Professional Documents

Culture Documents

Pop Up Camper Plans

Pop Up Camper Plans

Uploaded by

quirxiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pop Up Camper Plans

Pop Up Camper Plans

Uploaded by

quirxiCopyright:

Available Formats

BUILD AIM

Two plywood boxes, sliding one over the other, open up to make a truck camper that sleeps four

By A. S. RYAN

f you've been figuring that the cost of a truck plus a camper is a bit steep, or you're already a pickup-truck owner but the budget won't stretch to a camper, here's a collapsible plywood unit you can build yourself. Just follow the blueprint on the following pages. Opened up, this camper has over six feet of head room, lots of living space, and sleeping places for four. Closed, and lowered for minimum wind resistance, it's easy to drive, yet has enough head room to seat passengers while traveling. Removing the rear cab window makes easy access. Two bumper jacks raise or lower the upper section, and hinged sides unfold to give

two full-length bunks. Plastic side curtains button around the bunks to enclose the entire camper. How to plan yours. Make careful measurements of your truck box to determine the size of the unit you'll build. Some of the dimensions given apply only to my truck (a 1965 Dodge six-passenger pickup). Find the minimum inside height by seating the tallest in the family on a board across the wheel wells. Most truck beds have at least four feet between wheel wells. This lets you use a full sheet of plywood as the floor. Test-position all the main structural pieces after cutting. Be sure there's room to raise the tailgate. How to build it. First, lay out and cut the lower ends and side pieces, using B-B, concrete-form-grade fir plywood. Use the flattest panels you can find. Don't cut the door openings yet. To the end pieces, attach the guide strips (battens) that align the upper section for raising. Assemble the ends and the lengthwise structural pieces of " and " plywood. This is easier to do with the section turned upContinued

Raise the roof, using bumper jacks and extension supports at each end. Top door opens out, bottom door inward, to let you exit over tailgate if necessary. 162

POPULAR SCIENCE

Support raised roof inside with flip-up braces, outside with bolted-on safety brackets. Stairs and bunk supports store inside camper when not in use.

EXPANDABLE CAMPER

With roof raised, facilities in camper are readily available. Up front, Mom gets lunch going.

Set up for the night by opening out the side bunk and roof panels and bracing them with conduit. Lower braces rest on hooks that are bolted to truck.

Enclose the camper by attaching plastic or canvas curtains around side bunks. Snap buttons hold them securely. Windows open to provide ventilation. MAY 1967 163

To determine the size of your camper, measure your truck's dimensions as shown above. The standard pickup can sleep four, plus one in the cab (below). Next month, plans for kitchen facilities will show how to build a table that lowers to make a cross bunk.

side down. Use 6d finish nails and a good waterproof glue, and make sure all corners are square. Glue-nail the floor in place. Cut out a door in the lower section. Put a temporary brace across the opening (save the cutout for a door). Cut out the truck-cab access window. Attach doublers to lower sides, as shown in blueprint. Attach the fold-down sides to the lower section with five 3" hinges or a piano hinge. Put foam gaskets between the camper body and bunk sections to limit vibration, and use spring-loaded hooks to hold the sides up.

Raising the roof tree. As-

With top lowered for travel there's enough head room to sit inside camper. Six-passenger truck shown below sleeps two in its cab.

semble the roof by supporting the upper end pieces in vertical position (bracesnailed temporarily do i t ) , and glue-nailing two-by-four roof beams in place. Cover with " exterior plywood, using one full panel at center and a smaller curving panel on each side. To bend these, cut lengthwise grooves every 3/8" beginning about 1" from the edge. Make test cuts and bends on scrap. Glue-nail the panels to the end pieces and the beams. Attach the two-by-two molding at roof sides, beveled as shown in the drawing. Cut the wind-deflector crosspiece at front to fit the curve of the cab, leaving about an inch between them. Cut out the upper rear opening (saving the cutout for the door), and screw an angle iron across the top of the doorframe to stiffen it for jacking. Drill a hole in the center of the iron to receive a stud screwed into the top of the jack extension to keep it from slipping off. (A hole in one of the cleats on the

[Continued on page 209]

