Professional Documents

Culture Documents

Temperature Control Engine Water Pumpnce Paper

Uploaded by

mechanicalsrivasansCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Temperature Control Engine Water Pumpnce Paper

Uploaded by

mechanicalsrivasansCopyright:

Available Formats

Temperature Control Engine Water Pump

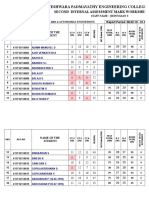

Srinivasan.S Department of Mechanical Engineering (M.E Engineering Design) St.Peters Institute Of Higher Education And Research

ABSTRACT This project presents the Brushless DC drive design of water pump system for automotive application. Electric water pumps offer several advantages. Among them, the efficiency is the main reason for electric water pumps. Conventional mechanical water pump is directly connected by the engine belt. For this reason, regardless of coolant circulation, the conventional mechanical water pump is always operated. The way which the mechanical water pump is replaced by electric water pump could reduce energy consumption. Here a simple compact design can be obtained therefore high speed can be achieved by eliminating belts and pulleys. Since every point of increase in temperature results in the increase of the speed of the pump. INTRODUCTION A water pump motor is device that is commonly found in motor vehicles like cars, trucks, buses, and trains. This pump distributes the heat that is produced by internal combustion engines. The heat is actually the end form of wasted energy produced when these motor engines work. Without the water pump, the heat can build up inside the engine causing the engine to overheat. If this process continues, the engine will be eventually destroyed. In simpler terms, a pump keeps the temperature at acceptable levels by dissipating the heat. Most water pumps look like a disc. It is circular and made from a combination of steel and aluminum. The inside of this device is also circular with chambers. Then a spindle is located in the middle with several protrusions that look more like paddles for small boats. It is usually found in front of the car, which is normally in front of the engine. It can be bolted against the radiator. At the same time, another set of hoses is used to connect the pump to the engine in a closed circuit. On the other hand, a fan belt is then utilized to connect the central spindle of the pump to the engine output.engine or on the mounting of the engine. Keeping the water pump bolted will keep it in place even during rough drives. A hose is used to connect this device to the NEED FOR THIS PROJECT The coolant needs to run round the engine taking the heat from the block and dissipating it in the radiator. Most cars come with mechanical water pumps which have a number of drawbacks, will take a look at the benefits of upgrading to an electric water pump. Mechanical pumps take a lot of power from the engine. They also rotate and therefore pump in proportion to the engine RPM. This does an adequate job but causes the following 2 issues. 1. After a hard run with lots of heat in the engine the pump will slow down as you slow down. This can mean the engine temperature raises to dangerously high levels. When the engine is cold the coolant is being pumped round at the same rate as a warm engine causing the engine to take longer to warm up.

2.

This is tolerable on a standard car which rarely is driven hard. But when you have a highly tuned car and frequently take it for a spirited drive you can start to experience problems associated with overheating ARDUINO Arduino is a popular open-source single-board microcontroller, descendant of the open-source Wiring platform designed to make the process of using electronics in multidisciplinary projects more accessible. The hardware consists of a simple open hardware design for the Arduino board with an Atmel AVR processor and on-board input/output support. The software consists of a standard programming language compiler and the boot loader that runs on the board. Arduino hardware is programmed using a Wiring-based language (syntax and libraries), similar to C++ with some slight simplifications and modifications, and a Processing based integrated development environment. Current versions can be purchased pre-assembled; hardware design information is available for those who would like to assemble an Arduino by hand. Additionally, variations of the Italian-made Arduino with varying levels of compatibility have been released by third parties; some of them are programmed using the Arduino software. DESIGN PROCESS TASK The task of our project is to overcome the problems in the mechanical water pump we are using ELECTRICAL WATER PUMP. REQUIREMENTS 1. 2. 3. 4. 5. Water pump DC motor Temperature sensor Electronic controller kit 12v adaptor

6. 7.

