Professional Documents

Culture Documents

Alloy Steels Nickel Cobalt Alloys

Uploaded by

Michaelben MichaelbenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alloy Steels Nickel Cobalt Alloys

Uploaded by

Michaelben MichaelbenCopyright:

Available Formats

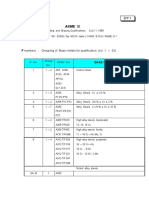

Alloy Steels, Nickel and Cobalt Alloys

SPECIFICATION GRADE TYPE OF STEEL AFNOR DIN WERKSTOFF AISI ACI AMS BS970 BRITISH/ USA 1970 EN UTS N/mm Min

ANC 1 A B C 13% Cr Martensitic Steels Z10C13 Z15C13 Z20C13 GX12 Cr14 GX2O Cr14 GX22 Cr14 1.4008 1.4027 403 420 420 CA 15 CA40 5349:5350D 410C21 420C29 BS3100:1976* 410 S21 56A 420 S29 56B 420 S37 56C 540 620 695

2

FERROUS METALS

CHARACTERISTICS AND TYPICAL APPLICATIONS

EI

IZOD

HARDNESS HB

Max

-

%

15 13 13

Ft lbs

Min

207 183 201

Max

229 255 Medium corrosion resistance and a range of strengths and hardnesses. ANC 1AChemical industry. High ductility engineering parts. ANC 1BHeat resistant parts not highly stressed. ANC 1CCutting blades, pumps, steam turbines.

ANC 2

18% Cr 2% Ni Martensitic Steel

Z22 CN 1802

GX22 Cr Ni 17

1.4059

431

CB 30

5363

S80 BS3100:1976

431 S29 57

850

1000

248

302

High tensile stainless with improved corrosion resistance. Resists oxidising atmospheres to 760C. Pumps valves, highly stressed aircraft and engineering parts. ANC 3ACorrosion and acid resistant stainless, excellent stability to 225C. Chemical, textile, dairy food industries eg pumps and valves. ANC 3BWeldable version usable up to 800C. Some exhaust and marine parts. Corrosion/acid resisting parts not heat-treated after welding. Good corrosion and acid resistance with medium tensile strength. Chemical and processing industriesvalves/pumps for acids at high temperature, chlorides and salts. Heat resistant alloys. Resistant to cyclic heating and useful creep strength up to 650C. Good resistance to scaling. Furnace parts, salt and lead baths. Heat resistant with good strength up to 900C and useful creep strength to 650C. Heat treatment parts and superheaters, welding fixtures, nozzle guide vanes for gas turbines.

ANC 3

A B

Austenitic 18% Cr 8% Ni Steels

Z12 CN 1810 Z8 CN MB 1810

GX10 Cr Ni 18.8 GX7 Cr Ni Nb 18.9

1.4312 1.4552

304 347

CF 8 CF 8C

5358:5341 5362E

304C15 347C17

302 S25 58A 347 S17 58F

460 460

20 20

ANC 4

A B C A B C A B C

Austenitic 18% Cr 10% Ni 3% Mo Steels 17.11.03 Nickel Chromium Steels

Z6 CND 19.12.03 Z6 CND 17.11.03 Z6 CND NB nb Z12 CNS 25.21 Fe N37 C18S NC15 Fe Z20 CNS 25.12 Z25 CNS W22 Z15 CNWS 22.13

GX6 Cr Ni Mo 18.10 GX6 Cr Ni Mo 18.10 GX7 Cr Ni Mo 18.10 Ni Cr 25.20 GX40 Ni Cr Si 36.16 Ni Cr 60.5 GX 35 Cr Ni Si 25.12

1.4408 1.4408 1.4581 1.4843 1.4865 2.4867 1.4837

317 316 318 310 330

CG 8M CF 8M

5524C

317C16 316C16 318C17 310C45 331C60 334C11 309C30 309C30

317 S16 58J 316 S16 58H 320 S17 58H 310 S24

500 500

12 12 12 -

ANC 5

CK 20:HK CK 20:HU CK 20:HW CH20:HF

5366B

ANC 6

Nickel Chromium Steels

309

55

460 460

17 17 17

ANC 8

Nickel 20% Cr 0.4% Ti Alloy Nickel 20% Cr 2.5% Ti 1.2% Al Alloy Nickel 20% Cr 16.5% Co 2.4% Ti 1.3% Al Alloy Nickel 21% Cr 10% Mo 10% Co Alloy Cobalt 26% Cr 10% Ni 7% W Alloy Cobalt 27% Cr 5.5% Mo 2.7% Ni Alloy Nickel 28% Mo Alloy Nickel 17% Mo 16.5% Cr 4.5% W Alloy Nickel 9% Si 3% Cu Alloy A B C Nickel 31% Cu 1-4% Si Alloy

