Professional Documents

Culture Documents

William Geoffrey Colin Roney Meng (Hons), MSC (Hons) ::// Uk - Linkedin - Com / in / Willroney at Willroney

William Geoffrey Colin Roney Meng (Hons), MSC (Hons) ::// Uk - Linkedin - Com / in / Willroney at Willroney

Uploaded by

willroney8146Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

William Geoffrey Colin Roney Meng (Hons), MSC (Hons) ::// Uk - Linkedin - Com / in / Willroney at Willroney

William Geoffrey Colin Roney Meng (Hons), MSC (Hons) ::// Uk - Linkedin - Com / in / Willroney at Willroney

Uploaded by

willroney8146Copyright:

Available Formats

William Geoffrey Colin Roney MEng (Hons), MSc (Hons)

Address: 18 Abbot Road, Bury St Edmunds, SUFFOLK, IP33 3UB

Email Address: willroney@hotmail.com

LinkedIn: http://uk.linkedin.com/in/willroney

Twitter: @willroney

Telephone (Mobile): +44 7950 659448

Personal Profile:

An enthusiastic, self motivated team player with over 15 years of

experience across a broad range of design disciplines. A well rounded

engineer with good interpersonal skills, combined with a balanced

understanding of manufacturing, commercial and programme

requirements. Excellent CATIA V4 capabilities coupled with a sound detail,

assembly and installation drafting background.

With a keen interest in the developing world of unmanned and manned

aerial systems, I am available to consult on all aspects of defence,

aerospace and automotive and all other types of Design & Project

Engineering.

Qualifications:

MSc in Aircraft Engineering (Cranfield University)

MEng (Hons) in Aeronautical Engineering (City University, London)

3 A-Levels (Maths, Physics, Chemistry), 8 GCSEs between Grades A&C

Employers

British Aerospace

Plc /

BAE SYSTEMS Plc

Saltgrounds Road,

Brough,

EAST YORKSHIRE,

HU15 1EQ

March 1997 August

2006

Design Engineer

Hawk/A380

(various Grades)

Change Control

Engineer F35

Marshall Specialist

Vehicles / Marshall

Vehicle Engineering

North Works, Airport Road,

Cambridge, CB5 8RX /

Hampstead Avenue,

Mildenhall, SUFFOLK, IP28

7RE

August 2006 October

2008

Project Verification

Engineer General Support

Vehicle UK MOD

References:

Supplied on request

AMOT (Roper

Industries) Ltd

Western Way,

Bury St

Edmunds,

SUFFOLK,

IP33 3SZ

November 2008 Date

Applications

Engineer /

Project

Applications

Engineer /

Quality Engineer

William Geoffrey Colin Roney CV

Telephone: +44 07950 659448

Roles, Skills and Core Competencies

Applications Engineer / Project Applications Engineer / Quality

Engineer (AMOT)

Overview of role: Project managing thermostatic valves for nuclear

applications. Principal point of contact for all nuclear application enquiries,

as well as progressing existing supply contracts to powerplants across the

world. Additional responsibilities is management of the AMOT Change

Control process for Engineering tasks - ensuring that all submitted tasks

are integrated into IFS and prioritised according to importance.

Following transfer into the Quality Department, and with full stakeholder

input I have been responsible for reviewing, rationalising and rewriting the

internal manufacturing procedures . In addition I have been creating

Product-Specific Inspection Guides for Chalwyn Products to ensure

enhanced final inspection. Further activities include internal auditing to

ensure that the procedures are correctly followed by manufacturing

updates occur when appropriate development opportunities are spotted.

Skills and Core Competencies: Understanding customer requirements;

matching products to customer specifications; building and maintaining

customer relationships; project management of time-critical products;

organising and expediting customer inspection and testing of nuclear

products; use of inspection reporting for concessed & rejected

components; assessment of AMOT and Chalwyn products with respect to

ATEX and PED certification; maintenance of product certification when

required by customer order; internal auditing for all products

manufactured on site.

Project Verification Engineer (Marshall Specialist Vehicles - Marshall

Vehicle Engineering)

Overview of role: Project managing verification of loadbed product for

General Support Vehicle contract for UK MoD (6500 vehicles over 7 years),

ensuring that the performance of the product met the customer

requirements. This involved arranging and being present at customer

inspections to prove that the product worked as advertised. Also, Project

Manager for integration of HIAB loader crane onto all variants of Support

Vehicle (11 major types of vehicle, 30+ all variants). Also, day to day

management of Riotous Armour Protection Kit for GSV (approx 200 kits).

Kit is designed to withstand rocks and non-explosive damage whilst

keeping crew safe and vehicle moveable. Was responsible for seeing

project from initial tender, through design reviews and verification, to

delivery to the customer.

