Professional Documents

Culture Documents

Safety & Piping Color Codes

Safety & Piping Color Codes

Uploaded by

Prince Q ChanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety & Piping Color Codes

Safety & Piping Color Codes

Uploaded by

Prince Q ChanCopyright:

Available Formats

TECHNICAL BULLETIN #7

SAFETY & PIPING COLOR CODES

OSHA SAFETY COLORS

GENERAL INFORMATION: The Occupational Safety and Health Act (OSHA) requires that all industries color-code safety equipment locations, physical hazards and protective equipment. Safety color codes were established by the American National Standards Institute (ANSI) and adopted by OSHA for use in hazardous areas. Porter Coatings Safety Colors conform to OSHA and ANSI guidelines. OSHA does not specify the exact shade of color, but the color-coding should be consistent throughout a facility. For complete information, please consult the reference documents** noted at the end of this bulletin.

RED:

THE BASIC COLOR FOR THE IDENTIFICATION OF: -Fire Protection Equipment and Apparatus. Used for: fire alarm boxes, fire blanket boxes, fire buckets or pails, fire exit signs, fire extinguishers, fire hose locations, fire hydrants, fire pumps, fire sirens, post indicator valves for sprinkler system and sprinkler piping. -Danger. Used for: safety cans or other portable containers of flammable liquids having a flashpoint at or below 80F, table containers of flammable liquids (with additional clearly visible identification of the contents either in the form of a yellow band around the can or the name of the contents conspicuously stenciled or painted on the can in yellow and danger signs. -Stop. Used for: Emergency stop bars on hazardous machines and stop buttons or electrical switches used for emergency stopping of machinery.

PORTER COATINGS SAFETY RED: 2772 PORTER GUARD Fast Dry Gloss Enamel Safety Red 2912 PORTER GUARD DTM Acrylic Gloss Enamel Safety Red PC4072 PORTERGLAZE 4000 Gloss Epoxy Safety Red

YELLOW:

THE BASIC COLOR FOR DESIGNATING CAUTION. Used for: marking physical hazards such as striking against, stumbling, falling, tripping and caught in between. Solid yellow, yellow and black stripes, yellow and black checkers (or yellow with suitable contrasting background) should be used interchangeably, using the combination which will attract the most attention in the particular environment.

PORTER COATINGS SAFETY YELLOW: 2754 PORTER GUARD Fast Dry Enamel Safety Yellow 2913 PORTER GUARD DTM Acrylic Gloss Enamel Safety Yellow PC4074 PORTERGLAZE 4000 Epoxy Gloss Yellow Base PC9074 PORTERTHANE 9000 Urethane Gloss Yellow Base

GREEN:

THE BASIC COLOR FOR DESIGNATING SAFETY AND THE LOCATION OF FIRST AID EQUIPMENT (OTHER THAN FIREFIGHTING EQUIPMENT)

PORTER COATINGS SAFETY GREEN: Tint* from: 2744 PORTER GUARD Fast Dry Enamel Ultra Deep Base 2904 PORTER GUARD DTM Acrylic Gloss Enamel Ultra Deep Base PC4044 PORTERGLAZE 4000 Epoxy Gloss Neutral Base PC9044 PORTERTHANE 9000 Urethane Gloss Neutral Base

ORANGE:

THE BASIC COLOR FOR DESIGNATING DANGEROUS PARTS OF MACHINES OR ENERGIZED EQUIPMENT WHICH MAY CUT, CRUSH, SHOCK, OR OTHERWISE INJURE. Used to emphasize such hazards when enclosure doors are open or when gear belt or other guards around moving equipment are open or removed, exposing unguarded hazards.

PORTER COATINGS SAFETY ORANGE: Tint* from: 2754 PORTER GUARD Fast Dry Gloss Enamel Safety Yellow 2913 PORTER GUARD DTM Acrylic Gloss Enamel Safety Yellow PC4074 PORTERGLAZE 4000 Epoxy Gloss Yellow Base PC9074 PORTERTHANE 9000 Urethane Gloss Yellow Base

BLUE:

THE BASIC COLOR FOR DESIGNATING CAUTION, LIMITED TO WARNING AGAINST THE STARTING, THE USE OF, OR THE MOVEMENT OF EQUIPMENT UNDER REPAIR OR BEING WORKED ON.

