Professional Documents

Culture Documents

Electro-Oxidation of Methanol On TiO2 Nanotube Supported Platinum Electrodes

Electro-Oxidation of Methanol On TiO2 Nanotube Supported Platinum Electrodes

Uploaded by

Kutty NilaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electro-Oxidation of Methanol On TiO2 Nanotube Supported Platinum Electrodes

Electro-Oxidation of Methanol On TiO2 Nanotube Supported Platinum Electrodes

Uploaded by

Kutty NilaCopyright:

Available Formats

Copyright 2006 American Scientic Publishers All rights reserved Printed in the United States of America

Journal of Nanoscience and Nanotechnology Vol. 6, 20672071, 2006

Electro-Oxidation of Methanol on TiO2 Nanotube Supported Platinum Electrodes

T. Maiyalagan, B. Viswanathan , and U. V. Varadaraju

Department of Chemistry, Indian Institute of Technology Madras, Chennai 600036, India TiO2 nanotubes have been synthesized using anodic alumina membrane as template. Highly dispersed platinum nanoparticles have been supported on the TiO2 nanotube. The supported system has been characterized by electron microscopy and electrochemical analysis. SEM image shows that the nanotubes are well aligned and the TEM image shows that the Pt particles are uniformly distributed over the TiO2 nanotube support. A homogeneous structure in the composite nanomaterials is indicated by XRD analysis. The electrocatalytic activity of the platinum catalyst supported on Delivered by Ingenta to: TiO2 nanotubes for methanol oxidation is found to be better than University College Cork that of the standard commercial E-TEK catalyst.

Sat, 29 Synthesis, Jul 2006 Catalyst 16:20:05 Keywords: TiO2 Nanotubes, Template Support, Methanol Oxidation.

1. INTRODUCTION

Fuel cells operating by the electrochemical oxidation of hydrogen or methanol, as fuels at the anode and reduction of oxygen at the cathode are attractive power sources due to their high conversion efciencies, low pollution, light weight, and high power density. While methanol offers the advantage of easy storage and transportation in comparison to hydrogen oxygen fuel cell, its energy density (2000 Wh/kg) and operating cell voltage (0.4 V) are lower than the theoretical energy density (6000 Wh/kg) and the thermodynamic potential (1.2 V).1 2 However, the fuel cells could not reach the stage of commercialization due to the high cost which are mainly associated with the noble metal loaded electrodes as well as the membrane. In order to reduce the amount of Pt loading on the electrodes, there have been considerable efforts to increase the dispersion of the metal on the support. Pt nanoparticles have been dispersed on a wide variety of substrates such as carbon nanomaterials,3 4 Naon membranes,5 6 polymers,7 8 polymer-oxide nanocomposites,9 threedimensional organic matrices,10 and oxide matrices.1118 Most often the catalyst is dispersed on a conventional carbon support and the support material inuences the catalytic activity through metal support interaction. Dispersion of Pt particles on an oxide matrix can lead, depending mainly on the nature of support, to Pt supported oxide system that shows better behaviour than pure Pt. On the other hand, if the oxide is not involved in the electrochemical

IP : 143.239.65.56

Author to whom correspondence should be addressed.

reactions taking place on the Pt sites, it might just provide a convenient matrix to produce a high surface area catalyst.17 18 Titanium dioxide is an attractive system for electrocatalysis, since if used as the support for metallic catalysts or electrocatalysts, it may enhance their catalytic activity on the basis of strong metal support interaction (SMSI).23 24 TiO2 is an effective photocatalysts for oxidation of methanol.19 Pt/TiO2 is stable in acidic or alkaline medium, which has higher active surface area than Pt and shows high activity for oxygen reduction.15 20 21 There are several articles, which deal with the methanol oxidation reaction on TiO2 supported Platinum catalyst.17 18 Titanium mesh supported electrodes showed high activity on the methanol oxidation, therefore appears to be a promising alternative to carbon-supported catalysts.22 More important in the present case, Pd/TiO2 nanotube has been recently shown to act as a good catalyst for the oxidation of methanol.23 The present report focuses on the efforts undertaken to develop unconventional supports based on platinum catalysts for methanol oxidation. The catalyst supported on metal oxide nanotubes yields a better dispersion and shows better catalytic activity. TiO2 nanotubes of the anatase form have been synthesized by sol gel method using anodic aluminium oxide (AAO) as the template. TiO2 nanotubes were used to disperse the platinum particles effectively without sintering and to increase the catalytic activity for methanol oxidation. The tubular morphology and the oxide nature of the support have inuence on the dispersion as well as the catalytic activity of the electrode. Titanium dioxide is also known to have strong metal

