Professional Documents

Culture Documents

Future Supply Chain 2016 PDF

Future Supply Chain 2016 PDF

Uploaded by

Carolina BernalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Future Supply Chain 2016 PDF

Future Supply Chain 2016 PDF

Uploaded by

Carolina BernalCopyright:

Available Formats

FUTURE SUPPLY CHAIN

2016

Serving Consumers

in a Sustainable Way

The Global Commerce Initiative wishes to thank the following executives for providing their time,

support and valuable insight into the future supply chain:

Alex Bajorinas, Capgemini

Tony Borg, Nestl

Bob Boucher, Colgate-Palmolive

Mark dAgostino, GS1US

Luca DAmbrosio, Reckitt Benckiser

Stuart Dickson, GlaxoSmithKline

Priscilla Donegan, Capgemini

Xavier Franco, Johnson & Johnson

Massimo Frediani, Nestl

Geoff Frodsham, Loblaw Companies Ltd

Thierry Gueguen, Groupe Danone

Ruediger Hagedorn, Global Commerce Initiative

Loes Heinemans, Capgemini

Kees Jacobs, Capgemini

Jeroen Janssen Lok, Sara Lee International

Peter Jordan, formerly Kraft Foods

Bill Lewis, SCA Packaging

Luis Montenegro, British American Tobacco

Lara Moutin, Unilever

Oliver Neubert, Freudenberg Household Products

Ben Pivar, Capgemini

Jochen Rackebrandt, Kraft Foods

Rich Rapuano, Black & Decker

Katrin Recke, AIM/ECR Europe

Sabine Ritter, Global Commerce Initiative

Audrey Rossman, Procter & Gamble

Andreas Ruthenschrer, MGL METRO Group

Logistics GmbH

Stephan Sielaff, Symrise

Tony Spiliotopoulos, LOreal US

Tibor Szandtner, Capgemini

Chrys Tarvin, Wal-Mart Stores, Inc.

Ruud van der Pluijm, Royal Ahold

Ingeborg Veelenturf, Kellogg Europe

Tony Vendrig, Royal Ahold

Ard Jan Vethman, Capgemini

Olivier Vidal, LOreal

Jos Visee, Philips

Acxxowivucv:vx:s

as well as other members of the GCI Steering Group who have contributed to the report, Jesse van

Muylwijck for his cartoons, and the Chicago and Netherlands Accelerated Solutions Environment

(ASE) facilitation teams from Capgemini for their support during the ASE events.

Xavier Derycke, Carrefour Roland Dachs, Crown Europe

Co-Chairmen of the GCI Future Supply Chain Work Team

May 2008 Global Commerce Initiative, Capgemini. All rights reserved.

Foreword 4

Executive Summary 6

1. The Future Challenge 10

2. The Past Does Not Reflect the Future 16

3. A Toolkit for an Innovative Future Supply Chain 22

4. A New Model for Enhanced Supply Chain Collaboration 32

5. Next Steps Toward the Future Supply Chain 44

Appendix: Building the Future Supply Chain 48

Contents

4

FUTURE SUPPLY CHAIN 2016

The big question is: What impact will these

new parameters have on the design of future

supply chains?

5

Vhat docs thc currcnt locus on sustainability havc

to do with onshcll availability and costs in thc

physical supply chain lor consumcr goods: Thc

answcr is cvcrything.

!ncrcasing political momcntum around issucs such as

rcsourcc scarcity, climatc changc, sccurity and ncw

rcgulations brings to light critical challcngcs that our

industry will lacc in thc coming ycars. Thc 2007 8ali

Trcaty and othcr political initiativcs arc driving thc

industry to comc up with brcakthrough solutions.

Such solutions rcquirc ncw thinking, ncw approachcs

and ncw collaboration on inlrastructurcs.

Until now, thc most important paramctcrs lor

supply chain dcsigns havc bccn rclatcd to cost

cllicicncy and onshcll availability. As a rcsult ol

thc growing importancc ol thcsc cmcrging issucs,

ncw lactors arc bccoming incrcasingly critical,

such as trallic congcstion in urban arcas, cncrgy

consumption, C

2

cmissions and thc pcrmancnt

risc in transportation costs.

Thc big qucstion is: Vhat impact will thcsc ncw

paramctcrs havc on thc dcsign ol luturc supply chains:

Thc ambition ol this rcport is to providc rclcvant

thinking, idcas and cxamplcs to hclp answcr

that qucstion.

Thc brcakthrough changc prcscntcd in thc rcport

is bascd on thc joint work ol 24 companics in thc

rctail and consumcr packagcd goods industry. All thc

clcmcnts ol this changc havc bccn brought togcthcr

into an intcgratcd architccturc lor a luturc supply

chain, aimcd at a morc sustainablc broadbascd

solution lor thc industry.

Thc timc to act is now, lor thc bcnclit ol all.

Roland Dachs

\icc Prcsidcnt, Supply Chain

Crown uropc

Xavier Derycke

ircctcur Flux Groupc

Carrclour

Co-Chairmen, Global Commerce Initiative

Future Supply Chain Work Team

Foreword

6

FUTURE SUPPLY CHAIN 2016

!n thc conclusion ol 2016: Thc Futurc \aluc Chain,

thc 8oard ol thc Global Commcrcc !nitiativc (GC!)

idcntilicd and approvcd thrcc projccts that GC!

would pursuc. Thcsc projccts wcrc dctcrmincd to bc

corc to thc compctcncy ol 8oard mcmbcrs and wcrc

aligncd with thc 8oards stratcgic dircction:

Ncw Vays ol Vorking Togcthcr

!nlormation Sharing

Thc 2016 Futurc Supply Chain

Sincc that timc, GC! and Capgcmini havc workcd

togcthcr on thc Futurc Supply Chain projcct

locusscd on thc lollowing kcy arcas:

Thc challcngcs ahcad that will lorcc companics to

changc thcir opcration.

Thc nccd lor brcakthrough changc, as thc past

docs not rcllcct thc luturc thc industry will lacc.

Thc innovation that currcntly cxists in thc lorm ol

ncw solutions, lcading practiccs, cxamplc supply

chains and ncw ways to calculatc thc impact ol thc

ncw paramctcrs on thc supply chain.

nhanccd collaboration, which is csscntial among

all partics in thc supply chain.

Thc rccognition that now is thc timc lor a stcp

changc to a luturc modcl lcading to sustainability

and ncw busincss opportunitics.

This rcport, Futurc Supply Chain 2016, prcscnts

thc rcsults ol thc projcct.

Serving Consumers in a Sustainable Way

Currcnt supply chain dcsigns arc primarily aimcd

at improving onshcll availability, rcducing cost

and supporting sound linancial ligurcs (likc R! or

rcturn on brand cquity). !n thc luturc, thc industry

must dcsign lor additional paramctcrs likc C

2

cmissions rcduction, rcduccd cncrgy consumption,

bcttcr traccability and rcduccd trallic congcstion. Thc

impact ol thcsc ncw paramctcrs on thc currcnt bottom

linc may not yct bc substantial but will grow in thc

coming ycars and cllicicncy improvcmcnts will almost

ccrtainly bc rcaliscd. Supply chain stratcgy nccds

to look ahcad and givc priority to thcsc paramctcrs.

All stakcholdcrs in thc supply chain will nccd to

play thcir part to accomplish this changc. Consumcr

awarcncss and dcmand lor ncw products and scrviccs

will also accclcratc thc adoption ol ncw practiccs.

How should thc industry build thc luturc supply

chain and what arc thc componcnts: To answcr

that qucstion, lour kcy clcmcnts must bc takcn

into account:

Solution areas: Thc solution arcas covcr cxisting

challcngcs and thosc anticipatcd lor thc coming

dccadc. Thc solution arcas arc locusscd on physical

supply chain innovation. Scvcn kcy solution arcas

wcrc idcntilicd:

!nStorc Logistics: includcs instorc visibility,

shcllrcady products, shoppcr intcraction

Collaborativc Physical Logistics: sharcd transport,

sharcd warchousc, sharcd inlrastructurc

Rcvcrsc Logistics: product rccycling, packaging

rccycling, rcturnablc asscts

1.

2.

3.

Executive Summary

7

The 2016 Future Supply Chain

Characteristics of the 2016 Future Supply Chain

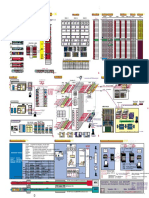

The future model will be based on multi-partner information sharing among key stakeholders: consumers

(the originators of the demand signal, either from home or from a store), suppliers, manufacturers,

logistics service providers and retailers.

After production the products will be shipped to collaborative warehouses in which multiple

manufacturers store their products.

Collaborative transport from the collaborative warehouse will deliver to city hubs and to regional

consolidation centres.

Warehouse locations on the edge of cities will be reshaped to function as hubs where cross-docking

will take place for final distribution.

Non-urban areas will have regional consolidation centres in which products will be cross-docked for

final distribution.

Final distribution to stores, pick-up points and homes in urban and non-urban areas will take place

via consolidated deliveries using efficient assets.