PORTER COATINGS SAFETY BLUE: Tint* from: 2744 PORTER GUARD Fast Dry Enamel Ultra Deep Base 2904 PORTER GUARD DTM Acrylic Gloss Enamel Ultra Deep Base PC4044 PORTERGLAZE 4000 Epoxy Gloss Neutral Base PC9044 PORTERTHANE 9000 Urethane Gloss Neutral Base

Continued back page 1/99

BACK PAGE TECHNICAL BULLETIN #7 SAFETY & PIPING COLOR CODES

PURPLE:

THE BASIC COLOR FOR DESIGNATING RADIATION HAZARDS (X-RAY, ALPHA, BETA, GAMMA, NEUTRON, PROTON, DEUTERON, AND MESON TYPES). Used in combination with purple for markers such as tags, labels, signs and floor markers.

PORTER COATINGS SAFETY PURPLE: Tint* from: 2744 PORTER GUARD Fast Dry Enamel Ultra Deep Base 2904 PORTER GUARD DTM Acrylic Gloss Enamel Ultra Deep Base PC4044 PORTERGLAZE 4000 Epoxy Gloss Neutral Base PC9074 PORTERTHANE 9000 Urethane Gloss Neutral Base

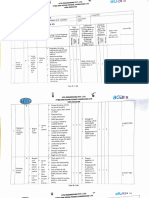

Color may be used to identify the characteristic properties of the contents as outlined in the table below using safety colors listed above.

MATERIALS CLASSIFICATION HAZARDOUS MATERIALS Flammable, Explosive, Chemically active, Toxic, Extreme pressure or extreme temperature. Radioactive LOW HAZARD MATERIALS Liquid or liquid admixture Gas or gaseous admixture FIRE QUENCHING MATERIALS Water, Foam, CO2, etc.

COLOR OF FIELD

COLOR OF LETTERS FOR LEGEND BLACK

YELLOW

BLACK, WHITE, OR COMBINATIONS OF BLACK AND WHITE:

THE BASIC COLORS FOR DESIGNATING TRAFFIC AND HOUSEKEEPING MARKINGS. Solid white, solid black, single color striping, alternate stripes of black and white, or black and white checkers should be used in accordance with local conditions.

PORTER COATINGS SAFETY BLACK: 2728 PORTER GUARD Fast Dry Enamel Black 2928 PORTER GUARD DTM Acrylic Gloss Black

PURPLE GREEN BLUE RED

YELLOW BLACK WHITE WHITE

*NOTE: See the Porter Coatings Industrial Color Selection Guide (Order #5860/E) for safety color tint formulas.

Where pipe lines are located above the normal line of vision, the lettering shall be placed below the horizontal centerline of the pipe in such a manner as to make the legends visable to the eye.

IDENTIFICATION OF CONTENTS OF PIPING SYSTEMS IN INDUSTRIAL PLANTS

GENERAL INFORMATION: The American National Standard Scheme for the Identification of Piping Systems provides guidelines for the use of color on piping in plant facilities. Please consult this publication** for complete details. Some general guidelines are: Pipes are defined as conduits for the transport of gases, liquids, semi-liquids or plastics. This scheme does not cover pipes buried in the ground, or electrical conduits. The Standard considers legend (written description of contents) to be primary. Color coding is considered secondary. Positive identification of the content of a piping system shall be by lettered legend giving the name of the contents in full or abbreviated form. Arrows shall be used to indicate direction of flow. Legends shall be applied close to valves and adjacent to changes in direction, branches, and where pipes pass through walls or floors, and at frequent intervals on straight pipe runs. Identification may be accomplished by stenciling, the use of tape, or markers.

**References: The Occupational Safety and Health Administration, Labor, CODE OF FEDERAL REGULATIONS, 29 1910.144 Safety color code for marking physical hazards; and ANSI (American National Standards Institute) American National Standard Scheme For The Identification of Piping Systems A13.1-1975 published by the American Society of Mechanical Engineers, 345 East 47th Street, New York, NY 10017.

