Professional Documents

Culture Documents

TI077DEN

Uploaded by

ChevronelleCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TI077DEN

Uploaded by

ChevronelleCopyright:

Available Formats

Technical Information

CNGmass

Coriolis Mass Flow Measuring System For fueling with Compressed Natural Gas (CNG)

Applications The Coriolis measuring principle works independently of the physical fluid properties. Specially designed flowmeter for fueling vehicles with CNG (compressed natural gas) Fluid temperature up to +125 C Process pressures up to 350 bar Mass flow measurement up to 150 kg/min Approvals for hazardous area: ATEX, FM, CSA Connection to common control systems: MODBUS RS485

Your benefits The Promass measuring devices allow you record multiple process variables (mass/density/temperature) simultaneously during operation for diverse process conditions. The transmitter concept comprises: ToF-Tool/FieldTool Package for onsite operation and diagnosis Very low energy consumption The Promass sensors, tried and tested in over 100,000 applications, offer: Space-saving and compact design Insensitivity to vibrations thanks to balanced twintube measuring system Easy installation without taking inlet or outlet runs into account

TI077D/06/en/12.06 71036552

CNGmass

Table of contents

Function and system design. . . . . . . . . . . . . . . . . . . . . 3

Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Setting up custody transfer mode . . . . . . . . . . . . . . . . . . . . . . . . 10 Disabling custody transfer mode . . . . . . . . . . . . . . . . . . . . . . . . . 10

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . 11 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Measured variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Measuring ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Operable flow range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Design / dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Material load diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Process connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 11 11 12 12

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Galvanic isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Human interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Display elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Remote operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electrical connection, measuring unit . . . . . . . . . . . . . . . . . . . . . . 5 Electrical connection, terminal assignment . . . . . . . . . . . . . . . . . . 5 Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Cable entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Cable specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Power supply failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Potential equalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Certificates and approvals . . . . . . . . . . . . . . . . . . . . . 14

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-tick mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ex approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MODBUS certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pressure device approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Other standards and guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . 14 14 14 14 14 14

Ordering information. . . . . . . . . . . . . . . . . . . . . . . . . 14 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . . 15

Performance characteristics. . . . . . . . . . . . . . . . . . . . . 6

Reference operating conditions for factory calibration . . . . . . . . . 6 Maximum measured error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Influence of medium temperature . . . . . . . . . . . . . . . . . . . . . . . . . 7 Influence of medium pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operating conditions: Installation . . . . . . . . . . . . . . . . 7

Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Inlet and outlet runs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operating conditions: Environment. . . . . . . . . . . . . . . 8

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Shock resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Vibration resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Electromagnetic compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . 8

Operating conditions: Process . . . . . . . . . . . . . . . . . . . 9

Medium temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Medium pressure range (nominal pressure) . . . . . . . . . . . . . . . . . 9 Rupture disk in the sensor housing . . . . . . . . . . . . . . . . . . . . . . . . 9 Limiting flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Custody transfer measurement . . . . . . . . . . . . . . . . . 10

Custody transfer variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Suitability for custody transfer measurement, approval by the Standards Authorities, repeated calibration due to legal metrology controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Approval for custody transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Verification process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Endress+Hauser

CNGmass

Function and system design

Measuring principle The measuring principle is based on the controlled generation of Coriolis forces. These forces always occur in a system where translational (linear) and rotational movements are superimposed simultaneously. FC = 2 m (v ) FC = Coriolis force m = moving mass = rotational velocity v = radial velocity in rotating or oscillating system The size of the Coriolis force depends on the moving mass m, its velocity v in the system, and thus the mass flow. Instead of a constant rotational velocity , Promass uses oscillation. In the sensor, two parallel measuring tubes containing flowing fluid oscillate in antiphase, acting like a tuning fork. The Coriolis forces produced at the measuring tubes cause a phase shift in the tube oscillations (see illustration): At zero flow, in other words when the fluid is at a standstill, the two tubes oscillate in phase (1). Mass flow causes deceleration of the tube oscillation at the inlet (2) and acceleration at the outlet (3).

