Professional Documents

Culture Documents

Tolerante ISO 286

Uploaded by

Sam SebastyanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tolerante ISO 286

Uploaded by

Sam SebastyanCopyright:

Available Formats

ISO 286 / DIN 7151

Steel Hardness Chart

287

Tensile Strength

288

Determining Metric Tolerances

291

Technical Reference

287

Steel Hardness Chart

U.S. 800-626-6653

Values in parentheses are not contained in the normal

definition range for hardness checking, but are often

used in comparable measure.

N�

Canada 800-387-6600

N�

www.dme.net

20

21

22

24

25

26

28

29

30

32

33

34

36

37

38

40

41

42

45

47

50

52

55

57

59

62

64

66

67

69

71

72

74

75

77

79

80

81

83

84

86

87

88

91

93

Steel Hardness Chart

Also known as Firth

Diamond Hardness

Number.

SHORE HARDNESS

HS

*A 10mm steel ball is used

for 450 BHN and below.

A 10mm carbide ball is

used above 450 BHN.

CROSS-REFERENCE BETWEEN DIFFERENT HARDNESS MEASUREMENTS

VICKERS HARDNESS

ROCKWELL HARDNESS ROCKWELL HARDNESS ROCKWELL HARDNESS

HV

HRA

HRB

HRC

136 DIAMOND

BRALE PENETRATOR,

1/16 INCH BALL,

BRALE PENETRATOR,

PYRAMID, 10kgf LOAD

60kgf LOAD

100kgf LOAD

150kgf LOAD

90

48

100

56.2

110

62.3

120

66.7

130

71.2

140

75

150

78.7

160

81.7

(0)

170

85

(3)

180

87.1

(6)

190

89.5

(8.5)

200

91.5

(11)

210

93.4

(13.4)

220

95

(15.7)

230

96.7

(18)

240

60.7

98.1

20.3

250

61.6

99.5

22.2

260

62.4

(101)

24

270

63.1

(102)

25.6

280

63.8

(103.5)

27.1

290

64.5

(104.5)

28.5

300

65.2

(105.5)

29.8

320

66.4

(107)

32.2

340

67.6

(108)

34.4

360

68.7

(109)

36.6

380

69.8

(110)

38.8

400

70.8

40.8

420

71.8

42.7

440

72.8

44.5

460

73.6

46.1

480

74.5

47.7

500

75.3

49.1

520

76.1

50.5

540

76.7

51.7

560

77.4

53

580

78

54.1

600

78.6

55.2

620

79.2

56.3

640

79.8

57.3

660

80.3

58.3

680

80.8

59.2

700

81.3

60.1

720

81.8

61

740

82.2

61.8

760

82.6

62.5

780

83

63.3

800

83.4

64

840

84.1

65.3

880

84.7

66.4

Technical Reference

BRINELL HARDNESS

BHN*

10mm BALL,

3000kgf LOAD

86

95

105

114

124

133

143

152

162

171

181

190

200

209

219

228

238

247

256

265

275

284

303

322

341

360

379

397

415

433

452

471

488

507

525

545

564

582

601

620

638

656

670

684

698

710

722

745

767

Technical Reference

288

Technical Reference

Tensile Strength

Tensile Strength

HARDNESS

BRINELL

ROCKWELL

HARDNESS

HARDNESS

BHN*

HRC

BRALE

10mm BALL,

PENETRATOR,

3000kgf LOAD

60kgf LOAD

86

95

105

114

124

133

143

152

(0)

162

(3)

171

(6)

181

(8.5)

190

(11)

200

(13.4)

209

(15.7)

219

(18)

228

20.3

238

22.2

247

24

256

25.6

265

27.1

275

28.5

284

29.8

303

32.2

322

34.4

341

36.6

360

38.8

379

40.8

397

42.7

415

44.5

433

46.1

452

47.7

471

49.1

488

50.5

507

51.7

525

53

545

54.1

564

55.2

*A 10mm steel

ball is used

for 450 BHN

and below.

A 10mm

carbide ball

is used above

450 BHN.

GENERAL STEEL GROUP THROUGH HARDNESS VERSUS APPROXIMATE TENSILE STRENGTH

TENSILE STRENGTH

STAINLESS STEEL

AUSTENITIC TYPE

PLAIN CARBON STEEL

AND LOW ALLOY STEEL

STAINLESS STEEL

CHROMIUM TYPE

N/mm2

(APPROX.)

PSI

(APPROX.)

kgf/mm2

(APPROX.)

N/mm2

(APPROX.)

PSI

(APPROX.)

kgf/mm2

(APPROX.)

N/mm2

(APPROX.)

PSI

(APPROX.)

285

320

350

385

415

450

480

510

545

575

610

640

675

705

740

770

800

835

865

900

930

965

1,030

1,095

1,155

1,220

1,290

1,350

1,420

1,485

1,555

1,630

1,700

1,775

1,845

1,920

1,995

41,334

46,410

50,761

55,837

60,188

65,264

69,615

73,966

79,042

83,393

88,470

92,820

97,897

102,248

107,324

111,675

116,026

121,102

125,453

130,529

134,880

139,856

149,383

158,810

167,512

176,939

187,091

195,793

205,945

215,372

225,525

236,402

246,554

257,432

267,584

278,461

289,339

50

56

62

62

68

68

75

75

80

80

85

88

91

94

97

100

109

118

127

136

145

156

167

178

189

200

209

218

227

236

245

490

549

608

608

667

667

736

736

785

785

834

863

892

922

951

981

1,069

1,157

1,245

1,334

1,422

1,530

1,638

1,746

1,853

1,961

2,050

2,138

2,226

2,314

2,403

71,115

79,649

88,183

88,183

96,716

96,716

106,673

106,673

113,784

113,784

120,896

125,162

129,429

133,696

137,963

142,230

155,031

167,831

180,632

193,433

206,234

221,879

237,,524

253169

268,815

284,460

297,261

310,061

322,862

335,663

348,464

50

53

59

59

65

65

71

71

78

78

81

490

520

579

579

637

637

696

696

765

765

794

71,115

75,382

83,916

83,916

92,450

92,450

100,983

100,983

110,939

110,939

115,206

88

863

125,162

96

941

136,541

106

113

120

127

134

1,040

1,108

1,177

1,245

1,314

150,764

160,720

170,676

180,,632

190588

Values in

The Tensile Strength relationship to hardness is inexact, even for the steel, unless it is determined for a specific material. Therefore, this

parentheses are chart provides only very general approximate Tensile Strength values.

not contained

in the normal

definition range

for hardness

checking, but

are often used

in a comparable

measure.

U.S. 800-626-6653

N�

Canada 800-387-6600

N�

www.dme.net

Technical Reference

291

Determining Metric Tolerances

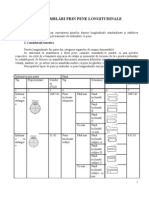

Table 1: Description of Preferred Fits

Table 1 is pulled from the ANSI metric tolerances section of thee machinists handbook, which conforms to the ISO and DIN tolerances for hole

basis and shaft basis ts. Table 1 provides an overview of the hole basis and shaft basis ts that make up clearance t, transition t and interference t combinations.

