Professional Documents

Culture Documents

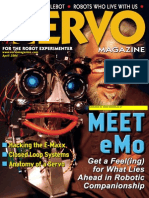

Servo2007 09

Servo2007 09

Uploaded by

Karina Cristina ParenteCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Servo2007 09

Servo2007 09

Uploaded by

Karina Cristina ParenteCopyright:

Available Formats

V

o

l

.

5

N

o

.

9

S

E

R

V

O

M

A

G

A

Z

I

N

E

V

E

X

A

U

T

O

M

O

T

I

V

E

B

A

S

H

B

A

L

L

C

A

N

N

E

T

W

O

R

K

I

N

G

R

O

B

O

C

U

P

M

-

B

O

T

S

e

p

t

e

m

b

e

r

2

0

0

7

Cover.qxd 8/8/2007 9:33 PM Page 84

Order 24 hours a day, 7 days a week

www.Jameco.com

Or call 800-831-4242 anytime

Jameco Electronics. *According to their web sites on July 23, 2007. Trademarks are the property of their respective owners.

OTHER JAMECO ADVANTAGES:

I More major passive, interconnect and electro-

mechanical brands than other distributors.

I 99% of catalog products ship the same day.

I Lowest prices guaranteed, or we pay 10%.

I Major brand names and generic equivalents

for even greater cost savings.

5

10

15

20

25

Were semi nuts

Weve got semis on the brain. Jameco offers more major brands of semiconductors than anyone

almost twice as many as these catalog distributors.* Its another Jameco advantage.

Mouser

Newark

Allied

Jameco

Atmel Semiconductor Altera Analog Devices Altera

Avago Technologies Analog Devices Atmel Semiconductor Analog Devices

Cypress Semiconductor Avago Technologies Avago Technologies Atmel Semiconductor

Diodes, Inc. Cypress Semiconductor Freescale Semiconductor Avago Technologies

Fairchild Semiconductor Fairchild Semiconductor Infineon Technologies Cypress Semiconductor

Freescale Semiconductor Freescale Semiconductor Integrated Devices Diodes, Inc.

Intersil Integrated Devices Intel Corporation Fairchild Semiconductor

Lattice Semiconductor Intel Corporation Intersil Freescale Semiconductor

Lite-On Semiconductor Intersil Lattice Semiconductor Infineon Technologies

NEC Corporation Lattice Semiconductor Maxim Integrated Devices

Sharp Microelectronics Maxim National Semiconductor Intel Corporation

ST Microelectronics National Semiconductor NXP (formerly Philips) Intersil

Texas Instruments ST Microelectronics ST Microelectronics Lattice Semiconductor

Texas Instruments Texas Instruments Linear Technology

Lite-On Semiconductor

Maxim

Micron Technology

Microsemi

National Semiconductor

NEC Corporation

NXP (formerly Philips)

Renesas Technology

Sharp Microelectronics

ST Microelectronics

Texas Instruments

Toshiba

Free shipping

on these and

79 other brands.

Call for details.

CoverInside.qxd 8/8/2007 7:50 PM Page 2

First-class customer service...

You have provided polite, detailed support when have

needed it, have been more than accommodating when it comes

to purchasing assistance as well as providing me with lightning

Iast email responses, prompt delivery and have met and greatly

exceeded my expectation Irom a retailer in every regard

Robert 0ordon University, Aberdeen

0R0ER 0NLNE:

WWW.A0TVE-R0B0T5.00M - TEL: + I0J171 23 27

Robonova-1

H0KUY0 PB5-03JN

nIrared range nder Ior

indoor environments

AUTH0R5E0 H0KUY0 0EALER

H0KUY0 UR0-0LX state oI

the art laser range nder

5ensor Mounting Hardware

Robot chassis, parts

& accessories

Easy 5tep 3000, advanced

stepper motor drive and

control system

Micromouse chassis

Entry level controller

suited to small robotics

and control applications

Full Page.qxd 8/8/2007 7:54 PM Page 3

4 SERVO 09.2007

35 BASHBALL!

by Steve Judd

BotBash returns with a new game,

a radically updated Active Arena,

and a dif ferent approach to extreme

robotic sports.

38 RoboCup 2007

by Dennis Hong, Karl Muecke,

Robert Mayo, Jesse Hurdus,

and Brad Pullins

DARwIns first soccer tournament.

44 Build an Inexpensive

Solar Trickle Charger

From Junk

by Alan Federman

Harness the rays from the sun to

power your outdoor bots.

46 Beginners Guide to

Programming

by Michael Simpson

Lesson 3: Branch, LookUp, LookDown,

and LCD commands.

51 M-BOT

by Ron Hackett

Part 1: Begin construction on this

intelligent, autonomous robot

controlled only by an eight-pin

processor.

55 CAN Networking

Southern Style

by Fred Eady

Put some CAN application code

together and control an LED

before adding additional motor

driver hardware.

62 RoboGames 2007

by Peter Smith

Recap of this years event.

Features & Projects

SERVO Magazine (ISSN 1546-0592/CDN Pub Agree

#40702530) is published monthly for $24.95 per year by T &

L Publications, Inc., 430 Princeland Court, Corona, CA 92879.

PERIODICALS POSTAGE PAID AT CORONA, CA AND AT

ADDITIONAL ENTRY MAILING OFFICES. POSTMASTER:

Send address changes to SERVO Magazine, P.O.

Box 15277, North Hollywood, CA 91615 or

Station A, P.O. Box 54, Windsor ON N9A 6J5; cpcreturns@

servomagazine.com

PAGE 62

TOC Sep07.qxd 8/8/2007 3:47 PM Page 4

09.2007

VOL. 5 NO. 9

SERVO 09.2007 5

ENTER WITH CAUTION!

26 The Combat Zone

Columns

08

Robytes by Jeff Eckert

Stimulating Robot Tidbits

10

GeerHead by David Geer

AUVSI UV Sampling

14

Dif ferent Bits

by Heather Dewey-Hagborg

Neural Networks for the PIC Microcontroller

Part 2 Backpropagation

20

Ask Mr. Roboto by Pete Miles

Your Problems Solved Here

67

Twin Tweaks

by Bryce and Evan Woolley

Robot vs. Wild

72

Robotics Resources

by Gordon McComb

Juicing Up Your Bot With the Best

Rechargeable Batteries

79

Appetizer by Dan Danknick

Time to Innovate

80

Then and Now by Tom Carroll

People of Robotics

Departments

06 Mind/Iron

07 Bio-Feedback

22 New Products

24 Events Calendar

34 Robotics Showcase

50 Robo-Links

76 SERVO Store

82 Advertisers Index

PAGE 38 PAGE 51

TOC Sep07.qxd 8/8/2007 3:47 PM Page 5

Published Monthly By

T & L Publications, Inc.

430 Princeland Court

Corona, CA 92879-1300

(951) 371-8497

FAX (951) 371-3052

Product Order Line 1-800-783-4624

www.servomagazine.com

Subscriptions

Inside US 1-877-525-2539

Outside US 1-818-487-4545

P.O. Box 15277

North Hollywood, CA 91615

PUBLISHER

Larry Lemieux

publisher@servomagazine.com

ASSOCIATE PUBLISHER/

VP OF SALES/MARKETING

Robin Lemieux

display@servomagazine.com

EDITOR

Bryan Bergeron

techedit-servo@yahoo.com

CONTRIBUTING EDITORS

Jeff Eckert Tom Carroll

Gordon McComb David Geer

Pete Miles R. Steven Rainwater

Michael Simpson Kevin Berry

Fred Eady Dennis Hong

Karl Muecke Robert Mayo

Jesse Hurdus Brad Pullins

Steve Judd Peter Smith

Alan Federman Ron Hackett

Dan Danknick Chris Olin

Ray Billings Jay Johnson

Bryce Woolley Evan Woolley

Heather Dewey-Hagborg

CIRCULATION DIRECTOR

Tracy Kerley

subscribe@servomagazine.com

MARKETING COORDINATOR

Brian Kirkpatrick

WEB CONTENT/STORE

Michael Kaudze

sales@servomagazine.com

PRODUCTION/GRAPHICS

Shannon Lemieux

Michele Durant

ADMINISTRATIVE ASSISTANT

Debbie Stauffacher

Copyright 2007 by

T & L Publications, Inc.

