Professional Documents

Culture Documents

Chapter 8 - Tablets: Uy, Alyssa V. 2Bph

Chapter 8 - Tablets: Uy, Alyssa V. 2Bph

Uploaded by

Chesmar MacapalaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 8 - Tablets: Uy, Alyssa V. 2Bph

Chapter 8 - Tablets: Uy, Alyssa V. 2Bph

Uploaded by

Chesmar MacapalaCopyright:

Available Formats

Uy, Alyssa V.

2BPh CHAPTER 8 Tablets

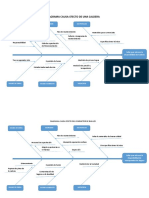

Tablets - solid dosage forms usually prepared with the aid of suitable pharmaceutical excipients Majority are administered orally, while others sublingually, buccally or vaginally contain features most applicable to their routes of administration. Types of Tablets: Compressed Tablets (C.T.) - manufactured with tablet machine capable of exerting great pressure or compacting the powdered or granulated tableting material. DILUENTS, BINDERS, DISINTEGRANTS,

ANTIADHERENTS/ GLIDANTS/LUBRICANT, COLORANTS/FLAVORANTS

Effervescent Tablets prepared by compressing granular effervescent salts that release gas when in contact with water. This tablet contains medicinal substance which dissolves rapidly when in contact with water. Molded Tablet Triturate (M.T.T.) small & cylindrical, very soft, soluble & designed to dissolve rapidly. Compressed Tablet Triturate (CTT) prepared by compression (limited pressure) usually containing potent substance. Sucrose and lactose are used for diluent. Hypodermal Tablet (H.T.) used by physicians for extemporaneous preparations of parenterals. It is meant to be dissolved in suitable vehicle, sterility attained, and the injection performed. The advent of prefabricated injectable products and disposable syringes declined its use. Dispensing Tablets (D.T.) or compounding tablets used by pharmacists when compounding prescriptions and not dispensed to patients. It contains large amount of potent subs. enabling the pharmacist to obtain pre-measured amounts. For compounding multiple dosage units. Immediate Release Tablets (I.R.) designed to disintegrate and release their medication and therefore are devoid of special rate controlling features like coating and other ways. Instant Disintegrating/Dissolving Tablets characterized to dissolve within 10 seconds to 1 minute. This is possible with the use of lyophilization techniques, soft direct compression, or the use of water-soluble excipients designed to wick water into the tablet for rapid disintegration. Extended Release Tablet (E.R.) /Controlled Release (C.R.) designed to release their medication in a predetermined manner over an extended period of time. Vaginal Tablet/Inserts uncoated and bullet- or ovoid- shaped tablets for localized effect. Prepared by compression and shaped to fit smugly into plastic inserter devices. They contain antibacterials (against Hemophilia vaginitis) and antifungals (against Candida albicans) The physical features of compressed tablets are varied; its diameter and shapes are determined by the die and punches used in the compression. The less concave the punch, the more flat the resulting tablets. Punches with raised impressions will have recessed impressions on the tablets.

Multiple Compressed Tablets (MCT) prepared by subjecting the fill material to more than a single compression, the core (inner) and shell (outer) Sugar-Coated Tablet (S.C.T.) the coating maybe colored or uncolored sugar layer, water soluble and quickly dissolved after swallowing. Purposes: to protect the enclosed drug from the environment and to provide a barrier to objectionable taste and smell of the drug. Disadvantages: time and expertise needed in the coating process and increased shipping costs Film-Coated Tablets (F.C.T.) coating is made of thin layer of a polymer capable of forming a skin-like usually colored film over the tablet. Polymer is cellulose acetate phthalate. Advantages of film coating over sugar coating: more durable, less bulky and less time consuming to apply. Gelatin Coated Tablet capsule-shaped compressed tablet with 1/3 the size of capsule with the same amount of fill, more ease in swallowing & more tamper evident. (GelCaps) Enteric-Coated Tablets (E.C.T.) have delayed release features, designed to pass the stomach to the intestines where the tablet will disintegrate allowing drug dissolution & absorption. Needed when drug substance: a) b) c) is destroyed by gastric acid is irritating to the gastric mucosa by-passed the stomach enhances the drug absorption in the intestines