166 POPULAR SCIENCE

Build an Expandable Camper [Continued from page 166]

front panel does the same job.) A cross brace bolted to the jack extension keeps it vertical while it's being jacked up. The jack extension is sized to provide enough height to raise the top in position to receive the roof supports. Hinge the "-plywood upper sides to the roof molding. These open up to form a roof for each side bunk. Add weatherproofing to the inside edges of the end panels and the folding roof sections. Put two windows in each of the open-out roof sections. Be sure the windows open outward. Finishing it off. Paint the upper and lower sections before you put them together. Sand all rough edges, and countersink and putty all nails and screws. Coat the camper inside and out with an oil-base, sandable primer, and finish all surfaces with high-quality enamel. Cover the top with canvas, or fiberglass and plastic resin. Up she goes! Telescope together the upper and lower sections, and test-raise them several times. Adjust the batten guides unt i l they're nonbinding. Sand them glass smooth to aid sliding action. Hinge four one-by-two uprights (two at front, two at back) to the lower section of the camper to support the upper one in the raised position. Put catches on them to hold them in the up position. Also, fit two angleiron and block assemblies (as shown in the blueprint) to each end of the raised top. These are placed on the outside and bolted through the end walls. They provide extra bracing and act as a safety support when the top is up. When raising the top, unhook the folding sides so that the side curtain snaps don't catch on the lower section. Before placing the camper in the truck, remove the truck's rear window. Then, with a neighbor's help, lift each section onto the truck. Run four bolts through the floor and truck bed to hold it in place. Make the conduit supports to lengths that keep the foldout bunks level, and the bunk roofs sloped slightly outward (for rain runoff). Cut and sew plastic or canvas curtains to fit around the bunks, and attach them with canvas snaps. Fix up the interior to suit your needs, or follow the plans in next month's issue for outfitting the camper with storage cabinets, gas stove, sink, and icebox.

You might also like

- Bikesport Micro-Camper PDFDocument15 pagesBikesport Micro-Camper PDFviocons72No ratings yet

- Bang Olufsen Beocenter - 2 Service Manual 1Document54 pagesBang Olufsen Beocenter - 2 Service Manual 1Seb Schauer- QuigleyNo ratings yet

- Empi Sportster PDFDocument17 pagesEmpi Sportster PDFgeanmsNo ratings yet

- Houseboat $1000Document6 pagesHouseboat $1000boon1961100% (2)

- Bonnie Two SailboatDocument18 pagesBonnie Two SailboatJim96% (27)

- Sabot 8 FT Pram DinghyDocument6 pagesSabot 8 FT Pram DinghyFrenchwolf420100% (2)

- Sabot 8 FT Pram DinghyDocument6 pagesSabot 8 FT Pram DinghyFrenchwolf420100% (2)

- 05-Humble Homemade Hifi - HATT MK-VIIIDocument9 pages05-Humble Homemade Hifi - HATT MK-VIIIjns0110No ratings yet

- La 212 DiyDocument58 pagesLa 212 Diyema94mayNo ratings yet

- Ebook - Wind Power - Building A Homemade Vertical Axis Wind Turbine - Savonius Homescale VawtDocument17 pagesEbook - Wind Power - Building A Homemade Vertical Axis Wind Turbine - Savonius Homescale VawtYasser HassanNo ratings yet

- Viking Tent Frame and Cloth For The Real Viking Project, Level 1Document12 pagesViking Tent Frame and Cloth For The Real Viking Project, Level 1mono1144No ratings yet

- The Infinite Oval: Tools For WoodworkingDocument2 pagesThe Infinite Oval: Tools For Woodworkingoqab18No ratings yet

- 2021 Issue 5 Jaguar E-Type British IconsDocument102 pages2021 Issue 5 Jaguar E-Type British Iconsbalazs666No ratings yet

- Si 1927 02Document108 pagesSi 1927 02Aurelio Barrios OpazoNo ratings yet

- What Is Grid Beam?: 1.1: Bunk BedDocument10 pagesWhat Is Grid Beam?: 1.1: Bunk BedsendflowersNo ratings yet