A B

A B

A B

3

A0006995

The phase difference (A-B) increases with increasing mass flow. Electrodynamic sensors register the tube oscillations at the inlet and outlet. System balance is ensured by the antiphase oscillation of the two measuring tubes. The measuring principle works independently of temperature, pressure, viscosity, conductivity and flow profile. Density measurement The measuring tubes are always excited at their resonance frequency. A change in the mass and thus the density of the oscillating system (comprising measuring tubes and fluid) results in a corresponding, automatic adjustment in the exciter frequency. Resonance frequency is thus a function of fluid density. The microprocessor utilizes this relationship to obtain a density signal. Temperature measurement To make calculations to compensate for temperature effects, the temperature of the measuring tubes is measured. This signal corresponds to the process temperature and is also available as an output signal.

Endress+Hauser

CNGmass

Measuring system

The measuring system consists of the transmitter and sensor which together form a mechanical unit. Measuring system

CNGmass Without onsite operation Configuration via MODBUS RS485 and "ToF Tool - FieldTool Package" Limiting medium pressure range max. 350 bar Ambient temperature range: 40 to +60 C

A0006979

Input

Measured variable Mass flow (proportional to the phase difference between two sensors mounted on the measuring tube which record differences in the pipe oscillation geometry during flow) Volume flow (measured from the mass flow and density) Fluid density (proportional to the resonance frequency of the measuring tube) Fluid temperature (measured with temperature sensors) Measuring ranges for Compressed Natural Gas (CNG), non-custody transfer operation.

DN 15 25 mmin to mmax 80 kg/min 150 kg/min

Measuring ranges

!

Operable flow range

Note! The values of the corresponding custody transfer certificate apply for custody transfer operation. 1:100

Output

Output signal Pulse / frequency output: Passive Galvanically isolated Open Collector Max. 30 V DC Max. 250 mA Frequency output: end frequency 100 to 5000 Hz, on/off ratio 1:1 Pulse output: pulse value and pulse polarity selectable, pulse width configurable (0.1 to 1000 ms)

Status output: Passive Open Collector Max. 30 V DC Max. 250 mA

Endress+Hauser

CNGmass

MODBUS interface: Signal on alarm MODBUS device type: slave Address range: 1 to 247 Functions codes supported: 03, 04, 06, 08, 16, 23 Broadcast: supported with the function codes 06, 16, 23 Physical interface: RS485 in accordance with standard EIA/TIA-485 Baud rates supported: 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200 Baud Transmission mode: RTU or ASCII Response time = typically 5 ms

Pulse / frequency output: Failsafe mode can be selected Status output: Assignment can be selected MODBUS RS485: Failsafe mode can be selected

Galvanic isolation

All circuits for outputs and power supply are galvanically isolated from each other.

Power supply

Electrical connection, measuring unit

c d c d

A

a

b

27 26 25 24 23 22 + + + 2 1 N L1 (L-) (L+)

A0006923

Connecting the transmitter, cable cross-section: max. 2.5 mm2 A a b c View A Safety claw Terminal compartment cover Signal cable: terminal Nos. 22-27 (shield for Modbus RS485 is mandatory; shield for pulse, frequency and status outputs is not required, but recommended) Cable for power supply: 20 to 28 V AC, 10 to 30 V DC Terminal No. 1: L1 for AC, L+ for DC Terminal No. 2: N for AC, L- for DC

Electrical connection, terminal assignment

CNGmass

Terminal No. (inputs/outputs) Order version 8FF**-***********N 22 (+) / 23 () Pulse/frequency/status output 2 24 (+) / 25 () Pulse/frequency/status output 1 26 (+) / 27 () MODBUS RS485

Endress+Hauser

CNGmass

Supply voltage

24 V DC nominal voltage (10 to 30 V DC) 24 V AC nominal voltage (20 to 28 V AC) Power supply and signal cables (outputs): Cable entry M20 x 1.5 (8 to 12 mm) Threads for cable entries, " NPT, G " Each compatible cable, with a temperature specification at least 20C higher than the ambient temperature prevailing in the application. We recommend using a cable with a temperature specification of +80C. for MODBUS RS485: Characteristic impedance = 120 Cable capacitance = < 30 pF/m Core cross-section = > 0.34 mm2, corresponds to AWG 22 Cable type = twisted pairs Loop-resistance = 110 /km Shielding = copper braided shielding or braided shielding and foil shielding

Cable entries

Cable specifications

Power consumption

AC: < 4 VA DC: < 3.2 W Typical switch-on current at 24 V DC nominal voltage at Ri = 0.1 of the source.

t [ms] 0 0.1 0.2 0.5 1 2 5 10 I [A] 10 8 7.5 7 6 4 1.5 0.125 (operating current)

!