Buccal tablets flat, oval tablets intended to be dissolved slowly in the buccal pouch. It is for oral absorption of drugs destroyed by gastric acid or poorly absorbed in the GI tract. Sublingual Tablets designed to erode promptly underneath the tongue for rapid drug effect. Lozenges or troches disc-shaped solid forms containing a medicinal substance in a hard candy or sugar base. Meant to dissolve slowly for localized effect or systemic effect Chewable Tablets have rapid disintegration when chewed or allowed to dissolve in the mouth, have a creamy base usually specially flavored and colored mannitol. Meant for large-sized tablets given to children and adults with difficulty in swallowing solid dosage forms

Quality Standards and Compedial Requirements: USP Weight Variation Test: 10 tablets are individually weighed and average weight calculated. Content Uniformity: Dosage units are assayed individually and requires that each dosage unit is 85% - 115% of the label claim (S.D. is less than 6%) Tablet thickness is determined by a. b. c. d. the diameter of the die the amount of fill the compactibility of the fill material the force of pressure applied during compression.

Page 1 of 3

Tablet thickness is measured by a hand gauge. Tablet hardness affects its disintegration & drug absorption. The greater the pressure, the harder the tablet. It should be hard enough to resist breaking during the normal handling and yet soft enough to disintegrate properly after swallowing. A force of 4 kilograms as determined by hardness tester is minimum requirement for a satisfactory tablet. Tablet friability the tendency to crumble by allowing it to roll and fall within the rotating machine (friabilator). A maximum weight loss of not more than 1% of the weight of the tablets being tested is acceptable. Tablet Disintegration Test uses a basket-rack assembly containing 6 open ended transparent tubes held vertically upon a 10-mesh stainless steel wire screen. The basket is raised and lowered in the immersion fluid (water at 37oC) at a frequency of 29-32 times per minute. Result: the residue of the tablet on the screen is a soft mass having no palpable inner core. Disintegration time ranged from 2 mins. to 4 hours depending upon the monograph. For enteric coated tablets, test is done in a simulated gastric fluid for 1 hr. No sign of disintegration must be seen. They are immersed in a simulated intestinal fluid for the time stated in the monograph where they disintegrate completely.

are withdrawn for chemical analysis. Samples must meet the requirement stated in the monograph. Pooled dissolution testing samples coming from different batches placed in individual dissolution vessel in the apparatus or multiple dosage units in a single vessel. This recognizes the concept of batch characteristics.

3 methods for compressed tablet: Wet Granulation: Weighing and blending of ingredients (A.I. & adjuvants) + liquid binder screen the damp mass (Sieve 6-8) dry size the granules (Sieve 12-20) + lubricant and blend compress Fillers lactose and microcrystalline cellulose Binder to facilitate adhesion of powder particles. Starch, povidone, methylcellulose. Flavorant and colorant are added to binder. Lubricant to improve the flow of granules from the hopper to the die; prevent adhesion to the punches and die during compression; reduce friction between tablet and dies wall during tablet ejection and provide tablet sheen. Calcium and magnesium stearate are examples. All-In-One Methods: 1) Fluid-bed Process fluid-bed granulator which performs the blending, granulating, drying into 1 continuous process 2) Microwave Vacuum Process powder mix is mixed, wetted, agglomerated and dried using microwave Dry Granulation the powder mixture is compacted to large pieces and broken down or sized into granules Active ingredient or diluent must have cohesive properties. Advantages: For materials that are degraded by moisture or by elevated temperature during drying Steps in Dry Granulation: Weighing & blending powder mix slugging sizing + lubricant compression Tableting machine compress tablet formulation within a steel die cavity by the pressure exerted by the movement of the two steel punches (upper and lower). Imperfections of tablets: a) a)Laminations horizontal striations b) Tablet capping the top of tablet separates from the whole c) Tablet splitting Reasons: a) particles has no time to bond due to fast high speed production b) air is entrapped during direct compression c) punches not clean d) aging

Tablet dissolution test - Uses: guides formulation and product development performance of manufacturing process can be monitored by it (quality assurance) c. Consistent results assure bioequivalence from batch to batch d. As a requirement for regulatory approval Its goal to provide a reasonable prediction or correlation with the products in vivo bioavailability. a) b) c) d) High Solubility and High Permeability IVIVC Low Solubility and High Permeability IVIVC High Solubility and Low Permeability limited IVIVC Low Solubility and Low Permeability none a. b.

