Professional Documents

Culture Documents

Kit Instructions

Uploaded by

Arm InOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kit Instructions

Uploaded by

Arm InCopyright:

Available Formats

8x8x8 LED Cube PART NO.

2168940

This LED Cube will light up any party. Your friends will be mesmerized by its hypnotic effect as lights dazzle and dance in brilliant patterns. It utilizes code based off of Instructables designer, CHR, and uses an Arduino UNO to power the cube and act as a programmer. This cube gives of a warm glow that is pleasant to the eye to entertain any person of any age. Though it might quite a commitment to build, the effort will be worth the wait. Surprise your friends and family with this incredible art piece, as it will be sure to turn heads. Don't skip this wonderful project because it offers invaluable opportunities for electronic construction and Arduino coding. I'll just leave it up to this video to convince you that this will be the next project you will be building. http://www.youtube.com/watch?feature=player_embedded&v=6mXM-oGggrM Time Required: Several Days depending on experience Experience Level: Advanced Required tools and parts:

Soldering Iron Solder Helping Hands Wire Cutters/Strippers Needle Nose Pliers Vice Aluminum Foil Peg Board or piece of wood Drill

Bill of Materials:

Qty

100 1 3 8 1 8 1 9 3 16 1 1 1 1 1 9 1 2 4

Jameco SKU

690620 206587 333973 38608 37373 46084 45330 153702 70755 178511 330722 93761 29891 690718 643831 525325 2151486 139231 139222

Component Name

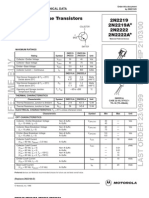

100 ohm Resistors Prototyping Board Status Red LEDs 20 Pin Chip Sockets 16 Pin Chip Socket SN74HC574N Chip 74HC138N Chip 8 Pin Male Header 8 Pin Female Header 2222A Transistor 1000uF Capacitor 100uF Capacitor 10uF Capacitor 240 ohm Resistor 16 Strand Ribbon Cable Ribbon Cable Header Arduino UNO 1" Standoffs 3/4" Standoffs

4 4 1 1 550 10 1

40970 40943 222010 2138636 2168421 25523 2153705

Screws, 4-40x3/8 Nuts, 4-40 USB Cable AC Adapter 3mm Round Diffused Blue LED 5K MCD Bulb Light .1uF Capacitor 25-Foot Hook-up Wire Bundle

Step 1 - Test the LEDs You will need 512 properly working LEDs in the lattice. They will need to be stable and bright. This step will show you how to separate the faulty ones from the usable ones. Lots of times there are broken LEDs, especially when they come in large packages. The damage may be noticeable but sometimes it is not. Start by bending the shorter leg (the cathode) at a 90 degree angle. Hook it up to a power supply and run 3V across it. You can do this with 2 AA batteries in series, but I had a power supply with alligator clips. Either way, just make sure the LEDs are working before you begin to solder.

Step 2 - Build the Rig Create an 8x8x8 template so you can create the layers. You will need a peg board and you will need to drill holes into the peg board to space the LEDs 1/2" apart. I put foil over my rig to hold the LEDs in place so that they wouldn't move while I solder, otherwise they would jiggle to much. Use the LEDs to punch holes into the foil.

Step 3 - Starting the Layer The picture should show you how to do it, but basically have all of the LEDs in the row facing the same way. Begin with the corner first. The corner row should be 90 degrees facing the other way. You should also align each LED so it is just barely touching the next

one. When you solder, don't hold the iron more than 2 seconds on the LED, otherwise it can be damaged. Apply minimal solder between each LED. I would NOT recommend to cut any wires until you have a working structure.

Step 4 - Solder in Rows Go row by row, in the same way as before. Make sure to apply minimal heat, and place the legs just close enough to each other, but not too close.