NC20 T

Ni Cr 20 Ti

2.463

Nimocast 75* Nimonic 75* Nimocast 80* Nimonic 80*

Readily weldable heat resistant alloy. Excellent resistance to oxidation up to 1100C and with useful strength. Furnace parts.

ANC 9

NC20TA

Ni Cr 20 Ti Al

2.4631

ANC 10

NC20K17TA

Ni Cr 20 Co 18 Ti

2.4632

Nimocast 90* Nimonic 90*

ANC 11

NC21DK 10

C242

40

ANC 13

KC 25 NW

Co Cr 25 Ni W

2.4966

5382E

X40 Atellite 31

ANC 14

KD 27 DN

Co Cr 28 Mo

2.4979

5385D

Stellite 8

34

ANC 15 ANC 16

ND28FeKV NCD 16 Fe

Ni Mo 30 Ni Mo 16 Cr W

2.4482 2.4537 CW 12

5396 5388C

Hastelloy B Hastelloy C

ANC 17

Ni Si 10 Cu

2.4566

Hastelloy D

ANC 18

NU30Fe

Ni Cu 30 Fe*

2.4360*

4544*

Monel* Monel H* Monel H* PE 10 MC 102 PV 520 FV 520 1200 1250 12 8 15 8 High strength with good corrosion resistance, good weldability. Variety of strengths depending on heat treatment. Aerospace and marine parts.

ANC 19

PH Nickel-Cr Nb Mo Fe W Alloy A B PH-Cr Ni Cu Mo Steels

NC20NbDW

ANC 20

1500

ANC 21

Cr Ni Cu Mo Steel

CD 4 MCu

This list gives details of the main alloys cast but we would be pleased to discuss any other materials required. As this is intended to be a guide only, the full relevant standard specifications should be referred to when determining suitable materials for a particular product and its application.

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Valve MaterialsDocument1 pageValve MaterialsMarcel BolovedeaNo ratings yet

- Range of Supply 03 16Document12 pagesRange of Supply 03 16Ruben PauwelsNo ratings yet

- item8-LNT NiCro60.20Document1 pageitem8-LNT NiCro60.20VVan TanNo ratings yet

- FSH TigDocument105 pagesFSH TigChee WeiNo ratings yet

- Valve Spec.Document15 pagesValve Spec.koner_debasishNo ratings yet

- CorrespondanceDocument1 pageCorrespondanceAyoub BOUFTININo ratings yet

- Cross-Reference - DIN & ASTM MaterialsDocument3 pagesCross-Reference - DIN & ASTM MaterialsLightAcolyte100% (1)

- Casting Standards PDFDocument1 pageCasting Standards PDFamaestrelNo ratings yet

- Valve Material EquivalentsDocument3 pagesValve Material EquivalentsAndre Villegas Romero100% (1)

- Steel GradesDocument2 pagesSteel GradesAmit Rajmane100% (1)

- UTP For Chemical IndustryDocument12 pagesUTP For Chemical Industrykamals55No ratings yet

- Kevinsteel SA 1210Document4 pagesKevinsteel SA 1210meisamNo ratings yet

- SuperAlloy Catalog 2013Document5 pagesSuperAlloy Catalog 2013Muhammad SalehNo ratings yet

- Abreviaturas Comunes en La Industria ValvuleraDocument10 pagesAbreviaturas Comunes en La Industria Valvulerataz_007No ratings yet

- UTP Chemical GBDocument12 pagesUTP Chemical GBajaychackotecsoNo ratings yet

- Valve Material Equivalents PDFDocument3 pagesValve Material Equivalents PDFmahdi.guidara100% (1)

- Material Nach Normen: DLN, Astm,: En, BSDocument13 pagesMaterial Nach Normen: DLN, Astm,: En, BSugljevikNo ratings yet

- Mathers Foundry Steel Alloy ListDocument2 pagesMathers Foundry Steel Alloy Listعزت عبد المنعمNo ratings yet