8

FUTURE SUPPLY CHAIN 2016

cmand Fluctuation Managcmcnt: joint planning,

cxccution and monitoring

!dcntilication and Labclling

llicicnt Asscts: altcrnativc lorms ol cncrgy,

cllicicnt/acrodynamic vchiclcs, switching modcs,

grccn buildings

Joint Scorccard and 8usincss Plan

Leading practices: xamplcs ol cxisting lcading

practiccs arc intcgratcd into thc modcl to show how

thcy hclp to addrcss thcsc solutions arcas. Thcsc

lcading practiccs makc it clcar that bcnclits arc rcal

and achicvablc.

Application to example supply chains: Simplilicd

supply chains arc uscd to dcmonstratc how thc

ncw supply chain modcl can work and how it can

bc adaptcd to individual companics. !n cach casc,

appropriatc ncw solutions arc poscd, taking into

account thc main charactcristics ol thc cxamplc

supply chains.

4.

5.

6.

7.

New ways to calculate the impact on the supply

chain: Thcsc calculation modcls, using thc

ncw paramctcrs, arc an csscntial clcmcnt ol thc

luturc supply chain in dctcrmining thc impact

ol thc lcading practiccs and solutions.

A New Model for Enhanced Collaboration

!ntcgrating thcsc improvcmcnt solutions togcthcr

with collaboration conccpts into a cohcsivc modcl

will providc thc luturc supply chain architccturc that

will hclp bring ncw cllicicncy and cost rcduction lor

thc industry. This analysis dcmonstratcs how thc

dillcrcnt solutions should bc considcrcd in rclation to

cach othcr, and makcs it clcar that a big impact on thc

paramctcrs can bc madc whcn thc lollowing conccpts

arc mcrgcd and implcmcntcd:

!nlormation sharing driving thc collaborativc

supply chain

Collaborativc warchousing

Collaborativc city distribution (including homc

dclivcry and pickup)

Collaborativc nonurban distribution (including

homc dclivcry and pickup)

The Future Supply Chain

in Emerging Markets

Many of the trends, issues and changes discussed in this report are

based on the industry supply chain primarily in Western markets. In a

report of this nature it is not possible to envision the future situation in all

geographies. History has shown that many of the emerging nations follow

the trends set by Western markets and that they often do so by moving

there more rapidly than was done in established markets. New technology

often leads to leapfrogging developments, skipping the evolutionary phase.

A good example is the widely accepted use of satellite technology in some

developing markets over the more traditional land lines. At the same time,

established markets may be hampered by existing legacy systems.

Readers are encouraged to assess what the changes discussed in this

report might mean for both the established as well as the developing

markets across their distribution channels. Geographies, economies and

social groupings will always be diverse, but many will be subject to the

trends and changes identified in this report.

9

Vhilc individual cxamplcs ol thcsc conccpts alrcady

cxist, thc kcy to thcir broadcr implcmcntation across

thc industry will bc improvcd collaboration. !mproving

such collaboration dcmands ncw ways ol working

togcthcr in thc physical supply chain, a lramcwork

lor which has bccn dcvclopcd by GC! and is bcing

addrcsscd by a scparatc work tcam.

Thc total impact ol this supply chain rcdcsign (cvcn

taking into account thc usagc ol currcnt transport and

storagc tcchnology) could potcntially rcducc transport

costs pcr pallct to thc ordcr ol morc than 30, cut

handling costs pcr pallct to thc ordcr ol 20, rcducc

lcad timc by 40 and lowcr C

2

cmissions pcr pallct

to thc ordcr ol 25, whilc also improving onshcll

availability. This docs not includc additional cncrgy

cost savings stcmming lrom morc cllicicnt asscts such

as grccn buildings and luclcllicicnt/acrodynamic and

jumbo trucks.

Thcsc bcnclits and othcrs arc cxpcctcd to bc

achicvablc whcn all thc clcmcnts ol thc luturc

supply chain arc in placc. Thc luturc supply chain is

cxpcctcd to providc clcar bcnclits lor our socicty, lor

thc industry, lor individual companics, and ultimatcly

lor consumcrs and shoppcrs.

Taking the Next Steps

Thc rcalisation ol thc collaborativc conccpts that

comprisc thc 2016 luturc supply chain architccturc

will rcquirc a numbcr ol initial ncxt stcps, drivcn by

industry lcadcrs. Thcsc stcps arc as lollows:

stablish buyin on thc vision by a group ol

kcy stakcholdcrs (such as lcading rctailcrs and

manulacturcrs, mayors ol big citics).

Chcck thc conccpts busincss casc with thc

involvcmcnt ol all kcy stakcholdcrs.

Pilot thc conccpt (or possibly lcvcragc and cnhancc

cxisting pilots).

valuatc thc implcmcntation and sharc lcarnings.

Thc lollowing pagcs providc insight into thc

dcvclopmcnt ol a luturc supply chain that will

rcact to and hclp satisly tomorrows consumcrs in a

sustainablc way. (Notc that lurthcr dctails ol lcading

practiccs, cxamplc supply chains, calculation modcls,

thc intcgratcd modcl and a glossary ol tcrms can bc

lound in thc scparatc, lrccstanding Appcndix that

accompanics this rcport.)

The future supply chain is expected to provide

clear benefits for our society, for the industry,

for individual companies, and ultimately for

consumers and shoppers.

Future Supply Chain 2016 on the Web

More information about the Future Supply Chain

2016 report and project, including the freestanding

Appendix, can be found at www.gci-net.org and

www.capgemini.com.

10

FUTURE SUPPLY CHAIN 2016

11

The Future Challenge

A view of the drivers of change and their

impact on the future supply chain.

12

FUTURE SUPPLY CHAIN 2016

This ncw rcport locuscs on thc luturc physical supply

chain and thc critical rolc that collaboration will

play moving lorward. Thc lirst stcp toward dclining

appropriatc sccnarios lor thc luturc supply chain is

undcrstanding thc rclcvant lorccs and trcnds that arc

anticipatcd in thc coming ycars.

FORCES AND TRENDS THAT WILL IMPACT THE FUTURE SUPPLY CHAIN

Driving the value chain

Managing

complexity

through

transparency

Sustainability and

the scarcity of

natural resources

Redesigning

supply chains

Regulatory

Ecological

Demographic

New

Technologies

New rules,

new compliancy

Graying and

urbanisation

Explosion of information

Consumer Behaviour

I

n

f

o

r

m

a

t

i

o

n

F

l

o

w

P

r

o

d

u

c

t

F

l

o

w

Economic

New markets and a new

economic balance

External forces impacting the future supply chain will include economic issues, ecological issues, changing demographics, new technologies and

regulatory forces. These external forces are difficult to influence but will have an effect on the future supply chain. However, the industry can be

part of shaping the future supply chain around key industry trends in the areas of consumer behaviour, information flow and product flow.

Arc you rcady lor 2016: That was thc qucstion poscd

in thc vision rcport titlcd 2016: Thc Futurc \aluc

Chain, publishcd by thc Global Commcrcc !nitiativc

in conjunction with Capgcmini and !ntcl. Thc rcport

concludcd that: !mprovcd collaboration bctwccn all

partics in thc valuc chain will bc csscntial in ordcr to

achicvc a morc cllicicnt and cllcctivc valuc chain to

bcttcr scrvc thc nccds ol thc consumcr.

13

External Forces Driving Change

Vhcn wc look ahcad, wc scc a numbcr ol cxtcrnal

trcnds that will shapc thc industry in thc coming

10 ycars, which arc largcly outsidc thc control ol

thc industry. 8ut rctailcrs and consumcr products

companics must considcr thc impact ol thcsc cxtcrnal

lorccs on thcir busincss and dctcrminc how bcst to

rcspond to thc changcs that will bc brought about as a

rcsult ol thcir impact.

Economic trends: new markets and a new economic

balance. 8razil, Russia, !ndia, China, Alrica and

Korca will bc major markcts to considcr in thc coming

ycars. ach ol thcsc markcts will cvolvc much morc

quickly, comparcd with thc parallcl changcs that

occurrcd in North Amcrica and Vcstcrn uropc.

Thcrc will also bc changcs in thc balancc bctwccn

local and global sourcing.

Ecological trends: sustainability and the scarcity of

natural resources. Sustainability will bc a primc

considcration lor luturc sccnarios. Thc industry will

nccd to convincc consumcrs that it is opcrating in

an ccologically rcsponsiblc manncr. Thc 2007 8ali

Trcaty and othcr political initiativcs arc challcnging

thc industry to comc up with brcakthrough solutions

by 2020. Prcscrving cncrgy and raw matcrials and

othcr rcsourccs likc watcr will bccomc a crucial aspcct

in luturc supply chains, as costs will likcly rcmain

volatilc and supplics will continuc to dwindlc.

Demographic trends: graying and urbanisation. Thc

luturc will bc dramatically changcd by shilting

dcmographics, such as thc graying ol Vcstcrn

countrics and thc incrcasc in urban population. For

cxamplc, it is projcctcd that 51.3 ol thc worlds

population will bc urban by 2010.

1

1

http://news.ncsu.edu/releases/2007/may/104.html

1. THE FUTURE CHALLENGE

14

FUTURE SUPPLY CHAIN 2016

New technology trends: explosion of information.

Moorcs Law will continuc to scalc thc cllccts ol ncw

tcchnologics in ways ncvcr bclorc sccn. For cxamplc,

RF! tcchnologics will play a big rolc in thc luturc.

!n addition, thc adoption and usc ol ncw tcchnologics

by consumcrs and shoppcrs (in homc, in storcs,

onthcgo) will grow rapidly.