All Rights Reserved

All advertising is subject to publishers approval.

We are not responsible for mistakes, misprints,

or typographical errors. SERVO Magazine

assumes no responsibility for the availability or

condition of advertised items or for the honesty

of the advertiser. The publisher makes no claims

for the legality of any item advertised in SERVO.

This is the sole responsibility of the advertiser.

Advertisers and their agencies agree to

indemnify and protect the publisher from any

and all claims, action, or expense arising from

advertising placed in SERVO. Please send all

editorial correspondence, UPS, overnight mail,

and artwork to: 430 Princeland Court,

Corona, CA 92879.

Academic vs. Commercial Robotics

I had the fortune of participating in

the 7th IEEE International Symposium on

Computational Intelligence in Robotics

and Automation (CIRA) conference, held

this summer in Jacksonville, FL. Academic

researchers from Asia, Africa, Europe, and

the Americas presented their work on

topics ranging from robot manipulators

and cooperative robotics, to robot vision.

As expected, the event was a

concentrated refresher on the leading

edge of robotics research. An unexpected

take-away from my conversations with the

researchers at the conference was the

differences between academic and

commercial robotics, and the merit of

each perspective.

The most obvious differences are a

result of the reward systems applied to

each group. Academic roboticists are

rewarded for tackling intellectually

challenging problems that can result in

academic publications, with little or no

regard for short-term commercial

significance. As a result, academic

roboticists tend to focused on niche areas

that they can explore and perhaps claim

for their own whether its a novel

algorithm, manipulator design, or robot

configuration. Intellectual property,

which provides leverage for academic

promotion and securing government- and

industry-sponsored grants, is guarded

until publication. I liken the academic

model to an inverted funnel, in which

researchers drill down on an intellectually

stimulating and novel domain, and only

later broaden their approach to consider

the broader applications of their work,

including commercialization.

Commercial roboticists, in contrast,

are entrepreneurs. They are rewarded by

the marketplace for recognizing and

understanding a problem and then

identifying a commercially viable technical

solution. Their approach can be modeled

as a funnel in that broad issues are

considered first, and then choices are

narrowed by issues such as intellectual

property protection, cost of manufacture,

competition, availability of distribution

channels, support requirements, liability,

and likelihood of follow-on products that

will insure growth of a company.

Commercial roboticists tend to

focus on problem areas that are dull,

dangerous, and dirty and know that

superior technology is necessary but

insufficient for commercial success.

Intellectual property is either kept as

trade secrets or protected with patents,

trademarks, and copyrights.

Despite these and other

differences, academic and commercial

robotics are intertwined in a symbiotic

relationship. The best marketing

strategy and business model will

eventually fail if the underlying

technology doesnt adequately solve the

buyers problems. Conversely, academic

researchers increasingly rely on funding

from private firms and corporations to

supplement their typically limited

academic funding.

Academic departments are also

aware of the pressure to develop robotic

applications that eventually see the light

of day, as opposed to a short-lived

appearance on the Web or as a

reference in an academic journal.

Academic programs in robotics are

judged in part on the placement success

of their graduates in industry, which

adds pressure on programs to produce

graduates with knowledge and skills

applicable to commercial products.

The take-away for you is that, as an

independent robotics innovator, you can

Mind / Iron

by Bryan Bergeron, Editor

Mind/Iron Continued

6 SERVO 09.2007

Mind-FeedSep07.qxd 8/8/2007 6:52 PM Page 6

Dear SERVO:

I read Pete Miles reply in the July

SERVO about the problems of using

infrared beacons in the house and wanting

to offer another approach.

I use RobotBASIC to develop a

complete house navigation simulation

using infrared beacons. It works

perfectly, mainly because I used a very

different approach. (Note: If you are not

familiar with RobotBASIC, please see my

article in the June issue).

The assumption in the simulation was

that I had 10 or so beacons (each with a

unique ID code) that could be turned on by

remote control (BlueTooth, for example).

The program used a computer

science data structure called a graph that

essentially provided a map of the house.

When the robot was requested from any

given room, the program checked the map

and turned on the beacons one at a time,

in the proper order, allowing the robot to

move (using the shortest path) from

where it was to where it wanted to go.

The simulation involved a complex

floor plan and demonstrated how simple

navigation can be if only some

manufacturer would provide a beacon

detector, and several beacons (that perhaps

look like smoke detectors) each with their

own ID code that could be set with DIP

switches. Since beacons could be placed

throughout the house (probably primarily

over doorways) they do not need to be

extremely powerful ... typically, they would

only need to be detectable from 15-20

feet. In the rare cases where that was not

enough, two beacons could be used to get

through a room or a hallway.

The point is, I believe infrared

beacons can provide an extremely

easy-to-use, economical way for hobbyists

to navagate a complex environment. My

simulation would even go around objects

found to be blocking the path and then

resume movement toward the beacon.

Of course, most microcontroller-based

robots would not have the memory or math

ability to deal with the graph data but the

new version of RobotBASIC (2.0) provides a

built-in protocol that allows all the standard

simulation commands to control a real robot

over a wireless link. This means even small

robots now have the ability to be controlled

by a complete, powerful language giving new

life to the goal of AI in small machines.

Hmmm ... looks like I rambled some,

but I am very proud of the capablities of

RobotBASIC and I think it opens many

doors to more intelligent control that

have been overlooked because of previous

limitations imposed by the required use of

simple microcontrollers.

John Blankenship

Dear SERVO:

This correction refers to Tom Carrolls

article on robotic arms. The following

statements are incorrect: the advantage

of using R/C servos is the positional

feedback; potentiometric feedback, as in

R/C servos allow the controlling computer

to know where each joint is positioned.

There are no feedback mechanisms

built into any standard servo today, with

the exception of the AX-12+ and a few

specialized servos used in Biped type-robots.

Alex Dirks, CrustCrawler

benefit from aspects of both

commercial and academic approaches.

Before beginning your next robotics

project, consider how youd approach

design and development from a

commercial and then academic

perspective. Certainly, you want to

learn something from everything you

do, but if youre looking at making

your innovation applicable to a larger

audience, then you have to consider

the business issues in component

selection, design, potential sales

volume, and follow-on products.

When considering component

selection, it helps to imagine that

youre building, say, 5,000 robots.

Suddenly, a few cents for a component

or the cost of an added square

centimeter of pc board or aluminum

chassis makes a big difference in overall

cost. Sensors and other components

that are just good enough for your

application may not be pushing the

technology envelope, but customers

wont care if the robots work as

advertised. Conversely, a new

microprocessor might be more

expensive to install initially, but

incorporating it in your design will give

you a chance to learn about the device,

and may provide a growth path for

add-ons. The bottom line is that, with a

combined approach, your robotics

innovations can be both technologically

and financially sound. SV

SERVO 09.2007 7

Mind-FeedSep07.qxd 8/8/2007 6:52 PM Page 7

8 SERVO 09.2007

Research Seeks Human-Like

Movement

Robots are not generally known

for smooth movement and gentle

touch, but Oussama Khatib, a

computer science professor at

Stanford (www.stanford.edu) and a

participant in the Honda Humanoid

Robot Project, is trying to fix that.

Conducting a study of several

college students and a visiting Chinese

tai chi master, the professor noticed

that humans instinctively move so as

to minimize effort and discomfort

(such as how students throw their

beer cans and pizza boxes on the floor

rather than getting up and walking

over to the trash can). So, rather than

generating a slew of complicated

trajectory-computation algorithms, he

is taking an approach based on simply

minimizing the energy the robot uses

for a particular task.