Step 5 - Add Reinforcements You must strengthen each layer to make them stable and durable. This is so the layer doesn't come apart when you pull it off the rig. Cut a piece of wire longer than the length of your layer and strip off the insulation. Place the long, stripped wire into a vice and pull hard to straighten it. You can do this with another set of pliers as well. You should feel the wire get longer and straighter as you pull. Once it is straight enough, place it on the opposite end of the layer and solder it on the cathodes to stabilize the rear end. Do this once more for the middle section, as now it is the weakest part of the layer. I used clips to hold the reinforcement bar in place while I soldered. These bars should strengthen the rear and middle of the cube so it won't break.

Step 6 - 8 Identical Layers Repeat the last three steps another seven times to complete your layers. This will take patience and time.

Step 7 - Let's Get Vertical Now with eight different layers, we will build up! I used triangular folds of paper to hold each layer above the other when I soldered. Make sure to place the first layer in the rig and start from there. I would recommend to bend the leads slightly so you can have each layer directly above the other, otherwise it can come out slightly crooked. Apply minimal heat and solder, and be careful when going into the cube with the iron. Read Step 10 before you begin to solder.

Step 8 - Looks Like Raindrops It should be looking good up to here.

Step 9 - Ground Lines The final step in lattice construction. These eight extra wires will drop down from each row to connect them to the board. So far, we have column connections but with these lines we will be able to control individual LEDs by separating the columns and rows apart. Do this by stripping wire as before and creating hooks at the end to secure each to its layer. Use solder to hold in place only at the row each line is designated for. Make sure each line only touches its layer and no other. They should extend the same length as the bottom-most legs.

Step 10 - Finishing the Lattice It should look something like this, although mine came out slightly rectangular because I spaced the layers out more than half an inch. Ultimately, this won't affect animations but it adds a personal effect to it.

Step 11 - Start the Controller Now let's start on the controller. Start by placing the chip sockets next to each other but to leave enough room for resistors and headers. I would advise to economize space but to leave yourself enough room to solder and place wires. Allocate a common GND and VCC line that will connect to each socket. I used small 0.1uF capacitors that are placed in between each socket for the VCC and GND line. The black wires are for the common GND line. VCC goes to pin 20 and GND goes to pin 10. Refer to the schematic in Step 12 for the rest of the steps.

Step 12 - Circuit Schematic

Step 13 - Solder Trails Use solder trails to minimize wiring. I used them to bus a VCC line to each chip socket. Refer to this video if you don't know how: http://www.youtube.com/watch?feature=player_embedded&v=kROaQZOYNIw

Step 14 - Power Terminal This is the power portion of the controller board. It consists of a couple of capacitors and a status LED. Follow the top most diagrams in the schematic. You may or you may not want to include a power switch... I didn't.

Step 15 - Data Lines Connect the chip sockets to each other. You will need to connect each identical pin to the other in one bus. This is what that blue line on the schematic means. So connect pin 1 to all the other pin 1's and do this for the rest of pins 2-8. Think of it as daisy chaining the pins to each other.

Step 16 - Resistors and Headers Use those 100 ohm resistors in between pins 12-19 and the 8 pin male header for each chip. These resistors should be enough, assuming you're powering 5V from the Arduino. The male headers are used to connect to each of the eight rows of the lattice.

Step 17 - Address Selector The address selector chip will control the clock cycles to each chip. Start by soldering the GND and VCC connections. If you use the solder trace method to run GND/VCC lines, you want to do this before you solder any other wires in place. A 100nF ceramic filtering capacitor is placed close to the VCC and GND pins of the 74HC138. Then connect the address lines and the eight clock lines. If you look carefully at the connector, you can see two pins that are not used. These will be used for a button and debug LED later.

Step 18 - Transistor Schematic Use this schematic for the following step

Step 19 - Transistor Array The transistor array is responsible for switching on and off GND for each layer in the LED cube. For each layer, use two PN2222As in parallel. The collectors are connected together to GND. The emitters need to be connected together in pairs, then connected to a male header. Introduce the pull-up resistors to reduce ghosting. The base of each transistor is connected to it's own resistor, and they are paired up to be connected to an output pin on the Arduino. Connection to the Arduino will come shortly. We soldered in all the transistors and turned the thing on again, and it worked, perfectly!