- Panel Saw Plans: © 2005 by Robert E. Reedy All Rights ReservedDocument16 pagesPanel Saw Plans: © 2005 by Robert E. Reedy All Rights Reservedcorneliu.modilcaNo ratings yet

- Boat Data CalculatorDocument28 pagesBoat Data CalculatorKoukis PericlesNo ratings yet

- Camper Plans v1Document12 pagesCamper Plans v1Denis FaureNo ratings yet

- Chotia-460 NewManualDocument8 pagesChotia-460 NewManualErin LassleyNo ratings yet

- Extruded AluminumDocument2 pagesExtruded AluminumHomerSimsonnakisNo ratings yet

- 1940 - Mein Kampf - The Official Stalag Edition - Adolf HitlerDocument744 pages1940 - Mein Kampf - The Official Stalag Edition - Adolf Hitlerterry100% (1)

- Build A Better Stirling Engine PDFDocument15 pagesBuild A Better Stirling Engine PDFseo tolhuinNo ratings yet

- WhatIsKSS PDFDocument8 pagesWhatIsKSS PDFابو احمدNo ratings yet

- Secadora Whirpool Wed99hedw0Document100 pagesSecadora Whirpool Wed99hedw0orkys TenorioNo ratings yet

- Gokart Weight Distribution ProgramDocument3 pagesGokart Weight Distribution Programsivakrishna763No ratings yet

- Cabover Camper Framing 1Document8 pagesCabover Camper Framing 1rodriguleonel02No ratings yet

- Ludwig Sasse - Biogas PlantsDocument79 pagesLudwig Sasse - Biogas Plantsmisterx999No ratings yet

- VifacatalogDocument10 pagesVifacataloglumilanisNo ratings yet

- Best-Ever Solar Food Dehydrator Plans - DIY - MOTHER EARTH NEWSDocument30 pagesBest-Ever Solar Food Dehydrator Plans - DIY - MOTHER EARTH NEWSBunk WahisbullahNo ratings yet

- Casa Plan House PlansDocument23 pagesCasa Plan House Plansnwright_bester100% (1)

- The Christian Patriot by Norman M. ThomasDocument34 pagesThe Christian Patriot by Norman M. Thomasquakerpubs100% (2)

- Car That Runs On Tap Water - Plasma Spark - Oct 2005 - Hydrogen Fuel - Free Energy - Stanley MeyerDocument139 pagesCar That Runs On Tap Water - Plasma Spark - Oct 2005 - Hydrogen Fuel - Free Energy - Stanley MeyerGheorghe SilviuNo ratings yet

- Three-Wheeler - WikipediaDocument49 pagesThree-Wheeler - WikipediaEndhy Wisnu NovindraNo ratings yet

- My Foam Built CamperDocument132 pagesMy Foam Built CamperJeffrey WittyNo ratings yet

- Scientific American Architects and Builders Edition 1892 Jan-JunDocument218 pagesScientific American Architects and Builders Edition 1892 Jan-JunNickiedeposie100% (2)

- 30 Iconic Velomobile Designs From The Past 85 YearsDocument26 pages30 Iconic Velomobile Designs From The Past 85 YearsJulian Aleuy Santana100% (3)

- DuraGal DCM Lintels Sep01Document30 pagesDuraGal DCM Lintels Sep01Denise2512No ratings yet

- University of Evansville: Wm. C. Mitchell Software Racing by The Numbers Wingeo3 Suspension Geometry SoftwareDocument8 pagesUniversity of Evansville: Wm. C. Mitchell Software Racing by The Numbers Wingeo3 Suspension Geometry Softwarekadir_ÜnalNo ratings yet

- Axone 2000 ManualDocument42 pagesAxone 2000 ManualDragomirescu IrinaNo ratings yet

- DIY Anti Static MatDocument8 pagesDIY Anti Static Matazharjaved2000No ratings yet

- Wiring Diagram Manual Airplane 737Document1 pageWiring Diagram Manual Airplane 737EDUARDO RAFAEL GRANJA RIVERA0% (1)

- Lawn TrailerDocument3 pagesLawn Trailergrifter28No ratings yet

- Pudgy A 12 Foot Canvas Runabout Boat PlansDocument5 pagesPudgy A 12 Foot Canvas Runabout Boat PlansJim100% (5)