Smooth movements should use

less energy than jerky ones, so

the concept sounds valid (as long

as the robot doesnt decide to just

switch himself off). So far, StanBot

is a prototype that exists only as

a computer simulation. But in a year

or so, Khatib hopes to incorporate

his concepts into one of Hondas

ASIMO units. Eventually, with this

type of programming, it should be

able to iron clothes and pick up the

trash for us.

Machine Has Adaptable Gait

Last year, RunBot developed at

the University of Gttingen (www.

bccn-goettingen.de), the University

of Glasgow (www.gla.ac.uk), and

the University of Stirling (www.stir.

ac.uk) gained renown for becoming

the worlds fastest two-legged robot

(relative to its size). It moves along at

3.5 leg lengths per second, which

translates into 0.8 m/s or roughly

1.8 mph. The trick is that it walks

using just a few sensors and detects

only when a foot touches the ground

and when a leg swings forward,

mimicking the way control reflexes

work in humans.

Originally, RunBot just trotted

around in a circle, on a flat surface.

(A couple amusing mpeg videos

are accessible at www.cn.stir.ac.uk/

~tgeng/research.html) Now the 30

cm device has been fitted with an

infrared eye that detects a slope in

its path and automatically adjusts it

gait. Like a human, it leans forward

slightly to adjust for an uphill grade

and takes shorter steps. In its first

attempt to climb a hill, it fell over

backwards, but the control circuits

managed to learn from the experience

and did well after that.

Upgraded UAV Deployed

On a more menacing note, the US

Air Force Air Combat Command

(www.acc.af.mil) recently announced

that a new UAV, the MQ-1 Reaper (as

in grim), is ready for deployment in

Afghanistan soon. Larger (3,700 lbs,

66 foot wingspan) and more powerful

than the better known MQ-1 Predator,

it can fly at 300 mph, reach altitudes

of 50,000 feet, and carry payloads up

to 3,750 lbs.

The $69.1 million craft is designed

to attack time-sensitive targets and hit

them primarily with gravity bombs, but

it can also be fitted with Hellfire mis-

siles and some other things that could

spoil your day. A secondary mission is

to perform intelligence, surveillance,

and reconnaissance duties, using

sensors to send real-time data to com-

manders and intelligence specialists.

The MQ-9 isnt truly robotic at this

point, as it requires a crew of two

Oussama Khatib and a mechanical

pal. Photo courtesy of

Stanford University.

RunBot has been upgraded to deal

with sloped paths. Photo courtesy

of Bernstein Center for

Computational Neuroscience.

The MQ-9 Reaper UAV is ready

for action. Photo courtesy of USAF

Air Combat Command.

by Jeff Eckert

Robytes.qxd 8/7/2007 3:53 PM Page 8

(pilot and sensor operator). But at

least they sit at a remotely located

ground control station.

Eurobot Passes Tests

Under development since 2003 by

the European Space Agency (ESA,

www.esa.int), the multijointed

(seven joints plus one end effector

and camera per arm), three-armed

Eurobot has undergone operational

testing in the Neutral Buoyancy Facility

of the European Astronaut Centre

in Cologne.

In the trials, the wet model

which is similar in size and

configuration to the planned space

flight model was checked for its

ability to move and manipulate

objects, provide coordinated multi-

arm movement, and recognize

obscured targets. By all accounts, the

tests went very well.

According to Philippe

Schoonejans, the Eurobot project

manager, Not only has it been

demonstrated that Eurobot can

walk around an orbital station

autonomously and safely, using no

more than the existing EVA handrails,

it is also becoming clear that Eurobot

can really help the astronauts. And

in the next phase, we also plan

to demonstrate its use on a

planetary surface ...

Tuabot Aids Breeding

Research

Meanwhile, down in laid-back

New Zealands Stephens Island, a

robotic lizard is helping to preserve

the tuatara species by pretending

to be an available bachelor. The

creatures have been around for 200

million years, so it would seem

that they have this breeding thing

under control. Nevertheless, Victoria

University (www.vuw.ac.nz) post-

doctoral student Jennifer Moore

(actually a Michigan native) wants to

understand how males establish

dominance and attract females. Enter

Robo-Ollie, made from a cast of a

recently departed real lizard known

as Oliver.

The rubber-skinned creature runs

off a nickel-cadmium battery and tries

to imitate the aggressive behavior

typical of male tuataras. Ollie cant

actually walk around, but he can

move his head. He didnt do all that

well in initial trials, as he just bobbed

his head, which turned out to be

a female signal. He was then

reprogrammed to open his mouth and

gape, which apparently irritates other

males to no end. Among real tuatura,

this degenerates into puffing (which

Ollie hasnt learned yet) and all-out

warfare in which the reptiles often

lose their tails.

About 75 percent of the males

turn out to be lonely losers, and the

other 25 percent get to produce all of

the young. As one might expect, the

winners tend to be the largest

individuals, some of which can be

90 years old. Moore suspects that

smell could play a role in the mating

process, so research continues. SV

Robyt es

Eurobot is lowered into the Neutral

Buoyancy Facility for operational

concept testing. Photo courtesy of ESA.

A robotic version of this tuatara will

mimic the real thing to help researchers.

Photo courtesy of Ohio University

Research (www.research.ohiou.edu).

SERVO 09.2007 9

HobbyEngineering HobbyEngineering HobbyEngineering HobbyEngineering

The technology builder's source for kits, components, supplies, tools, books and education.

Robot Kits For All Skill Levels

Motors, Frame Components

and Scratch Builder Supplies.

ICs, Transistors, Project Kits

BEAM Kits and Components

Books and

Educational K

Most orders ship the day received! World-wide shipping. Convenient payment options.

Order by Internet, phone, fax or mail.

www.HobbyEngineering.com

1-866-ROBOT-50

1-866-762-6850

1-650-552-9925

1-650-259-9590 (fax)

sales@HobbyEngineering.com

180 El Camino Real

Millbrae, CA 94030

Visit our store near SFO!

Robytes.qxd 8/7/2007 3:54 PM Page 9

10 SERVO 09.2007

The 2007 Unmanned

Vehicle Show

The Unmanned Systems North

America arguably hosts the largest

robot, drone, and UV hardware

showcase and information exchange

in one place at one time. This

years extravaganza transformed the

Washington Convention Center in DC,

August 6th through the 9th. The event,

growing year after year for 35 years,

was the biggest thus far, according to

an AUVSI media release.

This years event sponsored by

Honeywell, Northrop Grumman, AAI

Corp., the Air Force Research Lab at

Tyndall AFB, EADS North America, the

Israel Aerospace Industries LTD,

NovAtel, and SpaceAge Control

hosted more than 200,000 square feet

of research and military robot vehicles.

The UVs conquered the Convention

Center, making it their own for four

days of presentations, speeches, techni-

cal sessions, and up-close examinations.

Airborne, water-treading, and

land-roving robots shared the stage

with representatives from the Army

Special Ops, Naval Meteorology

and Oceanography Command, The

Defense Science and Technology

Agency in Singapore, and other offices,

commands, and branches.

Details, Details

An audience of some 4,000 inter-

ested observers the world over flocked

to Washington to get a gander at the

latest trends in UVs. Visitors included

members of academia, representatives

of foreign governments, and industry

leaders and decision makers, according

to AUVSI.

Attendees were filled to the

brim with new technology briefings

and operational reports and live

UV exhibits. They were offered a

glimpse into the future in the form

of a live operation show at Webster

Field near Patuxent River Naval

Air Station in St. Inigoes, MD where

UVs trampled the ground, took flight,

and flaunted their larger-than-life

capabilities.

From Beyond the

Shadows, it Sees!

UVs making a showing at the

2007 AUVSI event (present in 2006, as

well) included AAI Corporations

Contact the author at geercom@alltel.net by David Geer

AUVSI UV Sampling

The Association for Unmanned Vehicle Systems International (AUVSI) the largest non-profit

globally that is dedicated to unmanned systems hosted its annual Symposium in August

2007. AUVSI members trek the world making their way to this event, packing their UV wares

and showing them for government organizations, industry, and academia.

