Professional Documents

Culture Documents

Minimum Pully Diameter

Uploaded by

shivmech12Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Minimum Pully Diameter

Uploaded by

shivmech12Copyright:

Available Formats

Minimum Pully Diameter

Technical Information

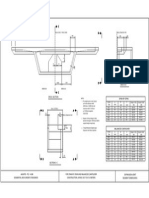

Minimum Pully Diameters (to DIN 22101)

The pulley diameters in a belt conveyor system depend on the design, on strains and on the type of splice of the conveyor belt. For determining the minimum

diameters, the following pulley groups will be distinguished:

Group A: Drive pulley and other pulleys in the range of higher belt tensions Group B: Deflection pulleys in the range of lower belt tensions Group C: Snub pulleys (change in belt moving direction = 30)

The minimum pulley diameter for Group A pulleys can be roughly determined by utilizing the thickness value of the tensile member in the belt as follows: (DTR min)GR.A = Material Characteristic Value dGK Tensilie member material in belt longitudinal material characteristic direction value E (Polyester) 106 P (Polyamide) 90 St (Steel cables) 145 A pulley diameter so obtained shall be rounded up to the next higher value of the table below, in which there are shown for each minimum values for group b and C, too. Minimum pulley diameter DTR min without lining (Quoted in mm) depending on utilizing the admissible tension in the steady operation state.

(DTR min)GR.A after rounding up 200 250 315 400 500 630 800 1000 1250 1400 1600 1800 2000

Utilization of the highest admissible belt tension over 60% to 100% Pullery over 30% to 80% Pullery Group Group A B C A B C 200 160 125 160 125 100 250 200 160 200 160 125 315 250 200 250 200 160 400 315 250 315 250 200 500 400 315 400 315 250 630 500 400 500 400 315 800 630 500 630 500 400 1000 800 630 800 630 500 1250 1000 800 1000 800 630 1400 1250 1000 1250 1000 800 1600 1250 1000 1250 1000 800 1800 1400 1250 1400 1250 1000 2000 1600 1250 1600 1250 1000

up to 30% Pullery Group A B C 125 125 100 160 160 125 200 200 160 250 250 200 315 315 250 400 400 315 500 500 400 630 630 500 800 800 630 1000 1000 800 1000 1000 800 1250 1250 1000 1250 1250 1000

You might also like

- Conveyor Belt Engineering TablesDocument5 pagesConveyor Belt Engineering Tablestaohung1120No ratings yet

- Conveyor Design CalcDocument6 pagesConveyor Design CalcGregory Nick Toledo VelizNo ratings yet

- Freyssibar enDocument12 pagesFreyssibar enDario MarcoraNo ratings yet

- Lec # 9 V-Belt DriveDocument46 pagesLec # 9 V-Belt DriveEl LordNo ratings yet

- MD Handb2 Belt CalcDocument5 pagesMD Handb2 Belt Calcoana2507No ratings yet

- Belt DrivesDocument37 pagesBelt Drivesmacoi123100% (2)

- Bending Machine Centurion ModelDocument4 pagesBending Machine Centurion ModelbharathaninNo ratings yet

- Column Boom Welding MachinesDocument8 pagesColumn Boom Welding Machinesbahram bahramiNo ratings yet

- Puma 2100 2600 3100 EnglishDocument32 pagesPuma 2100 2600 3100 EnglishUrke VukNo ratings yet

- Exhaust System Sizing and Back Pressure CalculationDocument15 pagesExhaust System Sizing and Back Pressure Calculationzoran_stevNo ratings yet

- Design (Metric) 6.25Document8 pagesDesign (Metric) 6.25Salih Has100% (2)

- Unimaster Dust Collectors Data SheetDocument9 pagesUnimaster Dust Collectors Data Sheetselviana42No ratings yet

- Expansion JointDocument1 pageExpansion JointGoanengineerNo ratings yet

- ANCHORAGE FOR TIMBER TRANSPORTDocument3 pagesANCHORAGE FOR TIMBER TRANSPORTAndrei GheorghicaNo ratings yet

- Beltconv (1) - Is11592Document17 pagesBeltconv (1) - Is11592Taha ZiaNo ratings yet

- Murr m900700 70dresskits2Document1 pageMurr m900700 70dresskits2wivawiy670No ratings yet

- 0810 - SEM VIII - R16 - Mech - QB - 100Document15 pages0810 - SEM VIII - R16 - Mech - QB - 100Aditya KhedaskarNo ratings yet

- Conveyor Pulley DesignDocument2 pagesConveyor Pulley DesignZoebair100% (1)

- BMG-BEL23042009 Idlers and RollersDocument16 pagesBMG-BEL23042009 Idlers and Rollersstevens75788No ratings yet

- Saej 1459Document6 pagesSaej 1459Nicole KeithNo ratings yet

- Arbore InventorDocument9 pagesArbore InventorIonut TamasNo ratings yet

- V-belt drive design factorsDocument12 pagesV-belt drive design factorsPeter IyereNo ratings yet

- In Oerlikon CitolineDocument10 pagesIn Oerlikon CitolineJavid Ibrahim MohamedNo ratings yet

- DMRC Ph-Iii Sod 1Document23 pagesDMRC Ph-Iii Sod 1Sahyadree Shah100% (1)