1/99

You might also like

- Extra Space Storage Incident ReportDocument19 pagesExtra Space Storage Incident ReportKSNV News 3No ratings yet

- Amada HA250W-400W Operators ManualDocument171 pagesAmada HA250W-400W Operators ManualmehrdadgeminiNo ratings yet

- BS 5588 9 1999 PDFDocument30 pagesBS 5588 9 1999 PDFBach Nguyen VanNo ratings yet

- MGS2500B - Brochures (Standby Duty)Document4 pagesMGS2500B - Brochures (Standby Duty)outfit49 besteverNo ratings yet

- Reverse Circulation Pump PDFDocument4 pagesReverse Circulation Pump PDFthawdarNo ratings yet

- Asbestos Cement PipeDocument6 pagesAsbestos Cement PipeAsaka1124No ratings yet

- Bill of Quantities For Plant Room FloorDocument3 pagesBill of Quantities For Plant Room FloorAwais JalaliNo ratings yet

- Operations & Maintenance Manual: ... Innovative Liquid Vaporizing and Gas Mixing SolutionsDocument64 pagesOperations & Maintenance Manual: ... Innovative Liquid Vaporizing and Gas Mixing SolutionsKALATUSNo ratings yet

- Project Stage Gate Introduction Guideline: National Project, O&M Management Organization (Mashroat)Document6 pagesProject Stage Gate Introduction Guideline: National Project, O&M Management Organization (Mashroat)tti67No ratings yet

- Official IELTS Practice Materials 1 PDFDocument26 pagesOfficial IELTS Practice Materials 1 PDFVaidotas Vaičeliūnas25% (4)

- Reference Guide: Mid-Rise Wood Construction in The Ontario Building CodeDocument44 pagesReference Guide: Mid-Rise Wood Construction in The Ontario Building CodeJosé Eduardo BaravelliNo ratings yet

- 01 Equipment Design Report FormatDocument15 pages01 Equipment Design Report FormatRA MemijeNo ratings yet

- Foster Adhesive: Technical Data SheetDocument2 pagesFoster Adhesive: Technical Data SheetMounir BoutaghaneNo ratings yet

- Oxygen Bulk Storage Safety Distances To Comply With BCGA CP19Document1 pageOxygen Bulk Storage Safety Distances To Comply With BCGA CP19HASSANNo ratings yet

- Plant Layout ConsiderationsDocument36 pagesPlant Layout ConsiderationsTissa1969No ratings yet

- Mto Piping and ValveDocument1 pageMto Piping and ValveAgus Marpaung100% (2)

- Active & Passive Protection SystemDocument31 pagesActive & Passive Protection SystemAhmed GhariebNo ratings yet

- LPG Design and Installation For Commercial and Industrial FacilitiesDocument171 pagesLPG Design and Installation For Commercial and Industrial Facilitiesnathanielvillanueva093086No ratings yet

- Case StudiesDocument46 pagesCase StudiesKTINE080% (1)

- Roll Grooved Anti-Vortex Plate - Hot Dipped GalvanisedDocument1 pageRoll Grooved Anti-Vortex Plate - Hot Dipped GalvanisedNikhil RajanNo ratings yet

- CSI MasterFormat 2018 Pentens MaterialDocument3 pagesCSI MasterFormat 2018 Pentens Materialウィリアムズ アンディNo ratings yet

- Ti e Protegol 32-55 RRM Nov 07Document4 pagesTi e Protegol 32-55 RRM Nov 07A MahmoodNo ratings yet

- Mechanical and Ventilation System SpecificationsDocument7 pagesMechanical and Ventilation System SpecificationsDCMS CONSTRUCTIONNo ratings yet

- AVK Product Programme BrochureDocument28 pagesAVK Product Programme Brochurehosny1987No ratings yet

- Xiangshui Chemical Factory's ExplosionDocument21 pagesXiangshui Chemical Factory's ExplosionnajihahNo ratings yet

- Q99020 Oss PDFDocument4 pagesQ99020 Oss PDFCarolineNo ratings yet

- Bawana BOQDocument28 pagesBawana BOQSasi Kiran VundamatlaNo ratings yet

- Steel Insight 4Document7 pagesSteel Insight 4sharjahsharjahNo ratings yet

- Fuel Storage Requirements Above 1,100 Gallon at Farms & Isolated SitesDocument3 pagesFuel Storage Requirements Above 1,100 Gallon at Farms & Isolated SitesYodit TesfayNo ratings yet

- Flowserve Butterfly ValveDocument8 pagesFlowserve Butterfly ValveDGWNo ratings yet

- Marine Loading ArmDocument2 pagesMarine Loading ArmAfolabi OlaniyiNo ratings yet