AUVSI Symposium 2006 show room with UVs on display.

Geerhead.qxd 8/7/2007 3:56 PM Page 10

GEERHEAD

Shadow 200 Tactical Unmanned

Aircraft Systems (TUAS) an

intelligence, surveillance, and recon-

naissance UAV.

During its average six hour journey,

the 11 foot plane (14 foot wing

span) collects target data via its

EO/IR (Electro-Optical/Infrared Remote

Sensing) payload. The EO/IR data is

transmitted back to a US Army brigade

tactical operations center (ground

control) within 125 kilometers range

via wireless technology.

The UAV takes flight from a

hydraulic launcher and trailer. The

TUAS has been in active duty in Iraq

since 2003.

Yes, its a Hauling

MULE

Lockheed Martins Multifunction

Utility, Logistics, and Equipment

(MULE) robotic vehicle uses a 6 x 6

independently articulated suspension

and in-hub wheel motors for each of six

wheels. The MULE is the most mobile

vehicle in otherwise impassable terrain,

largely due to its unduplicated suspen-

sion system and independent wheel

configuration.

The MULE vehicle is a hefty (2-1/2

ton) Unmanned Ground Vehicle (UGV)

designed to aid foot soldiers so they

dont have to carry heavy packs and

artillery on their backs.

The MULE will include a mobile

carriage atop a single chassis, an

autonomous navigation system, a

remote control unit, and three varia-

tions on the payload configuration,

depending on each MULEs application

and mission.

The Autonomous Navigation

System (ANS) gives the MULE the capa-

bility to follow other MULEs in a pack

or to move in a partially autonomous

fashion with the guidance of the

remote control unit.

The MULE can be transferred

by air in a sling beneath a rotorcraft

(helicopter).

The MULE is configurable in a

number of ways including a line-

of-sight, gun mount assault

configuration, an anti-tank version, and

a countermine version.

The assault configuration will

include a rapid-fire suppressive

weapon mount. This Armed Robotic

Vehicle (ARV)-Assault-Light (ARV-A-L)

configuration MULE uses an integrated

weapons and reconnaissance, surveil-

lance, and target acquisition (RSTA)

package to support the dismounted

infantrys efforts to locate and destroy

enemy platforms and positions.

The countermine MULE configura-

tion will provide the capability to find,

mark, and neutralize anti-tank mines

using a mine detection package.

The MULE can carry (obviously,

SERVO 09.2007 11

The Lockheed Martin MULE Unmanned Ground Vehicle appeared at

the AUVSI Symposium 2006 with sensors mounted atop.

(The 2007 photos were not available at press time.)

The Shadow is AAI Corps UAV with sensing for intelligence, surveillance,

and recon missions. The shadow (blue) is seen aboard a field hydraulic

launching unit, which sends it airborne.

Geerhead.qxd 8/7/2007 3:57 PM Page 11

12 SERVO 09.2007

given the acronym) equipment and

supply payloads sufficient for two

squads of infantry men and women. It

can carry up to 2,400 lbs of rucksacks

and equipment for foot soldiers

and follow those soldiers into the most

difficult terrain.

The MULE can also transport

evac and rescue operations; it is

extendable via reconfigurable side rails

to support a number of other mounts

and applications.

Heavens on Fire?

The Fire Scout UAV from Northrop

Grumman is an unmanned intelligence

and targeting helicopter with missile

weapons mounts.

Payloads include an EO/IR/LD

(electro-optical/infrared/laser designa-

tor) BRITE Star II sensing, a UHF/VHF

radio communications relay, a COBRA

mine detector, and an airborne com-

munications package. The BRITE Star II

system which offers optics, infrared,

and laser rangefinder sensing comes

with the basic model Fire Scout.

The flying heli-robot can be

launched and flown up to 110 nautical

miles from the launch site. The UAV is

controlled by tactical control system

(TCS) software from land or sea-going

vessels. The Fire Scout can remain

airborne for eight-hour missions. The

UAV is equipped with a four-blade

rotor system and state-of-the-art airfoil

blades, which help it to achieve its

longer flights.

The UAV is the first airborne robot

to land vertically on a sea-borne vessel

without a human pilot onboard.

The UAV can also use its Vertical

Take Off and Landing Tactical

Unmanned Aerial Vehicle (VTUAV)

technology to help extend communica-

tions range and capabilities. It does

this in tandem with ground control

stations, other air vehicles, data links,

remote data terminals, and tactical

communications hardware, according

to a source from Northrop Grumman.

Basically, it helps create a communica-

tions relay between these systems and

the robotic air vehicles using them in a

way not dissimilar to nodes that extend

the signal on a wireless network.

A VTUAV system will consist of

air vehicles, ground control stations

(GCSs), modular mission payloads

(MMPs), data links, remote data

terminals (RDTs), launch and recovery

equipment, and tactical communica-

tions equipment.

GEERHEAD

The Northrop Grumman Fire Scout appears with four-blade rotors,

weapons mounts, and sensor module.

The American Dynamics BattleHog

UAV on display at the 2006 AUVSI with

nose, wings, wheels and landing gear,

sensors (black), and special high torque

aerial lift for flight enclosed in the

center of the vehicle.

The BattleHog100x has a Turbine

Powerplant in the rear center of the

main trunk or shaft of the vehicle.

Forward from that is the HTAL vertical

lift and control system. Each wing, left

and right, houses fuel tanks and service

access for maintenance.

The main housing holds the center

fuel tank. Each wing has a payload

pylon for rocket launchers. Ruggedized

avionics, front and center, help fly

the plane. A modular mission payload

bay forward from that house the

sensing module.

BATTLE HOG!

Geerhead.qxd 8/7/2007 3:57 PM Page 12

Calling Hogs Into

Battle

The BattleHog100x Advanced

VTOL (Vertical Take-off and Landing)

Fixed-Wing UAS (Unmanned Aircraft

System) from American Dynamics

Corporation appeared at the 2006

AUVSI symposium.

The land or sea operations UV

flight system is an all-operations

platform for intelligence gathering,

area surveillance, recon, and targeting

(ISR&T) field missions, making it

attractive to all military cores. When

speaking of the system, were talking

about three BattleHog UAVs plus

ground control and data link communi-

cations technologies.

The BattleHog gets lift and even

navigation from its patented High

Torque Aerial Lift (HTAL) technology.

Through the HTAL, the BattleHog

can go straight up like a helicopter,

hover in a stationary position, and fly

horizontally (in fixed wing flight).

The craft can be fitted with

AGM-114K Hellfire missiles, Hydra-70

rockets, and an M134 Minigun

(7.62 mm shells).

The basic payloads include

EO/IR/LD sensing modules. The

BattleHog can also be outfitted with a

miniSAR (Synthetic Aperture Radar)

system, and environmental sensors

such as biological, chemical, and

meteorological apparatus. Payloads

can be reconfigured in the field

between operations.

BattleHog communications tech-

nologies include a CDL STANAG 7085

line-of-sight data link for forward

link (uplink) command and control,

telemetry, flight imagery data, and

payload image transmission return link

(a SATCOM satellite communications

data link is optional to ensure

communications beyond line-of-sight).

Why are so many companies

suddenly building unmanned vehicles?

