Professional Documents

Culture Documents

Nitrogen Dosing

Uploaded by

Edward ChohCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nitrogen Dosing

Uploaded by

Edward ChohCopyright:

Available Formats

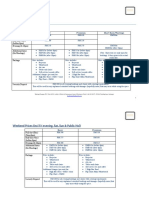

Part 1: Calculate Existing N2 Dosing Rate in Refinery Current Setting in Refinery Oil Flow rate (mass basis) N2 Pressure

N2 flow rate Oil Density N2 Density = 8 tonne / hr = 6 bar = 30 scfh ( 0.8495 m3/hr ) = 890 kg/m3 = 1.165 kg/ m3

N2 flow rate (mass basis ) N2 flow rate (mass basis) = N2 Density X N2 flow rate = 1.165kg/m3 * 0.8495 m3/hr = 0.9897kg/hr

N2 Dosing rate used in Refinery (mass basis) Mass Dosing Ratio (per hour basis) = Mass flow rate of N2 / Mass flow rate of Oil = 0.09897kg/hr / 8000 kg/hr = 0.00001237 = 0.0124 % Part 2: Calculate Required N2 for SONA 1 N2 Inject Current Setting in SONA 1 Oil Flow Rate (mass basis) N2 Pressure Oil Density N2 Tank Mass Dosing Ratio used in Refinery = 4.5 tonne/ hr = 7 bar = 890 kg/m3 = 7.2m3 @ 1 bar pressure = 0.0124%

Calculate Required amount of N2 for Dosing Mass of N2 used (per hour basis) = Oil Flow rate (mass basis) x Mass Dosing Ratio = 4.5 tonne/hr * 0.0124 % = 0.558 kg/hr Flowrate of N2 used = N2 flow rate (mass basis)/N2 Density = 0.558kg/hr / (1.165kg/m3) = 0.478 m3 / hr Flowmeter Reading for N2 Dosing Gas flowmeter doesnt accurately show the flow rate of actual flowing gas if the gas used is pressurized. A correction factor must be applied.

Rate of Usage of N2 tank Mass of N2 in tank = Tank volume * N2 Density = 7.2 m3 x 1.165kg/m3 = 8.39kg Hours required to finish up one tank = Mass of N2 in Tank x Density of N2 = 8.39kg / 0.558kg/hr = 15.1 hours

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Memoirs of Robert Kuok PDFDocument49 pagesThe Memoirs of Robert Kuok PDFEdward Choh80% (10)

- The Memoirs of Robert Kuok PDFDocument49 pagesThe Memoirs of Robert Kuok PDFEdward Choh80% (10)

- DND - LegNotLast BackstoryDocument2 pagesDND - LegNotLast BackstoryEdward ChohNo ratings yet

- JSDocument65 pagesJSEdward ChohNo ratings yet

- Hatch Info Pack - 24 June 2018Document5 pagesHatch Info Pack - 24 June 2018Edward ChohNo ratings yet

- How Not To Host A Murder (5e)Document12 pagesHow Not To Host A Murder (5e)Delfidus100% (2)

- Zuken E3 Modular Structure Technical SpecDocument2 pagesZuken E3 Modular Structure Technical SpecEdward ChohNo ratings yet

- KenafDocument7 pagesKenafEdward ChohNo ratings yet

- Mdot 8030Document2 pagesMdot 8030Edward ChohNo ratings yet

- Mdot 8030Document2 pagesMdot 8030Edward ChohNo ratings yet

- Process Plant Layout & Piping DesignDocument452 pagesProcess Plant Layout & Piping Designapi-3748845100% (8)

- Solid Edge Floating License Server Installation - 2Document14 pagesSolid Edge Floating License Server Installation - 2Edward ChohNo ratings yet

- EgyptDocument1 pageEgyptEdward ChohNo ratings yet

- Flange Standard ChartDocument5 pagesFlange Standard ChartEdward ChohNo ratings yet

- Guyuk Khan Vs Pope Innocent IVDocument2 pagesGuyuk Khan Vs Pope Innocent IVEdward Choh100% (2)

- Injection MoldingDocument22 pagesInjection MoldingEdward ChohNo ratings yet

- Guyuk Khan Vs Pope Innocent IVDocument2 pagesGuyuk Khan Vs Pope Innocent IVEdward Choh100% (2)