- NAFFCOInert Catalogue PDFDocument16 pagesNAFFCOInert Catalogue PDFMac ShaikNo ratings yet

- White Paper: M Modbus ProtocolDocument3 pagesWhite Paper: M Modbus ProtocolyogeunysNo ratings yet

- مواصفات التكييفDocument54 pagesمواصفات التكييفoth369No ratings yet

- Paint Data SheetDocument2 pagesPaint Data SheetdidiNo ratings yet

- Ducts ManholesDocument3 pagesDucts ManholesKhay SaadNo ratings yet

- Smoke Extraction Fans - 20100830174123Document10 pagesSmoke Extraction Fans - 20100830174123Kristaps PuļķisNo ratings yet

- Cooling Tower TNCDocument6 pagesCooling Tower TNCAarol Hatta100% (1)

- Manual de Vaporizadores AmbientalesDocument9 pagesManual de Vaporizadores AmbientalesJose Luis Tadeo SabinoNo ratings yet

- Project Punch List TemplateDocument1 pageProject Punch List TemplateMatt TupperNo ratings yet

- Composite Material Offshore Corrosion SolutionsDocument15 pagesComposite Material Offshore Corrosion SolutionsaruchellamNo ratings yet

- PT 20200520 Sungrow ESS Business Introduction V10 enDocument22 pagesPT 20200520 Sungrow ESS Business Introduction V10 enHoàng ChungNo ratings yet

- Nitric AcidDocument4 pagesNitric AcidAłéñà IqbàłNo ratings yet

- Emerging Technologies A Suggested Design Method For Curved Jacked Steel PipeDocument11 pagesEmerging Technologies A Suggested Design Method For Curved Jacked Steel PipefalokunNo ratings yet

- STP Blower Room Detail STP Concrete PadDocument1 pageSTP Blower Room Detail STP Concrete PadjoeyNo ratings yet

- QRA Scope of WorkDocument3 pagesQRA Scope of Workvarunkumar415100% (1)

- Division 14 - Elevator SpecificationsDocument9 pagesDivision 14 - Elevator Specificationseng_asayedNo ratings yet

- Delay Analysis in EPC Projects Using Ishikawa DiagramDocument6 pagesDelay Analysis in EPC Projects Using Ishikawa DiagramIjaems JournalNo ratings yet

- Summary of MaterialsDocument15 pagesSummary of MaterialsKirt MallariNo ratings yet

- Siba Field Development Project: Punch List Form (PLF)Document2 pagesSiba Field Development Project: Punch List Form (PLF)Midha NeerNo ratings yet

- Kanon Brochure ENGLISH 63bcdbDocument25 pagesKanon Brochure ENGLISH 63bcdbpandunugraha04No ratings yet

- Comment Sheet FormDocument2 pagesComment Sheet Formburerey100% (1)

- Previews 2002357 PreDocument5 pagesPreviews 2002357 PreSterlingNo ratings yet

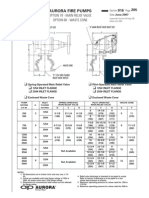

- Fire Pump Relief Valve, Waste Cone, AuroraDocument1 pageFire Pump Relief Valve, Waste Cone, Aurorawvwinters100% (1)

- Scope of WorkDocument20 pagesScope of WorkEM.SRBPH APGENCONo ratings yet

- Project Procurement Management Closing Punch ListDocument24 pagesProject Procurement Management Closing Punch ListLauren RosimoNo ratings yet

- CFD Request For QuotationDocument1 pageCFD Request For QuotationHedi Ben MohamedNo ratings yet

- Plant Location and LayoutDocument11 pagesPlant Location and LayoutashutoshNo ratings yet

- Besmm4f PDFDocument2 pagesBesmm4f PDFGodwin JohnNo ratings yet

- Salam Studio Stores, Salam Plaza Extention at Gate Mall: Bill of QuantitiesDocument4 pagesSalam Studio Stores, Salam Plaza Extention at Gate Mall: Bill of QuantitiesAko AkotoNo ratings yet

- KnaufDocument28 pagesKnaufprokaNo ratings yet

- WYN032Document13 pagesWYN032marvinNo ratings yet

- BaxterDocument2 pagesBaxterbambang.nurasNo ratings yet

- TDS Sikkens Primer Surfacer EP II 033017 EnglishDocument9 pagesTDS Sikkens Primer Surfacer EP II 033017 EnglishbellaantoNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Voter ListDocument27 pagesVoter ListSandip DasNo ratings yet

