Professional Documents

Culture Documents

Product Identification and Traceability: YES NO NA

Uploaded by

ViswaChaitanya NandigamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Identification and Traceability: YES NO NA

Uploaded by

ViswaChaitanya NandigamCopyright:

Available Formats

Product Identification and Traceability

YES

NO

NA

1. Is there a method and a procedure of identifying the product throughout its manufacturing, and delivery stages? 2. Do records indicate that lot identity and disposition are maintained throughout the suppliers manufacturing and delivery process to assure lot integrity and traceability to materials used and processes performed? 3. Does the method used indicate processing and inspection status of product throughout the system, including storage and in-process holding areas? 4. Does the supplier identify parts returned from the field for rework or sort with a unique lot number for traceability?

Process Control

1. Are individual operations specified by detailed work instructions on the traveler or posted at each operation per QS-9000 Element 4.9? 2. Does the supplier's procedures require approval of the operator, process and equipment after set-ups, tool changes, etc., prior to actual use? 3. Are workmanship standards defined to accept/reject criteria by written specifications, photographs, and/or labeled limit samples for operators?

Final Inspection and Testing

1. Is final inspection and testing performed in accordance with the quality plan or documented procedures to verify conformance of the final product to the specified requirements? 2. Is all product held until all activities associated with the quality or documented procedures have been satisfactorily completed and the associated data and documentation is verified and approved? 3. Are adequate records maintained of all inspections and tests? 4. Does the supplier have adequate safeguards in place to prevent product from being shipped without proper verification, acceptance, and authorization from designated personnel? 5. Do records indicate that the supplier tracks outgoing rejection trends and rejection rates in Parts Per Million (PPM) or by any other acceptable means?

You might also like

- As IA Checklist Sec7 5Document5 pagesAs IA Checklist Sec7 5Randy Wee AguilarNo ratings yet

- Good Distribution Practices A Complete Guide - 2021 EditionFrom EverandGood Distribution Practices A Complete Guide - 2021 EditionNo ratings yet

- Quality Management System Software A Complete Guide - 2019 EditionFrom EverandQuality Management System Software A Complete Guide - 2019 EditionNo ratings yet

- 1 Internal & Product AuditDocument3 pages1 Internal & Product AuditPrafull BhamareNo ratings yet

- Quality System Manual: Uncontrolled UncontrolledDocument83 pagesQuality System Manual: Uncontrolled UncontrolledEngr Saeed AnwarNo ratings yet

- Documented Information ManagementDocument8 pagesDocumented Information Managementdhir.ankurNo ratings yet

- Designing a Quality Management System using ISO 9000Document13 pagesDesigning a Quality Management System using ISO 9000Tausique SheikhNo ratings yet

- Assessment Report/Checklist: Isfahan, IranDocument19 pagesAssessment Report/Checklist: Isfahan, IranAnonymous q8lh3fldWMNo ratings yet

- Application For The Accreditation of Medical Laboratories ACCORDING TO EN ISO 15189:2012Document13 pagesApplication For The Accreditation of Medical Laboratories ACCORDING TO EN ISO 15189:2012arvindNo ratings yet

- Control of Nonconforming ProductsDocument2 pagesControl of Nonconforming ProductsPrince Moni100% (1)

- Supplier Evalution & Control ProcedureDocument4 pagesSupplier Evalution & Control ProcedurePrime Cap100% (1)

- Preventive Action ProcedureDocument1 pagePreventive Action ProcedureZharel AhmadNo ratings yet

- Installation, servicing and on-site support proceduresDocument3 pagesInstallation, servicing and on-site support proceduresBPG ServiceNo ratings yet

- Standard Operation Procedure Production ProcessDocument2 pagesStandard Operation Procedure Production ProcessHarits As SiddiqNo ratings yet

- Standard Operating Procedure For Product RecallDocument5 pagesStandard Operating Procedure For Product RecallRainMan75No ratings yet

- Manufacturing Process Audit for Factory ABCDocument18 pagesManufacturing Process Audit for Factory ABCmakubuya nasser100% (1)

- SKII Factory Inspection ReportDocument6 pagesSKII Factory Inspection Reportrgrao85No ratings yet

- Alabama Specialty Products, Inc.Document24 pagesAlabama Specialty Products, Inc.qmicertificationNo ratings yet

- GAPIII Audit ReportDocument5 pagesGAPIII Audit ReportAhmed HosneyNo ratings yet

- D Control of Records Section 4Document3 pagesD Control of Records Section 4Ngonidzashe ZvarevasheNo ratings yet

- CL 5313 17021-1 Requirements Matrix-1458-3Document6 pagesCL 5313 17021-1 Requirements Matrix-1458-3Amaro AlejandroNo ratings yet

- Quality Manual3Document9 pagesQuality Manual3Lokesh GandikotaNo ratings yet

- Job Description / Roles & ResponsibilitiesDocument2 pagesJob Description / Roles & ResponsibilitiesParveen (Atam Valves)No ratings yet

- How Can ISO 13485 Clause 7.4, Purchasing, Enhance ProcurementDocument3 pagesHow Can ISO 13485 Clause 7.4, Purchasing, Enhance ProcurementPavan MujawdiyaNo ratings yet