ISO SYMBOL

C11/h11

H9/d9

LOOSE RUNNING FIT

FOR WIDE COMMERCIAL TOLERANCES OR

ALLOWANCES ON EXTERNAL MEMBERS.

D9/h9

FREE RUNNING FIT

NOT FOR USE WHERE ACCURACY IS ESSENTIAL,

BUT GOOD FOR LARGE TEMPERATURE VARIATIONS, HIGH RUNNING SPEEDS, OR HEAVY

JOURNAL PRESSURES.

H8/f7

F8/h7

CLOSE RUNNING FIT

FOR RUNNING ON ACCURATE MACHINES

AND FOR ACCURATE LOCATION AT MODERATE

SPEEDS AND JOURNAL PRESSURES.

H7/g6

G7/h6

SLIDING FIT

NOT INTENDED TO RUN FREELY, BUT TO MOVE

AND TURN FREELY AND LOCATE ACCURATELY.

H7/h6

H7/h6

LOCATIONAL CLEARANCE FIT

PROVIDES SNUG FIT FOR LOCATING STATIONARY PARTS; BUT CAN BE FREELY ASSEMBLED

AND DISASSEMBLED.

H7/k6

K7/h6

LOCATIONAL TRANSITION FIT

FOR ACCURATE LOCATION, A COMPROMISE

BETWEEN CLEARANCE AND INTERFERENCE.

H7/n6

N7/h6

LOCATIONAL TRANSITION FIT

FOR MORE ACCURATE LOCATION WHERE

GREATER INTERFERENCE IS PERMISSIBLE.

H7/p6*

P7/h6

LOCATIONAL INTERFERENCE FIT

FOR PARTS REQUIRING RIGIDITY AND ALIGNMENT WITH PRIME ACCURACY OF LOCATION

BUT WITHOUT SPECIAL BORE PRESSURE

REQUIREMENTS.

H7/s6

S7/h6

MEDIUM DRIVE FIT

FOR ORDINARY STEEL PARTS OR SHRINK

FITS ON LIGHT SECTIONS, THE TIGHTEST FIT

USABLE WITH CAST IRON.

FORCE FIT

SUITABLE FOR PARTS WHICH CAN BE HIGHLY

STRESSED OR FOR SHRINK FITS WHERE THE

HEAVY PRESSING FORCES REQUIRED ARE

IMPRACTICAL.

H7/u6

U7/h6

Excerpt from Machinists Handbook, pg. 661, 25 Ed., Industrial Press.

*The H7/p6 Hole Basis t is a transition t for basic sizes in ranges from 0 through 3mm.

U.S. 800-626-6653

N�

Canada 800-387-6600

N�

www.dme.net

Determining Metric Tolerances

INTERFERENCE

FITS

H11/c11

TRANSITION

FITS

SHAFT BASIS

Technical Reference

CLEARANCE

FITS

HOLE BASIS

Technical Reference

292

Determining Metric Tolerances

Table 2: Commonly used Hole-Basis System of ts

Table 2 shows closer detail on the hole-basis system of ts than Table 1. When using the hole-basis system of ts, the smallest diameter in the

hole tolerance range is xed to the zero line (basic nominal hole size or diameter), and the clearance between the shaft and hole extends below

the zero line, or negative relative to the basic nominal hole size.

LETTER SYMBOLS AND GRADE NUMBERS OF SHAFTS

BASIC

HOLES

CLEARANCE FITS

b

TRANSITION FITS

f

H5

H10

js

6*

6*

6*

6*

7*

7*

*Exceptions occur in some steps of dimensions.

Table 3: Commonly used Shaft-Basis System of ts

Technical Reference

Determining Metric Tolerances

H9

4

5

H8

H6

H7

INTERFERENCE FITS

Table 3 shows closer detail on the shaft-basis system of ts than Table 1. When using the shaft-basis system of ts, the largest diameter in the

shaft tolerance range is xed to the zero line (basic nominal shaft size or diameter), and the clearance between the shaft and hole extends above

the zero line, or positive relative to the basic shaft size.

LETTER SYMBOLS AND GRADE NUMBERS OF HOLES

BASIC

SHAFTS

CLEARANCE FITS

B

TRANSITION FITS

F

h5

h6

h7

h8

h9

h10

10

INTERFERENCE FITS

Js

6*

6*

7*

7*

10

10

*Exceptions occur in some steps of dimensions.

U.S. 800-626-6653

N�

Canada 800-387-6600

N�

www.dme.net

Technical Reference

293

Determining Metric Tolerances

Table 4: IT Standard Tolerances

Table 4 details the ISO-basic tolerances (International Tolerance Grades, or, IT) which apply to all linear sizes (external and internal sizes, diameters, lengths, widths and thicknesses). An IT-grade number establishes the magnitude of the tolerance zone, while the tolerance position letter

determines where the tolerance zone is in relation to the zero line. The combination of tolerance position letter (A-X, a-x) and IT-grade number

(01-8) creates the overall tolerance symbol (i.e., F8/h7 when using the shaft-basis system of ts).

For nominal size range up to 500mm according to DIN 7151/ISO 286, and for nominal size range over 500mm, according to DIN 7172/ISO 286.

IT STANDARD TOLERANCES (UNITS IN 0.001MM)

OVER

TO

IT01

IT0

IT1

IT2

IT3

IT4

IT5

IT6

IT7

IT8

IT9

IT10

IT11

IT12

IT13

IT14

IT15

IT16

IT17

IT18

0.3

0.5

0.8

1.2

10

14

25

40

60

100

140

250

400

600

0.4

0.6

1.5

2.5

12

18

30

48

75

120

180

300

480

750

1500

10

0.4

0.6

1.5

2.5

15

22

36

58

90

150

220

360

580

900

10

18

0.5

0.8

1.2

11

18

27

43

70

110

180

270

430

700

1100 1800 2700

18

30

0.6

1.5

2.5

13

21

33

52

84

130

210

330

520

840

1300 2100 3300

30

50

0.6

1.5

2.5

11

16

25

39

62

100

160

250

390

620

1000 1600 2500 3900

50

80

0.8

1.2

13

19

30

46

74

120

190

300

460

740

1200 1900 3000 4600

1400 2200 3500 5400

120

1.5

2.5

10

15

22

35

54

87

140

220

350

540

870

180

1.2

3.5

12

18

25

40

63

100

160

250

400

630

1000 1600 2500 4000 6300

180

250

4.5

10

14

20

29

46

72

115

185

290

460

720

1150 1850 2900 4600 7200

250

315

2.5

12

16

23

32

52

81

130

210

320

520

810

1300 2100 3200 5200 8100

315

400

13

18

25

36

57

89

140

230

360

570

890

1400 2300 3600 5700 8900

400

500

10

15

20

27

40

63

97

155

250

400

630

970

1550 2500 4000 6300 9700

500

630

4.5

11

16

22

30

44

70

110

175

280

440

700

1100 1750 2800 4400

80

120

Technical Reference

NOMINAL SIZE RANGE

ITEMS IN MM

800

10

13

18

25

35

50

80

125

200

320

500

800

1250 2000 3200 5000

800

1000

5.5

11

15

21

29

40

56

90

140

230

360

560

900

1400 2300 3600 5600

U.S. 800-626-6653

N�

Canada 800-387-6600

N�

www.dme.net

Determining Metric Tolerances

630

Technical Reference

294

Determining Metric Tolerances

Table 5: Fundamental deviations of holes and shafts

Table 5 details fundamental deviations between holes and shafts, and is provided for reference.