- List of Welding StandardsDocument5 pagesList of Welding StandardsSandip Das100% (1)

- Thermodynamic Steam TrapDocument8 pagesThermodynamic Steam TrapMallela Sampath KumarNo ratings yet

- Ashrae D RP 1447 20161004Document77 pagesAshrae D RP 1447 20161004Simoncarter LawNo ratings yet

- Nps Chimney Tops 2 Fire Review ReportDocument116 pagesNps Chimney Tops 2 Fire Review ReportWVLT NewsNo ratings yet

- Add Ambiance With Our Large Selection of Candleholders. From Candle Lanterns To Elaborate Candelabras We Have Something To Suit Your NeedsDocument30 pagesAdd Ambiance With Our Large Selection of Candleholders. From Candle Lanterns To Elaborate Candelabras We Have Something To Suit Your NeedsnjlaporteNo ratings yet

- Stilp LawsuitDocument28 pagesStilp LawsuitRyan GraffiusNo ratings yet

- Safety Briefing Wordings PDFDocument2 pagesSafety Briefing Wordings PDFAndi Muhammad Aswin Anas100% (1)

- R0 AM20046 DALIAN 300K TANKER T300K-101 R-102 Galley Duct INSTRUCTION MANUALDocument85 pagesR0 AM20046 DALIAN 300K TANKER T300K-101 R-102 Galley Duct INSTRUCTION MANUALPranabNo ratings yet

- Bomba de Infusion ATOM S-1235 Syringe Pump Service ManualDocument135 pagesBomba de Infusion ATOM S-1235 Syringe Pump Service Manualservice iyadMedicalNo ratings yet

- Balanced Fire Attack and Iowa LawDocument34 pagesBalanced Fire Attack and Iowa LawJose Gregorio Prada RodriguezNo ratings yet

- N-VFT Manual - 080521Document34 pagesN-VFT Manual - 080521chucaonguyenrcNo ratings yet

- JPNR - Regular Issue 02, 2023 - 103Document8 pagesJPNR - Regular Issue 02, 2023 - 103Nuhu IddrissNo ratings yet

- Adobe Scan 02 Jul 2021Document10 pagesAdobe Scan 02 Jul 2021uttam mishraNo ratings yet

- Updates: Android Alchemy Cheat List (380 / 380)Document7 pagesUpdates: Android Alchemy Cheat List (380 / 380)Lucia ManettiNo ratings yet

- Sodium Bisulfite - MSDSDocument5 pagesSodium Bisulfite - MSDSJHUPEL ABARIALNo ratings yet

- Denah Fire Alarm LT.3Document1 pageDenah Fire Alarm LT.3IrwansyahNo ratings yet

- Class A (Solid) : and Hydrocarbon FiresDocument2 pagesClass A (Solid) : and Hydrocarbon FiresForum PompieriiNo ratings yet

- FDS and Smokeview SeminarDocument2 pagesFDS and Smokeview Seminarvishal guptaNo ratings yet

- CSCS Test RevisionDocument6 pagesCSCS Test RevisionAlan HoskerNo ratings yet

- Alchemy Cheat SheetDocument7 pagesAlchemy Cheat SheetRuby Lucía MercuryNo ratings yet

- 3 Hartindo AF11E Post Fire MaintenaceDocument17 pages3 Hartindo AF11E Post Fire Maintenacebudi utamaNo ratings yet

- Fire Pattern AnalysisDocument16 pagesFire Pattern AnalysisMs Paperworks100% (1)

- Fire Prevention Week 2016 - Grand ForksDocument3 pagesFire Prevention Week 2016 - Grand ForksDella MalletteNo ratings yet

- Fire DrillsDocument4 pagesFire Drillsandra347100% (1)

- List of TBT Agendas: S.# TBT Topic Reference NumberDocument31 pagesList of TBT Agendas: S.# TBT Topic Reference NumberRabban100% (1)

- WYN032Document13 pagesWYN032marvinNo ratings yet

- Sakai SV540Document108 pagesSakai SV540George PlishkoNo ratings yet

- Safety Data Sheet: According To Regulation (EC) No. 1907/2006Document9 pagesSafety Data Sheet: According To Regulation (EC) No. 1907/2006Timothy NathanielNo ratings yet