Professional Documents

Culture Documents

Workstring Buckling

Uploaded by

francisryan4519Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Workstring Buckling

Uploaded by

francisryan4519Copyright:

Available Formats

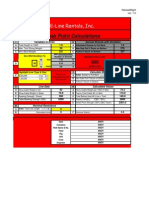

WORKSTRING BUCKLING

REQUIRED INFORMATION Workstring OD Workstring ID Pipe Wall Thickness Yield Strength Unsupported Length 0 0 0 0 0 inches inches inches psi inches This worksheet is used to to determine the bucklimg mode and required surface pressure to possibly cause the workstring to buckle.

STEP 1 COLUMN SLENDERNESS RATIO #DIV/0! STEP 2 EFFECTIVE SLENDERNESS RATIO Moment of Inertia 0.0000 Area of Steel 0.000 Radius of Gyration #DIV/0! Effective Slenderness Ratio #DIV/0! or #DIV/0! >>>>>> Use the larger of the two

Four parts

READ THIS CAREFULLY!! If the Column Slenderness Ratio (Step 1) > Effective Slenderness Ratio the pipe is prone to Local Buckling - go to STEP 3 If the Effective Slendernes Ratio (Step 2) > Column Slenderness Ratio the pipe is prone to Major Axis Buckling - go to Step 4

SELECTED EFFECTIVE SLENDERNESS RATIO (user input) 0 STEP 3 LOCAL BUCKLING #DIV/0! Pounds of Force STEP 4 MAJOR AXIS BUCKLING #DIV/0! Pounds of Force STEP 5 REQUIRED SURFACE PRESSURE TO CAUSE BUCKLING Calculated Buckling Force = 0 (User input from above) #DIV/0! psi

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- VAM TOP Torque TableDocument25 pagesVAM TOP Torque TableRafael Silva75% (4)

- S.C.S.S.V. Leakage RateDocument1 pageS.C.S.S.V. Leakage Ratefrancisryan4519No ratings yet

- SurgeDocument1 pageSurgefrancisryan4519No ratings yet

- TVD SpreadsheetDocument2 pagesTVD Spreadsheetfrancisryan4519No ratings yet

- TVD & Kill Weight CalculationsDocument40 pagesTVD & Kill Weight Calculationsfrancisryan4519No ratings yet

- Underbalance PerforatingDocument4 pagesUnderbalance Perforatingfrancisryan4519No ratings yet

- Tripping Out While PumpingDocument2 pagesTripping Out While Pumpingfrancisryan4519No ratings yet

- Strokes 2Document4 pagesStrokes 2francisryan4519No ratings yet

- Swab & Surge Pressure EstimationDocument1 pageSwab & Surge Pressure Estimationfrancisryan4519No ratings yet

- TIME TO EVACUATE RIG FOR HURRICANE IVANDocument1 pageTIME TO EVACUATE RIG FOR HURRICANE IVANfrancisryan4519No ratings yet

- Calculations Worksheet From BrooksDocument7 pagesCalculations Worksheet From Brooksfrancisryan4519No ratings yet

- RR ModifiedDocument5 pagesRR Modifiedfrancisryan4519No ratings yet

- P&a Cmt. Calcu.Document2 pagesP&a Cmt. Calcu.francisryan4519No ratings yet

- Vam Inter Chang AbilityDocument1 pageVam Inter Chang Abilityfrancisryan4519No ratings yet

- TenarisHydril Running HYDDocument6 pagesTenarisHydril Running HYDfrancisryan4519No ratings yet

- TH WedgeDocument4 pagesTH Wedgefrancisryan4519No ratings yet

- CSG CMT CalculationsDocument5 pagesCSG CMT Calculationsfrancisryan4519No ratings yet

- 1260708230chem and CMT Volume CalculationDocument4 pages1260708230chem and CMT Volume Calculationfrancisryan4519No ratings yet

- Casing Job Calculations From Tim TisonDocument10 pagesCasing Job Calculations From Tim Tisonfrancisryan4519No ratings yet

- Annular CapacityDocument2 pagesAnnular Capacityfrancisryan4519No ratings yet

- Calculations Worksheet From BrooksDocument7 pagesCalculations Worksheet From Brooksfrancisryan4519No ratings yet

- 1260708311chemical CalculationDocument10 pages1260708311chemical Calculationfrancisryan4519No ratings yet

- 1253021589copy of 1252105691casing Cement DesignDocument2 pages1253021589copy of 1252105691casing Cement Designfrancisryan4519No ratings yet

- CementDocument3 pagesCementfrancisryan4519No ratings yet

- Annular CapacityDocument2 pagesAnnular Capacityfrancisryan4519No ratings yet