Power supply failure Potential equalization

Note! The internal resistance of the source may not exceed Ri = 10 . Bridging of at least 20 ms. All measuring cell and measuring point data are maintained. This measuring instrument is suitable for potentially explosive atmospheres; refer to the correspondingly information in the specific Ex-specific supplementary documentation.

Performance characteristics

Reference operating conditions for factory calibration Error limits following ISO/DIS 11631: Fluid: water 15 to 45 C; 2 to 6 bar Calibration rigs traced to national metrology standards. Zero point calibrated under operating conditions Field density adjustment carried out Mass flow: 0.5 % of the quantity filled in typical CNG fueling with the coefficients determined during factory calibration. Mass flow: 0.25% of the quantity filled in typical CNG fueling.

Maximum measured error

Repeatability

Endress+Hauser

CNGmass

Influence of medium temperature Influence of medium pressure

When there is a difference between the temperature for zero point adjustment and the process temperature, the typical measured error is 0.0003% of the full scale value/C. The following section shows the effect on accuracy of mass flow due to a difference between calibration pressure and process pressure is negligible.

Operating conditions: Installation

Installation instructions Note the following points: No special measures such as supports are necessary. The housing absorbs external forces. The high oscillation frequency of the measuring tubes ensures that the correct operation of the measuring system is not influenced by pipe vibrations. No special precautions need to be taken for fittings which create turbulence (valves, elbows, T-pieces, etc.). Turning the transmitter housing The transmitter housing can be rotated counterclockwise continuously up to 360.

A0006921

1 = Allen screw

Endress+Hauser

CNGmass

Zero point adjustment All measuring devices are calibrated with state-of-the-art technology. The zero point obtained in this way is printed on the nameplate. Calibration takes place under reference operating conditions ( Page 6). Therefore, a zero point adjustment is generally not required! If you want to carry out a zero point adjustment, note the following points before doing so: The calibration can be carried out under stable pressure conditions only. The zero point adjustment is carried out a zero flow. This can be achieved, for example, with shutoff valves upstream and/or downstream of the sensor or by using existing valves and gates. Normal operation Valves 1 and 2 open Zero point adjustment with process pressure * Valve 1 open / valve 2 closed Zero point adjustment without process pressure * Valve 1 open / valve 2 closed A zero point adjustment is not possible if the SECURITY function is enabled or if an error message is pending.

A0006928

Zero point adjustment and shut-off valves

Inlet and outlet runs

There are no installation requirements regarding inlet and outlet runs.

Operating conditions: Environment

Ambient temperature range 40 to +60 C (sensor, transmitter) Note! Install the device at a shady location. Avoid direct sunlight, particularly in warm climatic regions. 40 to +80 C (preferably +20 C) Standard: IP 67 (NEMA 4X) for transmitter and sensor In accordance with IEC 68-2-31 and EN 60721 (Class 2M3) In accordance with IEC 68-2-31 and EN 60721 (Class 2M3) As per EN 61326 (IEC 1326)

!

Storage temperature Degree of protection Shock resistance Vibration resistance Electromagnetic compatibility (EMC)

Endress+Hauser

CNGmass

Operating conditions: Process

Medium temperature range Medium pressure range (nominal pressure) Rupture disk in the sensor housing 50 to +125 C Measuring tubes, connector: max. 350 bar

Triggering pressure in the housing 10 to 15 bar The position of the rupture disk is indicated by an adhesive label on top of the disk. If the rupture disk is triggered, the adhesive label is damaged and can thus be visually monitored.

