Professional Documents

Culture Documents

Maryland Metrics Technical Data Chart:: Surface Texture

Uploaded by

Fernando Ramos MorenoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maryland Metrics Technical Data Chart:: Surface Texture

Uploaded by

Fernando Ramos MorenoCopyright:

Available Formats

Maryland Metrics Technical Data Chart:

Surface Texture

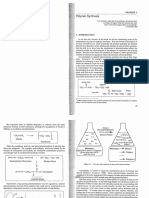

1. Method of indicating surface texture on drawings acc. to DIN 1302 1.1 Symbols Symbol without additional indications. Basic symbol. The meaning must be explained by additional indications. Symbol with additional indications. Any production method, with specified roughness. Symbol without additional indications. Removal of material by machining, without specified roughness. Symbol with additional indications. Removal of material by machining, with specified roughness. Symbol without additional indications. Removal of material is not permitted (surface remains in state as supplied). Symbol with additional indications. Made without removal of material (non-cutting), with specified roughness. 1.2 Position of the specifications of surface texture in the symbol a = Roughness value Ra in micrometres or microinches or roughness grade number N1 to N12 b = Production method, surface treatment or coating c = Sampling length d = Direction of lay e = Machining allowance f = Other roughness values, e.g. Rz Examples Production method Any Material removing Non-cutting Centre line average height Ra: maximum value = 0.8 m Mean peak-to-valley height Rz: maximum value = 25 m Mean peak-to-valley height Rz: maximum value = 1 m at cut-off = 0.25 mm 2. Explanation of the usual surface roughness parameters 2.1 Centre line average height Ra acc. to DIN 4768 The centre line average height Ra is the arithmetic average of the absolute values of the distancopyright 2008 maryland metrics

Ex lanation Explanation

ces y between the profile heights and the centre line within the measuring length. This is equivalent to the height of a rectangle (Ag) with a length equal to the evaluation length lm and with an area equal to the sum of the areas enclosed between the roughness profile and the centre line (Aoi and Aui) (see figure 1).

Maryland Metrics Technical Data Chart:

Surface Texture

Centre line

S A oi + S A ui

A g + S A oi ) S A ui

Figure 1

le = Sampling length lm = Evaluation length lt = Traversed length z1-z5 = Single irregularities

Start-up length

Run-out length

Figure 2 2.2 Mean peak-to-valley height Rz acc. to DIN 4768 The mean peak-to-valley height Rz is the arithmetic average of the single irregularities of five consecutive sampling lengths (see figure 2). Note: An exact conversion of the peak-to-valley height Rz and the centre line average height Ra can neither be theoretically justified nor empirically proved. For surfaces which are generated by manufacturing methods of the group metal cutting, a diagram for the conversion from Ra to Rz and vice versa is shown in supplement 1 to DIN 4768 Part 1, based on comparison measurements (see table Comparison of roughness values). 3. Comparison of roughness values

DIN ISO 1302 Roughness values Ra Roughness grade number m 0.025 0.05 in 1 N1 0.1 0.8 2 N2 0.25 1.6 0.1 4 N3 0.4 2.5 0.2 8 N4 0.8 4 0.4 16 N5 1.6 6.3 0.8 32 N6 3.15 12.5 1.6 63 N7 6.3 20 3.2 125 N8 12.5 31.5 6.3 250 N9 25 63 12.5 25 50

2.3 Maximum roughness height Rmax acc. to DIN 4768 (see figure 2) The maximum roughness height Rmax is the largest of the single irregularities z occurring over the evaluation length lm (in figure 2: z3). Rmax is stated in cases where the largest single irregularity (runaway) is to be recorded for reasons important for function. 2.4 Roughness grade numbers N.. acc. to DIN ISO 1302 In supplement 1 to DIN ISO 1302 it is recommended not to use roughness grade numbers. The N-grade numbers are most frequently used in America (see also table Comparison of roughness values).

