Professional Documents

Culture Documents

Solution Q 2

Uploaded by

Vivek KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solution Q 2

Uploaded by

Vivek KumarCopyright:

Available Formats

2) Setup time for Manual drill is less but as the order size increases corresponding time taken for

processing increases rapidly in comparison to CNC Drill, which makes it suitable for small order size. So after one point of order size, switching to CNC drill will be beneficial Optimized Order size for Drill Consideration 15+.08* 500 * x = 240 + .004 * 500 * x X = 6.184 For X < 6 go for manual drill, x>= 6 go for CNC Drill

Similarly for profiling the panel in to boards, Donner should choose between the CNC Router and Punch press based on the order size, where punch press is economical for lower order size but for larger size we need to switch to CNC Router. Optimized Order size for Profiling 50 + 1 * X = 150 + .5 *X X = 200 So for x > 200 we should go for CNC Router which will be consuming less time.

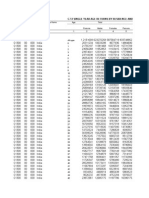

Assuming 22 workers working for 8 hours a day, So the capacity will vary based on the batch size and methodology used. Based on the above Calculation we choose the methodology for drilling and profiling. As a result following capacity can be achieved with respect to batch size.

Capacity ( Board Per day)

1800 1600 1400 1200 1000 800 600 400 200 0 1 5 10 20 50 100 150 200 300 500 1000 Capacity ( Board Per day)

No of Board per order Method Punch Press TIME CNC Router Punch Press CNC Router No of Panel Manual Drill CNC Drill CNC Drill Manual Dril Total Man Mins Min Cycle Time Per day Capacity

1 1 396.55 683.05 583.55 496.05 10560 396.55 26.63

5 1 566.55 699.05 601.55 664.05 10560 566.55 93.20

10 2 794.1 734.1 639.1 889.1 10560 639.1 165.23

20 3 1234.15 789.15 699.15 1324.15 10560 699.15 302.08

50 7 2569.35 969.35 894.35 2644.35 10560 894.35 590.37

100 13 4784.65 1259.65 1209.65 4834.65 10560 1209.65 872.98

200 25 9215.25 1840.25 1840.25 9215.25 10560 1840.25 1147.67

500 63 22537.15 3612.15 3762.15 22387.15 10560 3612.15 1461.73

1000 125 44720.25 6545.25 6945.25 44320.25 10560 6545.25 1613.38

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Age DataDocument147 pagesAge DataVivek KumarNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Wizz AirDocument2 pagesWizz AirVivek KumarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- PassportddDocument1 pagePassportddVivek KumarNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Travel PolicyDocument4 pagesTravel PolicyVivek KumarNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Leasecalculator: Keyed To "Valuation of Financial Lease Contracts," Myers SC, Dill DA, Bautista, AJ InputDocument3 pagesLeasecalculator: Keyed To "Valuation of Financial Lease Contracts," Myers SC, Dill DA, Bautista, AJ InputVivek KumarNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Ru 3 SQ de Y7 U 4 Uux QIDocument6 pagesRu 3 SQ de Y7 U 4 Uux QIVivek KumarNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- PrabhaSingh HealthStatusReport 101904Document9 pagesPrabhaSingh HealthStatusReport 101904Vivek KumarNo ratings yet

- MM Case Presentation - V4Document18 pagesMM Case Presentation - V4Vivek KumarNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Information On Visa Application Photograph: in Case An Applicant Wears GlassesDocument1 pageInformation On Visa Application Photograph: in Case An Applicant Wears GlassesVivek KumarNo ratings yet

- Industry SummaryDocument2 pagesIndustry SummaryVivek KumarNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Kartik - Oki Doki Hostel Booking ConfirmationDocument2 pagesKartik - Oki Doki Hostel Booking ConfirmationVivek KumarNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Pre-Test Chapter 6 Ed17Document8 pagesPre-Test Chapter 6 Ed17Vivek KumarNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- CCS ProposalDocument4 pagesCCS ProposalVivek KumarNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Assignment 2Document9 pagesAssignment 2Vivek KumarNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- MM - Sec F GroupsDocument2 pagesMM - Sec F GroupsVivek KumarNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- AdvMicroSolutions PDFDocument27 pagesAdvMicroSolutions PDFĐỗ Huy HoàngNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Bi BiDocument23 pagesBi BiJosephat MandaraNo ratings yet

- Plagiarism Checker - Viper - Free Plagiarism Checker and Scanner SoftwareDocument3 pagesPlagiarism Checker - Viper - Free Plagiarism Checker and Scanner SoftwareVivek Kumar0% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- RobinhoodDocument2 pagesRobinhoodApurva NadkarniNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- FUTURES SDocument20 pagesFUTURES SVivek KumarNo ratings yet

- Leadership MatrixDocument17 pagesLeadership MatrixVivek KumarNo ratings yet

- Financial Markets & Instruments: Investments Term 3 (2013-15)Document31 pagesFinancial Markets & Instruments: Investments Term 3 (2013-15)Vivek KumarNo ratings yet

- Excel Tool VBA Password RecoveryDocument1 pageExcel Tool VBA Password RecoveryMohammad AlshikhNo ratings yet

- Matching Dell - Cost AnalysisDocument1 pageMatching Dell - Cost AnalysisVivek Kumar100% (2)

- Viv 2Document9 pagesViv 2Vivek KumarNo ratings yet

- Matching Dell - Cost AnalysisDocument1 pageMatching Dell - Cost AnalysisVivek Kumar100% (2)

- Error SheetDocument3 pagesError SheetVivek KumarNo ratings yet

- Excel Tool VBA Password RecoveryDocument1 pageExcel Tool VBA Password RecoveryMohammad AlshikhNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Saraansh Volume3Document2 pagesSaraansh Volume3Vivek KumarNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)