- Pub100373 PDFDocument12 pagesPub100373 PDFedgelcer100% (1)

- ISO 9001 Internal Audit ChecklistDocument14 pagesISO 9001 Internal Audit ChecklistEsterNTNo ratings yet

- Dydacomp's Multichannel Order Manager 7i Setup GuideDocument312 pagesDydacomp's Multichannel Order Manager 7i Setup GuideDydacompNo ratings yet

- Quality Manual 9001-2015 06-10-2021Document27 pagesQuality Manual 9001-2015 06-10-2021Geoff EricksonNo ratings yet

- Conformity Assessment (Management System Certification)Document5 pagesConformity Assessment (Management System Certification)Talal AhmedNo ratings yet

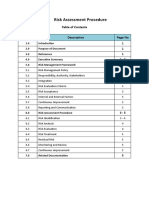

- M03 Risk Assessment ProcedureDocument7 pagesM03 Risk Assessment ProcedureMay Ann DuronNo ratings yet

- RP SP F 01 System Review MeetingDocument3 pagesRP SP F 01 System Review MeetingAnonymous SAWWr9Y3lyNo ratings yet

- Supplier Evaluation The First Step in Effective SoDocument4 pagesSupplier Evaluation The First Step in Effective SoShatender kumar Kumar100% (1)

- Good Distribution Practice A Complete Guide - 2020 EditionFrom EverandGood Distribution Practice A Complete Guide - 2020 EditionNo ratings yet

- Supplier Quality Management A Complete Guide - 2021 EditionFrom EverandSupplier Quality Management A Complete Guide - 2021 EditionNo ratings yet

- Integrated Management Systems: QMS, EMS, OHSMS, FSMS including Aerospace, Service, Semiconductor/Electronics, Automotive, and FoodFrom EverandIntegrated Management Systems: QMS, EMS, OHSMS, FSMS including Aerospace, Service, Semiconductor/Electronics, Automotive, and FoodNo ratings yet

- Specification For QMS Requirements 6-78-0001 - Rev. 1Document7 pagesSpecification For QMS Requirements 6-78-0001 - Rev. 1Ayush Choudhary100% (1)

- Procedure On Document ManagementDocument13 pagesProcedure On Document Managementndayiragije JMVNo ratings yet

- QP-024 Product IdentificationDocument7 pagesQP-024 Product Identificationesraa asemNo ratings yet

- SOP - Complaint & SurveyDocument5 pagesSOP - Complaint & SurveySheila BonusNo ratings yet

- Purpose: Document Name Retention of Sample Document NumberDocument2 pagesPurpose: Document Name Retention of Sample Document Numberumesh shindeNo ratings yet

- IAF - MD08 - 2020 - App ISO-IEC 17011 - ISO 13485Document19 pagesIAF - MD08 - 2020 - App ISO-IEC 17011 - ISO 13485Leonardo Navarro100% (1)

- Sop For Good Manufacturing Practices: Written by Verified by Function Name Signature DateDocument17 pagesSop For Good Manufacturing Practices: Written by Verified by Function Name Signature DateSreelakshmi RakeshNo ratings yet

- COMP-OPP-02 Procedure For Control and Validation of Service ProvisionDocument6 pagesCOMP-OPP-02 Procedure For Control and Validation of Service ProvisionISODCC DSPINo ratings yet

- Final AssignmentDocument6 pagesFinal Assignmentmhk665No ratings yet

- CONTROL AND TRACK STANDARD OPERATING PROCEDURESDocument7 pagesCONTROL AND TRACK STANDARD OPERATING PROCEDURESLooi Kok HuaNo ratings yet

- QSV 2 Product Release Procedure EN 01Document6 pagesQSV 2 Product Release Procedure EN 01prashanthNo ratings yet

- Nonconformity Report (NCR) : (Attach Separate Sheet, As Needed.)Document2 pagesNonconformity Report (NCR) : (Attach Separate Sheet, As Needed.)BALAJINo ratings yet

- F45 Follow Up Audit Report ISO 22000 EnglishDocument13 pagesF45 Follow Up Audit Report ISO 22000 Englishivan stojaovNo ratings yet

- Inspection Level IV Is Invoked, This System Meets The Requirements of Former MIL-I-45208ADocument18 pagesInspection Level IV Is Invoked, This System Meets The Requirements of Former MIL-I-45208AAdrian Copa JNo ratings yet

- Annual Repport SKFDocument20 pagesAnnual Repport SKFViswaChaitanya NandigamNo ratings yet

- GD TopicsDocument2 pagesGD TopicsViswaChaitanya NandigamNo ratings yet

- T-ENG CardDocument14 pagesT-ENG CardViswaChaitanya NandigamNo ratings yet

- T-ENG CardDocument14 pagesT-ENG CardViswaChaitanya NandigamNo ratings yet

- Central Excise ManualDocument391 pagesCentral Excise ManualKushalKale50% (2)

- Design Considerations or Factors of A Two Wheeler SuspensionDocument44 pagesDesign Considerations or Factors of A Two Wheeler SuspensionViswaChaitanya Nandigam100% (2)

- Letter of Recommendation Sample 1Document1 pageLetter of Recommendation Sample 1Arvind MuraliNo ratings yet