doi:10.1166/jnn.2006.324

J. Nanosci. Nanotechnol. 2006, Vol. 6, No. 7

1533-4880/2006/6/2067/005

2067

Electro-Oxidation of Methanol on TiO2 Nanotube Supported Platinum Electrodes

Maiyalagan et al.

support interaction with Pt particles. The present communication, deals with the preparation of highly dispersed platinum supported on TiO2 nanotubes, the evaluation of the catalytic activity for the methanol oxidation of the electrodes and a comparison with the catalytic activity of conventional electrodes.

Then the electrode was dried at 353 K and used as the working electrode. 2.4. Characterization Methods The scanning electron micrographs were obtained using JEOL JSM-840 model, working at 15 keV after the removal of alumina template. For transmission electron microscopic studies, the nanotubes dispersed in ethanol were placed on the copper grid and the images were obtained using Phillips 420 model, operating at 120 keV. The X-ray diffraction patterns were obtained on a Philips PW 1820 diffractometer with Cu K (1.54178 ) radiation. 2.5. Electrochemical Measurements

2. EXPERIMENTAL DETAILS

2.1. Materials All the chemicals used were of analytical grade. Titanium isopropoxide (Aldrich) and 2-propanol (Merck) were used as received. Hexachloroplatinic acid was obtained from Aldrich. 20 wt% Pt/Vulcan carbons were procured from E-TEK. Methanol and sulphuric acid were obtained from Fischer chemicals. The alumina template membranes (Anodisc 47) with 200 nm diameter pores were obtained from Whatman Corp. Naon 5 wt% solution Delivered by was obtained from Dupont and was used as received.

The catalyst was electrochemically characterized by cyclic voltammetry (CV) using an electrochemical analyzer (BioIngenta to: analytical Sciences, BAS 100). A common three-electrode University College Cork electrochemical cell was used for the measurements. The IP : 143.239.65.56 counter and reference electrodes were a platinum plate 2.2. Synthesis of Pt/TiO2 Nanotubes Sat, 29 Jul 2006 16:20:05 (5 cm2 ) and a saturated Ag/AgCl electrode respectively. Titanium isopropoxide (5 mL) was added to 25 mL of The CV experiments were performed using 1 M H2 SO4 2-propanol (mole ratio [Ti4+ ]/[2-propanol] = 1:20). The solution in the presence of 1 M CH3 OH at a scan rate solution was stirred for 3 h at room temperature (298 K). of 50 mV/s. All the solutions were prepared by using The alumina template membrane was dipped into this soluultra pure water (Millipore, 18 M ). The electrolytes tion for 2 min. After removal from the solution, vacuum were degassed with nitrogen before the electrochemical was applied to the bottom of the membrane until the entire measurements. volume of the solution was pulled through the membrane. The membrane was then air-dried for 60 min at 303 K, 3. RESULTS AND DISCUSSION and then placed in a furnace (in air) with a temperature ramp of 2 C min1 to 873 K for 2 h. The temperaThe scanning electron microscopic (SEM) image of the ture was then decreased at a ramp rate of 2 C min1 to TiO2 nanotubes obtained after dissolving the 200 nm aluroom temperature (303 K).24 The TiO2 /alumina composmina template membrane is shown in Figure 1. It can be ite obtained (before the dissolution of template membrane) was immersed in 73 mM H2 PtCl6 (aq) for 12 h. After immersion, the membrane was dried in air and the ions were reduced to the corresponding metal(s) by exposure to owing H2 gas at 823 K for 3 h. The resulting composite was immersed into 3 M aqueous NaOH for several minutes to dissolve the alumina template membrane. This procedure resulted in the formation of Pt nanocluster loaded TiO2 nanotubes. 2.3. Preparation of Working Electrode Glassy Carbon (GC) (Bas Electrode, 0.07 cm2 ) was polished to a mirror nish with 0.05 m alumina suspensions before each experiment and served as an underlying substrate of the working electrode. In order to prepare the composite electrode, the nanotubes were dispersed ultrasonically in water at a concentration of 1 mg ml1 and 20 l aliquot was transferred on to a polished glassy carbon substrate. After the evaporation of water, the resulting thin catalyst lm was covered with 5 wt% Naon solution. 2068

Fig. 1. SEM image of TiO2 nanotubes obtained by sol gel method calcined at 650 C for 2 h.