RUPTURE DISK

A0006920

Additional sign regarding the position of the rupture disk (RUPTURE DISK)

Limiting flow

See information in the "Measuring range" Section Page 4

Endress+Hauser

CNGmass

Custody transfer measurement

CNGmass is a flowmeter for Compressed Natural Gas (CNG) that is suitable for custody transfer measurement. Custody transfer variables Suitability for custody transfer measurement, approval by the Standards Authorities, repeated calibration due to legal metrology controls Approval for custody transfer Mass flow All flowmeters are typically verified on site using reference measurements. Only once it has been approved by the authority for legal metrology controls may the measuring device be regarded as verified and used for applications subject to legal metrology controls. The associated seal on the measuring device ensures this status.

The following guidelines for the custody transfer process were developed in accordance with the following authorities for legal metrology controls:

PTB NMi Germany Netherlands METAS BEV Switzerland Austria NTEP MC USA Canada

Verification process Setting up custody transfer mode

The verification process is regulated by national rules or regulations. The flowmeter must be locked for custody transfer measurement. For this purpose, the switches (c + d) are moved to the position shown below (1). You receive confirmation from the status LED ( Page 12). Then, fit the cover and have the safety claw sealed by a person authorized to do so (2).

d

A0006929

Switch locked

Disabling custody transfer mode

The flowmeter can be reset to exit custody transfer mode. To do so, destroy and remove the seal on the safety claw (1). This process may be carried out by authorized personnel only. Open the cover. Return switches (c + d) to the position shown below (2). You receive confirmation from the status LED ( Page 12).

d

A0006930

Switch unlocked

10

Endress+Hauser

CNGmass

Mechanical construction

Design / dimensions Dimensions (non-hazardous area and II2G / Zone 1)

D E I

F G di

A0006968

Dimensions in metric units DN 15 25 A 308 313 B 208 208 C 100 105 D 160 160 E 92 92 F 193 244 G 267 316 H 41 46 I 139 139 K G" G1" di 6.23 8.8

Weight

DN 15 = 8.3 kg DN 25 = 9.3 kg Transmitter housing: Powder coated die-cast aluminum Housing of sensor/secondary containment: Acid-resistant and alkali-resistant external surface, stainless steel 1.4301/304 Process connections Stainless steel 1.4404/316 Measuring tubes: Stainless steel 1.4435/316L

Material

Endress+Hauser

11

CNGmass

Material load diagram

CNGmass process connections Connection material: 1.4404/316

[bar] 350 300 250 200 150 100 50 0 50 20 0 20 40 60 80 100 125 [C]

A0006993-EN

Process connections

Cylindrical internal thread BSP (G) in accordance with ISO 228-I with sealing surfaces in accordance with DIN 3852-2/ISO 1179-1: G " for DN 15 G 1" for DN 25

Note! Sealed with profile seal in accordance with DIN 3869 or copper disk or steel seal disk with plastic lip.

Human interface

Display elements Status LED There is a Light Emitting Diode (LED) on the meter electronics board that allows simple fault diagnostics: If the status output was not configured to output errors or notes. If fault diagnostics are no longer possible via the Fieldtool operating program.

Warning! Risk of explosion! The electronics compartment may not be opened while there is an explosive atmosphere. This type of fault diagnostics can no longer be carried out in Ex-protected areas.

a

A0006980

Fault diagnostics using light emitting diode (a)

12

Endress+Hauser

CNGmass

Status of light emitting diode (LED) LED illuminated in green LED flashes green (once per second) LED not illuminated LED flashes red (three times per second) LED flashes red/green (once per second)

Status of measuring system Measuring system OK, creepage is active Measuring system OK, operation Measuring system no longer working Operation not possible Error (fault message) pending Operation possible, but may be limited by application conditions. Notice message pending Zero point adjustment running Custody transfer mode started Custody transfer mode exited SW update active

LED flashes red/green (three times per second) LED flashes green/orange (approx. 3 seconds long) LED flashes red/orange (approx. 3 seconds long) LED flashes red/(pause)/green (approx. 3 seconds long)

Remote operation

You have the following option for configuring and commissioning the device:

FXA291

Modbus RS485 3

= Security ON = Security OFF = Fact. Sett. All Parameter = Fact. Sett. Com. Para. Status LED Service Connector

d

A0006926

1 = Configuration/operating program for operating via the service interface FXA291 2 = Operation via Modbus RS485 process control system 3 = Situation sticker for the various DIP switch positions and their functions 4 = Operation via device-internal DIP switch (a) If the DIP switch (a) is switched upwards, the device restores the factory settings of the communication parameters of the Modbus RS485. 5 = Operation via device-internal DIP switch (b): If the DIP switch (b) is switched upwards, the device restores the factory settings of all the parameters.

