraNo ratings yet

- Libro 1Document7 pagesLibro 1Dawlin MorenoNo ratings yet

- LR90SCH160Document1 pageLR90SCH160Torres AndresNo ratings yet

- Wide Flange Steel Beam Specifications ChartDocument5 pagesWide Flange Steel Beam Specifications ChartJoseph Daguio JrNo ratings yet

- ANSI-ASME B16.5 Welding Neck Flange 300lbDocument1 pageANSI-ASME B16.5 Welding Neck Flange 300lbeustaquio.bhNo ratings yet

- Annex F ASME B16.5-2003Document1 pageAnnex F ASME B16.5-2003Panchal ShaileshNo ratings yet

- Computación Ii - Ms. ExcelDocument21 pagesComputación Ii - Ms. ExcelSheila Aleska Zapata JuárezNo ratings yet

- Nominal cross-section dimensions and properties of standard HEA and HEB I-beamsDocument43 pagesNominal cross-section dimensions and properties of standard HEA and HEB I-beamsjo greenNo ratings yet

- Design of Hooked Bolts: Fu 400 Mpa D 22.225 MM F'C 21 Mpa 1) T 51209.125 2) T A FDocument2 pagesDesign of Hooked Bolts: Fu 400 Mpa D 22.225 MM F'C 21 Mpa 1) T 51209.125 2) T A FShealtiel Regine Cinco-AyalaNo ratings yet

- AAC American Sizes ASTM B231 / B231M Stranded Aluminum ConductorsDocument2 pagesAAC American Sizes ASTM B231 / B231M Stranded Aluminum ConductorsRejnald ZyfiNo ratings yet

- Gi Pipe Size Is 1239Document4 pagesGi Pipe Size Is 1239sshnvlNo ratings yet

- ANSI-ASME B16.5 Welding Neck Flange 600lbDocument1 pageANSI-ASME B16.5 Welding Neck Flange 600lbeustaquio.bhNo ratings yet

- 36 38Document3 pages36 38JEORJENo ratings yet

- A Neolithic Ceremonial Complex in Galloway: Excavations at Dunragit and Droughduil, 1999–2002From EverandA Neolithic Ceremonial Complex in Galloway: Excavations at Dunragit and Droughduil, 1999–2002No ratings yet

- Mechanical (Turbines and Auxiliary Equipment): Second Revised and Enlarged EditionFrom EverandMechanical (Turbines and Auxiliary Equipment): Second Revised and Enlarged EditionA. SherryRating: 4 out of 5 stars4/5 (5)

- The Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsFrom EverandThe Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsNo ratings yet

- Table Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Coiijt'D)Document1 pageTable Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Coiijt'D)Panchal ShaileshNo ratings yet

- Sec-I 138Document1 pageSec-I 138Panchal ShaileshNo ratings yet

- Sec-I 139Document1 pageSec-I 139Panchal ShaileshNo ratings yet

- Sec-I 140Document1 pageSec-I 140Panchal ShaileshNo ratings yet

- Sec-I 136Document1 pageSec-I 136Panchal ShaileshNo ratings yet

- Table Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Document1 pageTable Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Panchal ShaileshNo ratings yet

- Sec-I 130Document1 pageSec-I 130Panchal ShaileshNo ratings yet

- Sec-I 131Document1 pageSec-I 131Panchal ShaileshNo ratings yet

- Table Pw-39 (Cont'D) Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and AttachmentsDocument1 pageTable Pw-39 (Cont'D) Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and AttachmentsPanchal ShaileshNo ratings yet

- Sec-I 132Document1 pageSec-I 132Panchal ShaileshNo ratings yet

- Sec-I 128Document1 pageSec-I 128Panchal ShaileshNo ratings yet

- Sec-I 133Document1 pageSec-I 133Panchal ShaileshNo ratings yet

- FIG. PW-19.4 (A) Some Acceptable Types of Diagonal Braces For Installation by WeldingDocument1 pageFIG. PW-19.4 (A) Some Acceptable Types of Diagonal Braces For Installation by WeldingPanchal ShaileshNo ratings yet

- Sec-I 129Document1 pageSec-I 129Panchal ShaileshNo ratings yet

- Sec-I 126Document1 pageSec-I 126Panchal ShaileshNo ratings yet

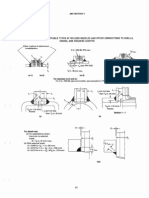

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Co NT'D)Document1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Co NT'D)Panchal ShaileshNo ratings yet

- Sec-I 117Document1 pageSec-I 117Panchal ShaileshNo ratings yet

- Sec-I 127Document1 pageSec-I 127Panchal ShaileshNo ratings yet

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Document1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Panchal ShaileshNo ratings yet

- Sec-I 121Document1 pageSec-I 121Panchal ShaileshNo ratings yet

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Document1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Panchal ShaileshNo ratings yet

- Boiler welding design rules for joints of unequal thicknessDocument1 pageBoiler welding design rules for joints of unequal thicknessPanchal ShaileshNo ratings yet

- Sec-I 119Document1 pageSec-I 119Panchal ShaileshNo ratings yet

- Sec-I 116Document1 pageSec-I 116Panchal ShaileshNo ratings yet

- Sec-I 112Document1 pageSec-I 112Panchal ShaileshNo ratings yet

- FIG. PW-15 Examples of Weld Strength Calculations: 2007 Section IDocument1 pageFIG. PW-15 Examples of Weld Strength Calculations: 2007 Section IPanchal ShaileshNo ratings yet

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Cot/Inections To Shells, Drums, and HeadersDocument1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Cot/Inections To Shells, Drums, and HeadersPanchal ShaileshNo ratings yet

- Sec-I 114Document1 pageSec-I 114Panchal ShaileshNo ratings yet

- Sec-I 113Document1 pageSec-I 113Panchal ShaileshNo ratings yet

- Horizontal-return tubular boiler locationsDocument1 pageHorizontal-return tubular boiler locationsPanchal ShaileshNo ratings yet