J. Nanosci. Nanotechnol. 6, 20672071, 2006

Maiyalagan et al.

Electro-Oxidation of Methanol on TiO2 Nanotube Supported Platinum Electrodes

(a) TiO2 Nanotube (b) TiO2- Degussa (c) Pt / TiO2 Nanotube A(112) R(203) A(103) (c) (b) (a) R(110) A(103) A(004) Pt R(211) A(200) A(105) R (220) A(211)

A(101) R(101)

Fig. 2. TEM images of (a) TiO2 nanotubes obtained by sol gel method calcined at 650 C for 2 h (b) Pt lled TiO2 nanotubes.

Intensity ( a.u )

20

30

40

50

60

2 theta

Fig. 3. X-ray diffraction patterns of (a) Degussa TiO2 as a reference, seen from the gure that an ordered array of nanotubes (b) TiO2 nanotube, and (c) Pt/TiO2 nanotube. with uniform diameter and length is formed. The open end and the hollow nature of the TiO2 nanotubes is also conIn order to evaluate the electrocatalytic activity of the rmed by transmission electron microscopy (TEM) image electrodes for the oxidation of methanol, Pt/TiO Delivered to: 2 nanotube as shown in Figure 2a. The outer diameter of the nanotubes by Ingenta cyclic voltammetric studies were carried out in 0.5 M University is ca. 200 nm, retaining the size and near cylindrical shape College Cork SO and 1 M CH OH. During the anodic scan, the curH IP : 143.239.65.56 2 4 3 of the pores of the aluminium oxide template membrane. rent increases due to dehydrogenation of methanol folSat,is 29 Jul 2006 16:20:05 shown The TEM image of a Pt/TiO2 nanotube electrode lowed by the oxidation of absorbed methanol residues in Figure 2b, which shows that the Pt particles are highly and reaches a maximum in the potential range between dispersed on the TiO2 nanotube support. The Pt particle 0.8 and 1.0 V versus Ag/AgCl. In the cathodic scan, the size was found to be around 34 nm while their crystal re-oxidation of the residues is observed. On the whole, the structure is conrmed by the XRD method. The optimal Pt behaviour of the Pt/TiO2 nanotube electrodes was found to particle size for reactions in the H2 /O2 fuel cell is around 25 be similar to that of Pt. This suggests that the electrooxida3 nm. The importance of the Pt particle size on the activtion reaction takes place on the Pt nanoparticles, dispersed ity for methanol oxidation is due to the structure sensitive on the TiO2 nanotube, involves basically the same reaction nature of the reaction and the fact that particles with difmechanism. ferent sizes will have different dominant crystal planes and hence the different intercrystallite distances, which might inuence methanol adsorption. The commercial Pt/C has a high specic surface area but contributed mostly by micropores less than 1 nm and are therefore more difcult to be fully accessible. It has been reported that the mean value of particle size for 20% Pt/Vulcan (E-TEK) catalyst was around 2.6 nm.26 The TiO2 nanotube matrix of anatase form can provide hydroxide ions to remove CO poisoning. Methanol oxidation studies on the prepared electrode have been carried out using cyclic voltammetry. The XRD patterns of the Pt/TiO2 nanotubes as well as P-25 are shown in Figure 3. Rutile and anatase were seen by XRD in P25 titania, but rutile was not seen in the TiO2 nanotubes. The diffractograms of the synthesized TiO2 nanotubes mainly belong to the crystalline structure of anatase TiO2 . XRD pattern of the TiO2 nanotubes evidenced the presence of anatase as the main phase. After Pt deposition, the colour of the TiO2 nanotubes changed to dark gray and during reduction of Pt, oxide reduction takes place and new diffraction peaks are formed. The presence of Pt could be observed at diffraction angle of 39.8 indexed to (111) plane of metallic Pt. However the Fig. 4. Cyclic voltammogram of (a) pure Pt, (b) Pt/C, and (c) Pt/TiO2 peak intensity is relatively weak, presumably due to the nanotube in 0.5 M H2 SO4 /1 M CH3 OH run at 50 mV/s (area of the electrode = 0.07 cm2 ). combination of its low content and small particle size.