IT6 TO IT16

LETTER SYMBOLS

SIGNS

260

145

76

22

290

160

80

24

320

170

86

350

195

98

ABOVE

UP TO

500

560

560

630

630

710

710

800

800

900

900

1000

1000

1120

1120

1250

1250

1400

1400

1600

1600

1800

1800

2000

Js

26

44

78

150

280

400

600

155

310

450

660

30

50

88

175

340

500

740

185

380

560

840

26

34

56

100

210

430

620

940

220

470

680

1050

28

40

66

120

250

520

780

1150

DEVIATIONS

(+/) IT/2

390

220

110

30

48

78

140

260

580

840

1300

300

640

960

1450

330

720

1050

1600

370

820

1200

1850

400

920

1350

2000

440

1000

1500

2300

460

1100

1650

2500

550

1250

1900

2900

580

1400

2100

3200

240

120

32

58

92

170

480

260

130

34

68

110

195

520

290

145

38

76

135

240

SIGNS

LETTER SYMBOLS

430

2000

2240

2240

2500

SHAFTS

FUNDAMENTAL DEVIATIONS

(UPPER DEVIATIONS)

FUNDAMENTAL DEVIATIONS

(LOWER DEVIATIONS)

DIVISIONS

Technical Reference

Determining Metric Tolerances

HOLES

GRADE

2500

2800

2800

3150

ABOVE

UP TO

DIVISIONS

js

FUNDAMENTAL DEVIATIONS

(LOWER DEVIATIONS)

FUNDAMENTAL DEVIATIONS

(UPPER DEVIATIONS)

GRADE

IT6 TO IT16

U.S. 800-626-6653

N�

Canada 800-387-6600

N�

www.dme.net

Technical Reference

295

Determining Metric Tolerances

Table 6: Tolerances for inside dimensions (holes)

Table 6 details tolerances for inside dimensions (holes) based relative to the tolerance symbol. Upper and lower values are provided as either positive or negative (or zero) values relative to the nominal size chosen. Pick the range in which the desired nominal value falls into, and then either

add or subtract the tolerances to nd the upper and lower tolerance range for the desired nominal size.

UNITS IN MM

OVER

TO

A11

B8

B11

C11

D9

D10

D11

E8

E9

F6

F7

F8

G6

G7

H5

H6

H7

H8

H9

H10

+120

+60

+45

+20

+60

+20

+80

+20

+28

+14

+39

+14

+12

+6

+16

+6

+20

+6

+8

+2

+12

+2

+4

0

+6

0

+10

0

+14

0

+25

0

+40

0

+345 +158 +215 +145

+270 +140 +140 +70

+60

+30

+78

+30

+105

30

+38

+20

+50

+20

+18

+10

+22

+10

+28

+10

+12

+4

+16

+4

+5

0

+8

0

+12

0

+18

0

+30

0

+48

0

10

+370 +172 +240 +170

+280 +150 +150 +80

+76

+40

+98

+40

+130

+40

+47

+25

+61

+25

+22

+13

+28

+13

+35

+13

+14

+5

+20

+5

+6

0

+9

0

+15

0

+22

0

+36

0

+58

0

+400 +177 +260 +205

+290 +150 +150 +95

+93

+50

+120 +160

+50 +50

+59

+32

+75

+32

+27

+16

+34

+16

+43

+16

+17

+6

+24

+6

+8

0

+11

0

+18

0

+27

0

+43

0

+70

0

+430 +193 +290 +240 +117 +149 +195

+300 +160 +160 +110 +65 +65 +65

+73

+40

+92

+40

+33

+20

+41

+20

+53

+20

+20

+7

+28

+7

+9

0

+13

0

+21

0

+33

0

+52

0

+84

0

+470 +209 +330 +280

+310 +170 +170 +120 +142 +180 +240

+480 +219 +340 +290 +80 +80 +80

+320 +180 +180 +130

+89

+50

+112

+50

+41

+25

+50

+25

+64

+25

+25

+9

+34

+9

+11

0

+16

0

+25

0

+39

0

+62

0

+100

0

+530 +236 +380 +330

+340 +190 +190 +140 +174 +220 +290 +106 +134

+550 +246 +390 +340 +100 +100 +100 +60 +60

+360 +200 +200 +150

+49

+30

+60

+30

+76

+30

+29

+10

+40

+10

+13

0

+19

0

+30

0

+46

0

+74

0

+120

0

+600 +274 +440 +390

+380 +220 +220 +170 +207 +260 +340 +126 +159

+630 +294 +460 +400 +120 +120 +120 +72 +72

+410 +240 +240 +180

+58

+36

+71

+36

+90

+36

+34

+12

+47

+12

+15

0

+22

0

+35

0

+54

0

+87

0

+140

0

+68

+43

+83

+43

+106

+43

+39

+14

+54

+14

+18

0

+25

0

+40

0

+63

0

+100 +160

0

0

+79

+50

+96

+50

+122

+50

+44

+15

+61

+15

+20

0

+29

0

+46

0

+72

0

+115 +185

0

0

+1240 +561 +800 +620

+920 +480 +480 +300 +320 +400 +510 +191 +240

+1370 +621 +860 +650 +190 +190 +190 +110 +110

+1050 +540 +540 +330

+88

+56

+108 +137

+56 +56

+49

+17

+69

+17

+23

0

+32

0

+52

0

+81

0

+130 +210

0

0

+1560 +689 +960 +720

+1200 +600 +600 +360 +350 +440 +570 +214 +265

+1710 +769 +1040 +760 +210 +210 +210 +125 +125

+1350 +680 +680 +400

+98

+62

+119 +151

+62 +62

+54

+18

+75

+18

+25

0

+36

0

+57

0

+89

0

+140 +230

0

0

+1900 +857 +1160 +840

+1500 +760 +760 +440 +385 +480 +630 +232 +290 +108 +131 +165

+2050 +937 +1240 +880 +230 +230 +230 +135 +135 +68 +68 +68

+1650 +840 +840 +480

+60

+20

+83

+20

+27

0

+40

0

+63

0

+97

0

+155 +250

0

0

14

18

18

24

24

30

30

40

40

50

50

65

65

80

80

100

100

120

120

140

+710 +323 +510 +450

+460 +260 +260 +200

140

160

+770 +343 +530 +460 +245 +305 +395 +148 +185

+520 +280 +280 +210 +145 +145 +145 +85 +85

160

180

+830 +373 +560 +480

+580 +310 +310 +230

180

200

+950 +412 +630 +530

+660 +340 +340 +240

200

225

+1030 +452 +670 +550 +285 +355 +460 +172 +215

+740 +380 +380 +260 +170 +170 +170 +100 +100

225

250

+1110 +492 +710 +570

+820 +420 +420 +280

250

280

280

315

315

355

355

400

400

450

450

500

U.S. 800-626-6653

N�

Canada 800-387-6600

N�

www.dme.net

Determining Metric Tolerances

10

14

+330 +154 +200

+270 +140 +140

Technical Reference

NOMINAL SIZE RANGE

TOLERANCES FOR INSIDE DIMENSIONS (HOLES) (UNITS IN 0.001MM)