- Stiletto BoatDocument7 pagesStiletto BoatJim100% (5)

- Breeze Baby Sailboat PlansDocument5 pagesBreeze Baby Sailboat PlansJim100% (5)

- Motor Canoe Boat PlansDocument4 pagesMotor Canoe Boat PlansJim100% (6)

- Station Wagon SkiffDocument8 pagesStation Wagon SkiffJim100% (3)

- Gamin Sailboat PlansDocument6 pagesGamin Sailboat PlansJim100% (11)

- Brando Plans-Instr DigitalDocument21 pagesBrando Plans-Instr Digital劉書良100% (1)

- Popular Mechanics Encyclopedia 06 PDFDocument260 pagesPopular Mechanics Encyclopedia 06 PDFeuqehtb100% (1)

- Full Download Ebook PDF Integrated Advertising Promotion and Marketing Communications Global Edition 11Th Ebook PDF Docx Kindle Full ChapterDocument22 pagesFull Download Ebook PDF Integrated Advertising Promotion and Marketing Communications Global Edition 11Th Ebook PDF Docx Kindle Full Chapterhomer.owens120100% (31)

- Assembly Instructions For Copper Canyon 1610: Component ListDocument1 pageAssembly Instructions For Copper Canyon 1610: Component ListWiz OzNo ratings yet

- Full Download Original PDF Advanced Macroeconomics 4Th Edition by David Romer Ebook PDF Docx Kindle Full ChapterDocument22 pagesFull Download Original PDF Advanced Macroeconomics 4Th Edition by David Romer Ebook PDF Docx Kindle Full Chaptermary.grooms166100% (33)

- Camp TrailerDocument6 pagesCamp TrailerGreg Phillpotts100% (3)

- 04 - Build Storage CabinetDocument8 pages04 - Build Storage CabinetMartin GyurikaNo ratings yet

- Book Case - Barrister 1Document6 pagesBook Case - Barrister 1Cris CondeNo ratings yet

- Tool Chest InstructionsDocument8 pagesTool Chest InstructionsChristian Cristo100% (1)

- Dingbat WaterscooterDocument8 pagesDingbat WaterscooterJim100% (2)

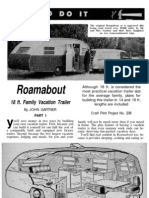

- SMFeb 56 Roamabout Part 1Document17 pagesSMFeb 56 Roamabout Part 1Jim86% (7)

- Unsinkable UniboatDocument6 pagesUnsinkable UniboatJim100% (4)

- Guppy Assembly ManualDocument11 pagesGuppy Assembly ManualAlfredo Arnéz Paz SoldánNo ratings yet

- Corky 18 FT Sloop Diy PlansDocument7 pagesCorky 18 FT Sloop Diy PlansFrenchwolf420100% (4)

- Multi SkiffDocument6 pagesMulti SkiffScaramagnao Miao BauNo ratings yet

- Happy Clam SkiffDocument11 pagesHappy Clam SkifffccfNo ratings yet

- Rowboat Sail ConversionDocument2 pagesRowboat Sail Conversionleather_nunNo ratings yet

- 15 Foot SailboatDocument4 pages15 Foot SailboatAntónio OliveiraNo ratings yet

- Merry MaidDocument6 pagesMerry MaidFrenchwolf420100% (3)

- 16 Foot Apache Outboard - PlansDocument8 pages16 Foot Apache Outboard - PlansRolando DaclanNo ratings yet

- This Fit-Bottomed Cruising Kuyak Over-All Length o F Feet, Inches %&inch BeamDocument7 pagesThis Fit-Bottomed Cruising Kuyak Over-All Length o F Feet, Inches %&inch BeamFrenchwolf420100% (2)

- Plywood RowboatDocument7 pagesPlywood RowboatAlphamatrix01No ratings yet

- 3 Piece BoatDocument4 pages3 Piece BoatFrenchwolf420No ratings yet

- Jon Boat PlansDocument3 pagesJon Boat Planslm13700100% (2)

- Float BoatDocument2 pagesFloat BoatFrenchwolf420No ratings yet