J. Nanosci. Nanotechnol. 6, 20672071, 2006

2069

Electro-Oxidation of Methanol on TiO2 Nanotube Supported Platinum Electrodes

Table I. Electrocatalytic activity of various catalysts for methanol oxidation. Electrocatalyst Bulk Pt Pt/C Pt/TiO2 nanotube Specic activity (mA cm2 ) 0 167 13 13 2 Mass activity (mA mg1 Pt) 3.25 33

Maiyalagan et al.

4. CONCLUSIONS

The Pt was deposited on TiO2 nanotubes in order to study the effect of the properties of the support for methanol oxidation reaction. The Pt/TiO2 nanotube catalyst exhibits a high electrocatalytic activity for methanol oxidation compared to the commercial E-TEK catalysts. Overall, the relative activities are of the order Pt/TiO2 nanotubes > E-TEK > pure Pt. The observed improved catalytic activity of Pt/TiO2 nanotube catalysts can be due to oxidation of CO to CO2 by the surface hydroxyl groups of TiO2 nanotube support which otherwise poison the active Pt sites. The electronic interaction between TiO2 support and the Pt particles could also be another factor contributing to the observed higher activity. Further study on the detailed mechanism and stability of the TiO2 nanotube supported catalysts are now under progress.

The results of the voltammetric curves for the oxidation of methanol obtained with the Pt/TiO2 nanotube, Pt and Pt/C (E-TEK) electrodes are shown in Figure 3. The Pt/TiO2 nanotube shows a higher current density of 13.2 mA/cm2 compared to Pt/C (E-TEK) electrodes (1.23 mA/cm2 ). The specic activity and the mass activity for the different electrodes are given in Table I. The results show that the high electrocatalytic activity for methanol oxidation for Pt/TiO2 nanotube electrode. It is evident Acknowledgment: We thank the Council of Scienthat the mass activity observed with the Pt supported Delivered by Ingenta tic and to: Industrial Research (CSIR), India, for a senior TiO2 nanotubes shows around ten-fold increase in current University College Cork research fellowship to one of the authors T. Maiyalagan. catthan Pt/C (E-TEK) electrode. The Pt/TiO2 nanotube IP : 143.239.65.56 alyst had a better electrocatalytic activity for methanol Sat, 29 Jul 2006 16:20:05 oxidation when compared with that of bulk Pt and Pt/C References and Notes (E-TEK) catalysts. This higher catalytic activity can be 1. B. D. McNicol, D. A. J. Rand, and K. R. Williams, J. Power Sources mainly attributed to remarkably platinum active reaction 83, 47 (2001). sites on the nanotube oxide matrix and the role of the TiO2 2. L. Carrette, K. A. Friedrich, and U. Stimming, Fuel Cells 1, 5 nanotube facilitates as a path for methanol (CH3 OH) as a (2001). 3. C. L. Lee, Y. C. Ju, P. T. Chou, Y. C. Huang, L. C. Kuo, and J. C. fuel and Protons (H+ ) produced during an electrochemical Oung, Electrochem. Commun. 7, 453 (2005). reaction. 4. T. Maiyalagan, B. Viswanathan, and U. V. Varadaraju, Electrochem. It is possible that TiO2 nanotube functions in the same Commun. 7, 905 (2005). way as Ru does in Pt-Ru/C catalysts because hydroxide 5. M. Watanabe, H. Uchida, and M. Emori, J. Phys. Chem. B 102, 3129 ion species could easily form on the surface of the TiO2 (1998). 6. H. Uchida, Y. Mizuno, and M. Watanabe, J. Electrochem. Soc. 149, nanotubes. The formation of hydroxide ion species on the A682 (2002). surface of the TiO2 nanotubes transforms CO like poi7. W. T. Napporn, H. Laborde, J. M. Leger, and C. Lamy, J. Elecsoning species on Pt to CO2 , leaving the active sites on troanal. Chem. 404, 153 (1996). Pt for further electrochemical reaction has been shown in 8. M. T. Giacomini, E. A. Ticianelli, J. McBreen, and M. Balasubramanian, J. Electrochem. Soc. 148, A323 (2001). Figure 5.27 28 The participation of the TiO2 nanotube sup9. B. Rajesh, K. R. Thampi, J. M. Bonard, N. Xanthapolous, H. J. port the high dispersion of Pt particles on TiO2 nanotube Mathieu, and B. Viswanathan, Electrochem. Solid-State Lett. 5, E71 electrode, OH groups generated near the Pt-oxide interface (2002). promote CO removal, and strong metal support interaction 10. H. Bonnemann, N. Waldofner, H. G. Haubold, and T. Vad, Chem. (SMSI) could be a reason for enhanced electrocatalytic Mater. 14, 1115 (2002). 11. V. Raghuveer and B. Viswanathan, Fuel 81, 2191 (2002). activity of methanol oxidation.29 30