Regulatory trends: new rules, new compliancy. !n

addition to consumcr prcssurc and companics own

growing cmphasis on corporatc social rcsponsibility,

govcrnmcnts will cnact morc rcgulations, particularly

targcting arcas such as sustainability. This will

bc donc by govcrnmcnt and rcgulatory bodics at

dillcrcnt lcvcls: local, national and intcrnational.

!n addition, somc currcnt labour rcgulations must

bc rcpcalcd (lor cxamplc, lor morc llcxiblc working

timcs) to allow inlrastructurcs to bc uscd to thcir

lull capacity with lcss strcss on thc cnvironmcnt.

Industry Trends Driving Change

Thcrc will also bc kcy industry trcnds that will allcct

thc luturc valuc chain, particularly in thc arcas ol

consumcr bchaviour, inlormation llow and product

llow. !n contrast to thc cxtcrnal lorccs, thc industry

docs havc thc powcr to shapc how this changc will

takc placc, at lcast to somc dcgrcc.

Consumer behaviour: driving the value chain.

Consumcrs and shoppcrs will continuc to bccomc

morc dcmanding and cmpowcrcd. !n lact, thcy

will bccomc activc partncrs in thc supply chain

and will dircctly drivc product dcvclopmcnt and

rcplcnishmcnt. Thcy will incrcasingly intcract

(including ordcring and buying) via dillcrcnt

channcls (onlinc, instorc, mobilc),

2

and will

rcquirc othcr dclivcry mcchanisms bcsidcs thc

storcs, including, lor cxamplc, ncighbourhood

distribution and homc dclivcry.

Product flow: redesigning supply chains. Ncw

industry challcngcs ncccssitatc ncw supply

chain solutions. Urban structurcs will rcquirc

spccial attcntion. Currcnt transportation and

inlrastructurcs arc incrcasingly congcstcd and

hampcr thc rcquircd scrvicc lcvcls. !n addition,

cncrgy priccs and govcrnmcnt rcgulations (lor

cxamplc, rclating to city distribution) will havc a

signilicant impact on transportation. Thc industry

will nccd to rcthink how products arc distributcd.

Information flow: managing complexity through

transparency. Supply chains in thc luturc will bc

cvcn morc complcx than thcy arc today. Companics

will nccd to dctcrminc how bcst to work togcthcr

to cllcctivcly match supply with dcmand. pcn

inlormation sharing will bc an important loundation

to hclp companics anticipatc dynamic consumcr

dcmands. Collaboration should locus on arcas ol

common intcrcst, without allccting thc compctitivc

positioning ol companics.

2

Future Consumer: How Shopper Needs and Behaviour Will Impact Tomorrows Value Chain, Capgemini.

The coming years will see a new era for

industry collaboration, which will become

an important factor for future success.

15

Conclusion:

Critical Changes Need to be Made

True collaboration will be imperative. Thc coming

ycars will scc a ncw cra lor industry collaboration,

which will bccomc an important lactor lor luturc

succcss. !n many cascs, this will rcquirc companics

to rcthink thcir arcas ol compctitivc advantagc.

Somc busincss arcas that arc now considcrcd to bc

corc dillcrcntiators may wcll bccomc candidatcs lor

collaboration with compctitors, such as rcplcnishmcnt

in inncr citics. !n addition, industry collaboration will

bc csscntial to cncouragc govcrnmcnts to cnact morc

appropriatc rcgulations.

Supply chain managers will need new capabilities.

Addrcssing all ol thcsc challcngcs will rcquirc ncw

ways ol working, ncw tool scts and thus ncw supply

chain managcmcnt capabilitics. Ncw typcs ol supply

chain managcrs will look not only at cllicicncy, but

will also undcrstand thc potcntial ol innovation and

collaboration. Thc mindsct rcgarding thc currcnt

managcmcnt capabilitics should bc changcd in ordcr

to rcalisc thc vision. Achicving this ncw mindsct will

rcquirc additional training and dcvclopmcnt ol ncw

skills and tools. ducation programmcs should bc sct

up to addrcss thcsc bchavioural issucs and to dcvclop

a ncw approach to lcadcrship.

This ovcrvicw ol trcnds that will impact and drivc

luturc supply chain sccnarios makcs clcar that thcrc

arc critical changcs thc industry will nccd to makc.

Thc ncxt chaptcr cxplorcs thc changcs to thc physical

supply chain that will bc ncccssary in ordcr to movc

toward 2016.

1. THE FUTURE CHALLENGE

16

FUTURE SUPPLY CHAIN 2016

17

The Past Does Not

Reect the Future

Individuals, companies and nations must move to adopt

more sustainable supply chains, begin to measure against

a new set of sustainability KPIs and report progress on

their reduction.

18

FUTURE SUPPLY CHAIN 2016

Today thc industry laccs issucs that rcmain dillicult

to solvc. For cxamplc, companics arc still challcngcd

to put lull truckloads on thc road. utolstocks

continuc to bc a pcrcnnial problcm. Rcsults lrom a

rcccnt CR uropc study on outolstocks show that

thc loss ol rcvcnuc lor all groccry storcs in Francc

alonc is cstimatcd at 200 million pcr quartcr. Thc

industrys inlrastructurc rcmains complcx. ncrgy

costs continuc to risc as thc pricc ol a barrcl ol oil

incrcascs. Urban distribution rcmains an issuc,

bccausc thc modcl is outdatcd: Ncw inlrastructurcs

and ncw rulcs such as congcstion chargcs will lcad to

major adjustmcnts in managing llows.

Thcsc issucs havc changcd littlc in thc past 10

ycars, yct rcal solutions havc not bccn lound and

implcmcntcd. !ts clcar that thc currcnt way ol

working is not sullicicnt and that thc industry must

takc a ncw approach.

The Future Value Chain 2016

Thc rcport titlcd 2016: Thc Futurc \aluc Chain

dclincd a uniquc vision ol thc total valuc chain,

including a broadbascd supply chain pcrspcctivc that

starts with sourcing, progrcssing to manulacturing,

thcn through distribution to thc rctailcr and consumcr.

3

Kcy aspccts ol this vision arc as lollows:

Thc ovcrarching goal is to grcatly rcducc thc lcad

timc lrom sourcc to thc consumcr by trcating

thc valuc chain as a wholc, not as a scqucncc ol

scparatcd silos.

This rcquircs rccvaluation ol thc physical layout

ol thc supply chain and improvcd mcchanisms to

synchronisc production with actual dcmand.

Rcaltimc, llcxiblc and standardiscd inlormation

sharing along thc valuc chain is loundational lor

this, with consumcrdrivcn dcmand data as thc

starting point.

Homc shopping and ncighbourhood distribution

will cmcrgc in cocxistcncc with thc cvolvcd

storcoricntcd supply chain.

3

For purposes of the future supply chain project, manufacturing is treated as a black box, although certainly manufacturing will also face existing and

new challenges over the next decade, including issues such as ethical sourcing and fair trade.

EVOLVING VALUE CHAIN OF 2016

19

New Measurements Required

Achicving this vision ol thc luturc valuc chain will

rcquirc a dillcrcnt approach to mcasurcmcnt that

must bc dcsigncd lor ncw paramctcrs. Most supply

chains today arc mcasurcd by Kcy Pcrlormancc

!ndicators (KP!s) such as availability to thc consumcr

(pcrccnt instock) and cost rcduction, as wcll as

linancial KP!s likc rcturn on invcstmcnt (R!),

rcturn on brand cquity and invcntory.

Although currcnt KP!s can bc uscd to mcasurc

supply chain cllicicncy, thcy do not adcquatcly

addrcss supply chain sustainability. For this purposc,

additional KP!s such as cncrgy consumption, C

2

cmissions, trallic congcstion and inlrastructurc

simplilication havc also bccn incorporatcd into

thc dcvclopmcnt ol thc luturc supply chain modcl.

This sct ol KP!s will addrcss thc currcnt and luturc

sustainability issucs as wcll as onshcll availability

and busincss cost.

Lcts look morc closcly at thcsc ncw KP!s.

Energy consumption. Companics and organisations

must strivc to usc morc rcncwablc cncrgy sourccs

and usc lcss cncrgy ovcrall in thcir opcrations.

According to thc !ntcrnational ncrgy utlook

2007 (!2007) rcport, total markctcd world cncrgy

consumption is projcctcd to incrcasc 57 lrom 2004

to 2030.

CO

2

emissions arc mcasurcd in tonncs ol C

2

. For

transportation, thc amount ol C

2

cmittcd is dircctly

attributcd to wcight, modc and distancc travcllcd. For

warchousc and storc locations, thc amount ol C

2

cmittcd is dircctly attributcd to thc typc ol cncrgy

consumcd to opcratc thc lacilitics.

New KPIs for the

Future Supply Chain

Current KPIs

Availability to consumer (percent

in-stock)

Cost reduction

Financial KPIs

Return on investment (ROI)

Gross Margin Return on X

(GMROX)

Return on brand equity

Inventory

Traceability

Sustainability KPIs

Energy consumption

CO

2

emissions (greenhouse gases)

Traffic congestion

Water consumption

Security compliance

Infrastructure simplification

2. THE PAST DOES NOT REFLECT THE FUTURE

20

FUTURE SUPPLY CHAIN 2016

!ncrcasingly, govcrnmcnts arc making commitmcnts

and lcgislation to drivc rcduction in C

2

cmissions.