Display unit gears BLOCK DIAGRAM

Fig .1 SPECIFICATION Operating voltage Nominal voltage Current Speed Torque Efficiency Weight Shaft diameter 5V to 15V 12V 1.9A 10700RPM 18 N-m 75% 91g 2.3mm

The LM35 series are precision integrated-circuit temperature sensors, whose output voltage is linearly proportional to the Celsius (Centigrade) temperature. The LM35 thus has an advantage over linear temperature sensors calibrated in Kelvin, as the user is not required to subtract a large constant voltage from its output to obtain convenient Centigrade scaling. The LM35 does not require any external calibration or trimming to provide typical accuracies of 14C at room temperature and 34C over a full 55 to +150Ctemperature range. Low cost is assured by trimming and calibration at the wafer level. The LM35s low output impedance, linear output, and precise inherent calibration make interfacing to readout or control circuitry especially easy. It can be used with single power supplies, or with plus and minus supplies. As it draws only 60 A from its supply, it has very low self-heating, less than 0.1C in still air. The LM35 is rated to operate over a 55 to +150C temperature range, while the LM35C is rated for a 40 to +110C range (10with improved accuracy). The LM35 series is available packaged in hermetic TO-46 transistor packages, while theLM35C, LM35CA, and LM35D are also available in the plastic TO-92 transistor package. The LM35D is also available in an 8-lead surface mount small outline package and a plastic TO-220 package. FEATURES 1. 2. Calibrated directly in Celsius (Centigrade) Linear + 10.0 mV/C scale factor

TEMPERATURE SENSOR The Thermistor is another type of temperature sensor, whose name is a combination of the words THERM-ally sensitive res-ISTOR. A thermistor is a type of resistor which changes its physical resistance with changes in temperature

3. 0.5C accuracy guarantee able (at +25C) 4. Rated for full 55 to +150C range 5. Suitable for remote applications 6. Low cost due to wafer-level trimming 7. Operates from 4 to 30 volts

8. 9. 10. 11. Less than 60 A current +drain Low self-heating, 0.08C in still air Nonlinearity only 14C typical Low impedance output, 0.1 W for 1 mA load

TYPICAL PERFORMANCE CHARACTERISTICS 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Fig.2 Thermal Resistance Junction to Air Thermal Time Constant Thermal Response in Still Air Thermal Response in Stirred Oil Bath Minimum Supply Voltage vs. Temperature Quiescent Current vs. Temperature Accuracy vs. Temperature Noise voltage Startup response

APPLICATIONS The LM35 can be applied easily in the same way as other integrated-circuit temperature sensors. It can be glued or cemented to a surface and its temperature will be within

GENERAL DESCRIPTION

about 0.01C of the surface temperature. This presumes that the ambient air temperature is almost the same as the surface temperature; if the air temperature were much higher or lower than the surface temperature, the actual temperature of the LM35 die would be at an intermediate temperature between the surface temperature and the air temperature. These devices are sometimes soldered to a small lightweight heat fin, to decrease the thermal time constant and speed up the response in slowly-moving air. On the other hand, a small thermal mass may be added to the sensor, to give the steadiest reading despite small deviations in the air temperature WORKING PRINCIPLE 1. A 12V adaptor is plugged into the 240V AC supply . 2. Adaptor plug is connected into the port of the electronic controller kit and switched on. 3. After few seconds system responds to work. Now temperature sensor reads the room temperature. 4. The corresponding room temperature is displayed in the LCD display unit. 5. Soldering stick was connected into the another plug point and switched on. So the heat is gradually increased at the soldering stick. 6. Now the soldering stick was made contact into the temperature sensor. Here sensor receiving every point of the raise in temperature. 7. After receiving the signal, it was send to the microcontroller to execute the program. 8. Controller ATmega8L processing the input temperature and sending the datas to the L293D motor driver. 9. L293D driver controls the speed of the motor shaft which is proportional to the input temperature. 10. If the input temperature raises then motor speed also raises and vise versa. ASSEMBLY PROCEDURE 1. 2. 3. 4. 5. 6. 7. Arduino board was designed using eagle software. ICs were positioned at the desired places on the board area using this eagle software. Now the designed board was taken into the manufacturing process. Program interfacing IC was soldered on the board primarily. Then the controller ATmega8(L) was soldered at the desired area on the board. The L293D motor driver also soldered opposite to the controller which is interfaced with it. Display port was soldered at the right top corner of the board and thus it was interfaced with the program chip. Then the separate display unit was plugged into the display port. Adaptor port is fixed at the bottom corner of the board and the 12V adaptor was plugged to it.