In (a) IVIVC is expected if the dissolution time is slower then gastric emptying time (limiting factor). Dissolution Test Apparatus consists of: 1. 2. 3. variable stirrer motor stainless basket on a stirrer shaft (Apparatus I) or a paddle as stirrer (Apparatus II) 1-L vessel glass with a cover having the shaft of the stirrer fitted at the center port, with 3 ports for samples and 1 port for the thermometer Water bath to maintain the temp. of the medium in the vessel

4.

Dissolution medium is placed in the vessel at 37oC + 0.5o C. The stirrer is rotated at speed specified and at stated intervals; samples of the medium

Page 2 of 3

Direct Compression appropriate for chemicals with flowing and cohesive properties Tablet Deduster to remove traces of loose powder adhering to the tablets following compression. Tablets are coated: 1) to protect from air and/or humidity 2) mask the taste 3) provide characteristics of drug release 4) to provide aesthetics or distinction to the product Sugarcoating tedious, time-consuming and needs expertise of qualified technician and the product doubles the size and wt. Film coating provides a thin, skin-tight coating of a plastic material over the compressed tablet. Components: a) Film former to produce thin smooth film. Cellulose acetate phthalate b) Alloying substance to provide water solubility/ permeability for body fluids to penetrate through and make the drug available. Polyethylene glycol c) Plasticizer to produce elasticity/flexibility to the coating & provide durability. Castor oil Advantages: Size and wt. almost the same as the tablet, more resistant to destruction by abrasion, markings can be embossed on the coating. Enteric coating maybe accomplished through coating with enough thickness or coating which allow dissolution at a pH 4.9 or higher. Example is shellac Fluid Bed or Air Suspension Coating spray coating of powder, pellets, granules or tablets held in suspension by a column of air Depending where the coating solution come from: a) Wurster the bottom of the cylinder b) Top spray sprayed downward c) Tangential spray techniques rotary fluid bed coater Top spray recommended for taste masking, enteric release and barrier film on tablets. Bottom spray for sustained release and enteric release Tangential layering coating, sustained and enteric releases Compression Coating the coating material (granulation or powder form) is compressed into the tablet core. Advantages: a) It is anhydrous process appropriate for drugs affected by moisture

more uniform coating uses less coating material resulting to lighter, smaller and easy to swallow tablets d) less expensive to package and ship Packaging and Storage: a) Use tight, light resistant (amber) containers, if adversely affected by light b) Store in places of low humidity and protected from extreme temperature c) Use desiccant pellet is affected by moisture

b) c)

Oral administration of solid dosage forms Lozenges by compression or molding. Meant to dissolve slowly in the mouth for localized effect. Impact of Changes on Solid dosage forms: 1. Changes in formulation a) active ingredients b) excipients c) their quantities d) addition of new excipients 2. Changes in methods of manufacturing a) new machineries b) different steps in manufacturing c) different in process controls, tests or assay methods d) production of different batch sizes e) use of different product reprocessing procedures f) suse of different manufacturing sites

Page 3 of 3

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Acupuncture System and The Liquid Crystalline Collagen Fibres of The Connective TissuesDocument17 pagesThe Acupuncture System and The Liquid Crystalline Collagen Fibres of The Connective Tissuesmkljhrguyt100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Paper 1Document295 pagesPaper 1Shreyas TiwariNo ratings yet

- Cellular Respiration Review WorksheetkeyDocument6 pagesCellular Respiration Review WorksheetkeyLiezel Cagais SanchezNo ratings yet

- Coatings Testing Capabilities PDFDocument6 pagesCoatings Testing Capabilities PDFcesar100% (2)

- PHAR3 LAB - Preparation 22-30Document2 pagesPHAR3 LAB - Preparation 22-30Gerard LeeNo ratings yet