Fig. 5. A possible mechanism for the removal of CO poisoning intermediates during methanol oxidation over TiO2 nanotube supported Pt catalysts.

12. L. F. DElia, L. Rincn, and R. Ortz, Electrochim. Acta 49, 4197 (2004). 13. M. I. Rojas, M. J. Esplandiu, L. B. Avalle, E. P. M. Leiva, and V. A. Macagno, Electrochim. Acta 43, 1785 (1998). 14. M. J. Esplandiu, L. B. Avalle, and V. A. Macagno, Electrochim. Acta 40, 2587 (1995). 15. V. B. Baez and D. Pletcher, J. Electroanal. Chem. 382, 59 (1995). 16. A. Hamnett, P. S. Stevens, and R. D. Wingate, J. Appl. Electrochem. 21, 982 (1991). 17. T. Ioroi, Z. Siroma, N. Fujiwara, S. Yamazaki, and K. Yasuda, Electrochem. Commun. 7, 183 (2001). 18. B. E. Hayden and D. V. Malevich, Electrochem. Commun. 3, 395 (2001). 19. P. A. Mandelbaum, A. E. Regazzoni, M. A. Blesa, and S. A. Bilmes, J. Phys. Chem. B 103, 5505 (1999).

2070

J. Nanosci. Nanotechnol. 6, 20672071, 2006

Maiyalagan et al.

Electro-Oxidation of Methanol on TiO2 Nanotube Supported Platinum Electrodes

26. E. Antolini, L. Giorgi, F. Cardellini, and E. Passalacqua, J. Solid State Electrochem. 5, 131 (2001). 27. L. Huaxin, J. Mol. Catal. A: Chem. 144, 189 (1999). 28. M. Takeuchi, K. Sakamoto, G. Martra, S. Coluccia, and M. Anpo, J. Phys. Chem. B 109, 15422 (2005). 29. S. J. Tauster, S. C. Fung, and R. L. Garten, J. Am. Chem. Soc. 100, 170 (1978). 30. S. G. Neophytides, S. Zafeiratos, G. D. Papakonstantinou, J. M. Jaksic, F. E. Paloukis, and M. M. Jaksic, Int. J. Hyd. Energy 30, 393 (2005).

20. L. Xiong and A. Manthiram, Electrochim. Acta 49, 4163 (2004). 21. J. Shim, C.-R. Lee, H.-K. Lee, J.-S. Lee, and E. J. Cairns, J. Power Sources 102, 172 (2001). 22. E. H. Yu and K. Scott, J. Electrochem. Commun. 6, 361 (2004). 23. M. Wang, D. J. Guo, and H. L. Li J. Solid State Chem. 178, 1996 (2005). 24. S. Lee, C. Jeon, and Y. Park, Chem. Mater. 16, 4292 (2004). 25. K. Kinoshita, J. Electrochem. Soc. 137, 845 (1990).

Received: 23 September 2005. Revised/Accepted: 2 February 2006.