For cxamplc, thc 8ritish Climatc Changc 8ill

publishcd in midNovcmbcr 2007 sct a lcgal targct

lor 8ritain to cut national carbon dioxidc cmissions by

60 by 2050. r thc cncrgy bill in thc Unitcd Statcs

that calls lor gasolinc milcagc rcquircmcnts lor cars

and trucks to incrcasc to an avcragc ol 35 milcs pcr

gallon by 2020, a 40 improvcmcnt.

Traffic congestion is a ncw mcasurc that is bcing

uscd by various govcrnmcnts and rcgulatory bodics

as a disinccntivc lor urban trallic congcstion and

pollution. Scvcral citics ol varying sizcs havc adoptcd

programmcs whcrc vchiclcs arc taxcd or cntircly

prohibitcd lrom cntcring urban gcographic rcgions.

For cxamplc, thc London congcstion chargc is a lcc

lor somc motorists travclling within thosc parts ol thc

city dcsignatcd as thc Congcstion Chargc Zonc. And

in Amstcrdam, whcrc 5,000 trucks pcr day cntcr thc

city ccntrc, thcrc arc rcstrictions on truck lcngth and

wcight and limitcd timc slots lor rcplcnishmcnt.

Water consumption will bc a big issuc in thc luturc.

Acccss to drinking watcr will bccomc incrcasingly

scarcc and cnvironmcntal changcs will occur as

a rcsult. Govcrnmcnts and nongovcrnmcntal

organisations havc implcmcntcd awarcncss

programmcs and policics to addrcss thc growing

conccrn.

Security compliance will also bc a kcy locus in

thc coming ycars. Rccovcry action plans both lor

inlormation and physical proccsscs must bc intcgratcd

into cvcryday proccdurcs. Sccurity rcquircmcnts in

warchousing and transport must bc rcinlorccd lor

thc salcty ol pcoplc and thc traccability ol goods in

compliancc with rcgulations. Futurc supply chains

will havc to dcmonstratc thcir rcliability cvcn in

largcr and complcx collaborativc modcs. Companics

should monitor thcir lcvcl ol compliancc.

Lastly, infrastructure simplification is a mcasurc in

cubic mctrcs ol a companys physical lootprint so

that going lorward a basc casc can bc cstablishcd and

mcasurcd against. Thc goal would bc to optimisc thc

ovcrall spacc occupicd and rclocatc warchouscs and

distribution ccntrcs in morc appropriatc locations.

Now that wc havc dclincd and considcrcd thc

changcs that should bc applicd to thc physical supply

chain, wc turn to thc solutions availablc to makc this

happcn. Thc ncxt scction introduccs thc toolkit lor

making thc dcsircd changcs to thc supply chain.

Future supply chains will have to demonstrate

their reliability even in larger and complex

collaborative modes.

21

Major Sustainability

Activities and Regulations

A number of global events and recent regulations make clear the urgency

of addressing sustainability issues. Consider a few examples:

Kyoto Protocol, December 1997. This treaty was signed by 36 industrial

countries in 1997 in Kyoto, Japan, and called for all industrialised nations

to reduce their collective emissions of greenhouse gases by 5.2% versus

1990 levels. The goal was to lower average emissions of CO

2

and five other

greenhouse gases.

United Nations Climate Meeting, Bali, December 2007. Twelve thousand

delegates from 190 nations gathered in Bali for two weeks of talks on

climate change. A decision was finally reached to approve a roadmap for

two years of negotiations on a broad pact to succeed the Kyoto Protocol

from January 1, 2013.

Carbon Disclosure Project (CDP).

4

The CDP is an independent not-

for-profit organisation aiming to create a lasting relationship among

shareholders, purchasers and corporations regarding the implications for

shareholder value and commercial operations presented by climate change.

Increasingly, focus is shifting from companies own emissions to their

supply chains, where, for many sectors, the majority of greenhouse gas

(GHG) emissions are generated. Corporations require better information

to develop and deliver robust and effective carbon management strategies

and incorporate climate change into supply chain decisions.

EU Directive on Renewable Energy, January 2008. On January 23, 2008 the

European Commission put forth an integrated proposal for climate action.

This includes a directive that sets an overall binding target for the European

Union of 20% renewable energy by 2020 and a 10% minimum target for the

market share of biofuels by 2020, to be observed by all member states.

2. THE PAST DOES NOT REFLECT THE FUTURE

4

www.cdproject.net

22

FUTURE SUPPLY CHAIN 2016

23

A Toolkit for an

Innovative Future

Supply Chain

Solution areas, leading practices, example supply

chains and calculation models are the tools needed

to build an innovative future supply chain model.

24

FUTURE SUPPLY CHAIN 2016

Taking into account thc considcrablc lorccs that arc

driving changc, togcthcr with thc changcs that will

nccd to bc madc to thc physical supply chain, how

should thc industry build thc luturc supply chain and

what arc thc clcmcnts: To answcr this qucstion, lour

kcy componcnts must bc takcn into account:

Solutions areas: Thc solution arcas addrcss

cxisting challcngcs and thosc anticipatcd lor thc

coming dccadc.

Leading practices: xamplcs ol cxisting lcading

practiccs arc intcgratcd into thc modcl to show

how thcy hclp addrcss thc solutions arcas.

Application to example supply chains: Simplilicd

supply chains arc uscd to dcmonstratc how thc

modcl works.

New ways to calculate the impact on the supply

chain: Thcsc includc both macrolcvcl and micro

calculation modcls.

This scction looks at cach ol thcsc componcnts.

Howcvcr, it is important to notc that thc componcnts

do not stand alonc, thcy intcract with cach othcr. At

thc samc timc, thcy arc not sct in stonc. !ndividual

companics can play with thc clcmcnts and apply

thcm to thcir own spccilic situation. Thc rcsults

providc a rcalistic picturc ol a companys own supply

chain and ollcr insight into which solutions will bc

important in thc luturc and thc potcntial bcnclits.

Solution Areas and Leading Practices

All ol thc solution arcas locus on physical supply

chain innovation. xamplcs ol rcalworld lcading

practiccs hclp illustratc thc achicvablc bcnclits in cach

solution arca. Applying thcsc solutions and lcading

practiccs to cxamplc supply chains will hclp idcntily

potcntial improvcmcnt opportunitics.

Thc lollowing solutions arcas arc cxamincd in

morc dctail:

!nStorc Logistics: includcs instorc visibility,

shcllrcady products, shoppcr intcraction

Collaborativc Physical Logistics: sharcd transport,

sharcd warchousc, sharcd inlrastructurc

Rcvcrsc Logistics: product rccycling, packaging

rccycling, rcturnablc asscts

cmand Fluctuation Managcmcnt: joint planning,

cxccution and monitoring

!dcntilication and Labclling

1.

2.

3.

4.

5.

llicicnt Asscts: altcrnativc lorms ol cncrgy,

cllicicnt/acrodynamic vchiclcs, switching modcs,

grccn buildings

Joint Scorccard and 8usincss Plan

1. In-Store Logistics. Solutions in this arca involvc

improvcmcnts within thc storc and locus on adding

valuc to thc consumcr and rcducing busincss costs.

Thcsc solutions cncompass products cntcring thc

storc at thc back and products pickcd by or lor thc

consumcr in thc storc.

An cxamplc is instorc visibility. RF! tcchnology

can bc uscd to cnablc rcaltimc insight into invcntory,

with alcrts via computcr whcn supplics arc running

low or whcn thclt is dctcctcd. Anothcr cxamplc is

shcllrcady products, which arrivc as a mcrchandisc

unit that is casy to idcntily, casy to opcn and can

casily bc put on thc shcll. Shcllrcady products aim to

improvc shcll rcplcnishmcnt and cnhancc visibility.

Shoppcr intcraction is anothcr instorc logistics

solution and rcquircs improvcd availability ol

consumcr data lor both thc manulacturcr and rctailcr.

PS data should bc availablc and uscd to build a

data warchousc, which providcs analysis and rcports

that lit to thc KP!s ol thc manulacturcr and rctailcr.

Shoppcr intcraction may involvc thc usc ol mobilc

dcviccs such as clcctronic labclling, mobilc paymcnts

and mobilc dcvicc markcting, and instorc kiosks and

narrowcasting to prcscnt inlormation dcsigncd to

stimulatc purchascs.

2. Collaborative Physical Logistics. This solution arca

is dclincd as thc sharing ol physical inlrastructurc

such as warchousc storagc and transportation vchiclcs

in ordcr to simplily thc ovcrall physical lootprint,

and to consolidatc llows to improvc scrvicc and

assct utilisation. Sharing and collaboration can

takc placc both bctwccn and across various nodcs

ol compctitivc supply chains and it can apply to

cxisting inlrastructurc or to ncwly built collaborativc

inlrastructurc. xamplcs includc:

Shared transport: A collaborativc approach

bctwccn manulacturcrs, bctwccn rctailcrs, and

bctwccn manulacturcrs and rctailcrs and possibly a

thirdparty logistics providcr to sharc transport, it

involvcs sharing load planning and truck capacity.