- Static MixersDocument12 pagesStatic MixersCal100% (2)

- HILTI Technical Manual PDFDocument134 pagesHILTI Technical Manual PDFleluz__No ratings yet

- Thermodynamic Data PDFDocument380 pagesThermodynamic Data PDFhumusdelombrizNo ratings yet

- Prep 22-27Document2 pagesPrep 22-27soubi_yodi100% (1)

- Iinternship 13Document35 pagesIinternship 13Darwin MangabatNo ratings yet

- Contraction of Whole MuscleDocument7 pagesContraction of Whole MuscleAli UyNo ratings yet

- Experiment With The First ClassDocument2 pagesExperiment With The First ClassaizatNo ratings yet

- Technical English QB I SEMDocument67 pagesTechnical English QB I SEMjothilakshmiNo ratings yet

- Refractory Dense Bricks Material Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationDocument4 pagesRefractory Dense Bricks Material Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationMohamed LotfyNo ratings yet

- Centralized Lubrication Systems (Single Line Orifice Systems)Document73 pagesCentralized Lubrication Systems (Single Line Orifice Systems)HECTOR IBARRANo ratings yet

- Material and Energy BalanceDocument8 pagesMaterial and Energy BalanceSatyamGuptaNo ratings yet

- Cambridge International AS & A Level: Chemistry 9701/41Document17 pagesCambridge International AS & A Level: Chemistry 9701/41Sanmith SanradaNo ratings yet

- Clearix Rex Liq en (Flayer)Document4 pagesClearix Rex Liq en (Flayer)Tayfun AltınoğluNo ratings yet

- MCW Performance TableDocument7 pagesMCW Performance Tablesnoopdogg89fakeNo ratings yet

- Sulfuric Acid Manufacturing: Introduction/BackgroundDocument2 pagesSulfuric Acid Manufacturing: Introduction/BackgroundavwnashNo ratings yet

- HCL MSDS PDFDocument6 pagesHCL MSDS PDFcryovikas1975No ratings yet

- Diagrama Causa-Efecto de Una Caldera: Materiales Metodos Mano de ObraDocument2 pagesDiagrama Causa-Efecto de Una Caldera: Materiales Metodos Mano de ObraDaniel Will Morales GuerreroNo ratings yet

- Hess's LawDocument15 pagesHess's Lawkamal touilebNo ratings yet

- Theoretical and Experimental Analysis of Liquid Flooded CompressiDocument622 pagesTheoretical and Experimental Analysis of Liquid Flooded CompressiTao YeNo ratings yet

- 5991-5412ES Agilent LC Hardware SpanishDocument45 pages5991-5412ES Agilent LC Hardware SpanishDANIEL-LABJMENo ratings yet

- CompressionDocument29 pagesCompressionSri Alma100% (1)

- C 769 - 98 - Qzc2oqDocument3 pagesC 769 - 98 - Qzc2oqneophymenNo ratings yet

- Guia de Mantenimiento HS200Document20 pagesGuia de Mantenimiento HS200luisoft88No ratings yet

- Geothermal Wells - Two Phase Flow ModelingDocument22 pagesGeothermal Wells - Two Phase Flow ModelingVassilios KelessidisNo ratings yet

- Lead Construction Sweat Tea Design NewDocument14 pagesLead Construction Sweat Tea Design NewsobhiNo ratings yet

- 11-6005 CS Process FinalDocument2 pages11-6005 CS Process FinalChung ChuanNo ratings yet

- Drag Coefficients and Strouhal Numbers of A Port Crane Boom Girder SectionDocument10 pagesDrag Coefficients and Strouhal Numbers of A Port Crane Boom Girder SectionNicolás MaggiNo ratings yet

- Dic PetDocument284 pagesDic PeteliodefedericoNo ratings yet

- Differential Scanning Calorimetry: G.W. H. Höhne, W. Hemminger, H.-J. FlammersheimDocument4 pagesDifferential Scanning Calorimetry: G.W. H. Höhne, W. Hemminger, H.-J. FlammersheimMiguel Angel Magaña FuentesNo ratings yet