Simple: congress has mandated that

one third of all military vehicles be

robotic by 2015. Not only is that

good for soldiers but it is certainly

good for established and emergent

defense contractors! SV

GEERHEAD

The AUVSI website

www.auvsi.org

AUVSI Symposium site

http://symposium.auvsi.org

Northrop Grumman site

www.northropgrumman.com

Lockheed Martin site

www.lockheedmartin.com

AAI Corp site

www.aaicorp.com

American Dynamics Corp site

www.americandynamics.us

RESOURCES

SERVO 09.2007 13

P

erform proportional speed, direction, and steering with

only two Radio/Control channels for vehicles using two

separate brush-type electric motors mounted right and left

with our mixing RDFR dual speed control. Used in many

successful competitive robots. Single joystick operation: up

goes straight ahead, down is reverse. Pure right or left twirls

vehicle as motors turn opposite directions. In between stick

positions completely proportional. Plugs in like a servo to

your Futaba, JR, Hitec, or similar radio. Compatible with gyro

steering stabilization. Various volt and amp sizes available.

The RDFR47E 55V 75A per motor unit pictured above.

www.vantec.com

STEER WINNING ROBOTS

WITHOUT SERVOS!

Order at

(888) 929-5055

Geerhead.qxd 8/7/2007 3:58 PM Page 13

14 SERVO 09.2007

T

o do this, we will examine

gradient descent learning

using the delta rule and will

teach a three layer network using

a technique called backpropagation.

And finally, we will implement

this program on a PIC16F877A

microcontroller with a serial connec-

tion and LEDs.

Linear Separation

The perceptron we programmed

last time is capable of learning a variety

of different classification tasks but is

ultimately limited due to its linear

activation function. The easiest way to

visualize this is to imagine input pairs

as points in two-dimensional space. For

example, the inputs to a logical AND

gate could be plotted as the x,y sets:

(1,1), (1,0), (0,1), (0,0). We want the

neuron to classify these points based

on whether they are true or false

according to AND logic. If we plot the

four points, we see that we can easily

draw a single line across the graph

between the points that should output

true and the points that should output

false (Figure 1). This means the prob-

lem has a linearly separable solution;

we can draw one straight line between

classifications in the solution space.

The XOR logic function is a

classic example of a problem which

is not linearly separable and, which

consequently, the perceptron is

incapable of solving. An XOR gate

has the following truth table:

X Y Output

1 1 0

1 0 1

0 1 1

0 0 0

by Heather Dewey-Hagborg

In Julys column, we looked at perceptrons the first and simplest incarnation of a neural

network algorithm. We discussed artificial neurons and their constituent parts: inputs, bias,

weights, activation, threshold, and output. We implemented a simple neuron on a

PIC16F877A microcontroller programmed in CCS C which was capable of learning the AND

logic function through gradual weight adjustment. This month, we will build upon this

knowledge to create a multi-neuron learning system called a feedforward neural network.

DIFFERENT

BITS

DIFFERENT

BITS

NEURAL NETWORKS FOR THE PIC MICROCONTROLLER

PART 2 BACKPROPAGATION

FIGURE 1. Linear separation of

the AND function.

FIGURE 2. The XOR function is linearly

inseparable.

DifferentBits.qxd 8/7/2007 12:06 PM Page 14

In Figure 2, you can see that it is

impossible to draw a single line

separating the true from the false

output classifications for this problem.

In order to solve the XOR function, we

need multiple layers of neurons, and

in order to teach multiple layers of

neurons, we need backpropagation.

Gradient Descent

Learning

Before we delve into backpropa-

gation, we are going to look

at two techniques which have

allowed neural networks to develop

finely-tuned error measurement:

continuous activation functions and

the delta rule. Together these

techniques allow for an intelligent

learning technique called gradient

descent learning.

With our perceptron, we used a

linear, hard-limiting activation function.

This means that we picked a strict

threshold and decided every output

above the threshold would output high

and every output below the threshold

would output low. With multi-layered

neural networks, we are going to

use a form of sigmoidal (s-shaped),

non-linear activation called the logistic

function:

activation = 1.0 / (1.0 +

exp( - input sum))

In other words, each individual

neuron is activated to 1 / 1 + the

exponential function of the negative

sum of all its inputs. For example, lets

look at a neuron with two input

weights: w0 with a value of .3 and w1

with a value of .65. If both weights are

connected to input values of 1,

the neuron activation will be computed

as follows:

input sum = (input0 * weight0) +

(input1 * weight1)

input sum = (1 * .3) + (1 * .65) = .95

activation = 1.0 / (1.0 + exp ( - .95))

activation = 0.721

If both inputs were activated to

values of 0 instead of 1, the activation

equations would look like this:

input sum = (0 * .3) + (0 * .65) = 0

activation = 1.0 / (1.0 + exp ( 0 ))

= 0.5

As you can see, the logistic

activation function normalizes values

around a center point of 0.5.

Now that we have a continuous

learning function, we can think of

neural network error as a curve in

two-dimensional space and use the

delta rule to minimize error during

each learning iteration. We dont

need to get too far into the mathe-

matical details here, just imagine

that the error curve is made up of

points from every possible configura-

tion of network weights, and gradient

descent is the slope of different

portions of this curve. With each

learning iteration, we want to

minimize our error by changing

individual neuron weights in the most

beneficial direction, and we can do

this by using the delta rule.

Simply stated, the delta rule choos-

es the direction of traversal on the

error curve which most rapidly reduces

our error. The delta rule formula is:

change in weight =

learning constant * (desired output

actual output) * f(x) * (1-f(x))

where f(x) is the logistic activation

function described above.

Feedforward

Now that we have an activation

function and a learning function, we

are ready to assemble our network. In

order to solve the XOR problem, we

need two inputs, one output, and four

hidden neurons plus one bias neuron

on both the input and hidden layers.

The network representation is shown

in Figure 3.

From the diagram, you can see

how network layers of nodes and

connections easily translate into arrays

of activation and weight values in our

C program.

These networks are called

feedforward because activation flows

through in a forward direction from

inputs to hidden and finally output.

Feedforward networks can have any

number of inputs, outputs, and hidden

neurons, but for the XOR example, this

is all we need.

We calculate the output of the

network by feeding activation from

input to output. For example, if we

start with input 0 = 1 and input 1 = 0,

we would begin by calculating the

activations of each hidden neuron as

we did above, but this time we will

include bias neurons:

hidden neuron 0

input sum = (input 0 * weight 0) +

(input 1 * weight 1) +

(bias 0 * weight 8)

activation = 1.0 / (1.0 + exp

( - input sum))

We add up our final output activa-

tion in the same way:

output activation

input sum = (hidden 0 * weight 0)

+ (hidden 1 * weight 1) + (hidden

2 * weight 2) + (hidden 3 * weight

3) + (bias 1 * weight 4)

activation = 1.0 / (1.0 + exp

( - input sum))

Propagate Back

Once we know our output

activation, we can compare it to our

desired output and adjust the weights

of the network toward this output.

Continuing our XOR example, if we

input (1, 0) we would like an output

of 1. If we get an output of .43, we

need to adjust the individual weights

to make this happen. We dont want

to adjust them too much though or

we will make it impossible to get

an output of 0 when we have an

input of (1,1), so we proceed to

tweak the weights ever so slightly

using the delta rule.

We begin by adjusting the weights

connected to the output neuron based

SERVO 09.2007 15

DIFFERENT BITS

DifferentBits.qxd 8/7/2007 12:06 PM Page 15

DIFFERENT BITS

16 SERVO 09.2007

on how far off the output was from

what we wanted. Then we propagate

this error back to the hidden neurons

and adjust the weights between the

inputs and hidden neurons based on

how much each hidden connection

was responsible for the incorrect

answer.

Lets walk through one example

from each layer, and then we will

see what this looks like in terms of

microcontroller C code.

Our first calculation is called delta

output (delta just means change in

math-speak):

delta output = output activation *

(1.0 output activation) * (desired

output output activation)

Next, we calculate delta weight

for each weight connected to the

output neuron:

delta weight = hidden activation

* delta output

Finally, we adjust the value of

the weight in question:

output weight = output weight +

(learning constant * delta weight)

We do this for each weight

connected to the output neuron. Then

we have to adjust the weights of the

connections between the input and

hidden neurons. This is a little bit

trickier because it is more difficult to

figure out how much each weight is to

blame for our error.

