Professional Documents

Culture Documents

E 2593-16 Electrode PDF

Uploaded by

Govindarajalu PadmanabhanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E 2593-16 Electrode PDF

Uploaded by

Govindarajalu PadmanabhanCopyright:

Available Formats

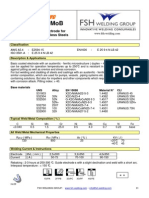

4460Cu

CATEGORY TYPE APPLICATIONS SMAW Stick Electrodes Rutile-Basic stainless steel electrode with extreme high corrosion resistance and mechanical properties. Welding wrought, forged or cast super duplex stainless steels for service in the as-welded condition. Heterogeneous welding between super duplex stainless steels and dissimilar welds between other stainless and mild or low alloyed steels Higher corrosion resistance then standard Duplex steels with also higher mechanical properties due to the addition of Nitrogen. AWS EN ISO DIN: W.Nr. DIN A 5.4: E 2593-16 3581-A: E 25 9 3 Cu N L B 22 1.4501 8556: E 25 9 3 Cu LR 23

PROPERTIES

CLASSIFICATION

SUITABLE FOR

Welding wrought, forged or cast super duplex stainless steels for service in the as-welded Condition. Heterogeneous welding between super duplex stainless steels and dissimilar welds between other stainless and mild or low alloyed steels. Examples: UNS S32550 :UR 52 N, Ferralium 255, UNS S32520 :UR 52 N+, UNS S32750 :SAF 2507, UR 47 N+, UNS S32760 :ZERON 100, UNS 32760, UR 76 N, SM22Cr, SAF 2507, ASTM S32760 (ZERON 100), S32550 and S31260., It can also be used for welding duplex type 2205, 1.4460, 1.4462,1.4463,1.4515, 1.4517, 1.4507 URANUS 52N, SAF 25.07, GX 3 CrNiMoCuN 26-6-3, (1.4515), GX 3 CrNiMoCuN 26-6-3-3, (1.4517), 25% Cr Super Duplex steels SAF 25/07, S32750 1.4410 - 25Cr-7Ni-4Mo-0.28N SAF2507, NAS74N, S32760 1.4501 - 25Cr-7Ni-3.8Mo-0.7Cu-0.7W-0.25N, S32506 - SUS329J4L 25Cr-7Ni-3Mo0.15N-0.2W NAS64 1.4507, S31803, S32205, CE approved

APPROVALS WELDING POSITIONS:

WELD DEPOSIT WEIGHT % C <0.02 Mn 1.0-1.2 Si <0.80 Cr 24-26 Ni 8-10 Mo 2.5-3.5 Cu 0.5-0.8 N 0.15-0.18 Fe Rem

MECHANICAL PROPERTIES Heat Treatment AW AW: as welded WELDING PARAMETERS PACKING Welding Parameters D (mm) 2.5 3.2 4.0 Length (mm) 300 350 350 Current (A) DC+/AC 60-90 80-120 100-150 kg / can 2.5 2.6 2.8 Packing kg / 6pack 15 15.6 16.8 kg / 1000 RP0,2 (N/mm 2) >550 Rm (N/mm 2) >730 A5 (%) >23 -20C 50 Impact Energy (J) ISO-V -40C -60C Hardness HB 300-390

REDRYING TEMPERATURE

if necessary for 2 hr, 300C (+ / - 10C)

You might also like

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel WeldingcfcshakerNo ratings yet

- Duplex Stainless Steels: Properties and Welding TechniquesDocument25 pagesDuplex Stainless Steels: Properties and Welding Techniqueskdsenipah6667No ratings yet

- Outokumpu Duplex DatasheetDocument12 pagesOutokumpu Duplex DatasheetzosternatNo ratings yet

- Datasheet For Stainless Steel Super Duplex 2507Document10 pagesDatasheet For Stainless Steel Super Duplex 2507Prem EditsNo ratings yet

- IIW, IX-H-736-11 DSS Welding DSS - Review of Current Recommendations 2011Document17 pagesIIW, IX-H-736-11 DSS Welding DSS - Review of Current Recommendations 2011Anonymous jlciIdX8q100% (1)