1) Start by placing all 16 transistors on the PCB and soldering each of their pins. 2) Run a solder trace between the the emitters of all 16 transistors. Connect this solder trace to GND. 3) Solder in a resistor for each transistor, the solder the resistors together in pairs of two. 4) Run wire from each of the eight resistor pairs to a female header. This is where the Arduino will connect. 5) Solder together the collectors of the transistors in pairs of two and run solder trace or wire from the collector pairs to an 8 pin male header. Place 100 ohm resistors between the header and VCC.

Step 20 - Connection Schematic Use this schematic and refer back to the first one in Step 10 to see how to wire the Arduino. Either an Arduino UNO or Diecimila will work. Also, refer to the connection key at the top of the picture, as this really ties both schematics together to make things easier for you. Special thanks to MAEWART for his translation to Arduino, and CHR for his invaluable guidance and schematic.

Step 21 - Connecting the Arduino Use two female headers side-by-side to act as the port to your controller. This port will have wires running from the Arduino to the controller so it can receive data. Refer back to the first schematic to see how it should be wired. I started by naming pins 1 and 2 across from each other and having the odd and even pins on separate headers. In addition, there will be two status LEDs that can be used later for debugging. This port will send information to the address selector and to the chips connected in parallel. Crimping won't be necessary.

Step 22 - Enclosure Base Create the base for the cube to make it look pretty. I was able to find a smoky reflective surface at my local Tap Plastics. Begin by drilling an 8x8 matrix of holes just big enough to fit the legs of the LEDs through. Space the holes out appropriately to your cube. In addition, add eight holes for the ground connections. Fitting the cube through these holes was probably the toughest part of the entire project, but it can be done. I recommend to start with one row and bend the legs as they pass through the base. Fit the rest in sections, as it will be impossible to do it all at once. It would be like threading 72 needles at once, yikes! Do this carefully without damaging the lattice of the base.

Step 23 - Ribbon Cables Place the cable and header into a vice and gently press the vice until the header snaps close around the cable. Strip the opposite ends of the cable, just enough to reveal an inch of exposed wire. Wrap two of the closest wires together and solder the pair to an LED on the underside of the base. Continue with the rest of the wire until each LED in a row is wired. You will need nine ribbon cables, counting the ground lines. They will connect to the nine male headers on your board. The orientation of the header shouldn't matter, but each cable should have its own designated chip in order.

Step 24 - Build an Enclosure This could be anything you'd like it to be, just be creative. Either you might want something ordinary, like a dark box, or you might want people to see all the electronics that are underneath the cube. Whatever it may be, have fun with this part.

Step 25 - Code and Sendoff! There are a variety of source codes and header files for you to use and play around with in order to add additional effects. So far on the code I have more than ten different effects going. Play around with the order, delay, and iterations to truly make it unique! Well, that's it for instructions. I hope you had fun building this project and at least pulled something worthwhile out of it. Show it off to your friends and family, because they will surely get a kick out of it. This project couldn't have been completed without the assistance from CHR and his Instructable, so a special thanks to him. Be sure to keep a creative attitude and never stop progressing. I'll set you off your own way now, and until next time! Here's CHR's Instructable for further guidance: http://www.instructables.com/id/Led-Cube-8x8x8/

You might also like

- 8x8x8 LED CubeDocument5 pages8x8x8 LED CubeFawaz Bin AbdullaNo ratings yet

- Blue 8x8x8 LED Cube Kit - PCB VersionDocument6 pagesBlue 8x8x8 LED Cube Kit - PCB VersionsiogNo ratings yet

- Build A Programmable LED CubeDocument8 pagesBuild A Programmable LED Cubeamitsahoo13-1No ratings yet

- Synth Manual V1Document26 pagesSynth Manual V1REMINTE100% (3)

- 1.0.0 - Arduino Plant Watering SystemDocument22 pages1.0.0 - Arduino Plant Watering Systemghoshsanjoy1986No ratings yet