For each hidden neuron, we calcu-

late an error sum based on the delta

output we computed earlier, and the

weight of that neurons connection to

the output neuron:

error sum = output weight *

delta output

Next, we compute a delta hidden

for each hidden neuron just like our

delta output above:

delta hidden = (hidden activation

* ( 1.0 hidden activation))

* error sum

Finally, for each connection

feeding into the hidden neuron, we

calculate a delta weight and adjust that

connections weight value:

delta weight = input value

* delta hidden

hidden weight = hidden weight +

(learning constant * delta weight)

Microcontroller

Implementation

a. Circuit

That is really all there is to it.

Constant tweaking over a few

thousand iterations and you have

evolved yourself an XOR gate! The

CCS (Custom Computer Services;

www.ccsinfo.com) C implementation

is pretty straightforward and similar

to the perceptron implementation

from last time. The trickiest part is

keeping all the array indexes straight

and having a clear picture of the

network layout.

FIGURE 3. XOR feedforward

neural network architecture.

DifferentBits.qxd 8/7/2007 12:07 PM Page 16

Figure 4 explains how the various

array indexes map back to the network

architecture from Figure 3. I will briefly

explain the circuit layout and the code

flow, as well as parts of the program

that might be confusing.

Wire up the PIC chip and MAX233

chip (see the July column for more

detailed instructions and illustrations).

Five of the LEDs are going to form a

level meter showing us intuitively

how well the neural network is

learning. I used different color LEDS

and ordered them top to bottom from

hottest to cool (red, orange, yellow,

green, white).

The other three LEDs show us the

status of the inputs and output of our

aspiring XOR gate. I used two white

LEDs for the inputs and a green LED for

the output.

Connect the cathode (-) of each

LED through a 220 ohm resistor to

ground and connect the anodes (+) to

the following microcontroller pins:

Pin LED

D2 Error meter red

D3 Error meter orange

C4 Error meter yellow

C5 Error meter green

D4 Error meter white

B3 Input 0 white

B4 Input 1 white

B5 Output green

When you are finished, your bread-

board should look like Figure 5.

b. Code

The code is broken down into

five functions plus main (download a

copy from the SERVO Magazine web-

site at www.servomagazine.com):

get_activation receives a neurons

input sum and returns the activation

value passed through the logistic

function.

output_error receives the current

root mean square error and sets

the LEDs in the error level meter

accordingly.

output receives the current input

values and sets the input and

output LEDs.

FIGURE 4. Array maps.

FIGURE 5.

Breadboard

setup.

DIFFERENT BITS

SERVO 09.2007 17

DifferentBits.qxd 8/7/2007 12:07 PM Page 17

feedforward receives the current

input values and calculates each

neurons current activation.

train receives the current input values

and the desired output value. It calls

feedforward to activate the network

and get the output_activation. It then

measures the actual output against the

desired output and backpropagates

the error, adjusting each weight value

accordingly.

main initializes the microcontroller

settings and performs a couple quick

tests to ensure that the serial port

and LEDs are working. It initializes

random hidden and output weights

and iterates through a training loop

8,000 times or until the root mean

square error is less than 0.35 (it

usually takes about 400 iterations).

Every 50 iterations, it prints the count

and current error value. When the

loop completes, it prints how many

iterations it took, the final error value,

and loops once through an LED

display sequence demonstrating what

it has learned.

After programming, you should

see the following behavior from

your circuit:

1) The LEDS perform their startup blink

and the hi! message prints out the

serial port.

2) Initial weight values print out the

serial port, I/O lights blink and the top

LED on the error meter lights up.

3) Every 50 iterations, a count and

error measurement print out the

serial port.

4) The error level starts to fall lower;

the level meter changes accordingly.

5) After 400-8,000 iterations, the

network has learned the XOR

function (have patience!). The last

LED in the error level meter lights

up and the program performs its

ending dance.

Final Thoughts

This is a simple circuit to display

neural network principles, but the

same ideas and basic code apply to

more complex problem sets.

Experiment with the code and circuit

and try to create your own input/

output mappings. Think about what

you would like to teach a robot to

learn, and how you could modify this

code so that your circuit could learn

from experience and feedback from its

environment. Have fun! SV

Breadboard

PIC16F877A microcontroller and

programmer

20 MHz ceramic resonator with

built-in capacitors (or equivalent)

Eight 220 ohm resistors (or similar)

One 10K resistor

Eight light emitting diodes (LEDs)

One pushbutton (for reset)

RS-232 level shifter (MAX233 or

similar)

1 F capacitor (if using MAX233)

Serial cable with receive pin

available for breadboard use

BILL OF MATERIALS

FIGURE 6. Error level meter.

FIGURE 7. Input/

output display.

DIFFERENT BITS

18 SERVO 09.2007

DifferentBits.qxd 8/7/2007 12:08 PM Page 18

SERVO 09.2007 19

Full Page.qxd 8/8/2007 8:03 PM Page 19

20 SERVO 09.2007

Q

. The other day, I stumbled

across a mini Sumo kit from

Solarbotics called a Sumovore.

I was wondering if this is a good robot

kit for beginners. It looks really cool.

Jackie Butler

Dallas, TX

A

. You cant go wrong with the

Sumovore kit from Solarbotics

(www.solarbotics.com). This is

an excellent robot kit. Many people

think that BEAM (Biology, Electronics,

Aesthetics, and Mechanics) robots are

too dumb to make an effective robot,

especially a mini Sumo robot. I would

have to say they are dead wrong. This

robot can track another robot better

than any of the other mini Sumo

kits currently available on the market,

in my opinion.

Though the basic kit is not

programmable, it will stay on the mini

Sumo ring all day long, and will search

out and push any opponent on the

ring. This basic kit will produce a very

competitive robot for mini Sumo

contests. It is a little lighter than the

maximum weight for most events, but

a few lead weights can easily fix that.

If you want to program the

Sumovore robot, Solarbotics sells add-

on boards for the BASIC Stamp, Atmel

Mega8L, and PIC16F877 microcon-

trollers. With these microcontrollers,

you will be able to add just about any

motion control feature you want.

Keep in mind, this is a kit that

requires a lot of soldering. Depending

on your soldering skills, it could take

from a couple hours to a full day to

assemble. If you are not comfortable

with soldering, get some help. By the

time you are done assembling this kit,

you will be an expert at soldering.

Q

. I found an old pistol grip

soldering iron in a junk pile at

school. It gets really hot and

melts solder fast, but it is really hard to

use to solder electronic parts. The tip

can be taken off with a screwdriver.

Are there any tips that come to a

smaller point for this soldering iron?

Adam Salie

A

. There is probably a reason that

that soldering iron was in

the junk pile. These pistol grip

soldering irons do put out a lot of

heat, but they are not very good at

soldering modern electronic circuits. In

the old days when vacuum tubes

were common, they were great

tools since many of the electronic

components were soldered wire-to-

wire, component-to-component, and

on the phenolic circuit boards, the

component spacing was far and wide.

These soldering irons do work well

at soldering large diameter wires

together, and it will even solder small

brass parts together (if you use

soldering flux). It is a good tool to have

around in case you need a lot of heat.

But for circuit boards? It is too bulky,

and the soldering iron tip is too big

to solder a single integrated circuit

leg/trace.

Yes, the tips are replaceable,

but not with the fine tips needed for

routine soldering of circuits. I would

recommend that you get a basic

pencil style soldering iron that is at

least 25 watts in power and has a

replaceable fine tip for soldering your

electronic circuits.

Q

. A friend of mine gave me a

huge box of old electronic

components, like resistors,

capacitors, transistors, ICs, switches,

LED displays, etc. Some of the

RadioShack receipts in the box are

from 1976. So my question is, do elec-

tronic components go bad with age?