!

Endress+Hauser

Note! Resetting the parameters can take several minutes. The device is then restarted. The power supply should not be switched off when restoring the factory settings.

13

CNGmass

Certificates and approvals

CE mark The measuring system is in conformity with the statutory requirements of the EC Directives. Endress+Hauser confirms successful testing of the device by affixing to it the CE mark. The measuring system meets the EMC requirements of the Australian Communications Authority (ACA). Information about currently available Ex versions (ATEX, FM, CSA) can be supplied by your E+H Sales Center on request. All explosion protection data are given in a separate Ex documentation, which is available upon request. The measuring device meets all the requirements of the MODBUS/TCP conformity and integration test and has the "MODBUS/TCP Conformance Test Policy, Version 2.0". The measuring device has successfully passed all the test procedures carried out and is certified by the "MODBUS/TCP Conformance Test Laboratory" of the University of Michigan. Measuring devices with a nominal diameter smaller than or equal to DN 25 correspond to Article 3(3) of the EC Directive 97/23/EC (Pressure Equipment Directive) and have been designed and manufactured according to good engineering practice. EN 60529 Degrees of protection by housing (IP code) EN 61010-1 Safety requirements for electrical equipment for measurement, control and laboratory use EN 61326/A1 (IEC 1326) "Emission in accordance with Class A requirements". Electromagnetic compatibility (EMC requirements) EN 60721 OIML R117 shock and vibration resistance OIML R117 suitability for custody transfer measurement

C-tick mark Ex approval

MODBUS certification

Pressure device approval

Other standards and guidelines

Ordering information

The Endress +Hauser service organization can provide detailed ordering information and information on the order code.

Accessories

Various accessories, which can be ordered separately from Endress +Hauser, are available for the transmitter and the sensor.

Note! Detailed information on the order codes in question can be obtained from your Endress +Hauser service organization.

Documentation

Flow measuring technology (FA005D/06/en) Operating Instructions incl. instrument functions CNGmass (BA123D/06/en) Ex-Supplementary documentation: ATEX (XA115D/06/a3) Ex-Supplementary documentation: FM/CSA (XA116D/06/en)

14

Endress+Hauser

CNGmass

Registered trademarks

HART Registered trademark of the HART Communication Foundation, Austin, USA MODBUS Registered trademark of the MODBUS Organization HistoROM, S-DAT, T-DAT, F-CHIP, ToF Tool - Fieldtool Package, Fieldcheck, Applicator Registered or registration-pending trademarks of Endress+Hauser Flowtec AG, Reinach, CH

Endress+Hauser

15

CNGmass

Instruments International

Endress+Hauser Instruments International AG Kaegenstrasse 2 4153 Reinach Switzerland Tel. +41 61 715 81 00 Fax +41 61 715 25 00 www.endress.com info@ii.endress.com

TI077D/06/en/12.06 71036552 FM+SGML6.0 ProMoDo

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Prfmi 1Document2 pagesPrfmi 1Jose A LopezNo ratings yet

- Alberta Dishwashing StandardDocument5 pagesAlberta Dishwashing StandardChevronelleNo ratings yet

- Prfmi 2Document1 pagePrfmi 2ChevronelleNo ratings yet

- Bombas Savino Barbera - Europump CE Marking GuidelineDocument11 pagesBombas Savino Barbera - Europump CE Marking GuidelineChevronelleNo ratings yet

- Instituto Superior T Ecnico Departamento de Matem Atica Sec C Aode Algebra e An AliseDocument2 pagesInstituto Superior T Ecnico Departamento de Matem Atica Sec C Aode Algebra e An AliseChevronelleNo ratings yet

- Bombas Savino Barbera - Europump Atex GuidelineDocument22 pagesBombas Savino Barbera - Europump Atex GuidelineChevronelleNo ratings yet

- Pump Efficiency For Single Stage Centrifugal PumpsDocument8 pagesPump Efficiency For Single Stage Centrifugal PumpsPerrobast100% (1)