- UNS S32760 Superduplex Stainless Steel For Wet FGD Air Pollution SystemsDocument15 pagesUNS S32760 Superduplex Stainless Steel For Wet FGD Air Pollution SystemsdsoNo ratings yet

- B-62 2507 Rev 06Document5 pagesB-62 2507 Rev 06Shaik ShahNo ratings yet

- Oxford Alloy 385-16 (E385)Document1 pageOxford Alloy 385-16 (E385)brunizzaNo ratings yet

- Everything You Need to Know About Duplex Stainless SteelsDocument4 pagesEverything You Need to Know About Duplex Stainless SteelsAndy PhoenixNo ratings yet

- Nippon Steel Data S001enDocument14 pagesNippon Steel Data S001enpower group100% (1)

- Presentation1 (1)Document35 pagesPresentation1 (1)S RNo ratings yet

- Duplex Stainless Steel SAF 2304, 2205, SAF 2507Document12 pagesDuplex Stainless Steel SAF 2304, 2205, SAF 2507Anonymous skBAwexNo ratings yet

- Sae Ams5659p (2014)Document9 pagesSae Ams5659p (2014)Yeonggeun Lee50% (2)

- Pubs 1049240Document12 pagesPubs 1049240cooki77No ratings yet

- Welding Technology Steelconstr - EngDocument32 pagesWelding Technology Steelconstr - EngLukman Tarigan SumatraNo ratings yet

- Atmospheric Corrosion Resisting SteelDocument10 pagesAtmospheric Corrosion Resisting SteelCarlos PadillaNo ratings yet

- How To Weld Fully Austenitic Stainless SteelsDocument20 pagesHow To Weld Fully Austenitic Stainless SteelsCarlos Bermejo AlvarezNo ratings yet

- Mega Mex Guide to Super Duplex Stainless Steels S32760 and S32750Document5 pagesMega Mex Guide to Super Duplex Stainless Steels S32760 and S32750Madan YadavNo ratings yet

- SAE - AMS 5659mv004Document9 pagesSAE - AMS 5659mv004Nilesh PatilNo ratings yet

- 06 VD Mee-Welding of Super Duplex Stainless Steels PDFDocument12 pages06 VD Mee-Welding of Super Duplex Stainless Steels PDFVishal Sparkle QE3No ratings yet

- 06 VD Mee-Welding of Super Duplex Stainless SteelsDocument12 pages06 VD Mee-Welding of Super Duplex Stainless SteelsKareem AbdelazizNo ratings yet

- Duplex Stainless Steel Guide - Strengths, Uses & LimitationsDocument7 pagesDuplex Stainless Steel Guide - Strengths, Uses & LimitationsRizalzi BachtiarNo ratings yet

- Dual Shield 7000a1Document1 pageDual Shield 7000a1Gokul RajanNo ratings yet

- TWI Article On Super Duplex Welding - 1Document4 pagesTWI Article On Super Duplex Welding - 1kapsarcNo ratings yet

- Practical Guide To Using Duplex Stainless Steels: A Guide To The Use of Nickel-Containing AlloysDocument20 pagesPractical Guide To Using Duplex Stainless Steels: A Guide To The Use of Nickel-Containing AlloysapNo ratings yet

- Experiences With Zeron 100® Superduplex Stainless Steel in The Process IndustriesDocument12 pagesExperiences With Zeron 100® Superduplex Stainless Steel in The Process IndustriesMukeshNo ratings yet

- Selectarc Selectarc Selectarc Selectarc: Inox 2509mobDocument1 pageSelectarc Selectarc Selectarc Selectarc: Inox 2509mobGogo PNo ratings yet

- Welding Practice For Duplex-1 PDFDocument18 pagesWelding Practice For Duplex-1 PDFBipin Rohit100% (1)

- Duplex WeldingDocument4 pagesDuplex WeldingVishal Sparkle QE3100% (1)

- Designation: A 928/A 928M – 04 Standard Specification for Ferritic/Austenitic (Duplex) Stainless Steel PipeDocument6 pagesDesignation: A 928/A 928M – 04 Standard Specification for Ferritic/Austenitic (Duplex) Stainless Steel PipeiuiuiooiuNo ratings yet

- BOEHLER SC127E Open Die ForgeDocument28 pagesBOEHLER SC127E Open Die Forgegacm98No ratings yet