Technical Reference

296

Determining Metric Tolerances

Table 6: Tolerances for inside dimensions (holes) continued

NOMINAL SIZE RANGE

Technical Reference

Determining Metric Tolerances

UNITS IN MM

TOLERANCES FOR INSIDE DIMENSIONS (HOLES) (UNITS IN 0.001MM)

OVER

TO

H11

H12

H13

J6

J7

J8

K6

K7

K8

M6

M7

M8

N6

N7

N8

R7

JS6

JS7

JS8

JS9

+60

0

+100 +140

0

0

+2

-4

+4

-6

+6

-8

0

-6

0

-10

0

-14

-2

-8

-2

-12

-2

-16

-4

-10

-4

-14

-4

-18

-10

-20

+3

-3

+5

-5

+7

-7

+12.5

-12.5

+75

0

+120 +180

0

0

+5

-3

+6

-6

+10

-8

+2

-6

+3

-9

+5

-13

-1

-9

0

-12

+2

-16

-5

-13

-4

-16

-2

-20

-11

-23

+4

-4

+6

-6

+9

-9

+15

-15

10

+90

0

+150 +220

0

0

+5

-4

+8

-7

+12

-10

+2

-7

+5

-10

+6

-16

-3

-12

0

-15

+1

-21

-7

-16

-4

-19

-3

-25

-13

-28

+4.5

-4.5

+7.5

-7.5

+11

-11

+18

-18

10

14

14

18

+110 +180 +270

0

0

0

+6

-5

+10

-8

+15

-12

+2

-9

+6

-12

+8

-19

-4

-15

0

-18

+2

-25

-9

-20

-5

-23

-3

-30

-16

-34

+5.5

-5.5

+9

-9

18

24

24

30

+130 +210 +330

0

0

0

+8

-5

+12

-9

+20

-13

+2

-11

+6

-15

+10

-23

-4

-17

0

-21

+4

-29

-11

-24

-7

-28

-3

-36

-20

-41

+6.5 +10.5 +16.5

-6.5 -10.5 -16.5

30

40

40

50

+160 +250 +390

0

0

0

+10

-6

+14

-11

+24

-15

+3

-13

+7

-18

+12

-27

-4

-20

0

-25

+5

-34

-12

-28

-8

-33

-3

-42

-25

-50

50

65

+190 +300 +460

0

0

0

+13

-6

+18

-12

+28

-18

+4

-15

+9

-21

+14

-32

-5

-24

0

-30

+5

-41

-14

-33

-9

-39

-4

-50

+220 +350 +540

0

0

0

+16

-6

+22

-13

+34

-20

+4

-18

+10

-25

+16

-38

-6

-28

0

-35

+6

-48

-16

-38

-10

-45

-4

-58

65

80

80

100

-30

-60

+23

-23

+37

-37

+11

-11

+17.5

-17.5

+27

-27

+43.5

-43.5

+12.5

-12.5

+20

-20

+31.5

-31.5

+50

-50

-63 +14.5

-109 -14.5

+23

-23

+36

-36

+57.5

-57.5

+26

-26

+40.5

-40.5

+65

-65

+18

-18

+28.5 +44.5

-28.5 -44.5

+70

-70

+20

-20

+31.5 +48.5 +77.5

-31.5 -48.5 -77.5

-38

-73

-41

-76

120

140

140

160

160

180

-53

-93

180

200

-60

-106

200

225

225

250

250

280

315

355

355

400

400

450

450

500

+31

-31

+15

-15

120

315

+12.5 +19.5

-12.5 -19.5

+26

-26

+9.5

-9.5

-32

-62

100

280

+8

-8

+13.5 +21.5

-13.5 -21.5

-48

-88

+250 +400 +630

0

0

0

+290 +460 +720

0

0

0

+18

-7

+22

-7

+26

-14

+30

-16

+41

-22

+4

-21

+47

-25

+5

-24

+12

-28

+13

-33

+20

-43

+22

-50

-8

-33

-8

-37

0

-40

0

-46

+8

-55

+9

-63

-20

-45

-22

-51

-12

-52

-14

-60

-4

-67

-5

-77

-50

-90

-67

-113

+320 +520 +810

0

0

0

+25

-7

+36

-16

+55

-26

+5

-27

+16

-36

+25

-56

-9

-41

0

-52

+9

-72

-25

-57

-14

-66

-5

-86

+360 +570 +890

0

0

0

+29

-7

+39

-18

+60

-29

+7

-29

+17

-40

+28

-61

-10

-46

0

-57

+11

-78

-26

-62

-16

-73

-5

-94

+400 +630 +970

0

0

0

+33

-7

+43

-20

+66

-31

+8

-32

+18

-45

+29

-68

-10

-50

0

-63

+11

-86

-27

-67

-17

-80

-6

-103

U.S. 800-626-6653

N�

Canada 800-387-6600

N�

-74

-126

-78

-130

-87

-144

-93

-150

-103

-166

-109

-172

+16

-16

www.dme.net

Technical Reference

297

Determining Metric Tolerances

Table 6: Tolerances for inside dimensions (holes) continued

TOLERANCES FOR INSIDE DIMENSIONS (HOLES) (UNITS IN 0.001MM)

TO

JS10

JS11

JS12

JS13

JS14

JS15

JS16

JS17

JS18

+20

-20

+30

-30

+50

-50

+70

-70

+125

-125

+200

-200

+300

-300

+24

-24

+37.5

-37.5

+60

-60

+90

-90

+150

-150

+240

-240

+375

-375

10

+29

-29

+45

-45

+75

-75

+110

-110

+180

-180

+290

-290

+450

-450

+750

-750

10

14

14

18

+35

-35

+55

-55

+90

-90

+135

-135

+215

-215

+350

-350

+550

-550

+900

-900

+1350

-1350

18

24

24

30

+42

-42

+65

-65

+105

-105

+165

-165

+260

-260

+420

-420

+650

-650

+1050

-1050

+1650

-1650

30

40

40

50

+50

-50

+80

-80

+125

-125

+195

-195

+310

-310

+500

-500

+800

-800

+1250

-1250

+1950

-1950

50

65

65

80

+60

-60

+95

-95

+150

-150

+230

-230

+370

-370

+600

-600

+950

-950

+1500

-1500

+2300

-2300

80

100

100

120

+70

-70

+110

-110

+175

-175

+270

-270

+435

-435

+700

-700

+1100

-1100

+1750

-1750

+2700

-2700

120

140

140

160

+80

-80

+125

-125

+200

-200

+315

-315

+500

-500

+800

-800

+1250

-1250

+2000

-2000

+3150

-3150

160

180

180

200

200

225

+92.5

-92.5

+145

-145

+230

-230

+360

-360

+575

-575

+925

-925

+1450

-1450

+2300

-2300

+3600

-3600

225

250

250

280

280

315

+105

-105

+160

-160

+260

-260

+405

-405

+650

-650

+1050

-1050

+1600

-1600

+2600

-2600

+4050

-4050

315

355

355

400

+115

-115

+180

-180

+285

-285

+445

-445

+700

-700

+1150

-1150

+1800

-1800

+2850

-2850

+4450

-4450

400

450

450

500

+125

-125

+200

-200

+315

-315

+485

-485

+775

-775

+1250

-1250

+2000

-2000

+3150

-3150

+4850

-4850

OVER

Technical Reference

U.S. 800-626-6653

N�

Canada 800-387-6600

N�

www.dme.net

Determining Metric Tolerances

NOMINAL SIZE RANGE

UNITS IN MM

Technical Reference

298

Determining Metric Tolerances

Table 7: Tolerances for outside dimensions (shafts)

Table 7 details tolerances for outside dimensions (shafts) based relative to the tolerance symbol. Upper and lower values are provided as either

positive or negative (or zero) values relative to the nominal size chosen. Pick the range in which the desired nominal value fall into, and then either

add or subtract the tolerances to nd the upper and lower tolerance range for the desired nominal size.