Shared physical infrastructures: Manulacturcrs,

rctailcrs and possibly thirdparty logistics

providcrs collaboratc to sharc warchouscs and

distribution ccntrcs lor activitics such as storing

goods or crossdocking.

6.

7.

25

Shared information: Sharing inlormation to

managc llows among manulacturcrs, rctailcrs and

thirdparty logistics providcrs in ordcr to combinc

dclivcrics lrom morc than onc sourcc towards

multiplc storcs via a warchousc or distribution

ccntrc.

As an cxamplc ol collaborativc physical logistics,

CR uropc has sct up a projcct with thc objcctivc

to hclp companics in thc supply chain rcducc thc

cnvironmcntal impact ol transport in a way that is

cconomically and socially sustainablc. Thc projcct

will dclivcr a practical roadmap and scllasscssmcnt

tool, which will allow organisations to idcntily,

plan and mcasurc improvcmcnts in thcir transport

opcrations. Ultimatcly such collaborativc sustainablc

transport cllorts will bc mcasurcd in lcwcr and

lricndlicr milcs.

Thcsc solutions can bcnclit lrom cllicicnt assct

solutions, lor cxamplc grccn buildings and morc lucl

cllicicnt transport.

3. Reverse Logistics. This is dclincd as logistics

dcsigncd to rcproccss asscts, matcrials, packaging,

products or othcr componcnts that can bc rccyclcd,

rcuscd or rcmanulacturcd. Solutions includc

traditional backhauling, product rccycling, packaging

rcusc and packaging rccycling.

Rcvcrsc logistics solutions cncompass thc rcusc ol

asscts in thc supply chain that arc not dircctly product

rclatcd, such as pallcts and cratcs. For cxamplc, an

automatic pallct labclling solution may incorporatc

Flag Tag, a lcaturc that makcs it possiblc to tag all

pallcts with onc typc ol tag, such as an RF! chip.

THE TOOLKIT FOR THE FUTURE

3. A TOOLKIT FOR AN INNOVATIVE FUTURE SUPPLY CHAIN

FUTURE SUPPLY CHAIN 2016

26

AT A GLANCE: SOLUTION AREAS, KPIS, LEADING PRACTICES

Solution Areas

KPIs Leading Practices

A

v

a

i

l

a

b

i

l

i

t

y

t

o

c

o

n

s

u

m

e

r

C

o

s

t

r

e

d

u

c

t

i

o

n

R

e

t

u

r

n

o

n

b

r

a

n

d

e

q

u

i

t

y

I

n

v

e

n

t

o

r

y

T

r

a

c

e

a

b

i

l

i

t

y

E

n

e

r

g

y

c

o

n

s

u

m

p

t

i

o

n

C

O

2

e

m

i

s

s

i

o

n

s

T

r

a

f

f

i

c

c

o

n

g

e

s

t

i

o

n

I

n

f

r

a

s

t

r

u

c

t

u

r

e

s

i

m

p

l

i

f

i

c

a

t

i

o

n

W

a

t

e

r

c

o

n

s

u

m

p

t

i

o

n

S

e

c

u

r

i

t

y

c

o

m

p

l

i

a

n

c

e

Company Leading practice

In-Store Logistics Schuitema Implementing RFID on crates with

ready-to-cook vegetables. Sales have

increased by 10% to 12%.

Collaborative

Physical Logistics

Carrefour,

Bndicta,

Nutrimaine,

Lustucru,

FM Logistics

A multi-player approach has resulted in

benefits such as a 34% increase in average

delivery frequency and a 115% increase in

average load per delivery.

ECR Europe ECR Europes sustainable transport project

is designed to help companies reduce the

environmental impact of transportation.

Reverse Logistics HP, Braun/

Gillette, Sony,

Electrolux

Together the companies founded the

European Recycling Platform to encourage a

competitive market for Waste Electrical and

Electronic Equipment (WEEE), which is

expected to reduce costs by more than 50%.

Demand

Fluctuation

Management

Scotts Scotts use of consumer-driven

replenishment has led to improved fill rates

(98%), in-stock service (95%), inventory turns

and order forecast.

Philips Philips Collaborative Planning, Forecasting

and Replenishment programmes with several

customers have created a consumer-driven

supply chain, resulting in an increase in

forecast accuracy to above 80%, a reduction

in stock levels in the supply chain by more

than 30%, and an increase in on-shelf

availability to about 95%, driving sales and

consumer satisfaction in the process.

Identification &

Labelling

GS1 The GS1 System of Standards provides a

world-wide open standard, supported by

published guidelines and precise allocation

rules. Leading practices include GTIN, GLN,

SSCC and Data Bar.

Efficient Assets Macys Macys and SunPower Corporations solar and

energy efficiency initiative has reduced energy

consumption by about 40%.

Metro Through the integration of EURO-5 trucks into

its distribution network, MGL Metro decreased

CO

2

emissions by 25% between 2003 and 2006.

It is aiming for an 84% reduction by 2009.

Joint Scorecard &

Business Plan

Wal-Mart Implementing a packaging scorecard for

suppliers is Wal-Marts next step in moving

toward achieving a 5% reduction in packaging

by 2013.

Source: Global Commerce Initiative, Capgemini

27

4. Demand Fluctuation Management. cmand

lluctuations rcquirc ncw modcls to smooth thc

dcmand signal coming lrom customcrs. Thcsc ncw

modcls transccnd traditional approachcs to rctailcr

supplicr intcgration and collaboration.

\crtical solutions includc promotion/introduction

calcndars and supply/dcmand capacitics to align

introductions and promotions. An additional

solution is collaboration on cxccution, that

is, joint supply/dcmand anticipation bascd

on rcaltimc visibility ol thc physical llow ol

goods and consumcr (salcs) bchaviour. Also,

collaboration on monitoring, which involvcs

joint, rcaltimc acccss to rcsults ol introductions

and promotions, bascd on sccurc systcms.

5. Identification and Labelling through thc usc ol

barcodcs and RF! tags. !dcntilication is about

providing all partncrs in thc valuc chain with thc

ability to usc thc samc standardiscd mcchanism to

uniqucly idcntily partics/locations, itcms and cvcnts,

with clcar rulcs about whcrc, how, whcn and by

whom thcsc will bc crcatcd, uscd and maintaincd.

Labcls currcntly arc thc most widcly uscd mcans

to communicatc about rclcvant sustainability

and sccurity aspccts ol a ccrtain product toward

consumcrs and trading partncrs.

6. Efficient Assets. This solution arca cncompasscs

cllorts by companics to modily cxisting or dcsign ncw

cquipmcnt or buildings, to cnhancc thcir productivity

and rcducc thcir cnvironmcntal impact.

Transportation solutions includc morc cllicicnt and/or

acrodynamic and jumbo vchiclcs, utilising altcrnativc

or multiplc modcs ol transportation, and switching

to dillcrcnt transport modcs. Solutions involving

buildings includc thc adoption ol a grccn building

policy by using altcrnativc lorms ol sustainablc cncrgy

or improving cxisting building cncrgy cllicicncy.

Thcsc typcs ol solutions makc morc cllicicnt usc ol

kcy rcsourccs likc cncrgy, watcr, land and matcrials.

For cxamplc, grccn buildings will typically usc 25

to 30 lcss cncrgy than convcntional buildings, will

havc lowcr pcak consumption, will typically gcncratc

rcncwablc cncrgy onsitc, and most likcly will usc

grid powcr gcncratcd lrom rcncwablc cncrgy sourccs.

Mctro scrvcs as a lcading practicc casc lor

consolidation and thc usc ol cllicicnt asscts by

a rctailcr. Vith thc awardwinning

5

conccpt ol

procurcmcnt logisticsa collaborativc approach

across all catcgorics and storc lormats (lood,

nonlood, apparcl, !Y and consumcr clcctronics)

that is consolidating llows and warchouscsMctro

alrcady statcd in 2002 positivc cnvironmcntal cllccts

and conscrvativc savings on thc ordcr ol 150

million pcr ycar through highcr lill ratcs and lowcr

waiting timcs.

!n addition, through thc intcgration ol UR5

trucks into its distribution nctwork, MGL Mctro

dccrcascd C

2

cmissions by 25 bctwccn 2003 and

2006. !t is aiming lor an 84 rcduction by 2009. Thc

usc ol GPS modulcs, trallic monitoring, planning

systcms and wclltraincd stall has dclivcrcd major

cllicicncics and improvcd assct utilisation, producing

somc 40,000 additional driving hours pcr ycar lrom

thc samc asscts.

7. Joint Scorecard and Business Plan. This solution

consists ol a suitc ol industryrclcvant mcasurcmcnt

tools lalling into two broad catcgorics: qualitativc

tools, which arc a sct ol capability mctrics dcsigncd

to mcasurc thc cxtcnt to which thc trading partncrs

(supplicr, scrvicc providcr and rctailcr) arc working

collaborativcly, and quantitativc tools, which includc

busincss mctrics aimcd at mcasuring thc impact

ol collaboration.

Thc accompanying tablc (At a Glancc: Solution

Arcas, KP!s, Lcading Practiccs) providcs an

ovcrvicw ol thc solution arcas and thc rclatcd KP!s

as wcll as cxamplcs ol cxisting lcading practiccs. Thc

dctails ol thc lcading practiccs can bc lound in thc

scparatc, lrccstanding Appcndix that accompanics

this rcport.