- Nippon Pulse: Your Partner in Motion ControlDocument2 pagesNippon Pulse: Your Partner in Motion ControlElectromateNo ratings yet

- 31-RR-400 - New2)Document1 page31-RR-400 - New2)Chozha Rajan100% (2)

- V Belts PDFDocument5 pagesV Belts PDFAsela BandaraNo ratings yet

- V Belt Technical Specification POLYESTER CORD Neoprene Jacketed HIC Manufactured UNIVERSAL BrandDocument5 pagesV Belt Technical Specification POLYESTER CORD Neoprene Jacketed HIC Manufactured UNIVERSAL Brandmonahend100% (1)

- BSB Series Single Inlet Centrifugal Fans with Backward WheelsDocument52 pagesBSB Series Single Inlet Centrifugal Fans with Backward WheelsZwe1991No ratings yet

- Technical Manual 1 Slide Rail SystemDocument48 pagesTechnical Manual 1 Slide Rail SystemLalaine23No ratings yet

- WallDocument0 pagesWallgks6043No ratings yet

- Acfan - SUNONDocument28 pagesAcfan - SUNONfraumoNo ratings yet

- Bending Machine CRC Evans Centurion 06 20Document4 pagesBending Machine CRC Evans Centurion 06 20bharathaninNo ratings yet

- Torque (Examples and Seatwork)Document4 pagesTorque (Examples and Seatwork)Laurence PaulNo ratings yet

- Nippon Pulse: Your Partner in Motion ControlDocument2 pagesNippon Pulse: Your Partner in Motion ControlElectromateNo ratings yet

- Current Transformers 03-06Document12 pagesCurrent Transformers 03-06noonbcc130No ratings yet

- B2017e-1 Proposal of Products For Machine ToolsDocument7 pagesB2017e-1 Proposal of Products For Machine ToolsElmer Lagua MalpasoNo ratings yet

- SG46 Hydraulic Diaphragm Wall GrabDocument6 pagesSG46 Hydraulic Diaphragm Wall GrabJens Bauer100% (1)

- An Serv 002 PDFDocument20 pagesAn Serv 002 PDFMario TapiaNo ratings yet

- Rexroth Star Linear GuidesDocument172 pagesRexroth Star Linear GuidesOguz AlbayrakNo ratings yet

- TM-ZT1004H: ModelDocument5 pagesTM-ZT1004H: ModelKormandi KDANo ratings yet

- Beltconv (1) - CemaDocument45 pagesBeltconv (1) - CemaGuiidoo' Churairaa'No ratings yet

- Design of Vbelt DrivesDocument8 pagesDesign of Vbelt DrivesSteven MendozaNo ratings yet

- TM-ZX1505HRS S GDocument13 pagesTM-ZX1505HRS S GВячеслав ТкаченкоNo ratings yet

- 10-Ton Pneumatic Suspension Technical SpecsDocument6 pages10-Ton Pneumatic Suspension Technical SpecsShashidhar ModemNo ratings yet

- Agitator Vessel (Design&Costing)Document34 pagesAgitator Vessel (Design&Costing)imrancenakk100% (2)

- Datasheet Panasonic Msma042Document39 pagesDatasheet Panasonic Msma042thiagofininhoNo ratings yet

- Linkbelt LS218H SpecificationsDocument8 pagesLinkbelt LS218H SpecificationsPaulo SemedoNo ratings yet

- S8A Aluminum Straight SectionsDocument2 pagesS8A Aluminum Straight SectionsjrymcdnlNo ratings yet

- SmartStepMotors DatasheetDocument8 pagesSmartStepMotors DatasheetZuhal AkbayırNo ratings yet

- Selection of Ball Screws 1Document4 pagesSelection of Ball Screws 1Minh Trí KnightNo ratings yet

- Thomson Super Metric Ball Bushing Bearings SpecsheetDocument11 pagesThomson Super Metric Ball Bushing Bearings SpecsheetElectromateNo ratings yet

- Tm-Ze555mh LNG en Gen S 2305Document7 pagesTm-Ze555mh LNG en Gen S 2305Arkhnae HatthaniranNo ratings yet

- 3.6.1 Busduct (Jis)Document29 pages3.6.1 Busduct (Jis)Kristine Grace LimatoNo ratings yet

- TADANO CARGO CRANE SPECIFICATIONSDocument13 pagesTADANO CARGO CRANE SPECIFICATIONSavisheklochunNo ratings yet

- 3 Link CalculatorDocument28 pages3 Link CalculatorNakkolopNo ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Britsh Universal ColumnDocument3 pagesBritsh Universal Columnshivmech12No ratings yet

- Interpretation of Weld RadiographsDocument8 pagesInterpretation of Weld Radiographsshivmech12No ratings yet

- About Insurance Policy: How To Buy Insurance Policies?Document7 pagesAbout Insurance Policy: How To Buy Insurance Policies?shivmech12No ratings yet

- Lagging and Power Info Dodge Short and GoodpdfDocument1 pageLagging and Power Info Dodge Short and GoodpdfMichael J. BaneNo ratings yet

- Teng 597Document6 pagesTeng 597vibhaveer2525No ratings yet

- 4049 1Document5 pages4049 1Amit MondalNo ratings yet