- 20 Electronics Beginner Led Projects Electronic Technology Simple Circuit and ProjectsDocument58 pages20 Electronics Beginner Led Projects Electronic Technology Simple Circuit and Projectsdavid reyesNo ratings yet

- Diy Minipro DC/DC ConverterDocument14 pagesDiy Minipro DC/DC Convertermrcinek01No ratings yet

- introLED Cube 4x4x4Document14 pagesintroLED Cube 4x4x4Harinder SinghNo ratings yet

- Some HintsDocument8 pagesSome HintsSyeda Zeilehuma JaffriNo ratings yet

- DPScope Assembly Guide V1 1Document27 pagesDPScope Assembly Guide V1 1alsan2002No ratings yet

- Synth Manual V2.0 PrintDocument30 pagesSynth Manual V2.0 PrintJonNo ratings yet

- Arduino CNC Controller For ESTLCAMDocument10 pagesArduino CNC Controller For ESTLCAMglamuraNo ratings yet

- LED Cube 4x4x4Document6 pagesLED Cube 4x4x4Dusan Petrovic100% (1)

- Share What You MakeDocument16 pagesShare What You MakeSameer ChakoleNo ratings yet

- Repair Neovo E17daDocument10 pagesRepair Neovo E17dasttecnicoNo ratings yet

- How To Make Your Own LED LightbulbsDocument13 pagesHow To Make Your Own LED LightbulbsNeagoe Cristian100% (1)

- From Schematic To VeroboardDocument12 pagesFrom Schematic To Veroboardcracker01No ratings yet

- Arduino LED Fuel GaugeDocument13 pagesArduino LED Fuel GaugeavalosheNo ratings yet

- EIGHT Electronic Games AdCal Instructions Nov21 - 230925 - 190245Document28 pagesEIGHT Electronic Games AdCal Instructions Nov21 - 230925 - 190245Curtis SawyerNo ratings yet

- Bread BoardDocument4 pagesBread BoardSathish BalaNo ratings yet

- Breadboarding Basics TCADocument27 pagesBreadboarding Basics TCARost Hariton100% (1)

- GMLAB Rondo Assembly InstructionsDocument14 pagesGMLAB Rondo Assembly InstructionsJames SpadavecchiaNo ratings yet

- How To Build Pedalshield Mega v1.0Document6 pagesHow To Build Pedalshield Mega v1.0CarlosNo ratings yet

- Digital Delay Kit Instructions (Bezel Free Version) : If Your Kit Contains An LED Bezel UseDocument13 pagesDigital Delay Kit Instructions (Bezel Free Version) : If Your Kit Contains An LED Bezel UseMike SkillicornNo ratings yet

- Your-First-Experiments Blink CircuitDocument20 pagesYour-First-Experiments Blink CircuitLandy AdianetNo ratings yet

- "Easy" Infinity Cube: InstructablesDocument19 pages"Easy" Infinity Cube: Instructablesmonocrome fajar tjahyonoNo ratings yet

- Breadboard TutorialDocument30 pagesBreadboard Tutorialkalscrib100% (1)

- Building Circuits On BreadboardsDocument23 pagesBuilding Circuits On Breadboardsniyop4allNo ratings yet

- 7-Segmen Led Display Digital VoltmeterDocument8 pages7-Segmen Led Display Digital VoltmeterJoey TorresNo ratings yet

- Golf Mk4 Cajgeri I OsvetljenjeDocument41 pagesGolf Mk4 Cajgeri I OsvetljenjeDejan Djukic0% (1)

- BYOC E.S.V. 2-Knob Bender Kit InstructionsDocument19 pagesBYOC E.S.V. 2-Knob Bender Kit Instructionsrick_marcominiNo ratings yet

- SNES Classic Mini Internal Bluetooth Modification: InstructablesDocument9 pagesSNES Classic Mini Internal Bluetooth Modification: InstructablesKIRUBEL MENBERUNo ratings yet

- TuringMachine Expanders 1.1Document14 pagesTuringMachine Expanders 1.1Nico PinealNo ratings yet