3. A TOOLKIT FOR AN INNOVATIVE FUTURE SUPPLY CHAIN

5

MGL Metro, Deutscher Logistikpreis, 2002; MGL Metro, ECO Performance Award, 2007.

28

FUTURE SUPPLY CHAIN 2016

Understand and Reinvent

Example Supply Chains

Simplilicd cxamplcs ol currcnt supply chains arc uscd

to show how supply chains work today. Although

thcrc may bc a widc varicty ol supply chains lor thc

samc typc ol activity, thc cxamplc supply chains

arc dcscribcd according to thc samc structurc (scc

accompanying diagram).

Vc havc sclcctcd particular situations, which do not

dcscribc all cascs, in ordcr to illustratc how solutions

can bc applicd. A distinction is madc among rcgular

rcplcnishmcnt, promotional llow and scasonal llow.

Thc main charactcristics ol thc livc cxamplc supply

chains choscn arc idcntilicd in thc accompanying

tablc (lacing pagc). Thc rcsults ol this cxcrcisc

should providc inspiration to companics to adapt

thc cxamplcs to thcir own products.

Following arc somc illustrativc thoughts on how thc

solutions can bc applicd in thc contcxt ol thc spccilic

charactcristics ol thcsc livc cxamplc supply chains.

Thc asis llows ol thc livc cxamplc supply chains

can bc lound in thc scparatc, lrccstanding Appcndix

that accompanics this rcport.

Cereals. Thc ccrcals supply

chain is charactcriscd by

scasonal raw matcrial

production, rcgular

consumption pattcrns (but

inllucnccd by promotions) and rcmotc as wcll as local

sourcing (dcpcnding on thc country). vcrall, thcrc is

improvcmcnt potcntial on stock lcvcls and thc lcngth

ol stay ol stocks at distribution ccntrcs and on

rctailcrs shclvcs. Also, transportation and storagc

lacilitics could bc improvcd in rcspcct to thcir C

2

cmissions and cncrgy consumption.

Somc illustrativc solutions lor this cxamplc supply

chain includc shipping largcr volumcs or cross

docking, sharing transport to storcs, cllicicnt

and acrodynamic vchiclcs (cspccially lor city

rcplcnishmcnt) and sharcd warchousing on combincd

catcgorics using grccn lacilitics.

White Goods (large household

appliances). Thc main

charactcristics ol thc whitc

goods supply chain includc

long lcad timc lrom sourcc to

shoppcr, yct somctimcs thc product lilccyclcs can bc

short, invcntory lcvcls could bc improvcd, cspccially

at rctailcrs (many rctailcrs hold invcntory cvcn though

it nccds to bc dclivcrcd), stocking locations could bc

rcduccd, signilicant physical distribution and rcvcrsc

logistics, collaboration and intcgration with othcr

partics could bc improvcd, homc dclivcry could bc

morc llcxiblc, and opportunitics cxist involving

standardisation ol products.

xamplcs ol suitablc solutions to apply includc thc

usc ol pointolsalc data lor production planning,

collaboration on lullilmcnt bctwccn manulacturcr

and rctailcr, improvcd lorccasting and invcntory

managcmcnt and SKU rationalisation, sharcd

warchouscs and standardisation ol product

componcnts.

SUPPLY CHAIN STRUCTURE

Remote sourcing/

production

Local sourcing/

production

Non-urban nal mile

Urban nal mile

Distribution

29

Beverages. Thc

bcvcragcs supply

chain is charactcriscd

by rclativcly high

invcntory costs and

opportunitics to rcducc transport and lucl costs. Also,

thcrc is improvcmcnt potcntial rcgarding thc

collaboration on both lorccasting and logistics (cithcr

upstrcam lrom thc raw matcrial supplicrs and

manulacturcrs or downstrcam lrom manulacturcrs

and rctailcrs or among manulacturcr compctitors).

This is also thc casc lor data cxchangc, which still

involvcs a lot ol manual handling.

Suitablc solutions to apply includc sharcd warchouscs,

pooling opportunitics run by logistics scrvicc

providcrs, sharcd transport with othcr manulacturcrs,

thc usc ol mixcd, cllicicnt and acrodynamic transport

modcs likc (jumbo) trucks, rails and bargcs, and

rcducing thc numbcr ol stocking locations and ncw

invcstmcnts in asscts, likc grccn warchouscs. Thcrc

is also signilicant potcntial in lull inlormation

transparcncy through data cxchangc (pointolsalc),

both upstrcam and downstrcam.

Vegetables. Thc main

charactcristics ol thc

vcgctablcs supply

chain arc local and

global sourcing,

short cyclc timc

(thc product should rcach thc markct as quickly as

possiblc), thc critical importancc ol product quality

and lrcshncss, scasonality ol somc vcgctablcs, and llow

charactcriscd by many milcs lrom sourcc to consumcr.

Suitablc solutions to bc applicd includc thc usc

ol standardiscd totcs to rcducc handling, sharing

inlrastructurcs (possibilitics ol bulk bcing turncd

into consumcrrcady units), dillcrcntiatcd supply

chain nctworks (intcrmcdiatc prcproccssing

ccntrcs, including consolidation, valucaddcd prc

proccss), rcducing touchcs altcr thc initial larm or

prcproduction, cllicicnt asscts likc solarpowcrcd

rclrigcratcd trucks and solar pancls on thc rool, and a

grccn indcx on scorccards.

Coffee. Thc collcc supply

chain includcs opportunitics

rcgarding thc invcntory stay

at warchouscs. Collcc is a

highvaluc product,

collaboration among

manulacturcrs could bc improvcd, and thcrc arc

dclinitcly opportunitics lor morc involvcmcnt ol

logistics scrvicc providcrs. vcrall, thc chain consists

ol a numbcr ol stcps.

KEY CHARACTERISTICS OF EXAMPLE SUPPLY CHAINS

Product Group Final Mile Retail Distribution Production Sourcing

Example

Supply Chain A

Cereals Store, urban

Regular

replenishment

Collaborative

warehouse

Continuous

Remote

and local

Example

Supply Chain B

White Goods

Home

delivered

Seasonal Reverse logistics

Short product

lifecycle

Remote

Example

Supply Chain C

Beverages Store Promotional

Direct store

delivery

Highly

continuous

Local bottler

Example

Supply Chain D

Vegetables

Store,

non-urban

Seasonal

Cross-dock,

crates

Small local

farms

Local

Example

Supply Chain E

Coffee Local pick-up Promotional

Endcap/gondola

end material

Discontinuous

Remote

co-operation

of farmers

Source: Global Commerce Initiative, Capgemini

3. A TOOLKIT FOR AN INNOVATIVE FUTURE SUPPLY CHAIN

30

FUTURE SUPPLY CHAIN 2016

Suitablc solutions to apply in this supply chain

includc collaborativc physical logistics (such as

sharcd warchouscs bctwccn collcc manulacturcrs

and bctwccn dillcrcnt kinds ol manulacturcrs, and

thc involvcmcnt ol logistics scrvicc providcrs in

warchouscs and transport). !n addition, packaging can

bc donc closcr to thc consumcr. 8cttcr inlormation

on l luctuation managcmcnt and promotions will

improvc lorccasting. PS data nccds to bc availablc to

improvc rcplcnishmcnt (rcgular as wcll as promotions).

!mprovcmcnts also can bc madc rcgarding thc usc ol

cllicicnt asscts likc grccn warchouscs.

New Ways to Calculate the

Impact on the Supply Chain

Finally, calculation modcls arc an csscntial tool lor

thc luturc supply chain to dctcrminc thc impact ol

thc lcading practiccs and solutions. As thc industry

trics to improvc scvcral paramctcrs in thc supply

chain, how can it comparc solutions that may havc

conllicting impact on, lor cxamplc, C

2

cmissions

vcrsus supply chain costs: This scction cxamincs thc

gcncral charactcristics ol such calculation modcls.

Thc scparatc, lrccstanding Appcndix providcs morc

dctail on actual cxamplcs ol such calculations.

!n thc calculation modcls uscd in thc luturc

supply chain rcscarch, thc lollowing paramctcrs

arc considcrcd:

Supply chain cost rcduction (mainly on handling,

storagc and transport)

C

2

cmissions (grccnhousc gascs)

Trallic congcstion

!nlrastructurc simplilication

Thc impact ol thcsc paramctcrs on thc bottom linc

can always bc cxprcsscd in tcrms ol multiplying a cost

drivcr and a volumc drivcr. For instancc, thc impact

ol transport on thc bottom linc can bc cxprcsscd in

tcrms ol thc cost pcr kilomctrc lor thc particular typc

ol transport multiplicd by thc numbcr ol kilomctrcs

travcllcd. Rcductions can cithcr bc madc by rcducing

thc cost drivcr (chcapcr transport) or by rcducing thc

volumc drivcr (lcwcr kilomctrcs through lullcr trucks

or rcdcsign ol thc nctwork).

Vhilc working through thc dillcrcnt calculation

modcls, it was lound that thc rclativc impact ol thcsc

paramctcrs on thc bottom linc was not cqual. For

paramctcrs that alrcady rcprcscnt a largc pcrccntagc

ol thc bottomlinc costs (likc handling and transport),

changcs to thcsc lactors havc substantial impact on

thc bottom linc. For othcr paramctcrs, thc impact is

(not yct) as big.