500 1000 2000 N10 N11 N12 40 100 80 160 160 250

Suppl. 1 Roughness from to DIN values Rz to in m 4768/1

copyright 2008 maryland metrics

You might also like

- Surface FinishDocument38 pagesSurface FinishSunilNo ratings yet

- Handbook of Chemistry and PhysicsDocument347 pagesHandbook of Chemistry and Physicsdonald1976No ratings yet

- Bs Centre DrillsDocument1 pageBs Centre Drillselango22No ratings yet

- Surface Finish TerminologyDocument30 pagesSurface Finish TerminologyXin YuNo ratings yet

- Surface Finish ChartsDocument5 pagesSurface Finish ChartsagssugaNo ratings yet

- Surface Finish NotesDocument8 pagesSurface Finish NotesSuhailshah1234No ratings yet

- Surface Roughness (JIS B 0601-2001)Document3 pagesSurface Roughness (JIS B 0601-2001)Prashantha Raju100% (3)

- Motif Parameters of ISO 12085: '96Document2 pagesMotif Parameters of ISO 12085: '96ubllc100% (1)

- Parameters Mahr Roughness PDFDocument19 pagesParameters Mahr Roughness PDFCarlos RamirezNo ratings yet

- Surface Roughness ParametersDocument2 pagesSurface Roughness Parametersamit02mech100% (1)

- Shafts and BearingsDocument43 pagesShafts and BearingsMario AndrewNo ratings yet

- 1984 Surf Roughness PGDocument8 pages1984 Surf Roughness PGSajjan SNo ratings yet

- Numerical Analysis - I. Jacques and C. Judd PDFDocument109 pagesNumerical Analysis - I. Jacques and C. Judd PDFMaria AquiseNo ratings yet

- Surface RoughnessDocument6 pagesSurface RoughnessCarlos BustamanteNo ratings yet

- Roughness Measurements of Stainless Steel Surfaces: Ra ValueDocument7 pagesRoughness Measurements of Stainless Steel Surfaces: Ra ValueBoilerStackGuy1No ratings yet

- Astm B348-13 PDFDocument9 pagesAstm B348-13 PDFMihail100% (1)

- Geometric Dimensioning and Tolerancing: Procedure / Drafting FNHA-3-B-072.00Document69 pagesGeometric Dimensioning and Tolerancing: Procedure / Drafting FNHA-3-B-072.00003689% (9)

- D0107 (2013-N) NES: Characteristic of Car Body Spot WeldsDocument8 pagesD0107 (2013-N) NES: Characteristic of Car Body Spot WeldsRicardo F.A.No ratings yet

- 3RD Quarter AssessmentsDocument6 pages3RD Quarter AssessmentsLorraine DonioNo ratings yet

- Quality 11Smn30: Lucefin GroupDocument1 pageQuality 11Smn30: Lucefin GroupPaulo ZechinNo ratings yet

- Assessment of Welding ConsumablesDocument17 pagesAssessment of Welding Consumablesmahmoud_allam3No ratings yet

- 1984 Surf Roughness PGDocument8 pages1984 Surf Roughness PGHussn YazdanNo ratings yet

- Characterization and Prediction of Water Droplet Size in Oil Water Flow - J Yao - MSDocument183 pagesCharacterization and Prediction of Water Droplet Size in Oil Water Flow - J Yao - MSGianmarco Corticelli100% (1)

- 1984 Surf Roughness PGDocument8 pages1984 Surf Roughness PGMaey AkimNo ratings yet

- Material Specifications: Zinc Plating 1. ScopeDocument12 pagesMaterial Specifications: Zinc Plating 1. ScopeHaroldo Hubner NetoNo ratings yet

- All About Threads PDFDocument85 pagesAll About Threads PDFSubodhNo ratings yet

- Instrumental Methods of Analysis ThakurDocument296 pagesInstrumental Methods of Analysis ThakurDivyanshu Aggarwal100% (1)

- Distillation Column InternalsDocument17 pagesDistillation Column InternalsAhmed Omar AmineNo ratings yet

- Iso 6411 1982 Simplified Representation of Centre HolesDocument7 pagesIso 6411 1982 Simplified Representation of Centre HolesDaniel WolfNo ratings yet

- Senfeng Laser 3015HDocument24 pagesSenfeng Laser 3015HAlejandro Melj'emNo ratings yet

- Unc Thread Ansi b1Document1 pageUnc Thread Ansi b1Shatish KumarNo ratings yet

- ISO System of Limits and Fits (Tolerances)Document6 pagesISO System of Limits and Fits (Tolerances)skakerNo ratings yet

- Ws - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaDocument1 pageWs - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaHassan MostajabNo ratings yet

- TM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)Document5 pagesTM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)方綵樺100% (1)

- Canlin Castings - Cast Iron GradesDocument2 pagesCanlin Castings - Cast Iron GradeshooijschuurNo ratings yet

- International Standards Conversion Table For Stainless SteelDocument7 pagesInternational Standards Conversion Table For Stainless SteelnarendraNo ratings yet