- Digital VoltmeterDocument7 pagesDigital VoltmeterKrishna KithuNo ratings yet

- Installation Guide: Thank You For Purchasing The Ultimate Sega Saturn Mod Chip!Document16 pagesInstallation Guide: Thank You For Purchasing The Ultimate Sega Saturn Mod Chip!jkNo ratings yet

- DIY - LAN Cable TesterDocument1 pageDIY - LAN Cable Testernetacc20052002No ratings yet

- Lecture 1 The BreadboardDocument25 pagesLecture 1 The BreadboardgopinathNo ratings yet

- LED Propeller ClockDocument22 pagesLED Propeller Clockkola vamshiNo ratings yet

- Nigc Kit-Users GuideDocument49 pagesNigc Kit-Users GuideJaco HerholdtNo ratings yet

- Casio DM100 Sample ExpansionDocument17 pagesCasio DM100 Sample ExpansionSesan del futuroNo ratings yet

- Wiring The Toyota Crown 1UZDocument11 pagesWiring The Toyota Crown 1UZLahiru MadusankaNo ratings yet

- Connections On Breadboard: The Diagram Shows How The Breadboard Holes Are ConnectedDocument3 pagesConnections On Breadboard: The Diagram Shows How The Breadboard Holes Are ConnectedyoungmoonNo ratings yet

- GK Build Instructions v5-5Document12 pagesGK Build Instructions v5-5Raghavendra RaoNo ratings yet

- Varikabo Manual 180815Document57 pagesVarikabo Manual 180815Antony KanourasNo ratings yet

- Arduino Plant Watering System: InstructablesDocument8 pagesArduino Plant Watering System: InstructablesMaaz MomindadaNo ratings yet

- The Optical Compressor: WWW - Jedspeds.co - UkDocument7 pagesThe Optical Compressor: WWW - Jedspeds.co - UkAndrés GaleottiNo ratings yet

- Nintendo 64 Power Supply Capacitor Replacement KitDocument12 pagesNintendo 64 Power Supply Capacitor Replacement KitlookeadorNo ratings yet

- Sound Card Oscilloscope - MakeDocument14 pagesSound Card Oscilloscope - MakezaphossNo ratings yet

- 40k LED Lighting TutorialDocument12 pages40k LED Lighting TutorialNicholas D. TerryNo ratings yet

- Lazy 7 MiniDocument36 pagesLazy 7 MinidiegargyNo ratings yet

- Dds 2016vmanualDocument11 pagesDds 2016vmanualalirisad aliNo ratings yet

- Mini Power Supply 33v 5A ScriptDocument8 pagesMini Power Supply 33v 5A ScriptIlago BenignoNo ratings yet

- Chibitronics Sketchbook-En-V1Document92 pagesChibitronics Sketchbook-En-V1api-299738243No ratings yet

- 3x3x3 Red LED Cube For ArduinoDocument8 pages3x3x3 Red LED Cube For Arduinoshahbaz75sbNo ratings yet

- Kastle v1.5 Assembly GuideDocument16 pagesKastle v1.5 Assembly GuideArto SillanpääNo ratings yet

- Installation Guide: Thank You For Purchasing The Ultimate Sega Saturn Mod Chip!Document17 pagesInstallation Guide: Thank You For Purchasing The Ultimate Sega Saturn Mod Chip!benoitveilleuxNo ratings yet

- ECU Tester Kit - Build Instructions V2.0Document10 pagesECU Tester Kit - Build Instructions V2.0JonatanNo ratings yet

- Digital LED Thermometer with Microcontroller AVR ATtiny13From EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Rating: 5 out of 5 stars5/5 (1)

- Repair VP 44 PumpDocument11 pagesRepair VP 44 PumpArvis ŽigalovsNo ratings yet

- Q2 - MODULE4-5 - G7 - G8 - CSS - San Nicolas NHSDocument20 pagesQ2 - MODULE4-5 - G7 - G8 - CSS - San Nicolas NHSDirty Sam LicudoNo ratings yet