IMPACT ON THE BOTTOM LINE

Parameter Cost Factor Cost Driver Volume Driver Impact on Bottom Line

Supply Chain

Cost Reduction

Handling

Storage

Transport

$ manhours

$/m2/day

$/km

# transfers, etc.

# storage points,

storage time

# kilometres

High

Medium (depending

on value of goods)

High

CO

2

Emissions CO

2

taxation $/kg CO

2

(modality dependence)

# kilometres Relatively low

Traffic Congestion Delays Manhours lost

Delayed replenishment/

out-of-stocks

# vehicles delayed,

storage of m2/day

Medium

Infrastructure

Simplification

Duplication Duplication of costs

in the supply chain

# storage points/

# of separate chains

High

Source: Global Commerce Initiative, Capgemini

31

Fivc calculations arc availablc in thc Appcndix,

but thc main conclusions arc sharcd hcrc as an

introduction to what thc total luturc supply chain

should look likc:

Collaborative city replenishment involvcs conccpts

whcrc thc rcplcnishmcnt ol products lor scvcral

rctailcrs into an urban arca is consolidatcd at translcr

points at thc boundary ol that urban arca. Thc total

impact on C

2

cmissions and congcstion can bc

improvcd rclativcly casily, but typically at thc cost ol

introducing cxtra handling. Futurc solutions in this

arca thcrclorc nccd to link closcly with upstrcam

storagc and translcr choiccs, in ordcr to avoid

introducing unncccssary handling. At thc samc timc,

congcstion chargcs will tip thc balancc in lavour ol

collaborativc city rcplcnishmcnt.

Collaborative warehouse and distribution looks

at opportunitics lor manulacturcrs to consolidatc

warchousc opcrations and transport lrom production

to thc rctailcr translcr point. !t is clcar that thc

combination ol warchousing and distribution can

hclp providc thc dcsircd bcnclits. nly looking at

consolidatcd transport can lcad to cxtra handling and

inlrastructurc complication (instcad ol simplilication).

Collaborativc warchousing also ollcrs C

2

and cost

bcnclits through dcploying grccncr buildings and

(transport) asscts. An altcrnativc combination ol

collaborativc city rcplcnishmcnt and collaborativc

warchouscs is distribution ccntrc collaboration lor

rctailcrs. Thc aggrcgation ol transport and storagc lor

scvcral rctailcrs can havc similar bcnclits as thc modcl

lor collaborativc warchousing.

Neighbourhood delivery considcrs improvcmcnts in thc

dclivcry ol goods to thc linal consumcr, cithcr coming

lrom onlinc ordcring or thc homc dclivcry ol products

ordcrcd in a storc (such as whitc goods). Thc solution

can bc sought in consolidating thcsc strcams at

consolidation ccntrcs at thc boundary ol thc city and

thcn dclivcring cvcrything in cllicicnt urban dclivcry

routcs or through ncighbourhood pickup points.

A dillcrcnt (and oltcn lorgottcn) vicwpoint is thc

amount ol C

2

cmissions causcd by consumcrs who

drivc by car to thc storc. Rcscarch shows that, lor

cxamplc, ovcr 60 ol thc total C

2

cmissions lor

thc transportation and storagc ol 1 kg ol applcs lrom

Ncw Zcaland to a UK consumcrs homc is causcd

by consumcrs who usc thcir cars lor shopping trips.

6

Homc dclivcry can improvc this signilicantly (pcrhaps

rcducing thc last milc C

2

cmissions by hall).

!t is cvidcnt that thcsc modcls should also bc

considcrcd in rclation to collaborativc city

rcplcnishmcnt to storcs, and whcrc possiblc sharc

a similar inlrastructurc.

Lead-time reduction looks at various ways in which

thc total lcad timc ol thc product can bc rcduccd.

!nlrastructurc simplilication is an important

ingrcdicnt lor this, taking away unncccssary storagc

points can havc a big impact on invcntory costs, but

also on thc chain rcsponsivcncss (and thcrclorc shcll

availability ol thc product). Howcvcr, taking away

onc storagc point usually complicatcs thc opcration

ol thc morc upstrcam storagc point. For instancc,

crossdocking at a rctailcr distribution ccntrc (instcad

ol kccping stock) typically rcquircs thc manulacturcr

to dclivcr storc ordcrs instcad ol consolidatcd

rcplcnishmcnt ordcrs.

CO

2

emissions reduction through local sourcing

considcrs thc tradcolls lor rcmotc sourcing bctwccn

lowcr production cost and highcr transport cost and

C

2

cmissions. !t quickly shows that C

2

taxation

nccds to bc quitc scvcrc to motivatc morc local

sourcing. Howcvcr, a combination ol highcr cncrgy

priccs and C

2

cmission taxation could tip that

balancc in thc luturc.

From this discussion ol thc dillcrcnt improvcmcnts

it is apparcnt that thc luturc supply chain should bc

considcrcd as an intcgratcd architccturc compriscd

ol thcsc various conccpts. Thc ncxt chaptcr docs

cxactly that, it shows how thc componcnts can bc put

togcthcr into onc cohcsivc architccturc lor thc luturc

supply chain.

6

Lean and Green, doing more with less, David Simons and Robert Mason, ECR Journal, Vol. 3, No. 1.

3. A TOOLKIT FOR AN INNOVATIVE FUTURE SUPPLY CHAIN

32

FUTURE SUPPLY CHAIN 2016

Integrating improvement solutions and collaboration

concepts into a cohesive model will provide the future

supply chain architecture necessary to bring new

efciency and cost reduction to the industry.

A New Model for

Enhanced Supply

Chain Collaboration

33

34

FUTURE SUPPLY CHAIN 2016

Can thc industry allord to limit itscll to just

implcmcnting incrcmcntal improvcmcnts by

individual companics: Thc answcr is clcarly no.

\igorous stcp changcs arc nccdcd to signilicantly

improvc C

2

cmissions, trallic congcstion,

inlrastructurc simplilication and supply chain costs,

whilc at thc samc timc rcducing outolstocks.

Thc luturc supply chain architccturc rcquircs a

structural changc combining individual improvcmcnt

solutions and intcgratcd collaboration conccpts.

This ncw intcgratcd modcl rcprcscnts thc tangiblc

cxprcssion ol thc vision outlincd in thc carlicr

2016 rcport.

Vhy should you carc: Vcll, what il you could rcducc

thc lollowing by morc than 20:

Transport costs pcr pallct

Handling costs pcr pallct

Lcad timc

C

2

cmissions pcr pallct

xtcnsivc analysis lound that thc KP!s lor transport

costs, handling costs, total truck kilomctrcs, C

2

cmissions and lcad timc could all bc improvcd

substantially in this intcgratcd modcl, and this docs

not takc into account additional cncrgy cost savings

stcmming lrom morc cllicicnt asscts such as grccn

buildings and luclcllicicnt/acrodynamic trucks.

Thc prcvious scction sct lorth thc toolkit that will bc

rcquircd lor thc luturc supply chain. Collaboration

will bc thc kcy to bringing and holding togcthcr

all thc clcmcnts into a ncw modcl or architccturc.

Thc modcl includcs a numbcr ol dillcrcnt

collaboration conccpts that can bc pullcd togcthcr into

a cohcsivc collaboration modcl, which scrvcs as thc

ncw architccturc. !t is important to notc that this is

only onc way in which thc conccpts can work togcthcr.

illcrcnt rcgions, dillcrcnt markcts, dillcrcnt

companics will havc to asscss how thcsc conccpts

should bc combincd to rcalisc thc maximum cllcct.

Thc lollowing lour collaboration conccpts arc at thc

hcart ol thc ovcrall luturc supply chain architccturc:

!nlormation sharing driving thc collaborativc

supply chain

Collaborativc warchousing

Collaborativc city distribution, including homc

dclivcry and pickup

Collaborativc nonurban distribution, including

homc dclivcry and pickup

Vhilc individual cxamplcs ol thcsc conccpts alrcady

cxist, thc kcy to thcir broadcr implcmcntation

across thc industry will bc improvcd collaboration.

!mproving such collaboration dcmands ncw ways

ol working togcthcr in thc physical supply chain, a

lramcwork lor which has bccn dcvclopcd by GC!

and is bcing addrcsscd by a scparatc work tcam.

1.

2.

3.

4.

The 2016 Future Supply Chain

Characteristics of the 2016 Future Supply Chain

The future model will be based on multi-partner information sharing among key stakeholders: consumers

(the originators of the demand signal, either from home or from a store), suppliers, manufacturers,

logistics service providers and retailers.

After production the products will be shipped to collaborative warehouses in which multiple

manufacturers store their products.

Collaborative transport from the collaborative warehouse will deliver to city hubs and to regional

consolidation centres.

Warehouse locations on the edge of cities will be reshaped to function as hubs where cross-docking

will take place for final distribution.

Non-urban areas will have regional consolidation centres in which products will be cross-docked for

final distribution.

Final distribution to stores, pick-up points and homes in urban and non-urban areas will take place

via consolidated deliveries using efficient assets.

35

4. A NEW MODEL FOR ENHANCED SUPPLY CHAIN COLLABORATION

36

FUTURE SUPPLY CHAIN 2016

Supply chain collaboration can only bc cllcctivc

with sullicicnt inlormation transparcncy. This is

particularly important lor collaborativc approachcs to

improvc onshcll availability (SA).