- Tetra S 316L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra S 316L-G: Technical Data Sheet Cored Welding WirePeter TvardzíkNo ratings yet

- FontargenDocument282 pagesFontargenMIHAINo ratings yet

- 5 - Duplex Stainless Steels and Nickel AlloysDocument44 pages5 - Duplex Stainless Steels and Nickel AlloysdennykvgNo ratings yet

- Piping ComponentDocument19 pagesPiping Componentreach_arindomNo ratings yet

- Cevi UniDocument6 pagesCevi UniGoran PatekNo ratings yet

- Useful Information For The Valve IndustryDocument9 pagesUseful Information For The Valve Industryhummingbird4uNo ratings yet

- Comparison Tables Comparison of Astm Specifications and Similar Standards For TubeDocument1 pageComparison Tables Comparison of Astm Specifications and Similar Standards For Tubeazam RazzaqNo ratings yet

- COMPARISON OF MATERIAL STANDARDS FOR TUBESDocument1 pageCOMPARISON OF MATERIAL STANDARDS FOR TUBESKarthikeyan ShanmugavelNo ratings yet

- COMPARISON OF MATERIAL STANDARDS FOR TUBESDocument1 pageCOMPARISON OF MATERIAL STANDARDS FOR TUBESRaja HoneNo ratings yet

- Material EquivalentsDocument25 pagesMaterial EquivalentsAditya B. Ryanto100% (6)

- Filler Rods and Wires For Stainless Steel: Gas Tungsten Arc WeldingDocument1 pageFiller Rods and Wires For Stainless Steel: Gas Tungsten Arc WeldingKarthikeyan ShanmugavelNo ratings yet

- P Numbers: Grouping of Base Metals For Qualification (No. 1Document5 pagesP Numbers: Grouping of Base Metals For Qualification (No. 1Lim DongseopNo ratings yet

- Steel GradesDocument1 pageSteel GradesBoris TrostyanezkyNo ratings yet

- Steel Grades For GB Standard JIS Standard ASTM Standard DIN Standard PDFDocument8 pagesSteel Grades For GB Standard JIS Standard ASTM Standard DIN Standard PDFsenthilkumar100% (1)

- Aluminium SpecificationDocument2 pagesAluminium SpecificationklhlNo ratings yet

- Common Abbreviations in The Valve IndustryDocument10 pagesCommon Abbreviations in The Valve IndustryNath BoyapatiNo ratings yet

- Welding Consumable Comparison ListDocument7 pagesWelding Consumable Comparison ListMPCReader100% (1)

- Material Linde: Asme Sec Ii A B 36.10 M B 16.25 Grade ASTMDocument40 pagesMaterial Linde: Asme Sec Ii A B 36.10 M B 16.25 Grade ASTMadarshNo ratings yet

- Valve Material EquivalentsDocument8 pagesValve Material EquivalentsFabio Peres de LimaNo ratings yet

- Electrode SelectionDocument1 pageElectrode SelectionAbhishek Nag100% (1)

- Alloy Reference LibraryDocument1 pageAlloy Reference LibraryDeepakNo ratings yet

- Electrodes EquivalentDocument15 pagesElectrodes Equivalentgrameshkreddy2013No ratings yet

- FK76M E LoresDocument18 pagesFK76M E LoresFRANCONo ratings yet

- Steel Grades For GB Standard - JIS Standard - ASTM Standard - DIN StandardDocument8 pagesSteel Grades For GB Standard - JIS Standard - ASTM Standard - DIN StandardElumalai Srinivasan75% (8)

- Cold Rolled 2010 DUNAFER HungriaDocument12 pagesCold Rolled 2010 DUNAFER HungriaBeatriz RizzoNo ratings yet

- Equivalent Material Cross Valve CastDocument2 pagesEquivalent Material Cross Valve CastsviswaNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Anshuman RoyNo ratings yet

- Untitled 1 PDFDocument35 pagesUntitled 1 PDFRAVI KANT BARANWALNo ratings yet

- Consumables For Duplex Stainless SteelDocument6 pagesConsumables For Duplex Stainless SteelMohamed FaragNo ratings yet

- Standard Allowable Stress Table: Material P No. UNS No. Allowable Stress, Ksi Min. Yield Stress, KsiDocument2 pagesStandard Allowable Stress Table: Material P No. UNS No. Allowable Stress, Ksi Min. Yield Stress, KsiGospel OgwuNo ratings yet