Delivered by Ingenta to: University College Cork IP : 143.239.65.56 Sat, 29 Jul 2006 16:20:05

J. Nanosci. Nanotechnol. 6, 20672071, 2006

2071

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Introduction To The Oil and Gas Industry For DummiesDocument17 pagesIntroduction To The Oil and Gas Industry For DummiesEzekwere Ndubuisi HenryNo ratings yet

- BS 6364-1984 Specification For Valves For Cryogenic ServiceDocument14 pagesBS 6364-1984 Specification For Valves For Cryogenic Service윤규섭100% (1)

- Arki Tabulated Reviewer 200501143515Document155 pagesArki Tabulated Reviewer 200501143515Charles Godwin CordialNo ratings yet

- Method StatementDocument65 pagesMethod Statementsenthil67% (3)

- Wood Floor Cleaning Guide: What You Should Use To Clean Your FloorDocument2 pagesWood Floor Cleaning Guide: What You Should Use To Clean Your FloorfNo ratings yet

- Soil Waste Design Installation Manual PDFDocument21 pagesSoil Waste Design Installation Manual PDFvinit joryNo ratings yet

- Shurjoint 2017 Installation InstructionsDocument241 pagesShurjoint 2017 Installation InstructionsbalotNo ratings yet

- BS en 10244-1-2009 - (2020-02-03 - 11-24-27 Am) PDFDocument12 pagesBS en 10244-1-2009 - (2020-02-03 - 11-24-27 Am) PDFJacky LeongNo ratings yet

- DeclarationDocument1 pageDeclarationacko80No ratings yet

- Chemistry of Complexes - 2Document58 pagesChemistry of Complexes - 2Kowser mahmudNo ratings yet

- Safe Handling of Cryogenic Liquids: Safetygram 16Document8 pagesSafe Handling of Cryogenic Liquids: Safetygram 16Alok RanjanNo ratings yet

- Objective: Alpha Academy ChemistryDocument1 pageObjective: Alpha Academy Chemistrymuhammad AsimNo ratings yet

- Process and Significance of DistillationDocument11 pagesProcess and Significance of DistillationSiddiquer Rehman SidNo ratings yet

- Anabond 652c Heat Sink Compound Thermally ConductiveDocument2 pagesAnabond 652c Heat Sink Compound Thermally ConductiveRohit MahaleNo ratings yet

- C2019 12787GalvanicCPwithVCIforASTsDocument13 pagesC2019 12787GalvanicCPwithVCIforASTsDAVID LARZON MARTINEZNo ratings yet

- Drawings Hanson Park H19!25!0010 Part4Document40 pagesDrawings Hanson Park H19!25!0010 Part4DhanyaNo ratings yet

- B-16-04884 KMT Tungsten Heavy Alloy Brochure EN LRPDFDocument12 pagesB-16-04884 KMT Tungsten Heavy Alloy Brochure EN LRPDFSina RashidiNo ratings yet

- National Gypsum Construction GuideDocument164 pagesNational Gypsum Construction Guidelglfan42No ratings yet

- Solubility of SaltsDocument2 pagesSolubility of SaltsDANSTAN GISORENo ratings yet

- Catalogo Phes 09.02.2021Document5 pagesCatalogo Phes 09.02.2021amarisNo ratings yet

- Lokfix E75 TDS 8072020Document5 pagesLokfix E75 TDS 8072020KumarRamNo ratings yet

- M6 - Lipids TestDocument9 pagesM6 - Lipids Testlarry machonNo ratings yet

- ISO - Hex Bolt Structural Grade C ISO 7411Document59 pagesISO - Hex Bolt Structural Grade C ISO 7411Trịnh Xuân LinhNo ratings yet

- 01 007 CCM Cable Support SystemDocument24 pages01 007 CCM Cable Support SystemAlan Tan Y RNo ratings yet

- Lesson 6N TreesDocument4 pagesLesson 6N TreesJake CanlasNo ratings yet

- Study of Steel Hardness Effect On The Abrasive Wear ResistanceDocument7 pagesStudy of Steel Hardness Effect On The Abrasive Wear ResistanceArslan Zulfiqar AhmedNo ratings yet

- CTC Details Export 2022 09 13 - 02 05 47Document150 pagesCTC Details Export 2022 09 13 - 02 05 47anil phougatNo ratings yet

- Welding ProcessDocument37 pagesWelding ProcessPandu Pratama YudhaNo ratings yet

- Insulation SpecificationDocument1 pageInsulation SpecificationKittisak SungsanaNo ratings yet

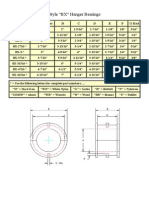

- StyleDocument3 pagesStyleYen Sebastian SantosNo ratings yet