- (Welding) MIG-MAG Welding Guide - Lincoln Electric (Ebook, 48 Pages)Document48 pages(Welding) MIG-MAG Welding Guide - Lincoln Electric (Ebook, 48 Pages)Ahmad Arafa100% (10)

- CatalogDocument0 pagesCatalogChevronelleNo ratings yet

- 13787, C, EIS, Probes Industrial, BetaDocument2 pages13787, C, EIS, Probes Industrial, BetaChevronelleNo ratings yet

- Bombas Savino Barbera - Europump Atex GuidelineDocument22 pagesBombas Savino Barbera - Europump Atex GuidelineChevronelleNo ratings yet

- Ultrasonic Flowmeter: Katflow 160Document4 pagesUltrasonic Flowmeter: Katflow 160ChevronelleNo ratings yet

- BETE Application Intake SheetDocument1 pageBETE Application Intake SheetChevronelleNo ratings yet

- Pump Life Cycle CostDocument19 pagesPump Life Cycle CostSAMEER100% (3)

- Failure Modes and Effects Analysis (FMEA)Document7 pagesFailure Modes and Effects Analysis (FMEA)DURANLEENo ratings yet

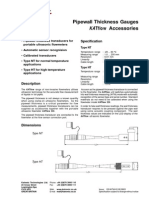

- Pipewall Thickness Gauges Accessories: KatflowDocument1 pagePipewall Thickness Gauges Accessories: KatflowChevronelleNo ratings yet

- Accessories: Components & SizesDocument1 pageAccessories: Components & SizesChevronelleNo ratings yet

- Ultrasonic Flowmeter: Katflow 160Document4 pagesUltrasonic Flowmeter: Katflow 160ChevronelleNo ratings yet

- Data Sheet Sonocontrol 20 Kat V10 E1198Document2 pagesData Sheet Sonocontrol 20 Kat V10 E1198ChevronelleNo ratings yet

- Data Sheet Sonometer 11 Kat V10 E0597Document2 pagesData Sheet Sonometer 11 Kat V10 E0597ChevronelleNo ratings yet

- Coin Meter Work Sheet: 3 Stack Rotary SwitchDocument1 pageCoin Meter Work Sheet: 3 Stack Rotary SwitchChevronelleNo ratings yet

- Data Sheet KATflow 110 V10 E0803Document4 pagesData Sheet KATflow 110 V10 E0803Chevronelle100% (1)

- Data Sheet Sonocontrol 11 Kat V10 E0698Document2 pagesData Sheet Sonocontrol 11 Kat V10 E0698ChevronelleNo ratings yet

- Data Sheet Sonometer 30 Kat V10 E0698Document2 pagesData Sheet Sonometer 30 Kat V10 E0698ChevronelleNo ratings yet

- Data Sheet KATflow 140 V09 E0803Document6 pagesData Sheet KATflow 140 V09 E0803ChevronelleNo ratings yet

- Start WashDocument0 pagesStart WashChevronelleNo ratings yet

- Pressure-Based Sprayer Plumbing DiagramsDocument1 pagePressure-Based Sprayer Plumbing DiagramsChevronelleNo ratings yet

- Flowmeter Based Sprayer Plumbing Diagrams: Console Should Be Ground Speed OrientedDocument1 pageFlowmeter Based Sprayer Plumbing Diagrams: Console Should Be Ground Speed OrientedChevronelleNo ratings yet

- Data Sheet KATflow 10 Kat V10 E0100Document2 pagesData Sheet KATflow 10 Kat V10 E0100ChevronelleNo ratings yet

- Coin Meter Work Sheet GuideDocument1 pageCoin Meter Work Sheet GuideChevronelleNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Fluid Mechanics Objective Type QuestionsDocument210 pagesFluid Mechanics Objective Type Questionspavankumar001No ratings yet

- DSA 2011 00815 - PPC 5660 - Technical Data SheetDocument1 pageDSA 2011 00815 - PPC 5660 - Technical Data SheetMehedi HasanNo ratings yet

- 10079-CV-LA-001-00 Tank Level Gauges (Revision 00)Document96 pages10079-CV-LA-001-00 Tank Level Gauges (Revision 00)Kunal Jhingan100% (3)