- Kroeplin - Katalog - 202110 ENDocument24 pagesKroeplin - Katalog - 202110 END.T.No ratings yet

- Surftest SJ-210 - 310 - 410 USB Communication Manual V5.007ADocument22 pagesSurftest SJ-210 - 310 - 410 USB Communication Manual V5.007AKamal Bhandari0% (1)

- ISO-n Exponent PDFDocument12 pagesISO-n Exponent PDFjavidokNo ratings yet

- Parallel Key Calculation According To DIN 6892Document21 pagesParallel Key Calculation According To DIN 6892zahirshah1436923No ratings yet

- Arcwelding 170804063548Document72 pagesArcwelding 170804063548Izzat TammamNo ratings yet

- Execution and Evaluation of Cyclic Tests at Constant Load Amplitudes - DIN 50100:2016Document8 pagesExecution and Evaluation of Cyclic Tests at Constant Load Amplitudes - DIN 50100:2016TrimakisNo ratings yet

- 04Cr18Ni10 PDFDocument3 pages04Cr18Ni10 PDFAvishekNo ratings yet

- Metric DIN 6921 Hexagon Flange Bolts: Visit Our For Product AvailabilityDocument5 pagesMetric DIN 6921 Hexagon Flange Bolts: Visit Our For Product AvailabilityJaganNo ratings yet

- Machine Screws: DIN 965 & ISO 7045 TorxDocument1 pageMachine Screws: DIN 965 & ISO 7045 TorxDerekNo ratings yet

- Stress-Strain GraphDocument10 pagesStress-Strain GraphEzy WaqaNo ratings yet

- Korloy Grades and Chip BreakersDocument33 pagesKorloy Grades and Chip Breakersznovak77No ratings yet

- Minfm32202 Din 17445 Grade G X5crni13 4 Quenched and Tempered qt1Document3 pagesMinfm32202 Din 17445 Grade G X5crni13 4 Quenched and Tempered qt1Biraj SahooNo ratings yet

- Pendulum Impact Testers - Impact Testing Machine - Aimil - Com - PDFDocument12 pagesPendulum Impact Testers - Impact Testing Machine - Aimil - Com - PDFAimil100% (1)

- Surface Texture: G Lancaster Marlborough Boys CollegeDocument22 pagesSurface Texture: G Lancaster Marlborough Boys CollegeJim JohnsonNo ratings yet

- Metric Dowel PinsDocument1 pageMetric Dowel PinszainudinNo ratings yet

- ISO 8750 DIN 7343 420-545 HV: Spiral Spring PinsDocument4 pagesISO 8750 DIN 7343 420-545 HV: Spiral Spring PinsViswanathan SrkNo ratings yet

- Worm and Worm Wheel NomenclatureDocument1 pageWorm and Worm Wheel NomenclaturemuhdqasimNo ratings yet

- Schallater Gaas80 Gaa100 DownloadDocument4 pagesSchallater Gaas80 Gaa100 DownloadRakesh SrivastavaNo ratings yet

- Drafting ThreadsDocument15 pagesDrafting Threadsm_stasys9939No ratings yet

- 1804Document1 page1804816623No ratings yet

- Material Specification Sheet: 1.7102 DIN EN 10089 SAE: 9254 Jis: Sup 12 Material Group: Chemical CompositionDocument1 pageMaterial Specification Sheet: 1.7102 DIN EN 10089 SAE: 9254 Jis: Sup 12 Material Group: Chemical CompositionRajaSekarsajjaNo ratings yet

- General Tolerances - DIN - IsO - 2768Document2 pagesGeneral Tolerances - DIN - IsO - 2768Pasca GheorgheNo ratings yet

- Experiment N 5: Surface RoughnessDocument3 pagesExperiment N 5: Surface RoughnessG. Dancer GhNo ratings yet

- Roughness ParametersDocument13 pagesRoughness ParametersAnoop KizhakathNo ratings yet

- EXP2-SURFACE ROUGHNESS MEASUREMENT-non GuidedDocument3 pagesEXP2-SURFACE ROUGHNESS MEASUREMENT-non GuidedRyan LauNo ratings yet

- 2 67 1582350721 9ijmperdapr20209Document10 pages2 67 1582350721 9ijmperdapr20209TJPRC PublicationsNo ratings yet

- DIN 1302 and Surface QualityDocument17 pagesDIN 1302 and Surface QualitylodraprabowoNo ratings yet

