0% found this document useful (0 votes)

376 views71 pagesEurocode vs AISI: Cold-Formed Steel Design

This document summarizes some key features of the European Norm (EC3) for cold-formed steel design compared to the American Iron and Steel Institute (AISI) specification. EC3 covers a wide range of materials, geometries, and limit states including local buckling, distortional buckling, member resistance, and design assisted by testing. It also provides an example calculation for local and distortional buckling of Z/C beams.

Uploaded by

MoonzeCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

376 views71 pagesEurocode vs AISI: Cold-Formed Steel Design

This document summarizes some key features of the European Norm (EC3) for cold-formed steel design compared to the American Iron and Steel Institute (AISI) specification. EC3 covers a wide range of materials, geometries, and limit states including local buckling, distortional buckling, member resistance, and design assisted by testing. It also provides an example calculation for local and distortional buckling of Z/C beams.

Uploaded by

MoonzeCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

- Introduction: Provides an introduction to the presentation, setting the context for the comparison between European Norm and AISI specifications.

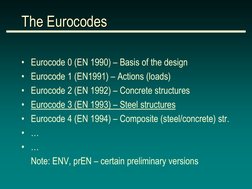

- The Eurocodes: Describes the various Eurocodes, which are standards for structural design in Europe, focused on design bases and different construction materials.

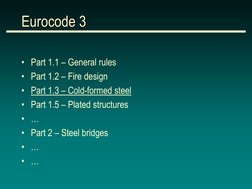

- Eurocode 3: Details Eurocode 3, specifically focused on steel structures, and its subdivisions such as general rules, fire design, and cold-formed steel.

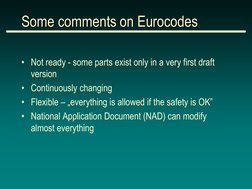

- Comments on Eurocodes: Provides commentary on the status and flexibility of the Eurocodes, including their adaptability through national documents.

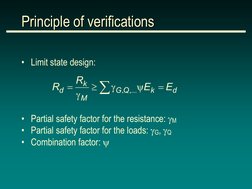

- Principle of Verifications: Explains the core verification principles used in structural design, including limit state design and safety factors.

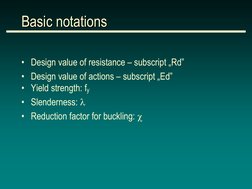

- Basic Notations: Defines fundamental notations used in the context of structural engineering and design value calculations.

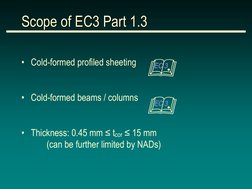

- Scope of EC3 Part 1.3: Outlines the scope of Eurocode 3 Part 1.3, covering cold-formed profiled sheeting and beams/columns.

- Materials: Covers the types of materials specified in the Eurocodes, including yield strength and standards compliance.

- Hardening due to Cold-forming: Discusses the effects of cold-forming on steel, focusing on yield strength and its application to effective sections.

- Rounded Corners: Explores the consideration of rounded corners in design, with limitations and necessary tests.

- Geometrical Limits: Sets out geometrical limits for cold-formed sections, ensuring compliance with AISI specifications and web inclination limits.

- Buckling - General Procedure: Describes the general procedures for assessing buckling, including stress calculations and effective width methods.

- Local Buckling: Focuses on local buckling conditions and effective width approaches, modified for Eurocode applications.

- Distortional Buckling: Addresses distortional buckling, detailing the calculation of reduced thickness and the necessity for numerical methods.

- Distortional Buckling for C/Z Sections: Specifically addresses distortional buckling for C/Z sections, including critical stress and stiffener reduction factors.

- Bending Moment Resistance: Explores the resistance of bending moments in cross-sections, differentiating between partially and fully effective situations.

- Torsional Moment Resistance: Discusses considerations for torsional moment resistance and how stresses are combined with other actions.

- Buckling Resistance for Compression: Covers the resistance to buckling under compression, using reduction factors and effective areas.

- Buckling Resistance for Bending: Examines methods used to determine bending buckling resistance, including the use of buckling curves and effective areas.

- Serviceability Limit States: Defines the serviceability limits in structural designs as per relevant Eurocodes, particularly for cold-formed applications.

- Design Assisted by Test: Illustrates how design principles are assisted by tests, with examples of structural tests included.

- Beams Restrained by Sheeting: Describes models for analyzing beams restrained by sheeting, including verification methods.

- Numerical Example: Provides a worked example focusing on local and distortional buckling for beams.