10. Next to the display port temperature sensor was plugged into the pin. 11. Water pump, motor and electronic controller kit were fitted on the rectangular wooden board. 12. A plastic spur gear was connected on the motor shaft and the another plastic spur gear was connected at the water pump shaft. 13. Finally the two spur gear teeths were made into contact to rotate the pump impeller for coolant circulation. ADVANTAGES 1. 2. 3. 4. 5. 6. 7. 8. Engine efficiency is increase. Energy upto 12% of the engine can be saved. Compact design. High speed of engine can be achieved. High cooling effect is obtained. More flexibility during operation Engine space can be reduced Noise can be reduced APPLICATIONS 1. 2. 3. Automobile race cars Electric race cars Electric hybrid vehicle CONCLUSION There are many uses of the temperature controlled water pump in the automobile vehicles. Because it is very compact and less space required to place the engine on the chassis then the mechanism can be able to perform at the different speeds at the different temperature of the engine in any on road condition application areas very easily. Nowadays mostly this water type water pumps are using in electric vehicles and race cars. In order to increase the very high cooling effect and engine overall efficiency temperature control water pump is introduced. The main advantage of this mechanism is giving the multiple advantage and high speed of engine can be achieved Future uses may be in the place of petrol or diesel engine vehicles in the automobile field. REFERENCE 1. Heywood J. B. (1988). Internal Combustion Engine Fundamentals, Mcgraw-Hill, Singapore, 1988 Automobile Technology, Kapil Singh. Advance Ic Engines,V.Ganesan. Diesel Engine Reference Book, Bernard Challen, Rodica Baranescu

2. 3. 4.

8. 9.

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- 1 s2.0 S0963869514001431 MainDocument7 pages1 s2.0 S0963869514001431 MainmechanicalsrivasansNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Defence Technology: Meltem Altin Karatas, Hasan G OkkayaDocument9 pagesDefence Technology: Meltem Altin Karatas, Hasan G Okkayaali aliNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 1464420717692369Document17 pages1464420717692369mechanicalsrivasansNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Effect of Nanofiller On Fibre Laser Drilling Quality of Carbon Fibre Reinforced Polymer Composite LaminatesDocument14 pagesEffect of Nanofiller On Fibre Laser Drilling Quality of Carbon Fibre Reinforced Polymer Composite LaminatesmechanicalsrivasansNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 1 s2.0 S0266353816300185 MainDocument9 pages1 s2.0 S0266353816300185 MainmechanicalsrivasansNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 1 s2.0 S2214785321047386 MainDocument7 pages1 s2.0 S2214785321047386 MainmechanicalsrivasansNo ratings yet

- An Optical Method For Measuring Surface Roughness of Machined Carbon Fibre-Reinforced Plastic CompositesDocument14 pagesAn Optical Method For Measuring Surface Roughness of Machined Carbon Fibre-Reinforced Plastic CompositesmechanicalsrivasansNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Me6602 & Auto Ia2Document12 pagesMe6602 & Auto Ia2mechanicalsrivasansNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 1 s2.0 S0043164816308572 MainDocument7 pages1 s2.0 S0043164816308572 MainmechanicalsrivasansNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- 1 s2.0 S0030399218313677 MainDocument12 pages1 s2.0 S0030399218313677 MainmechanicalsrivasansNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 2011Document3 pages2011mechanicalsrivasansNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Pult Rusi OnDocument60 pagesPult Rusi OnmechanicalsrivasansNo ratings yet

- Q PareDocument1 pageQ ParemechanicalsrivasansNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Name and Address of The Licensed Adoption Agencies Doing inDocument2 pagesName and Address of The Licensed Adoption Agencies Doing inmechanicalsrivasansNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Name and Address of The Licensed Adoption Agencies Doing inDocument2 pagesName and Address of The Licensed Adoption Agencies Doing inmechanicalsrivasansNo ratings yet

- Resume PooraniDocument2 pagesResume PooranimechanicalsrivasansNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- FM QuestDocument14 pagesFM QuestmechanicalsrivasansNo ratings yet

- 3rd Semester Mark ListDocument0 pages3rd Semester Mark ListmechanicalsrivasansNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Name and Address of The Licensed Adoption Agencies Doing inDocument2 pagesName and Address of The Licensed Adoption Agencies Doing inmechanicalsrivasansNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Figure 1.2 Output Window of ANSYSDocument17 pagesFigure 1.2 Output Window of ANSYSmechanicalsrivasansNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Rajesh ResumeDocument2 pagesRajesh ResumemechanicalsrivasansNo ratings yet