- Datasheet-Sandvik-254-Smo-En-V2021-04-22 18 - 35 Version 1Document10 pagesDatasheet-Sandvik-254-Smo-En-V2021-04-22 18 - 35 Version 1darioNo ratings yet

- Duplex Stainless SteelDocument24 pagesDuplex Stainless SteeljeffreymacaseroNo ratings yet

- S31803Document2 pagesS31803Elliott RussellNo ratings yet

- Duplex SSDocument12 pagesDuplex SSTushar PatilNo ratings yet

- AVESTA How To Weld Duplex SteelDocument20 pagesAVESTA How To Weld Duplex SteelGMacella100% (1)

- Duplex Stainless SteelDocument4 pagesDuplex Stainless SteelKumar RNo ratings yet

- Datasheet 25104l enDocument3 pagesDatasheet 25104l enwenigmaNo ratings yet

- The Australian Welding Guide PDFDocument220 pagesThe Australian Welding Guide PDFThành Nguyễn XuânNo ratings yet

- Austenitic Standard GradesDocument6 pagesAustenitic Standard Gradesfierro44No ratings yet

- This documentDocument44 pagesThis documentTran Thanh HaoNo ratings yet

- Ruukki Hot Rolled Steels Processing of Material WeldingDocument11 pagesRuukki Hot Rolled Steels Processing of Material Weldingprince5621No ratings yet

- Metrode Welding Duplex & Superduplex Stainless SteelsDocument18 pagesMetrode Welding Duplex & Superduplex Stainless SteelsClaudia Mms50% (2)

- Fluxes For Welding and SurfacingDocument4 pagesFluxes For Welding and SurfacingVăn Trường LêNo ratings yet

- Covered Electrodes For Stainless Steel: Avesta Electrodes Product ProgrammeDocument4 pagesCovered Electrodes For Stainless Steel: Avesta Electrodes Product Programmekamals55No ratings yet

- 20 SDMS 01Document43 pages20 SDMS 01tapas_jitu100% (1)

- Stainless Steel Grade Composition ChartDocument8 pagesStainless Steel Grade Composition ChartZaveri SagarNo ratings yet

- SS2205 Material SpecificationDocument4 pagesSS2205 Material SpecificationCh FaiNo ratings yet

- ESAB Consumable PDFDocument165 pagesESAB Consumable PDFbond8031No ratings yet

- FM 625Document1 pageFM 625yanryan78No ratings yet

- Aerospace Material SpecificationDocument6 pagesAerospace Material SpecificationAnonymous T6GllLl0No ratings yet

- Mild Steel 490mpa High Tensile Strength SteelDocument38 pagesMild Steel 490mpa High Tensile Strength SteelCarlos PadillaNo ratings yet

- Esab DublexDocument8 pagesEsab DublexSuphi YükselNo ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Yoga E Book 2016 PDFDocument120 pagesYoga E Book 2016 PDFVivekanandan Selvaganapathy100% (1)

- By Authority of Legally Binding Document: The United States of AmericaDocument22 pagesBy Authority of Legally Binding Document: The United States of AmericaGovindarajalu PadmanabhanNo ratings yet

- Yoga E Book 2016 PDFDocument120 pagesYoga E Book 2016 PDFVivekanandan Selvaganapathy100% (1)

- 849SalesTalk 1 PDFDocument3 pages849SalesTalk 1 PDFRahul SharmaNo ratings yet

- Api Spec 16a Drill ThroughDocument9 pagesApi Spec 16a Drill ThroughDaniel Sp Sitompul100% (1)

- ANSI Pipe ScheduleDocument2 pagesANSI Pipe ScheduleGovindarajalu Padmanabhan100% (2)

- Sambath YogaDocument1 pageSambath YogaGovindarajalu PadmanabhanNo ratings yet

- Hardness Conversion ChartDocument1 pageHardness Conversion ChartGovindarajalu PadmanabhanNo ratings yet

- Mott-T-5901-Equipment ListDocument17 pagesMott-T-5901-Equipment ListGovindarajalu PadmanabhanNo ratings yet

- Z-qualities/Z-testing: "Lamellar Tearing"Document2 pagesZ-qualities/Z-testing: "Lamellar Tearing"Govindarajalu PadmanabhanNo ratings yet