Bob Cook

A

. From my experience, electronic

parts generally dont go bad

when they are sitting on the

shelf not doing anything. Your biggest

problem will probably be some corro-

sion on the lead coated component

leads/wires. I personally have compo-

nents that are over 30 years old, and

they still work like a charm, and I use

them all the time. Mix and match

the old with the new. You might find it

difficult to find a data sheet for some

parts that have long become obsolete,

however.

With the electronic world moving

towards 3.3 volt electronics, those

older components may become

Tap into the sum of all human knowledge and get your questions answered here!

From software algorithms to material selection, Mr. Roboto strives to meet you

where you are and what more would you expect from a complex service droid?

by

Pete Miles

Our resident expert on all things

robotic is merely an Email away.

roboto@servomagazine.com

MrRoboto.qxd 8/7/2007 3:51 PM Page 20

valuable. I know a guy that collects

vacuum tubes and builds custom

vacuum tube amplifiers for peoples

radios and musical instruments. He

swears that the sound from vacuum

tube amps is better than what you can

get from modern digital equipment.

Q

. Where is a good place to buy

cheap electric gear motors?

Mike Coleman

A

. There are a lot of good places to

buy cheap electric gear motors,

like surplus houses and eBay. I

generally dont want to recommend

these places since inventory changes

without notice (i.e., the next time you

want the same motor, you may never

find it again), and quality is unknown

until you have it. Im not saying these are

bad places to get parts (since many of

the readers of SERVO Magazine buy

from these resources and appear to be

very happy with them). I prefer to recom-

mend places where you know you will

always be able to get the same parts.

With that said, Lynxmotion

(www.lynxmotion.com), Jameco

Electronics (www.jameco.com),

Solarbotics (www.solarbotics.com),

and the Robot Store (www.robot

store.com) are very good places to get

low cost motors. If you want some

really powerful motors, check out NPC

Robotics (www.npcrobotics.com).

Q

. I am curious to hear your

opinion on timing belt drives

vs. sprockets and chains for a

middleweight combat robot. Right

now, I am in the information-gathering

phase so I can build a winning robot.

Lynn Hickman

A

. Timing belts (or otherwise

known as synchronous belts) and

sprockets and chains will work

just fine for your robot. Performance

wise, you really are not going to notice

a difference between the two systems,

unless you under-size them. Timing belt

systems are lighter and quieter than

sprockets and chains, are not as readily

available as sprockets and chains and

are usually a little more expensive.

Finally, they usually require a little

more precision in the overall robotdrive

train construction. If you use a belt

tensioning pulley, then the precision

requirements are removed. Chain and

sprocket systems can tolerate a looser fit

and still function fully without slipping.

Choosing one drive system over

another drive system is really more of a

preference than anything else. Though

in your area of design, where weight is

paramount, the lightness of timing

belts may be well warranted.

Sprockets and chains and timing

belts and pulley components can be

obtained at Stock Drive Products

(www.sdp-si.com). They have

documents on their website that

explain how to properly size your

components and how to calculate the

center-to-center distances between the

different drive shafts. SV

SERVO 09.2007 21

HE8EJIFH;<;H>?J;9)0'

The results of an informal poll taken recently at the First

Annual World Domination Symposium are now in. Robots

prefer Hitec servos 3:1 over other servo brands. They know the wide

selection of Hitec analog and digital servos provide them with the power and depend-

ability needed to eventually take over the World. Make your robot happy, use Hitec servos.

12115 Paine Street | Poway | California | 92064 | 858-748-6948 | www.hitecrcd.com

>_j[Y

Ej^[h8hWdZ

.EW2OBOT3ERVOS

HSR-5980SG

Speed: 0.14 sec

Torque: 417 oz/in

Steel Gears

HSR-5498SG

Speed: 0.19 sec

Torque: 187 oz/in

Steel Gears

HSR-5990TG

Speed: 0.14 sec

Torque: 417 oz/in

Titanium

ALL SPECFCATONS AT 7.4 VOLTS

MrRoboto.qxd 8/7/2007 3:51 PM Page 21

No Bamboo Required

T

he animal kingdom has

been brought to life with

Robopanda from Wowwee

Robotics. Robopanda is

a fun-loving and curious

robotic friend who is

animated, talkative, playful,

and 100% interactive.

You can interact with

Robopanda in a natural way

by touching or activating

his many sensors located

throughout his body.

Standing approximately 19 inches tall, Robopanda is

equipped with lifelike behaviors and motions like that of a

genuine panda. Robopanda comes with activity and story

cartridges and is equipped with internal dual-axis

accelerometer tilt sensors. If left unattended for a couple

minutes, Robopanda will go into Sleep Mode. Robopanda

also features volume control and safety touch sensors.

Simply insert six C batteries (not included) and four AA

batteries (not included) and Robopanda is fully functional.

Robopanda (ages eight and up) comes equipped with

two activity and story cartridges and will be available

this fall for an approximate retail value of $169.99.

Additional cartridges are sold separately and will be

available soon.

For further information, please contact:

Sabertooth 2X25

S

abertooth 2X25 is

Dimension Engineerings

new high power dual 25A

motor controller. It accepts

battery voltages from 6V to

24V and will handle peak

currents of 50A per motor for several seconds. When

paired with suitable high current motors and batteries,

Sabertooth 2X25 is capable of driving around robots

weighing several hundred pounds.

The Sabertooth 2X25 allows you to control two

motors with analog voltage, radio control, and serial

modes, making it suitable for a wide variety of projects. A

built-in 5V BEC can provide power to an R/C receiver and

a selectable lithium mode will allow you to safely use R/C

LiPo battery packs.

As with Dimension Engineerings other motor drivers,

the products options are set with DIP switches and wiring

connections are made with screw terminals, making it

easy to reconfigure and move from project to project.

Sabertooths custom-designed synchronous

regenerative H-bridge topology returns the motors stored

inductive energy to the battery in every switching cycle.

This technique results in motors running cooler and

extends battery life. It also provides more responsive

control allowing you to make instant stops and reverses.

A heatsink comes preinstalled and the unit has

electronic thermal and overcurrent protection for

maximum durability.

The product retails for $124.99 at Dimension

Engineerings website, as well as other fine robotics stores.

For further information, please contact:

TReX Dual-Motor Controller

P

ololu introduces its new TReX Dual-

Motor Controller a versatile

DC motor controller suited for

mixed autonomous and radio

control of small- and medium-

sized robots. Three independent

interfaces are offered: radio control

(RC) servo pulse interface; analog voltage;

and asynchronous serial. The serial interface

can switch instantly with one of the other two interfaces,

allowing mixed autonomous and remote control.

For example, a robot could be configured to run

autonomously most of the time, but a human operator

could override the autonomous function if the robot gets

stuck or into a dangerous situation. If the serial

mode is selected as the primary interface, high-resolution

measurements of all five RC inputs are made available to

the autonomous robot controller, allowing for complex

New Products

CONSUMER ROBOTS

MOTOR CONTROLLERS

Website: www.dimension

engineering.com

Dimension Engineering

N

N

E

E

W

W

P

P

R

R

O

O

D

D

U

U

C

C

T

T

S

S

22 SERVO 09.2007

Website: www.wowwee.com

WowWee Robotics

Sep07NewProd.qxd 8/8/2007 10:12 AM Page 22

and unlimited mixing of operator control and sensor input.

The TReX motor controller operates from 6V to 16V,

and the two primary outputs provide bidirectional control

with peak currents of 30A and continuous currents of

13A, while a unidirectional auxiliary output delivers over

15A (continuous). A fourth control channel for invertible

robots allows improved control if the robot does get

turned up-side down, and the fifth control channel

determines which interface controls the motors. The unit

measures approximately 1.9 x 1.9 x 0.8, and it is

available in fully assembled or kit form starting at $99.95

at www.pololu.com/products/pololu/0777/.

For further information, please contact:

RobotBASIC

R

obotBASIC is a powerful computer language that

allows you to learn how to program a robot utilizing a

simulation that includes bumpers and infrared sensors for

avoiding collisions, ranging sensors to detect distant

objects, and ground sensors that can detect lines on

the floor and drop-offs such as stairways. It also has an

electronic compass, a GPS system, and a camera that

can detect the colors seen by the robot and navigational

beacons mounted within the simulated environment.