NOMINAL SIZE RANGE

Technical Reference

Determining Metric Tolerances

UNITS IN MM

TOLERANCES FOR OUTSIDE DIMENSIONS (SHAFTS) (UNITS IN 0.001MM)

OVER

TO

a11

b8

b11

c11

d9

d10

d11

e7

e8

e9

f6

f7

f8

f9

g5

g6

g7

h4

h5

h6

h7

-60

-270 -140 -140 -120

-330 -154 -200

-20

-45

-20

-60

-20

-80

-14

-24

-14

-28

-14

-39

-6

-12

-6

-16

-6

-20

-6

-31

-2

-6

-2

-8

-2

-12

0

-3

0

-4

0

-6

0

-10

-270 -140 -140 -70

-345 -158 -215 -145

-30

-60

-30

-78

-30

-105

-20

-32

-20

-38

-20

-50

-10

-18

-10

-22

-10

-28

-10

-40

-4

-9

-4

-12

-4

-16

0

-4

0

-5

0

-8

0

-12

10

-280 -150 -150 -80

-370 -172 -240 -170

-40

-76

-40

-98

-40

-130

-25

-40

-25

-47

-25

-61

-13

-22

-13

-28

-13

-35

-13

-49

-5

-11

-5

-14

-5

-20

0

-4

0

-6

0

-9

0

-15

10

14

14

18

-290 -150 -150 -95

-400 -177 -260 -205

-50

-93

-50 -50

-120 -160

-32

-50

-32

-59

-32

-75

-16

-27

-16

-34

-16

-43

-16

-59

-6

-14

-6

-17

-6

-24

0

-5

0

-8

0

-11

0

-18

18

24

24

30

-300 -160 -160 -110 -65 -65 -65

-430 -193 -290 -240 -117 -149 -195

-40

-61

-40

-73

-40

-92

-20

-33

-20

-41

-20

-53

-20

-72

-7

-16

-7

-20

-7

-28

0

-6

0

-9

0

-13

0

-21

30

40

40

50

-50

-75

-50

-89

-50

-112

-25

-41

-25

-50

-25

-64

-25

-87

-9

-20

-9

-25

-9

-34

0

-7

0

-11

0

-16

0

-25

50

65

65

80

-60

-90

-60 -60

-106 -134

-30

-49

-30

-60

-30

-76

-30

-104

-10

-23

-10

-29

-10

-40

0

-8

0

-13

0

-19

0

-30

80

100

100

120

-380 -220 -220 -170

-600 -274 -440 -390 -120 -120 -120 -72 -72 -72

-410 -240 -240 -180 -207 -260 -340 -107 -126 -159

-630 -294 -460 -400

-36

-58

-36

-71

-36

-90

-36

-123

-12

-27

-12

-34

-12

-47

0

-10

0

-15

0

-22

0

-35

120

140

-460 -260 -260 -200

-710 -323 -510 -450

140

160

-520 -280 -280 -210 -145 -145 -145 -85 -85 -85

-770 -343 -530 -460 -245 -305 -395 -125 -148 -185

-43

-68

-43

-83

-43 -43

-106 -143

-14

-32

-14

-39

-14

-54

0

-12

0

-18

0

-25

0

-40

160

180

-580 -310 -310 -230

-830 -373 -560 -480

180

200

-660 -340 -340 -240

-950 -412 -630 -530

200

225

-740 -380 -380 -260 -170 -170 -170 -100 -100 -100

-1030 -452 -670 -550 -285 -355 -460 -146 -172 -215

-50

-79

-50

-96

-50 -50

-122 -165

-15

-35

-15

-44

-15

-61

0

-14

0

-20

0

-29

0

-46

225

250

-820 -420 -420 -280

-1110 -492 -710 -570

250

280

280

315

-920 -480 -480 -300

-1240 -561 -800 -620 -190 -190 -190 -110 -110 -110

-1050 -540 -540 -330 -320 -400 -510 -162 -191 -240

-1370 -621 -860 -650

-56

-88

-56 -56 -56

-108 -137 -186

-17

-40

-17

-49

-17

-69

0

-16

0

-23

0

-32

0

-52

315

355

355

400

-1200 -600 -600 -360

-1560 -689 -960 -720 -210 -210 -210 -125 -125 -125

-1350 -680 -680 -400 -350 -440 -570 -182 -214 -265

-1710 -769 -1040 -760

-62

-98

-62 -62 -62

-119 -151 -202

-18

-43

-18

-54

-18

-75

0

-18

0

-25

0

-36

0

-57

400

450

450

500

-1500 -760 -760 -440

-1900 -857 -160 -840 -230 -230 -230 -135 -135 -135 -68 -68 -68 -68

-1650 -840 -840 -480 -385 -480 -630 -198 -232 -290 -108 -131 -165 -223

-2050 -937 -1240 -880

-20

-47

-20

-60

-20

-83

0

-20

0

-27

0

-40

0

-63

-310 -170 -170 -120

-470 -209 -330 -280

-80 -80 -80

-320 -180 -180 -130 -142 -180 -240

-480 -219 -340 -290

-340 -190 -190 -140

-530 -236 -380 -330 -100 -100 -100

-360 -200 -200 -150 -174 -220 -290

-550 -246 -390 -340

U.S. 800-626-6653

N�

Canada 800-387-6600

N�

www.dme.net

Technical Reference

299

Determining Metric Tolerances

Table 7: Tolerances for outside dimensions (shafts) continued

UNITS IN MM

TOLERANCES FOR OUTSIDE DIMENSIONS (SHAFTS) (UNITS IN 0.001MM)

