Professional Documents

Culture Documents

FS-Thermal Barrier Foam Coating

FS-Thermal Barrier Foam Coating

Uploaded by

littlepaoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FS-Thermal Barrier Foam Coating

FS-Thermal Barrier Foam Coating

Uploaded by

littlepaoCopyright:

Available Formats

Roberge & Co (Thailand) Co.,Ltd.

SSP Tower3, 14 Fl. Unit A3, 88 Silom Rd., Suriyawong Bangrak Bangkok 10500

Tel: (66)2-634-4005 Fax: (66)2-634-4199 Email: sale@robergeandco.co.th www.robergeandco.co.th

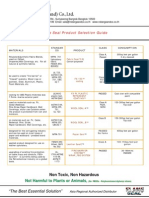

FLAME SEAL-TB™ - THERMAL BARRIER FOAM COATING

Coating Passed UL-1715 test specifications at Intertek Laboratory

on Polyurethane Foam (Less than 18 mils...Thin Film "Paint-On" Coating)

RECOMMENDED USE: Total Solids: 61% - 66%

"FLAME SEAL-TB™ FIRE BARRIER COATING" - CLASS A: Weight per Gallon: 10.8 lbs.- 11.2 lbs.

thermal barrier intumescent coating, designed for use over

Polyurethane Foam Insulation. Application may be accomplished by Specific Gravity: 1.3 - 1.4

either brush, roller, or spray methods. Blend well in original

container before use, as some solids may settle on the bottom of the

pH: 2.5 - 3.5

container. Mix with T50-TB™ curing agent at a mix ratio of 4:1 (4

parts FLAME SEAL-TB™ resin to 1 part T50-TB™ by volume. Ex:

4 gallons FLAME SEAL-TB™ + 1 gallon T50-TB™) Mix thoroughly Flash Point: None

with low-medium speed mixer for 5 minutes. The coverage rate

should be 65 square feet per gallon. (See Intertek UL-1715 Test Color: White

Report) This product recommended for Interior use only.

65 Square Feet-Gallon

Coverage:

Compliant with FDA/USDA for incidental food contact. Volatility: Non-volatile

This product complies with U.S. Federal Regulations

concerning the use of lead in paint AND hydrocarbon Water (Contains no petroleum

Solvents:

emissions. derivatives)

Toxicity: Non-toxic

Fungus Resistance: Good

Mold Resistance: Good

Bacteria Resistance Mildly resistant

Linear Shrinkage: None

Moisture

None

Absorption:

Corrosive: Mildly, none when dry

FLAME SEAL-TB™ COATING is mixed with T50-TB™ CURING AGENT (both arrive in correct mixture ratios)

Non Toxic, Non Hazardous

Not Harmful to Plants or Animals, (No PBDEs - Polybrominated diphenyl ethers)

“The Best Essential Solution” Asia Regional Authorized Distributor

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ASC Roof Deck Design GuideDocument42 pagesASC Roof Deck Design Guiderhonald2000No ratings yet

- HL770 9SDocument570 pagesHL770 9SAnonymous yjK3peI788% (24)

- Watercolour Lesson BookDocument38 pagesWatercolour Lesson BookIan50% (2)

- Innovatum DLP WPDocument9 pagesInnovatum DLP WPlittlepaoNo ratings yet

- LH Series Flight Helmet Instruction Manual PDFDocument14 pagesLH Series Flight Helmet Instruction Manual PDFRadunNo ratings yet

- How To Mothball and Decommission Industrial PlantsDocument4 pagesHow To Mothball and Decommission Industrial Plantswholenumber100% (2)

- FX-100 Fire Retardant CoatingDocument1 pageFX-100 Fire Retardant CoatinglittlepaoNo ratings yet

- FX-100 Application Method Catalog1Document1 pageFX-100 Application Method Catalog1littlepao100% (2)

- Paper SealDocument1 pagePaper SeallittlepaoNo ratings yet

- FX-100 Fire Retardant Coating CatalogDocument1 pageFX-100 Fire Retardant Coating Cataloglittlepao100% (2)

- FX-100 Application Method Catalog1Document1 pageFX-100 Application Method Catalog1littlepao100% (2)