Skills and Core Competencies: Understanding customer requirements;

building and maintaining customer relationships; project management of

time-critical products from tender to delivery; organising and expediting

customer inspection and testing of loadbed and crane products;

maintaining a pro-active project management style to facilitate positive

customer relations; representing the Company in inter-project meetings

and customer inspections; proving the performance of the loadbed and

2

email: willroney@hotmail.com, http://uk.linkedin.com/in/willroney

William Geoffrey Colin Roney CV

Telephone: +44 07950 659448

crane product to the satisfaction of all stakeholders; planning and

management of external vehicle trials to meet programme milestones;

Change Control Champion for baseline+ changes to the loadbed product

Design Engineer / Change Control Engineer (British Aerospace BAE

SYSTEMS)

Overview of role: working as a Design Engineer in the New Business and

R&D Departments on the Hawk aircraft. This involved creation and

modification of drawings, schemes and concepts using CATIA 3D CAD

systems (up to V4.2)

Working as a Design Engineer on various Hawk aircraft contracts

(Australia LIF, Canada NFTC, South Africa Mk120, Bahrain AJT, RAF Mk128

AJT and India Mk132). My role was to produce detail and assembly

drawings, schemes and hydraulic drawings to enable new-design

manufacture to take place on the forward end of the aircraft. This involved

liaising with all departments to ensure that the designs did not breach

major surface constraints (e.g. aerodynamic considerations), stress limits

or physical size limitations.

Working on secondment with Airbus Filton, producing 3D models & 2D

drawings of double-sided machined components. All design work was

produced in conjunction with

Technical Support Design Engineer working in Bangalore, India on licence

build technical support for the Mk132 Hawk Aircraft. My role was to

consult and advise on the technical design aspects of the Mk132 Hawk

Aircraft (Design Information), to support its licence build by Hindustan

Aircraft Limited (Bangalore). This involved interpreting the drawing set for

the Indian customer, and suggesting possible manufacturing solutions, in

conjunction with the parallel supplied engineering processes.

Working as a Change Control Engineer on the Horizontal Tail for F35 Joint

Strike Fighter. My role was to control the baseline configuration of the

horizontal tail design activities, to ensure that integration was maintained

with other parts of the Global Engineering Team, in the US (Texas and

California). This involved liaising with all departments to ensure that the

designs did not breach major surface constraints (e.g. aerodynamic

considerations), stress limits or physical size limitations, as well as

mainatining a robust configuration control system for the work package.

Starting and completing a second Masters Degree (MSc in Aerospace

Engineering) as part of a BAE-sponsored scheme. Course consisted of

nine week-long modules and an individual & group thesis. My Individual

Thesis was entitled Cost Optimisation of Lean Assembled Structures. The

principle techniques discussed were the integration of FEA software,

design constraints and advanced machining capabilities. This report drew

on the work I undertook on secondment with Airbus (from BAE SYSTEMS)

3

email: willroney@hotmail.com, http://uk.linkedin.com/in/willroney

William Geoffrey Colin Roney CV

Telephone: +44 07950 659448

on the Inner-Outer Fixed Leading Edge work package on the A380 airliner

project.

The MSc Group report was called Total Eclipse Unmanned Aerial Vehicle.

The scope was to demonstrate the suitability of the Eclipse UAV to allow

removal of the main vertical flight control surfaces. My contribution was to

analyse the original air vehicle structure and to propose a Change Control

method to qualify the new design. This project has subsequently become

the Demon UAV, which recently successfully demonstrated flapless flight

(i.e. flight without the use of moveable aerodynamic surfaces).

Skills and Core Competencies: - Conceptual and Detail Design; Basic

Design Stressing; CATIA V4 CAD experience (8000+ hrs); BAe ANVIL2000

2D CAD experience; Report Writing; MS Word, Excel, Powerpoint

proficient; MSC NASTRAN / PATRAN Basic Understanding; Understanding

customer requirements; building and maintaining customer relationships;

project management of time-critical products;; maintenance of product

certification when required by customer order; maintaining a pro-active

project management style to facilitate positive customer relations;

representing the Company in inter-project meetings and customer

inspections; Control Champion for baseline+ changes to the F35

Horizontal Tail configurations; Understand and usage of typical and

specific Production Management Systems to confirm and maintain

configuration control of all work.

Aircraft Projects worked on

Hawk Mk127 (Australia), Hawk Mk115 (Canada, NFTC), Hawk Mk120

(South Africa), Hawk Mk128 (RAF AJT), Hawk Mk129 (Bahrain), Hawk

Mk132 (India)

Eurofighter Typhoon

Airbus A380 (Inner-Outer Fixed Leading Edge package)

F35 Joint Strike Fighter (Horizontal Tail)

Engineering & IT Skills:

8000 hrs CATIA DESIGN - detail mechanical structure, piping,

assys & schemes.

2500 hrs ANVIL2000 DESIGN - detail mechanical structure, assys &

schemes.

BAE SYSTEMS In-house DPDS & PEGS proficiency.

Understanding in Metaphase Product Data Manager.

Proficiency in many commercial standard PC packages e.g MSWord,

MSExcel,

MSPowerpoint, MSAccess, MSProject.