- Indexable Inserts PCD (7°) : N N N N NDocument1 pageIndexable Inserts PCD (7°) : N N N N NGia BeNo ratings yet

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20From EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20No ratings yet

- Die Casting Metallurgy: Butterworths Monographs in MaterialsFrom EverandDie Casting Metallurgy: Butterworths Monographs in MaterialsRating: 3.5 out of 5 stars3.5/5 (2)

- Lesson 1: Cylinder and CrankcaseDocument35 pagesLesson 1: Cylinder and CrankcasefgfgffgdfgdfgfNo ratings yet

- Lesson 1: Cylinder and CrankcaseDocument35 pagesLesson 1: Cylinder and CrankcasefgfgffgdfgdfgfNo ratings yet

- 15 StartingAirSystem PDFDocument58 pages15 StartingAirSystem PDFMichaelben MichaelbenNo ratings yet

- CPCB Emission Standards For Diesel Engines More Than 800 KWDocument3 pagesCPCB Emission Standards For Diesel Engines More Than 800 KWRSNo ratings yet

- Nesam Plans PDFDocument2 pagesNesam Plans PDFMichaelben MichaelbenNo ratings yet

- Lesson 1: Cylinder and CrankcaseDocument35 pagesLesson 1: Cylinder and CrankcasefgfgffgdfgdfgfNo ratings yet

- Prices PDFDocument4 pagesPrices PDFdfgdfgdsNo ratings yet

- CPWD List 1Document0 pagesCPWD List 1Michaelben MichaelbenNo ratings yet

- 12governor PDFDocument60 pages12governor PDFMichaelben MichaelbenNo ratings yet

- What Are The Differences in High Performance Flexible Couplings For Turbomachinery?Document0 pagesWhat Are The Differences in High Performance Flexible Couplings For Turbomachinery?Michaelben MichaelbenNo ratings yet

- Price LsitDocument8 pagesPrice LsitMichaelben MichaelbenNo ratings yet

- Pricelist ChallengerDocument4 pagesPricelist ChallengerMichaelben Michaelben50% (4)

- C 10Document3 pagesC 10Michaelben MichaelbenNo ratings yet

- Latest Income Tax Slabs and Rates For FY 2013-14 and AS 2014-15Document6 pagesLatest Income Tax Slabs and Rates For FY 2013-14 and AS 2014-15Michaelben MichaelbenNo ratings yet

- Oil Gas Split CaseDocument2 pagesOil Gas Split CaseMichaelben MichaelbenNo ratings yet

- FreedomRewardz - PartnersDocument2 pagesFreedomRewardz - PartnersMichaelben MichaelbenNo ratings yet

- 07 Mathematics 2013 Scoring KeyDocument16 pages07 Mathematics 2013 Scoring KeyMichaelben MichaelbenNo ratings yet

- Pay CommissionDocument0 pagesPay CommissionMichaelben MichaelbenNo ratings yet

- C15EDocument3 pagesC15EMichaelben MichaelbenNo ratings yet

- C15EDocument3 pagesC15EMichaelben MichaelbenNo ratings yet

- Exotica Location MapDocument1 pageExotica Location MapMichaelben MichaelbenNo ratings yet

- Xel Before 2006Document4 pagesXel Before 2006Michaelben MichaelbenNo ratings yet

- Fit MentDocument0 pagesFit MentMichaelben MichaelbenNo ratings yet

- Prices PDFDocument4 pagesPrices PDFdfgdfgdsNo ratings yet

- Journal Bearing VibrationDocument6 pagesJournal Bearing VibrationEmanuel Bruno Santos100% (1)

- TNEA 2013 Information BrochureDocument38 pagesTNEA 2013 Information BrochureRajarajanNo ratings yet

- CMTN07-0014 OMT HotkeysDocument3 pagesCMTN07-0014 OMT HotkeysMichaelben MichaelbenNo ratings yet

- Xel Before 2006Document4 pagesXel Before 2006Michaelben MichaelbenNo ratings yet

- Xel Before 2006Document4 pagesXel Before 2006Michaelben MichaelbenNo ratings yet

- Xel Before 2006Document4 pagesXel Before 2006Michaelben MichaelbenNo ratings yet