- Engineering Tribology: Lecture 2:nature of SurfacesDocument32 pagesEngineering Tribology: Lecture 2:nature of SurfacesAhmed Ayman AhmedNo ratings yet

- Complete Guide To Surface Finish Symbols, Charts, RA, RZ, Measurements, and Callouts Definition of Surface FinishDocument15 pagesComplete Guide To Surface Finish Symbols, Charts, RA, RZ, Measurements, and Callouts Definition of Surface Finishbhavin178No ratings yet

- Novel Sesquiterpene, 1,2-Epoxyfurano-L0 (15) - Germacren-6-One, The Resin of Engl.Document3 pagesNovel Sesquiterpene, 1,2-Epoxyfurano-L0 (15) - Germacren-6-One, The Resin of Engl.РусланNo ratings yet

- Catalyst Attrition in Ebullated-Bed Hydrotreator Operations: Ezra K.T. Kam, Fatma Jasam, Mohammad Al-MashanDocument12 pagesCatalyst Attrition in Ebullated-Bed Hydrotreator Operations: Ezra K.T. Kam, Fatma Jasam, Mohammad Al-MashanLindsey BondNo ratings yet

- Organic Chemistry - Chapter 14 - Conjugation, Resonance, DienesDocument10 pagesOrganic Chemistry - Chapter 14 - Conjugation, Resonance, DienesSairille ManejaNo ratings yet

- Introduction of Nanomaterials 1Document58 pagesIntroduction of Nanomaterials 1Thanh KieuNo ratings yet

- Chemical Reactions and Equations-1Document14 pagesChemical Reactions and Equations-1Manwinder Singh GillNo ratings yet

- 17-Superheated Water ExtractionDocument43 pages17-Superheated Water ExtractionJayanath Nuwan SameeraNo ratings yet

- Piis0960982216000464 PDFDocument2 pagesPiis0960982216000464 PDFministerenqiNo ratings yet

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDocument36 pagesCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncVikram BillalNo ratings yet

- Comparative Analysis of Essential Oils of CitrusDocument5 pagesComparative Analysis of Essential Oils of CitrusLadi LawalNo ratings yet

- 06tl (47) 4823 PDFDocument4 pages06tl (47) 4823 PDFpaula salamancaNo ratings yet

- Aluminum Hydroxide GelDocument1 pageAluminum Hydroxide GelThu PhamNo ratings yet

- Verifying The Alignment of X-Ray Diffraction Instrumentation For Residual Stress MeasurementDocument4 pagesVerifying The Alignment of X-Ray Diffraction Instrumentation For Residual Stress MeasurementGina f AlmeidaNo ratings yet

- Lecture Planner - Chemistry PDF OnlyDocument1 pageLecture Planner - Chemistry PDF OnlyJai ChandNo ratings yet

- 01 Anjan Scientific ProfileDocument2 pages01 Anjan Scientific ProfilePushpa RamalingaNo ratings yet

- Demineralization Resin: Strong Base Anion (Gel)Document2 pagesDemineralization Resin: Strong Base Anion (Gel)Ari WijayaNo ratings yet

- Chapter 2: Polymer SynthesisDocument17 pagesChapter 2: Polymer SynthesisDerek EstrellaNo ratings yet

- What Are Allosteric Enzymes?Document2 pagesWhat Are Allosteric Enzymes?Anila zafarNo ratings yet

- TracersInTheSea SearchableDocument705 pagesTracersInTheSea SearchableAvan AngelNo ratings yet

- Alkaloids Chemistry and BiologyDocument108 pagesAlkaloids Chemistry and BiologyChiến NguyễnNo ratings yet

- Metallic Filter - dhP-NADocument2 pagesMetallic Filter - dhP-NAGiovanny MosqueraNo ratings yet

- University of Calcutta: Faculty Academic Profile/ CVDocument3 pagesUniversity of Calcutta: Faculty Academic Profile/ CVmunro_85No ratings yet

- ASTM A182 BallDocument16 pagesASTM A182 Ballsigurdur hannessonNo ratings yet

- Number 106 Fall 2009: Fiftieth Anniversary IssueDocument48 pagesNumber 106 Fall 2009: Fiftieth Anniversary IssueMón Quà Vô GiáNo ratings yet

- Carbon Fiber For A Better WorldDocument3 pagesCarbon Fiber For A Better WorldKhánh Nguyễn NgHNo ratings yet