- FET and MOSFETDocument46 pagesFET and MOSFETKULWANT SINGHNo ratings yet

- 1978 Fairchild Linear Interface Data BookDocument538 pages1978 Fairchild Linear Interface Data Bookkgrhoads100% (1)

- Excel Item Master Template and ExampleDocument60 pagesExcel Item Master Template and Examplevaibhavmalhotra140% (1)

- The Blocking OscillatorDocument2 pagesThe Blocking OscillatorJoseGarciaRuizNo ratings yet

- PYHSIC FORM 5 Short TRANSISTOR NoteDocument3 pagesPYHSIC FORM 5 Short TRANSISTOR NoteFahmi IsNo ratings yet

- Engineering Design Handbook - Servomechanisms, Sections 1-4Document477 pagesEngineering Design Handbook - Servomechanisms, Sections 1-4sandi123in100% (2)

- Electrical SymbolsDocument7 pagesElectrical SymbolsZativa AlyaNo ratings yet

- Water Level Indicator Project PaperDocument4 pagesWater Level Indicator Project PaperMichelle Batad0% (1)

- Effect of Intensity of Light On A LDR (Light Dependent Resistor) PDFDocument26 pagesEffect of Intensity of Light On A LDR (Light Dependent Resistor) PDFMiguel PenarandaNo ratings yet

- BJT 1Document33 pagesBJT 1Deepthi S RNo ratings yet

- A1488 SavantICDocument4 pagesA1488 SavantICScabiesNo ratings yet

- Dark Sensor Using LDR On PCB FINALDocument14 pagesDark Sensor Using LDR On PCB FINALÃrunãv ÃdhikãryNo ratings yet

- Previous Year Board Exam Questions (2007-2016) : Semiconductor DevicesDocument13 pagesPrevious Year Board Exam Questions (2007-2016) : Semiconductor DevicesRishabh AgarwalNo ratings yet

- ECE464 589-SyllabusDocument3 pagesECE464 589-SyllabusHUANG YINo ratings yet

- Point Contact TransistorDocument3 pagesPoint Contact TransistorGilberto ManhattanNo ratings yet

- NavDocument202 pagesNavfcoespinosa100% (1)

- Chetan Waghchoure BxeDocument10 pagesChetan Waghchoure BxeHimanshu BhusariNo ratings yet

- Using High Accuracy Models To Achieve First Pass Design Success - A Transmitter Case Study - Part 2, Power Amplifier Design PDFDocument11 pagesUsing High Accuracy Models To Achieve First Pass Design Success - A Transmitter Case Study - Part 2, Power Amplifier Design PDFArun KumarNo ratings yet

- SOC Unit 1 Part2Document24 pagesSOC Unit 1 Part2Karthick NpNo ratings yet

- Electronics 1968 02 19Document250 pagesElectronics 1968 02 19Manuel ĆulibrkNo ratings yet

- AutomotiveEngineering 1Document138 pagesAutomotiveEngineering 1Adrian Mendoza100% (1)

- Assignment Questions ECE VLSI NITTDocument6 pagesAssignment Questions ECE VLSI NITTAkhilGovindNo ratings yet

- Two Marks Q&A Unit - I: CO BeoDocument21 pagesTwo Marks Q&A Unit - I: CO BeoReddyvari VenugopalNo ratings yet

- Multiple Choice Questions and Answers On FET - Electronics Post PDFDocument24 pagesMultiple Choice Questions and Answers On FET - Electronics Post PDFmokhalad0% (1)

- 2N2222A MotorolaDocument6 pages2N2222A MotorolaRucelle Chiong GarcianoNo ratings yet

- B.sc. Maths III & IV Sem 2018Document16 pagesB.sc. Maths III & IV Sem 2018Pranjal SharmaNo ratings yet

- Analyze Transistor Biasing Circuits - Load Lines (FET - MOSFET)Document19 pagesAnalyze Transistor Biasing Circuits - Load Lines (FET - MOSFET)KishenNo ratings yet

- Form 5 Physics Chapter 4 - Teacher'sDocument11 pagesForm 5 Physics Chapter 4 - Teacher'sPavithiran75% (4)