- Is 17342Document10 pagesIs 17342AnuradhaPatraNo ratings yet

- Integrated Science 8 & 9 Final PDFDocument54 pagesIntegrated Science 8 & 9 Final PDFAnthony Mabaso SichaliNo ratings yet

- PorosityDocument13 pagesPorosityRamesh Konakalla0% (1)

- Getting Done With Input of Characterized CompositionsDocument4 pagesGetting Done With Input of Characterized Compositionszorro21072107No ratings yet

- Formulation and Evaluation of Tablet of Nicardipine HCL As A Solid Self-Emulsifying Drug Delivery SystemDocument6 pagesFormulation and Evaluation of Tablet of Nicardipine HCL As A Solid Self-Emulsifying Drug Delivery SystemWJPSR JournalNo ratings yet

- International Society For Soil Mechanics and Geotechnical EngineeringDocument7 pagesInternational Society For Soil Mechanics and Geotechnical EngineeringchristiandjegwesNo ratings yet

- Solid Liquid ExtractionDocument13 pagesSolid Liquid ExtractionAsfand Yar Khan80% (5)

- Comprehensive Group Pile Settlement Formula Based On 3D Finite Element AnalysesDocument15 pagesComprehensive Group Pile Settlement Formula Based On 3D Finite Element AnalysesPhetole Pat RaseteloNo ratings yet

- Pressure Safety Valve Process Calculation NoteDocument14 pagesPressure Safety Valve Process Calculation NoteKhanh PhamNo ratings yet

- E DBL 018 Elastomer PDFDocument4 pagesE DBL 018 Elastomer PDFCostas AggelidisNo ratings yet

- Lubricant and Lubrication FundamentalsDocument51 pagesLubricant and Lubrication FundamentalsMustafa100% (11)

- Fluid Mechanics: OutlineDocument8 pagesFluid Mechanics: OutlineJohn Carlo LisondatoNo ratings yet

- Density DeterminationsDocument16 pagesDensity Determinationssomjit saranai100% (1)

- SF6 Gas Monitoring and AlarmingDocument11 pagesSF6 Gas Monitoring and AlarmingsherifmoussaNo ratings yet

- ASTM E4 16 Standard Practices For Force Verification of Testing MachinesDocument14 pagesASTM E4 16 Standard Practices For Force Verification of Testing Machinesoki handinataNo ratings yet

- Conplast F292Document4 pagesConplast F292Mohammed AdilNo ratings yet

- Tutorial A Pipe System AnalysisDocument38 pagesTutorial A Pipe System AnalysisLuis OrtizNo ratings yet

- Design of Bituminous Mixtures: Test Procedure ForDocument40 pagesDesign of Bituminous Mixtures: Test Procedure ForAlhilali ZiyadNo ratings yet

- Determination of Bulk Density of Rock Core Using Standard IndustrDocument217 pagesDetermination of Bulk Density of Rock Core Using Standard IndustrPetrulerz GhulamNo ratings yet

- Modeling CO2 - Water MixturesDocument30 pagesModeling CO2 - Water Mixturesaegean227No ratings yet

- Ficha Técnica - Titan 1000 AE (Inglés)Document2 pagesFicha Técnica - Titan 1000 AE (Inglés)Pedro Ramos PAchecoNo ratings yet

- Feb 8 WeekDocument51 pagesFeb 8 WeekMohammad Iqbal Mahamad Amir100% (2)

- Formulae BookDocument74 pagesFormulae Bookimran khanNo ratings yet

- Autodyn Verberne Pieter 201411 MAS Thesis PDFDocument115 pagesAutodyn Verberne Pieter 201411 MAS Thesis PDFYousaf SaidalaviNo ratings yet

- TheTrueValueofseparatorsandMD PDFDocument6 pagesTheTrueValueofseparatorsandMD PDFanjnaNo ratings yet

- PIPE Ch1Document335 pagesPIPE Ch1Rex Sotelo BaltazarNo ratings yet

- Thermophysical Characterisation of Tropical Wood Used As Building Materials: With Respect To The Basal DensityDocument10 pagesThermophysical Characterisation of Tropical Wood Used As Building Materials: With Respect To The Basal DensityMohamed Ben MansourNo ratings yet