- FS Paper SealDocument1 pageFS Paper Seallittlepao100% (2)

- FS-Fabric N CatalogDocument1 pageFS-Fabric N CataloglittlepaoNo ratings yet

- Fs ConcentrateDocument1 pageFs ConcentratelittlepaoNo ratings yet

- FS-Fabric Application CON DILUTIONDocument1 pageFS-Fabric Application CON DILUTIONlittlepaoNo ratings yet

- Flame Seal Product Selection GuideDocument1 pageFlame Seal Product Selection GuidelittlepaoNo ratings yet

- Ma So NiteDocument1 pageMa So NiteBoris LazicNo ratings yet

- Royale Neu 2017 Final ArtworksDocument16 pagesRoyale Neu 2017 Final Artworksrajath96No ratings yet

- Damp Protection Method StatementDocument5 pagesDamp Protection Method Statementalfaaleem_1830No ratings yet

- Zinc It 2085 TdsDocument3 pagesZinc It 2085 TdsajuhaseenNo ratings yet

- Hardtop Optima Technical Data SheetDocument5 pagesHardtop Optima Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Enoh Paint Data SheetDocument3 pagesEnoh Paint Data SheetIbrahim ElnoshokatyNo ratings yet

- Meguiars Prospect Brochure Website SmallDocument16 pagesMeguiars Prospect Brochure Website SmallmakanculaNo ratings yet

- Cement Plaster, Pointing Work, Washing WorkDocument95 pagesCement Plaster, Pointing Work, Washing WorkEngr SwapanNo ratings yet

- 1985-Architectural-and-Urban-Conservation-A-Review-of-the-State-of-the-Art - Bernard FeildenDocument25 pages1985-Architectural-and-Urban-Conservation-A-Review-of-the-State-of-the-Art - Bernard FeildenAliNo ratings yet

- Running Bill For Construction WorkDocument5 pagesRunning Bill For Construction WorkAaron ShresthaNo ratings yet

- Selfheating and Spontaneous Ignition Spontaneous CombustionDocument2 pagesSelfheating and Spontaneous Ignition Spontaneous CombustionKhoirul WaladNo ratings yet

- Chemical Safety Data Sheet: Section 1: Chemical Product & Company IndentificationDocument7 pagesChemical Safety Data Sheet: Section 1: Chemical Product & Company IndentificationSyerifaizal Hj. MustaphaNo ratings yet

- Mcqs For Basics Civil EngineeringDocument44 pagesMcqs For Basics Civil EngineeringWasim KhanNo ratings yet

- THIXATROL GST Coatings Specialities I LTDDocument2 pagesTHIXATROL GST Coatings Specialities I LTDManoel Caetano DamascenoNo ratings yet

- Piopoxy AF Tie Coat - TDSDocument2 pagesPiopoxy AF Tie Coat - TDSIsabelo AbaoNo ratings yet

- Measurement of Adhesion StrengthDocument4 pagesMeasurement of Adhesion StrengthVirgilio Cabato, Jr.No ratings yet

- Cemcoat PuttyDocument2 pagesCemcoat Puttyosama mohNo ratings yet

- Welding Products CatalogueDocument12 pagesWelding Products CatalogueEko Setyo BudiNo ratings yet

- Wattyl Killrust Brochure 2Document6 pagesWattyl Killrust Brochure 2Tech 84No ratings yet

- Enhancing Titanium Dioxide: With Calcium CarbonateDocument8 pagesEnhancing Titanium Dioxide: With Calcium CarbonateLong An DoNo ratings yet

- CBDD Standard Paint Spec (With SW Data)Document5 pagesCBDD Standard Paint Spec (With SW Data)lightsonsNo ratings yet

- A.M.C. Akola Street Light 4 RoadsDocument24 pagesA.M.C. Akola Street Light 4 RoadsBharat Namdeo AmbhoreNo ratings yet

- Po SM InfraDocument5 pagesPo SM InfraAvi DantkaleNo ratings yet

- Interzone 954: Modified EpoxyDocument4 pagesInterzone 954: Modified EpoxyRishiNo ratings yet

- Series NG 5000 Maintenance For PaintingDocument33 pagesSeries NG 5000 Maintenance For PaintingrohanZorbaNo ratings yet