TO

h8

h9

h10

h11

j5

j6

j7

k5

k6

k7

k8

m5

m6

m7

n5

n6

n7

r6

js6

js7

0

-14

0

-25

0

-40

0

-60

+2

-2

+4

-2

+6

-4

+4

0

+6

0

+10

0

+14

0

+6

+2

+8

+2

+12

+2

+8

+4

+10

+4

+14

+4

+16

+10

+3

-3

+5

-5

0

-18

0

-30

0

-48

0

-75

+3

-2

+6

-2

+8

-4

+6

+1

+9

+1

+13

+1

+18

0

+9

+4

+12

+4

+16

+4

+13

+8

+16

+8

+20

+8

+23

+15

+4

-4

+6

-6

10

0

-22

0

-36

0

-58

0

-90

+4

-2

+7

-2

+10

-5

+7

+1

+10

+1

+16

+1

+22

0

+12

+6

+15

+6

+21

+6

+16

+10

+19

+10

+25

+10

+28

+19

+4.5

-4.5

+7.5

-7.5

0

-27

0

-43

0

-70

0

-110

+5

-3

+8

-3

+12

-6

+9

+1

+12

+1

+19

+1

+27

0

+15

+7

+18

+7

+25

+7

+20

+12

+23

+12

+30

+12

+34

+23

+5.5

-5.5

+9

-9

0

-33

0

-52

0

-84

0

-130

+5

-4

+9

-4

+13

-8

+11

+2

+15

+2

+23

+2

+33

0

+17

+8

+21

+8

+29

+8

+24

+15

+28

+15

+36

+15

+41

+28

+6.5 +10.5

-6.5 -10.5

0

-39

0

-62

0

-100

0

-160

+6

-5

+11

-5

+15

-10

+13

+2

+18

+2

+27

+2

+39

0

+20

+9

+25

+9

+34

+9

+28

+17

+33

+17

+42

+17

+50

+34

0

-46

0

-74

0

-120

0

-190

+6

-7

+12

-7

+18

-12

+15

+2

+21

+2

+32

+2

+46

0

+24

+11

+30

+11

+41

+11

+33

+20

+39

+20

+50

+20

0

-54

0

-87

0

-140

0

-220

+6

-9

+13

-9

+20

-15

+18

+3

+25

+3

+38

+3

+54

0

+28

+13

+35

+13

+48

+13

+38

+23

+45

+23

+58

+23

10

14

14

18

18

24

24

30

30

40

40

50

50

65

80

80

100

+12.5

-12.5

+9.5

-9.5

+15

-15

+11

-11

+17.5

-17.5

+12.5

-12.5

+20

-20

+109 +14.5

+80 -14.5

+23

-23

+60

+41

+62

+43

+73

+51

100

120

120

140

140

160

160

180

+113

+84

180

200

+106

+77

200

225

225

250

250

280

280

315

315

355

355

400

400

450

450

500

+88

+63

0

-63

0

-72

0

-100

0

-115

0

-160

0

-185

0

-250

0

-290

+7

-11

+7

-13

+14

-11

+22

-18

+16

-13

+25

-21

+21

+3

+24

+4

+28

+3

+33

+4

+43

+3

+50

+4

+63

0

+72

0

+33

+15

+37

+17

+40

+15

+46

+17

+55

+15

+63

+17

+45

+27

+51

+31

+52

+27

+60

+31

+67

+27

+77

+31

+90

+65

+113

+84

+126

+94

0

-81

0

-130

0

-210

0

-320

+7

-16

+16

-16

+26

-26

+27

+4

+36

+4

+56

+4

+81

0

+43

+20

+52

+20

+72

+20

+57

+34

+66

+34

+86

+34

0

-89

0

-140

0

-230

0

-360

+7

-18

+18

-18

+29

-28

+29

+4

+40

+4

+61

+4

+89

0

+46

+21

+57

+21

+78

+21

+62

+37

+73

+37

+94

+37

0

-97

0

-155

0

-250

0

-400

+7

-20

+20

-20

+31

-32

+32

+5

+45

+5

+68

+5

+97

0

+50

+23

+63

+23

+86

+23

+67

+40

+80

+40

+166

+103 +126

+40 +172

+132

U.S. 800-626-6653

N�

Canada 800-387-6600

N�

www.dme.net

+130

+98

+144

+108

+150

+114

+16

-16

+26

-26

+18

-18

+28.5

-28.5

+20

-20

+31.5

-31.5

Determining Metric Tolerances

+76

+54

65

+8

-8

Technical Reference

NOMINAL SIZE RANGE

OVER

Technical Reference

300

Determining Metric Tolerances

Table 7: Tolerances for outside dimensions (shafts) continued

UNITS IN MM

Technical Reference

NOMINAL SIZE RANGE

Determining Metric Tolerances

OVER

TOLERANCES FOR OUTSIDE DIMENSIONS (SHAFTS) (UNITS IN 0.001MM)

TO

js8

js9

js10

js11

js12

js13

js14

js15

js16

js17

js18

+7

-7

+12.5

-12.5

+20

-20

+30

-30

+50

-50

+70

-70

+125

-125

+200

-200

+300

-300

+9

-9

+15

-15

+24

-24

+37.5

-37.5

+60

-60

+90

-90

+150

-150

+240

-240

+375

-375

10

+11

-11

+18

-18

+29

-29

+45

-45

+75

-75

+110

-110

+180

-180

+290

-290

+450

-450

+750

-750

+13.5

-13.5

+21.5

-21.5

+35

-35

+55

-55

+90

-90

+135

-135

+215

-215

+350

-350

+550

-550

+900

-900

+1350

-1350

+16.5

-16.5

+26

-26

+42

-42

+65

-65

+105

-105

+165

-165

+260

-260

+420

-420

+650

-650

+1050

-1050

+1650

-1650

+19.5

-19.5

+31

-31

+50

-50

+80

-80

+125

-125

+195

-195

+310

-310

+500

-500

+800

-800

+1250

-1250

+1950

-1950

+23

-23

+37

-37

+60

-60

+95

-95

+150

-150

+230

-230

+370

-370

+600

-600

+950

-950

+1500

-1500

+2300

-2300

+27

-27

+43.5

-43.5

+70

-70

+110

-110

+175

-175

+270

-270

+435

-435

+700

-700

+1100

-1100

+1750

-1750

+2700

-2700

+31.5

-31.5

+50

-50

+80

-80

+125

-125

+200

-200

+315

-315

+500

-500

+800

-800

+1250

-1250

+2000

-2000

+3150

-3150

+36

-36

+57.5

-57.5

+92.5

-92.5

+145

-145

+230

-230

+360

-360

+575

-575

+925

-925

+1450

-1450

+2300

-2300

+3600

-3600

+40.5

-40.5

+65

-65

+105

-105

+160

-160

+260

-260

+405

-405

+650

-650

+1050

-1050

+1600

-1600

+2600

-2600

+4050

-4050

+44.5

-44.5

+70

-70

+115

-115

+180

-180

+285

-285

+445

-445

+700

-700

+1150

-1150

+1800

-1800

+2850

-2850

+4450

-4450

+48.5

-48.5

+77.5

-77.5

+125

-125

+200

-200

+315

-315

+485

-485

+775

-775

+1250

-1250

+2000

-2000

+3150

-3150

+4850

-4850

10

14

14

18

18

24

24

30

30

40

40

50

50

65

65

80

80

100

100

120

120

140

140

160

160

180

180

200

200

225

225

250

250

280

280

315

315

355

355

400

400

450

450

500

U.S. 800-626-6653

N�

Canada 800-387-6600

N�

www.dme.net

Technical Reference

301

Determining Metric Tolerances

Table 8: Tolerances for inside dimensions (holes)

Table 8 details tolerances for inside dimensions (holes) based relative to the tolerance symbol. This table works the same way as Table 6, but is

pulled from a different source (ANSI standards) and details S7 and U7 ts. Pick the nominal size value that is closest to the desired nominal size to

determine the required tolerance range relative to the chosen tolerance symbol.

