Professional Documents

Culture Documents

Combustion Chambers

Combustion Chambers

Uploaded by

megaspiceCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Combustion Chambers

Combustion Chambers

Uploaded by

megaspiceCopyright:

Available Formats

COMBUSTION CHAMBERS

COMBUSTION CHAMBERS- SI Engines The design of combustion chamber has an important influence upon the engine performance and its knock properties. The design of combustion chamber involves the shape of the combustion chamber, the location of the sparking plug and the disposition of inlet and exhaust valves. Because of the importance of combustion chamber design, it has been a subject of considerable amount of research and development in the last fifty years. It has resulted in raising the compression ratio from 4: 1 before the First World War period to 8: 1 to 11:1 in present times with special combustion Chamber designs and suitable anti-knock fuels. BASIC REQUIREMENTS OF A GOOD COMBUSTION The basic requirements of a good combustion chamber are to provide: High power output High thermal efficiency and low specific fuel consumption Smooth engine operation Reduced exhaust pollutants.

HIGHER POWER OUTPUT REQUIRES THE FOLLOWING: igh compression ratio. The compression ratio is limited by the phenomenon of detonation. Detonation depends on the design of combustion chamber and fuel quality. Any change in design that improves the anti-knock characteristics of a combustion chamber permits the use of a higher compression ratio which should result in higher output and efficiency. mall or no excess air. omplete utilization of the air no dead pockets. n optimum degree of turbulence. Turbulence is induced by inlet flow configuration or squish . Squish is the rapid ejection of gas trapped between the piston and some flat or corresponding surface in the cylinder head. Turbulence induced by squish is preferable to inlet turbulence since the volumetric efficiency

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (347)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Regression III: Dummy Variable Regression: Regression Applications - We Will Look atDocument7 pagesRegression III: Dummy Variable Regression: Regression Applications - We Will Look atmegaspiceNo ratings yet

- Braking SystemDocument3 pagesBraking SystemmegaspiceNo ratings yet

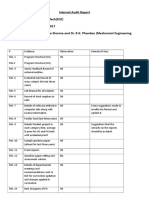

- Audit ReportDocument2 pagesAudit ReportmegaspiceNo ratings yet

- ASHRAE EntranceDocument3 pagesASHRAE EntrancemegaspiceNo ratings yet

- Inspection ChecklistsDocument6 pagesInspection Checklistsmegaspice0% (1)

- Suspension SystemDocument11 pagesSuspension Systemmegaspice100% (1)

- VCRDocument2 pagesVCRmegaspice100% (1)

- VCRDocument2 pagesVCRmegaspice100% (1)

- Placementdata OthersDocument48 pagesPlacementdata OthersmegaspiceNo ratings yet

- Selected Alumni - Auup: (Appendix)Document1 pageSelected Alumni - Auup: (Appendix)megaspiceNo ratings yet

- Wipro FinalDocument11 pagesWipro FinalmegaspiceNo ratings yet

- Weekly Progress Report: Select Course: Page (1) ofDocument1 pageWeekly Progress Report: Select Course: Page (1) ofmegaspiceNo ratings yet

- Mpfi (Multi Point Fuel Injection)Document25 pagesMpfi (Multi Point Fuel Injection)megaspiceNo ratings yet

- Clubs & Committees DSW DataDocument1 pageClubs & Committees DSW DatamegaspiceNo ratings yet

- Lean Management: Warehousing Decisions & LayoutsDocument55 pagesLean Management: Warehousing Decisions & Layoutsmegaspice100% (5)