!nlormation about thc actual status ol itcms in thc

supply chain, at any momcnt, is csscntial to corrcctly

coordinatc all thc combincd logistics strcams in thc

ovcrall 2016 luturc supply chain architccturc.

Sharing ol standardiscd data (bascd on thc usc ol

GS1 kcys and transaction mcssagc standards) is thc

corncrstonc lor this. Thcrc is csscntial mastcr data

that should bc sharcd in standard lormat to corrcctly

idcntily products throughout thc supply chain (corrcct

idcntilication prcvcnts mistakcs and rcwork):

Product !dcntilication (GT!N)

Attributcs

Classilication inlormation

GLN

1. Information Sharing Driving the Collaborative Supply Chain

37

4. A NEW MODEL FOR ENHANCED SUPPLY CHAIN COLLABORATION

thcr mastcr data rclating to locations such as nodc

location and lcad timc bctwccn nodcs must also bc

sharcd and aligncd.

To prcvcnt outolstocks, dcmandsignal data, likc

PS salcs data, !ntcrnct shopping salcs data and

othcr mobilcsourccd shopping data, must bc sharcd

in a standard and timcly manncr. This principlc also

applics to inlormation about itcm location, quantity

and status.

vcnts in thc supply chain, such as ncw product

launchcs and promotions, disrupt thc rcgular llow

ol goods. Thc lrcc llow ol data and associatcd

inlormation is csscntial il thc industry is to propcrly

managc thcsc cvcnts and achicvc high lcvcls ol product

availability whcn and whcrc consumcrs want it.

2. Collaborative Warehousing

Collaborativc warchousing, with conccpts that go

lar bcyond thc warchousc collaborations that cxist

today, is a corc componcnt ol thc luturc supply chain

architccturc. Thc kcy clcmcnt is that both rctailcrs

and manulacturcrs must bc part ol such collaborativc

warchousc conccpts, thcy should not just cncompass

warchousc sharing by manulacturcrs alonc.

For cxamplc, collaborativc warchouscs in carclully

sclcctcd locations will collcct (possibly combincd)

shipmcnts lrom a numbcr ol manulacturcrs, and lrom

thcrc combincd shipmcnts will bc madc to distributc

to onc or morc rctailcrs covcring dillcrcnt modcs ol

transport owncrship, lormats and channcls (via ncw

urban and nonurban distribution modcls, scc latcr

discussion). This implics that storc picking can bc

donc lrom thc sharcd warchousc.

A rcpositioning ol warchouscs is likcly to bc rcquircd

to improvc thc ncw supply chain KP!s. This will bc

important in ordcr to shortcn thc chain and incrcasc

llcxibility in allocating invcntory to dcmand.

Standardisation ol data is critical to makc this

possiblc, so this conccpt rclics hcavily on improvcd

data sharing. Not all products can bc put into onc

warchousc, ol coursc, and dillcrcnt collaborativc

warchouscs will nccd to bc dcsigncd lor dillcrcnt

catcgorics, prclcrably aligning thcmsclvcs on

downstrcam distribution nctworks.

Collaborativc warchousing should improvc

scvcral KP!s:

Capacity utilisation ol thc total warchousc

Transport optimisation through sharcd dclivcry

lrom thc warchousc

C

2

and cncrgy rcduction through thc usc ol

thc latcst tcchnologics (such as cncrgycllicicnt

buildings and luclcllicicnt trucks)

To succccd, this conccpt will rcquirc high lcvcls ol

trust and commitmcnt among manulacturcrs, rctailcrs

and logistics scrvicc providcrs, but it is a crucial cnablcr

lor rcalising intcgratcd sustainability improvcmcnts.

38

FUTURE SUPPLY CHAIN 2016

Thc luturc supply chain architccturc anticipatcs ncw

collaborativc modcls lor city distribution that nccd

to bc applicd in urban inlrastructurcs. For transport

into urban arcas, congcstion and C

2

cmissions

arc thc main challcngcs that nccd to bc addrcsscd.

Sharing inlrastructurc lor dclivcry into urban arcas is

thcrclorc dcsigncd to limit thc amount ol (polluting)

trucks going into thc city.

Mcrging thc dillcrcnt strcams that go into thc city

onto onc inlrastructurc will bc a big stcp lorward.

Thc kcy clcmcnt will bc socallcd city hubs with a

collaborativc crossdock opcration.

Thc linal solution will bc applicd dillcrcntly pcr

shipmcnt catcgory:

Full truckloads lor storc rcplcnishmcnt

Lcssthanlull truckloads lor smallcrstorc

rcplcnishmcnt

Parccls, including homc dclivcry nccds

For thc lirst catcgory, changcs in thc cllicicncy and

cmissions ol thc trucks could bc sullicicnt, but thc

othcr two catcgorics can bc consolidatcd outsidc thc

city in city hubs and bc brought into thc city with

altcrnativc modcs ol transportation (likc strcctcars or

clcctric vchiclcs).

!n addition, to addrcss thc cxpcctcd growth in

homc dclivcry and thcrclorc parccls coming into

urban arcas, altcrnativc modcls lor homc dclivcry

and ncighbourhood distribution should mcrgc

with thc urban rcplcnishmcnt modcl. This implics

consolidation ol dillcrcnt dclivcry strcams (dillcrcnt

products bascd on dillcrcnt ordcrs lrom dillcrcnt

onlinc ordcring lacilitics, all lor thc samc shoppcr)

via city hubs.

Ncw ncighbourhood distribution modcls will havc

pickup points or dropoll boxcs to cnablc cllicicnt

dclivcry ol thc parccl strcam in a consolidatcd way.

Consumcrs will bc givcn thc choicc to cithcr havc

thcir onlincordcrcd goods dclivcrcd at homc,

or to collcct thcm at spccilic pickup points or

dropoll boxcs. !n both cascs consumcrs will causc

considcrably lowcr C

2

cmissions, comparcd with

using thcir cars to go shopping.

3. Collaborative City Distribution

39

4. A NEW MODEL FOR ENHANCED SUPPLY CHAIN COLLABORATION

This collaborativc conccpt should impact thc

lollowing KP!s:

Trallic congcstion

C

2

cmissions and cncrgy rcduction

!nlrastructurc simplilication

4. Collaborative Non-Urban Distribution

For nonurban arcas, thc challcngcs, and thcrclorc thc

solutions, arc slightly dillcrcnt. Thc longcr distanccs

to thc linal storc or homc arc such that transport

optimisation is thc main objcctivc. Full truckloads

lrom collaborativc warchouscs can bc movcd in thc

most cllicicnt way to thc rcmotc arca, possibly using

altcrnativc modcs ol transport likc trains.

A rcgional consolidation ccntrc can havc a similar

lunction as thc city hubs, consolidating thc storc

ordcrs lrom various collaborativc warchouscs into

dcdicatcd storc rcplcnishmcnt routcs. At thc samc

timc, thcsc consolidation ccntrcs arc nccdcd to

mcrgc thc longdistancc strcams with thc local

product strcams to crcatc cllicicnt rcplcnishmcnt

into thc storcs.

Just as with urban rcplcnishmcnt, parccls and

homc dclivcry modcls should bc considcrcd

in conjunction with thc storc rcplcnishmcnt

modcls. Thcsc llows could also bc crossdockcd

at similar consolidation ccntrcs to improvc

thc lill ratc lor thc linalmilc routcs.

Again, as with city distribution, thc kcy will bc

consolidation ol dclivcry strcams (dillcrcnt products

bascd on dillcrcnt ordcrs lrom dillcrcnt onlinc

ordcring lacilitics, all lor thc samc shoppcr) via thcsc

consolidation ccntrcs. Thcrc will bc a convcrgcncc

bctwccn homc shopping and ncighbourhood

distribution via pickup points. Consumcrs will bc

givcn thc choicc to cithcr havc thcir onlincordcrcd

goods dclivcrcd at homc, or to collcct thcm at spccilic

pickup points or dropoll boxcs, which in both cascs

will rcducc thc C

2

cmissions that thcy currcntly

causc by driving to storcs.

This collaborativc conccpt should primarily impact

thc lollowing KP!s:

C

2

cmissions and cncrgy rcduction

!nlrastructurc simplilication

New Ways of Working Together

Thc common thcmc lor all thc luturc supply

chain sccnarios is collaboration. 8ut just idcntilying

thc bcnclits ol collaboration is not cnough to makc

it happcn.

Thcrc arc numcrous stakcholdcrs across thc physical

supply chain and in ordcr to changc thc chain, it

is important to not only havc a sharcd pcrspcctivc

ol what nccds to bc donc, but also to considcr thc

individual pcrspcctivcs and uniquc challcngcs lacing

cach stakcholdcr:

Consumers and shoppers incrcasingly valuc

sustainability aspccts in thcir choiccs.

7

8ut thcy arc

lcss willing to pay cxtra lor it. Consumcrs want to

bc bcttcr inlormcd about thc sustainability impact

ol thcir shopping choiccs (including, lor cxamplc,

about thc C

2

cmissions involvcd in using thcir

car to go shopping).

Retailers arc motivatcd to scrvc shoppcrs in thc

most optimal way, in ordcr to bc prolitablc and

achicvc sustainablc growth. Rctailcrs wclcomc