Since all the sensors are integrated into the language,

users can concentrate their efforts on learning to program

the robot to do interesting things instead of spending time

downloading code, adjusting sensors, charging batteries,

and other things that keep most hobbyists from doing

what they really want to do program intelligence into

their machine.

In the new release (2.0), RobotBASIC provides

support for real-world control via parallel and serial ports,

USB, and a built-in robot protocol for BlueTooth. The new

protocol is easy to use yet flexible enough to allow you

to build the target robot using a wide variety of motors,

sensors, and other hardware.

Visit the RobotBASIC website to download a

free copy. (This is NOT a crippled copy or one that

will time-out.)

For further information, please contact:

SOFTWARE

Website: www.RobotBASIC.com

RobotBASIC

New Products

6000 S. Eastern Ave., Ste. 12-D

Las Vegas, NV 89119

Tel: 8777POLOLU or 7022626648

Fax: 7022626894

Email: www@pololu.com

Website: www.pololu.com

Pololu

Corporation

SERVO 09.2007 23

MaximumRobotics.com

1-800-979-9130

Wiring Robot Controller

Atmel ATMega 128

128k Memory

43 Digital I/O Pins

8 Analog Inputs

8 External Interupts

6 PWM Channels

2 Serial Ports including Bi-Directional USB

The Wiring Programming Language

The Wiring language provides a simplified subset of

C or C++ that hides more advanced concepts like

classes, objects, pointers (while still making them

accessible for advanced users). You get the power

of C or C++ with the ease of a language like Basic.

Programs execute at full C++ speed on the board.

$69.95

Robot Controllers

ARC1.1 Robot Controller

Atmel ATMega16

1k SRAM, 16k Flash

Dual 1.1 amp motor drives

Supports motors up to 25V

Dual quadrature encoder support

Programming cable included with kit

No additional hardware needed

Works with BASCOM and AvrDude programming software

Ideal for controlling your small robot. With a Microcontroller

and onboard motor controllers, you get all the electronics

that you need (except sensors) on one board.

Kit $37.95 / Assembled $41.95

Programmable Robot Kits

INEX MicroCamp Mega8

Atmel ATMega8

Dual DC motor drivers

2 Buttons, 2 LEDs

Serial port

5-Analog ports for sensors

+5V switching power supply

No soldering required

Supports In-system Programming via ISP connector

with included PX-400 Serial Programmer

Includes eveything you need to build a simple mobile

robot. Add your own additional sensors for even

more complex robots.

$59.95

MicroBric Viper

Screw-together Assembly

BasicAtom Microcontroller

2 motor modules

Bump sensor modules

Switch Modules

IR Remote & Receiver Module

With microbric, you can build complex electronic

devices with little or no prior electronics knowledge.

As no soldering is involved and the parts are fully

reusable, you can build and rebuild programmable

robots as many times as you like.

$89.95

Also Available:

Electronic Components

Servos

Motors

Hardware

Wheels & Tires

and More!

More New Products on the way!

Sep07NewProd.qxd 8/8/2007 10:12 AM Page 23

Know of any robot competitions Ive missed? Is your

local school or robot group planning a contest? Send an

email to steve@ncc.com and tell me about it. Be sure to

include the date and location of your contest. If you have a

website with contest info, send along the URL as well, so we

can tell everyone else about it.

For last-minute updates and changes, you can always

find the most recent version of the Robot Competition FAQ

at Robots.net: http://robots.net/rcfaq.html

R. Steven Rainwater

S Se ep pt te em mb be er r

3 DragonCon Robot Battles

Atlanta, GA

Remote-control vehicles destroy each other at a

well-known Atlanta Science Fiction convention.

www.dragoncon.org

15 BotTrot 4Bottle Race

Robot Magazine and the Robot Dreams website

have combined forces to create a robot contest

that you can enter from home. Build the course,

record a video of your robot completing it, and

submit the video by the contest date. The rules

are minimal so almost any robot can enter whether

it has wheels, legs, or tracks; whether it's

autonomous or remote-control.

www.botmag.com/articles/06-10-07_4bottle_

robot_race.shtml

18-21 US-European Micro Air Vehicle Competition

Toulouse, France

Tiny autonomous flying robots compete against each

other indoors and outdoors. The indoor mission con-

sists of flying into a 3.6 meter square room through

a window and identifying two targets while avoiding

randomly placed coat hangers. The outdoor mission

requires the robots to fly through obstacles and over

two 1.2 x 1.5 meter placards within a 1 km radius.

www.mav07.org

21-23 Robothon

Seattle Center, Seattle, WA

Lots of events including Robo-Magellan,

Micromouse, line-following, line maze solving, the

Walking Robot Contest, mini Sumo, and 3 kg Sumo.

www.robothon.org

O Oc c t to ob be er r

12-13 Cal Games

Woodside High School, Woodside, CA

This years event will be a recreation of the FIRST

Robotics 2007 Rack and Roll contest.

www.wrrf.org/Events/index.php

17-20 Russian Olympiad of Robots

Moscow, Russia

Russian robots compete in Sumo, fire-fighting,

line-following, and RoboCup events. There is also a

cross-country robot race and remote-controlled

vehicle combat to keep things interesting.

http://intronics.bogorodsk.ru

19-21 Elevator:2010 Climber Competition

Event Center, Greater Salt Lake City, UT

Autonomous climber robots must ascend a scale

model of a space elevator using power beamed

from the base.

www.elevator2010.org

21 Chibotica

Donald E. Stephens Convention Center, Rosemont, IL

Chibotica returns with even more events: maze

solving, line-following, mini Sumo, Robo-One, a robot

talent show, and remote-controlled vehicle combat.

www.chibots.org

26-28 Critter Crunch

Hyatt Regency Tech Center, Denver, CO

Held in conjunction with MileHiCon. See robot

combat by the folks who invented robot combat

competitions.

www.milehicon.org

26-28 Korea Intelligent Robot Contest

Pohang Indoor Gymnasium, Pohang City, Korea

Several events are planned for autonomous robots

including Micromouse, MIROzSOT games, and

intelligent robot demonstrations.

http://irc.piro.re.kr

Send updates, new listings, corrections, complaints, and suggestions to: steve@ncc.com or FAX 972-404-0269

24 SERVO 09.2007

Events.qxd 8/8/2007 10:09 AM Page 24

Full Page.qxd 8/8/2007 8:08 PM Page 25

Featured This Month

Participation

26 Table Saw Safety

by Kevin Berry

27 Club Corner by Chris Olin

Feature

27 Battery Pack Construction

by Ray Billings

Technical Knowledge

30 *******Aided Design

by Kevin Berry

Events

30 Results Jun 11th - Jul 15th

33 Upcoming Sept & Oct

Software Review

32 ExpressSCH v5.6

by Jay Johnson

W

hether you are

roughing out a

design using wooden

mockups, cutting plas-

tics, or even working

metal, most builders

wind up using a table

saw. Even if you meticu-

lously follow all safety

rules , this is still one

dangerous piece of

equipment. Besides all the

standard rules you learned in

shop class, you need to follow

some specialized ones when

using this beast.

One discussion I hear a lot

is the gloves/no gloves

debate. Most feel that gloves

limit your feeling for whats

happening, are likely to snag

and pull your hand INTO

the blade, and dont

provide any protection

anyway. I must confess, I

wear gloves when cutting

metal that has sharp edges

or burrs, and when cutting

really splintery wood. I make sure

to have safety guards in place, use

push sticks if possible, THINK

about where my hands will go if

snagged or slipped, and then

think again if I could do without

them. Metal gets really hot on a

table saw, especially if using a

composite blade, so I often wind

up wearing them.

Another tip you might not get

in shop class: clean out the