Proficiency in IFS Document and Component Management System

Currently learning to code in Java via an online training course

4

email: willroney@hotmail.com, http://uk.linkedin.com/in/willroney

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- AS - CBSE - X - Math - Practise - Standard 2Document11 pagesAS - CBSE - X - Math - Practise - Standard 2Kattirsitti Jeet Govind100% (1)

- Automatic TransmissionDocument20 pagesAutomatic TransmissionDwy Bagus NNo ratings yet

- Part 2. FIDP - Flexible Instruction Delivery PlanDocument5 pagesPart 2. FIDP - Flexible Instruction Delivery PlanRynMar VillNo ratings yet

- TIERNO, Michael. Aristotle's Poetics For Screenwriters: Storytelling Secrets From The Greatest Mind in Western CivilizationDocument121 pagesTIERNO, Michael. Aristotle's Poetics For Screenwriters: Storytelling Secrets From The Greatest Mind in Western Civilizationlinharesf147No ratings yet

- Ahmedabad BRTS - Wikipedia, The Free EncyclopediaDocument16 pagesAhmedabad BRTS - Wikipedia, The Free EncyclopediaPrabhakar Kumar BarnwalNo ratings yet

- New Lucena National Comprehensive High: SchoolDocument8 pagesNew Lucena National Comprehensive High: Schoolriverastudy01No ratings yet

- Spent Fuel Assessment and ResearchDocument126 pagesSpent Fuel Assessment and ResearchEryk Ryzko100% (1)

- Utility of Endoscopic Ultrasound in Symptomatic Cut Corners of A ClotDocument3 pagesUtility of Endoscopic Ultrasound in Symptomatic Cut Corners of A ClotDjabhi SpinzzNo ratings yet

- Becoming A Cisco Select Certified Partner-Step by Step GuideDocument7 pagesBecoming A Cisco Select Certified Partner-Step by Step Guidemwaseemno181No ratings yet

- Corporate Social Responsibility: Global Responsibility Local ImpactDocument46 pagesCorporate Social Responsibility: Global Responsibility Local ImpactfariaNo ratings yet

- Deep State Coup Chart-V0.7Document1 pageDeep State Coup Chart-V0.7agitpapa100% (1)

- Service Support Catalog 2020Document178 pagesService Support Catalog 2020Xin GaoNo ratings yet

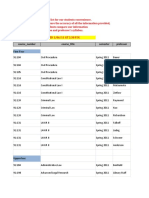

- Course - Number Course - Title Semester Professor: First YearDocument52 pagesCourse - Number Course - Title Semester Professor: First Yearkari262No ratings yet

- Service Manual LP4235!40!45Document131 pagesService Manual LP4235!40!45assitec9650% (2)

- Syllabus of 2nd Year LMD English at ENS Algeria Semster 4Document363 pagesSyllabus of 2nd Year LMD English at ENS Algeria Semster 4belbachir100% (1)

- Computer Bus Architecture, Pipelining and Memory ManagementDocument13 pagesComputer Bus Architecture, Pipelining and Memory ManagementniroseNo ratings yet

- Courses List IiDocument15 pagesCourses List IiShareef Sabi100% (1)

- WSH Alert, 3 February 2023, Pump Attendant Knocked Down by A CarDocument1 pageWSH Alert, 3 February 2023, Pump Attendant Knocked Down by A CarGoodLink EnquiryNo ratings yet

- JHS LCP English Grade 7 10Document25 pagesJHS LCP English Grade 7 10Daryl RiveraNo ratings yet

- Modern Marvels Fast Food TechDocument2 pagesModern Marvels Fast Food TechadeaversNo ratings yet

- Irradiation of PotatoesDocument26 pagesIrradiation of PotatoesChantre ToiNo ratings yet

- STEAMcalcDocument3,270 pagesSTEAMcalcSteve WanNo ratings yet

- Metal Buttons Making ProcessDocument2 pagesMetal Buttons Making ProcessZain Ali Kidwai100% (1)

- AR1740 EdD User Guide HomeLYnk enDocument162 pagesAR1740 EdD User Guide HomeLYnk enjcalberdiNo ratings yet

- Report On Compensation ManagementDocument30 pagesReport On Compensation ManagementBana Zeeshan100% (1)

- Cast Application Form 2023Document1 pageCast Application Form 2023arvin supanNo ratings yet

- GAS FLOW MEASUREMENT - PPSXDocument47 pagesGAS FLOW MEASUREMENT - PPSXMasood Alam Farooqui100% (2)

- Guidelines To Avoid ADMsDocument4 pagesGuidelines To Avoid ADMshekoxe6441No ratings yet

- Emperor OS New Features v2Document27 pagesEmperor OS New Features v2Saqib HussainNo ratings yet

- Oracle Cloud IPSec VPNDocument34 pagesOracle Cloud IPSec VPNUdo DudoNo ratings yet