HOLE BASIS FIT

Example:

This Gives:

[mm]

60

50 to 65

IT7 (hole), IT6 (shaft)

H7/k6

Locational Transition Fit

0.030mm

0.019mm

Nominal size:

Size range to be used:

ISO-Grade No.:

Tolerance Symbol:

Desired Fit:

Allowance for hole:

Allowance for shaft:

Hole:

[mm]

H7

+0.030

-0

(0.030mm range)

k6

+0.021

+0.002

(0.019mm range)

60

Shaft:

[mm]

60

S7

U7

-14

-24

-18

-28

1.2

-14

-24

1.6

PICK CLOSEST VALUE TO DESIRED

DIMENSION (UNITS IN MM)

U7

25

-27

-48

-40

-61

-18

-28

30

-27

-48

-40

-61

-14

-24

-18

-28

40

-34

-59

-51

-76

-14

-24

-18

-28

50

-34

-59

-61

-86

2.5

-14

-24

-18

-28

60

-42

-72

-76

-106

-14

-24

-18

-28

80

-48

-78

-91

-121

-15

-27

-19

-31

100

-58

-93

-111

-146

-15

-27

-19

-31

120

-66

-101

-131

-166

-15

-27

-19

-31

160

-85

-125

-175

-215

-17

-32

-22

-37

200

-105

-151

-219

-265

10

-17

-32

-22

-37

250

-123

-169

-267

-313

12

-21

-39

-26

-44

300

-150

-202

-330

-382

16

-21

-39

-26

-44

400

-187

-244

-414

-471

20

-27

-48

-33

-54

500

-229

-292

-517

-580

U.S. 800-626-6653

N�

Canada 800-387-6600

N�

www.dme.net

Determining Metric Tolerances

S7

NOMINAL SIZE RANGE

PICK CLOSEST VALUE TO DESIRED

DIMENSION (UNITS IN MM)

Technical Reference

TOLERANCES FOR INSIDE DIMENSIONS (HOLES) (UNITS IN 0.001MM)

Technical Reference

302

Determining Metric Tolerances

Table 9: Tolerances for outside dimensions (shafts)

Table 9 details tolerances for outside dimensions (shafts) based relative to the tolerance symbol. This table works the same way as Table 7, but is

pulled from a different source (ANSI standards) and details s6 and u6 ts. Pick the nominal size value that is closest to the desired nominal size to

determine the required tolerance range relative to the chosen tolerance symbol.

HOLE BASIS FIT

Example:

Determining Metric Tolerances

This Gives:

Hole:

[mm]

F6

+0.033

-0

(0.013mm range)

h6

0

-0.013

(0.013mm range)

24

Shaft:

[mm]

24

TOLERANCES FOR OUTSIDE DIMENSIONS (SHAFTS) (UNITS IN 0.001MM)

PICK CLOSEST VALUE TO DESIRED

DIMENSION (UNITS IN MM)

s6

u6

+20

+14

+24

+18

1.2

+20

+14

1.6

NOMINAL SIZE RANGE

PICK CLOSEST VALUE TO DESIRED

DIMENSION (UNITS IN MM)

s6

u6

25

+48

+35

+61

+48

+24

+18

30

+48

+35

+61

+48

+20

+14

+24

+18

40

+59

+43

+76

+60

+20

+14

+24

+18

50

+59

+43

+86

+70

2.5

+20

+14

+24

+18

60

+72

+53

+106

+87

+20

+14

+24

+18

80

+78

+59

+121

+102

+27

+19

+31

+23

100

+93

+71

+146

+124

+27

+19

+31

+23

120

+101

+79

+166

+144

+27

+19

+31

+23

160

+125

+100

+215

+190

+32

+23

+37

+28

200

+151

+122

+265

+236

10

+32

+23

+37

+28

250

+169

+140

+313

+284

12

+39

+28

+44

+33

300

+202

+170

+382

+350

16

+39

+28

+44

+33

400

+244

+208

+471

+435

20

+48

+35

+54

+41

500

+292

+252

+580

+540

|

Technical Reference

[mm]

24

18 to 30

IT6

F6/h6

Clearance Fit

0.013mm

0.013mm

Nominal size:

Size range to be used:

ISO-Grade No.:

Tolerance Symbol:

Desired Fit:

Allowance for hole:

Allowance for shaft:

U.S. 800-626-6653

N�

Canada 800-387-6600

N�

www.dme.net

You might also like

- Tehnologia de Cultura A FasoleiDocument35 pagesTehnologia de Cultura A FasoleiCacencu Ţuca Cristina100% (6)

- Arsenie Boca-Cuvinte ViiDocument353 pagesArsenie Boca-Cuvinte ViiAnghelus Oana100% (19)

- Cap 6 1Document4 pagesCap 6 1velu22100% (1)

- Gramatica Muzicii Psaltice N LunguDocument132 pagesGramatica Muzicii Psaltice N LunguSam Sebastyan100% (1)

- Gramatica Muzicii Psaltice N LunguDocument132 pagesGramatica Muzicii Psaltice N LunguSam Sebastyan100% (1)

- Din 743-3-2000 (A)Document5 pagesDin 743-3-2000 (A)Sergio Rolla GuimaraesNo ratings yet

- Date Tehnice Motostivuitor R 70 35Document5 pagesDate Tehnice Motostivuitor R 70 35asxl113No ratings yet

- Cuplaje Cu FlanseDocument7 pagesCuplaje Cu FlanseQaz Ro100% (1)

- Tehnologia Asamblarilor Demontabile Prin FiletDocument22 pagesTehnologia Asamblarilor Demontabile Prin FiletOpris Orlando Sorin100% (1)

- Proiectarea Procesului Tehnologic de Prelucrare Mecanica A Unui ArboreDocument21 pagesProiectarea Procesului Tehnologic de Prelucrare Mecanica A Unui ArboreIulian GateiuNo ratings yet

- Cultivarea Fasolei Boabe Si PastaiDocument35 pagesCultivarea Fasolei Boabe Si PastaiSam SebastyanNo ratings yet

- Radiatia Solara - Referat de 10Document9 pagesRadiatia Solara - Referat de 10Christofer Wiliam100% (1)

- Din 65308 e 2008-05Document11 pagesDin 65308 e 2008-05jcNo ratings yet

- Chaveta Paralela DIN 6885 A 2Document2 pagesChaveta Paralela DIN 6885 A 2Renato CardosoNo ratings yet

- Din 3961 1 Precision Gears TechDocument19 pagesDin 3961 1 Precision Gears Techbrijesh4evNo ratings yet

- Din 743-2 e 2008-10 PDFDocument24 pagesDin 743-2 e 2008-10 PDFYuryNo ratings yet

- Din 743-1-2000 (A)Document10 pagesDin 743-1-2000 (A)Sergio Rolla GuimaraesNo ratings yet

- 13 Pene Si Caneluri PDFDocument23 pages13 Pene Si Caneluri PDFCristin PasatNo ratings yet

- Inele O (O-Rings) - Dimensiuni Si Locasuri Pentru EleDocument32 pagesInele O (O-Rings) - Dimensiuni Si Locasuri Pentru Elejo_rz_57No ratings yet