- Fault Code 3911 (Cont)Document22 pagesFault Code 3911 (Cont)John MichaelNo ratings yet

- General Description Features: High-Current Low-Dropout RegulatorsDocument23 pagesGeneral Description Features: High-Current Low-Dropout RegulatorsKamran ManafzadeNo ratings yet

- MCP6022Document34 pagesMCP6022Михаил МалсюковNo ratings yet

- Avr 2311 CiDocument181 pagesAvr 2311 CiDigwas BellemaneNo ratings yet

- 10 ElectricityDocument42 pages10 ElectricityVikash SharmaNo ratings yet

- Type EP Series: Wirewound Anti-Surge ResistorsDocument12 pagesType EP Series: Wirewound Anti-Surge ResistorsmohamadeisaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Circuit Analysis I With MATLABDocument46 pagesCircuit Analysis I With MATLABsalemabu9No ratings yet

- Automatic Road Reflector LightDocument27 pagesAutomatic Road Reflector LightSujesh ChittarikkalNo ratings yet

- Fundamentals of Electrical Engg. Lab ManualDocument54 pagesFundamentals of Electrical Engg. Lab Manualtanay jaiswal100% (2)

- Features DescriptionDocument16 pagesFeatures DescriptionAlex VladNo ratings yet

- Science8 Q1 Module7 Cuurent-and-Charge V2-1Document26 pagesScience8 Q1 Module7 Cuurent-and-Charge V2-1Twela Dea Dela CruzNo ratings yet

- Basic Electrotechnology PDFDocument570 pagesBasic Electrotechnology PDFIrofte Iulian100% (3)

- Lexium 17D Series Servo Drive User Guide: ModiconDocument182 pagesLexium 17D Series Servo Drive User Guide: ModiconRodrigo DuarteNo ratings yet

- BL0940 APPNote TSSOP14 V1.04 ENDocument6 pagesBL0940 APPNote TSSOP14 V1.04 ENGeorgi IlievNo ratings yet

- LED Flasher Circuit PPT PresentationDocument6 pagesLED Flasher Circuit PPT PresentationBharath100% (1)

- An 6026Document23 pagesAn 6026Иван АлексиевNo ratings yet

- Week 3Document11 pagesWeek 3Marcos Infante20% (10)

- Last Minute Review MCQDocument34 pagesLast Minute Review MCQIB Experts for 7on7 Pvt. Ltd.No ratings yet

- Project 1 I V Curve of A DiodeDocument6 pagesProject 1 I V Curve of A DiodeBắc LêNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- LM 6172Document25 pagesLM 6172miltoncgNo ratings yet

- Ohm's LawDocument32 pagesOhm's LawDezz Balleta-BonaNo ratings yet

- Tetrode ManualDocument50 pagesTetrode ManualDragan AntonićNo ratings yet

- ELEC1111 Lab Manual F2F (2020 - 10 - 19 10 - 35 - 29 UTC)Document92 pagesELEC1111 Lab Manual F2F (2020 - 10 - 19 10 - 35 - 29 UTC)shirleyNo ratings yet

- Arduino Micro QuadcopterDocument5 pagesArduino Micro QuadcopterA Lo mejorNo ratings yet

- Instruction Manual: Modbus Slave Interface For Digital Mass Flow / Pressure InstrumentsDocument39 pagesInstruction Manual: Modbus Slave Interface For Digital Mass Flow / Pressure InstrumentsmahaprabuasNo ratings yet

- Applied Phy Lab ManualDocument109 pagesApplied Phy Lab Manualamirmehmood88No ratings yet

- 20-D C - CircuitsDocument40 pages20-D C - CircuitsRobert mukwekweNo ratings yet

- COAS P1 Ch13 ItDocument7 pagesCOAS P1 Ch13 ItDyna MoNo ratings yet

- Data Sheet Ad 532Document7 pagesData Sheet Ad 532arnoldmoyaNo ratings yet

- MOdul Pengganti Untuk Egsv3Document18 pagesMOdul Pengganti Untuk Egsv3yumarestuNo ratings yet

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialFrom EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialRating: 3.5 out of 5 stars3.5/5 (3)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 4.5 out of 5 stars4.5/5 (9)