- Curs NR 08Document19 pagesCurs NR 08LucianNo ratings yet

- Standarde - ProfileDocument18 pagesStandarde - Profilesoniey_kaNo ratings yet

- Ajustaje PreferentialeDocument17 pagesAjustaje PreferentialeAnonymous cR5KRafyMvNo ratings yet

- Unelte Scule de Mana WURTHDocument184 pagesUnelte Scule de Mana WURTHBoldeanu NicoletaNo ratings yet

- Cane LuraDocument9 pagesCane Lurazota_alex01No ratings yet

- Bs 729 / Din 267-10Document19 pagesBs 729 / Din 267-10amrmoeenNo ratings yet

- ElectropalanDocument19 pagesElectropalanGeorge BasnoNo ratings yet

- Regent Pflug 5474Document13 pagesRegent Pflug 5474bogar1015No ratings yet

- SR en 1366-9Document2 pagesSR en 1366-9Otelea Stefan100% (1)

- Eurostar 4 Mfa Lista PieseDocument23 pagesEurostar 4 Mfa Lista PieseTecu CristiNo ratings yet

- Catalog Poansoane Si Bucsi Pentru Stante PagesDocument24 pagesCatalog Poansoane Si Bucsi Pentru Stante PagesDeanna LambNo ratings yet

- Stas 2755 1 74Document8 pagesStas 2755 1 74Oranceanu AndreiNo ratings yet

- Curs 02 MOM EIM 2020Document52 pagesCurs 02 MOM EIM 2020Elena SoareNo ratings yet

- Curs 02 MOM1 EIM 2023Document42 pagesCurs 02 MOM1 EIM 2023Viorel PanturuNo ratings yet

- Cap.6 CaneluriDocument12 pagesCap.6 CaneluriAlexandru DraghiciNo ratings yet

- Masini de Ridicat Si TransportatDocument26 pagesMasini de Ridicat Si TransportatEnache PopescuNo ratings yet

- Hilti 17894 Hilti Aparate de Implantat Cuie Si BolturiDocument22 pagesHilti 17894 Hilti Aparate de Implantat Cuie Si BolturiEmily StaffordNo ratings yet

- B.utilaje Si SDV-Urile2003Document7 pagesB.utilaje Si SDV-Urile2003Neculae AlexandruNo ratings yet

- Asamblari Prin Pene LongitudinaleDocument16 pagesAsamblari Prin Pene Longitudinalejulia007No ratings yet

- Test ICC Pentru BoltingDocument3 pagesTest ICC Pentru BoltingScribdTranslationsNo ratings yet

- Standarde - ProfileDocument18 pagesStandarde - Profilestelu_haiducNo ratings yet

- STAS 6465 Asamblari Filetate (Dimensionare Suruburi)Document8 pagesSTAS 6465 Asamblari Filetate (Dimensionare Suruburi)Gabriel Rasoi100% (1)

- Manual Service TicoDocument343 pagesManual Service TicoAndrei SarchisianNo ratings yet

- VD40REURXS500-REXESS2 785 Rotund V RODocument3 pagesVD40REURXS500-REXESS2 785 Rotund V ROAdrian StanescuNo ratings yet

- Hobas - Conducte PafsinDocument40 pagesHobas - Conducte Pafsinmuntean_mihai_2004No ratings yet

- Robinet de Reglare Cu Functie InversaDocument5 pagesRobinet de Reglare Cu Functie InversagangatilfrettarNo ratings yet

- RulmentiDocument11 pagesRulmentivelu22100% (1)

- Tolerantele Si Ajustajele Pieselor Filetate: Capitolul 7Document35 pagesTolerantele Si Ajustajele Pieselor Filetate: Capitolul 7LucianNo ratings yet

- HAURATONDocument72 pagesHAURATONSimon KatalinNo ratings yet

- Funcţiile Frezei Verticale (Vedere Din Faţă)Document6 pagesFuncţiile Frezei Verticale (Vedere Din Faţă)Iosif MargineaNo ratings yet

- Hauraton CatalogDocument148 pagesHauraton Catalog&R1No ratings yet

- Activitate Cercetare 1Document30 pagesActivitate Cercetare 1Cristi PopNo ratings yet

- SNT Capitolul3Document17 pagesSNT Capitolul3Gigi Mihai LazărNo ratings yet

- CatalogDocument58 pagesCatalogapis21100% (1)

- Evaluarea Si Marirea Puterii Calorice A Biomasei LemnoaseDocument56 pagesEvaluarea Si Marirea Puterii Calorice A Biomasei LemnoaseSam Sebastyan100% (1)

- Profețiile TimpuluiDocument8 pagesProfețiile TimpuluiSam SebastyanNo ratings yet

- Bazele Fizice Ale MecanoterapieiDocument14 pagesBazele Fizice Ale MecanoterapieiSam SebastyanNo ratings yet

- Sfantul Siluan Athonitul - Intre Iadul Deznadejdii Si Iadul SmerenieiDocument246 pagesSfantul Siluan Athonitul - Intre Iadul Deznadejdii Si Iadul SmerenieiRP100% (22)

- Jumatate Nu Te Nasti, Ci DeviiDocument4 pagesJumatate Nu Te Nasti, Ci DeviiSam SebastyanNo ratings yet

- Secretele Vaticanului - Limba Latină Se Trage Din Română - Magazin Cultural ŞtiinţificDocument4 pagesSecretele Vaticanului - Limba Latină Se Trage Din Română - Magazin Cultural ŞtiinţificSam SebastyanNo ratings yet

- Despre Plictiseala Si Nu NumaiDocument3 pagesDespre Plictiseala Si Nu NumaiSam SebastyanNo ratings yet

- Tehnologia Culturii FasoleiDocument3 pagesTehnologia Culturii FasoleivictorpoedeNo ratings yet

- FasoleDocument10 pagesFasoleSam SebastyanNo ratings yet

- Acte PT A Cumpara TerenDocument1 pageActe PT A Cumpara TerenSam SebastyanNo ratings yet

- Drumul Sufletului Dupa MoarteDocument13 pagesDrumul Sufletului Dupa MoarteSam SebastyanNo ratings yet

- ConcentratoriDocument13 pagesConcentratoriCleopatra PurcaruNo ratings yet

- Tehnologia Culturii FasoleiDocument3 pagesTehnologia Culturii FasoleivictorpoedeNo ratings yet

- Energia SolaraDocument4 pagesEnergia SolaraSam SebastyanNo ratings yet

- Vietile Sfintilor DecembrieDocument323 pagesVietile Sfintilor DecembrieFilip Horatiu-CristianNo ratings yet

- Energia SolaraDocument4 pagesEnergia SolaraSam SebastyanNo ratings yet

- Parintele Justin ParvuDocument5 pagesParintele Justin ParvuConstantin BucurNo ratings yet

- 23 Minute in IadDocument18 pages23 Minute in IadCornel ZamfirNo ratings yet

- Vietile Sfintilor - Vol.1 (Septembrie)Document211 pagesVietile Sfintilor - Vol.1 (Septembrie)Marcel VoineaNo ratings yet

- Tolerante Si Abateri La Executia Lucrarilor de ZidarieiDocument3 pagesTolerante Si Abateri La Executia Lucrarilor de ZidarieiSam Sebastyan100% (1)